Content Menu

● What Are Tungsten Steel and Tungsten Carbide?

>> Tungsten Steel

>> Tungsten Carbide

● Key Differences Between Tungsten Steel and Tungsten Carbide

● Detailed Comparison

>> 1. Composition and Manufacturing Process

>> 2. Hardness and Wear Resistance

>> 3. Toughness and Brittleness

>> 4. Density and Weight

>> 5. Heat Resistance and Thermal Stability

● Manufacturing Processes in Detail

>> Tungsten Steel Manufacturing

>> Tungsten Carbide Manufacturing

● Expanded Applications

>> Medical Industry

>> Electronics and Electrical Industry

>> Mining and Construction

>> Jewelry and Fashion

● Environmental and Recycling Considerations

● Future Trends and Innovations

● Conclusion

● FAQ

>> 1. What is the main difference between tungsten steel and tungsten carbide?

>> 2. Which material is harder, tungsten steel or tungsten carbide?

>> 3. Can tungsten carbide be machined easily?

>> 4. What are typical applications for tungsten steel?

>> 5. Is tungsten carbide recyclable?

● Citations:

Understanding the distinction between tungsten steel and tungsten carbide is essential for industries ranging from manufacturing to jewelry making. Both materials are prized for their hardness and durability but differ significantly in composition, properties, and applications. This comprehensive article explores these differences in detail, supported by images illustrating their structures and uses.

What Are Tungsten Steel and Tungsten Carbide?

Tungsten Steel

Tungsten steel, also known as tungsten-titanium alloy, high-speed steel (HSS), or tool steel, is an alloy made by adding tungsten (typically 15-25%) into molten steel during the steelmaking process. It is a type of cemented carbide but not synonymous with all cemented carbides. Tungsten steel is known for its high hardness (around 85-92 HRC), excellent wear resistance, and toughness. It is commonly used in lathe tools, drill bits, glass cutter heads, and tile cutters due to its ability to maintain hardness even at elevated temperatures (up to 1000°C).

Tungsten Carbide

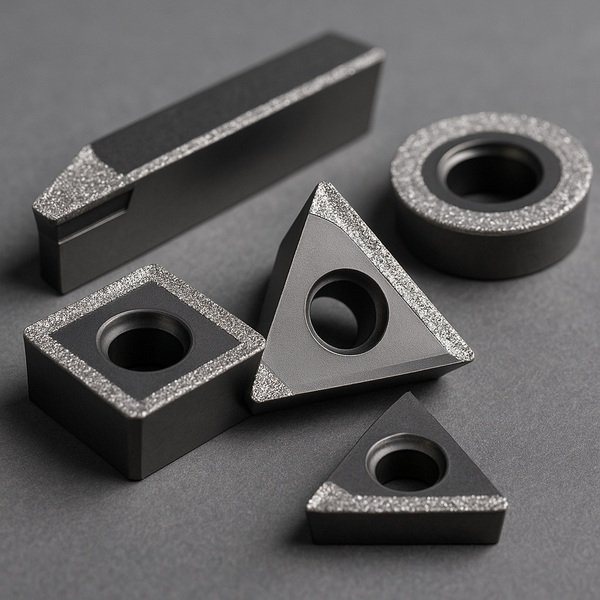

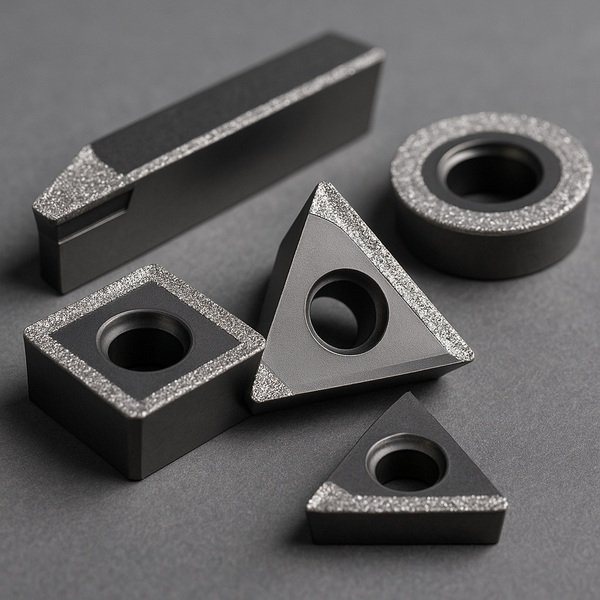

Tungsten carbide is a chemical compound composed of tungsten and carbon (WC), typically produced by powder metallurgy processes involving sintering tungsten carbide powder with a metallic binder such as cobalt. It contains a much higher tungsten content (above 80%) compared to tungsten steel. Tungsten carbide is a ceramic-metal composite known for its exceptional hardness (9-9.5 on the Mohs scale), rigidity, and wear resistance, second only to diamond. It is widely used in cutting tools, mining equipment, wear-resistant parts, and jewelry.

Key Differences Between Tungsten Steel and Tungsten Carbide

| Feature | Tungsten Steel | Tungsten Carbide |

| Composition | Steel alloy with 15-25% tungsten | Compound of tungsten and carbon (>80% W) |

| Manufacturing | Steelmaking process with tungsten addition | Powder metallurgy and sintering |

| Hardness | 85-92 HRC (Vickers ~10K) | Mohs 9-9.5, extremely hard and brittle |

| Density | ~19.3 g/cm³ (similar to pure tungsten) | ~15.6-15.8 g/cm³ (less dense than tungsten) |

| Toughness | Higher toughness, less brittle | More brittle due to ceramic nature |

| Wear Resistance | Good wear resistance | Superior wear and abrasion resistance |

| Heat Resistance | Maintains hardness up to ~1000°C | Stable up to 800-1000°C |

| Machinability | Easier to machine and shape | Difficult to machine; requires diamond tools |

| Applications | Cutting tools, drill bits, industrial tools | Mining, machining, wear parts, jewelry |

| Cost | Generally less expensive | More costly due to complex processing |

Detailed Comparison

1. Composition and Manufacturing Process

Tungsten steel is produced by adding tungsten iron (ferro tungsten) during steelmaking, resulting in an alloy with moderate tungsten content (15-25%). It is often referred to as high-speed steel or tool steel. In contrast, tungsten carbide is manufactured by mixing tungsten carbide powder with a binder metal like cobalt and sintering it at high temperatures (1300-1600°C). This powder metallurgy process yields a dense, extremely hard material with tungsten content exceeding 80%.

2. Hardness and Wear Resistance

Tungsten carbide exhibits exceptional hardness, rated 9-9.5 on the Mohs scale, making it nearly as hard as diamond. This hardness translates to superior wear resistance, allowing tungsten carbide tools to maintain sharpness and resist abrasion far longer than tungsten steel tools. Tungsten steel, while very hard (85-92 HRC), is softer and more ductile, making it less prone to chipping under impact but less wear-resistant overall.

3. Toughness and Brittleness

Tungsten steel is tougher and less brittle than tungsten carbide, which is a ceramic-metal composite. Tungsten carbide's rigidity makes it prone to fracturing or chipping under heavy impact or vibration, whereas tungsten steel can absorb more mechanical shock without damage. This makes tungsten steel preferable in applications requiring impact resistance, while tungsten carbide excels in abrasive and wear-intensive environments.

4. Density and Weight

Pure tungsten steel has a density close to 19.3 g/cm³, making it one of the densest metals. Tungsten carbide's density is slightly lower, around 15.6-15.8 g/cm³, due to the carbon content and binder metals. Despite this, tungsten carbide remains significantly denser and heavier than common steels, contributing to its durability and stability in precision tools.

5. Heat Resistance and Thermal Stability

Both materials maintain hardness at elevated temperatures, but tungsten carbide tends to lose hardness above 1000°C, while tungsten steel can sustain hardness up to about 1000°C. Tungsten carbide's thermal conductivity (about 110 W/m·K) allows it to dissipate heat efficiently during high-speed machining, enhancing tool life. Tungsten steel also performs well in heat but is generally less thermally conductive than carbide.

Manufacturing Processes in Detail

Tungsten Steel Manufacturing

Tungsten steel is produced through a complex steelmaking process where tungsten is added to molten steel. This process involves precise control of temperature and alloy composition to ensure the tungsten is evenly distributed within the steel matrix. The resulting alloy benefits from the combined properties of steel and tungsten, offering enhanced hardness and heat resistance. The steel is then subjected to heat treatment processes such as quenching and tempering to optimize its mechanical properties for specific applications.

Tungsten Carbide Manufacturing

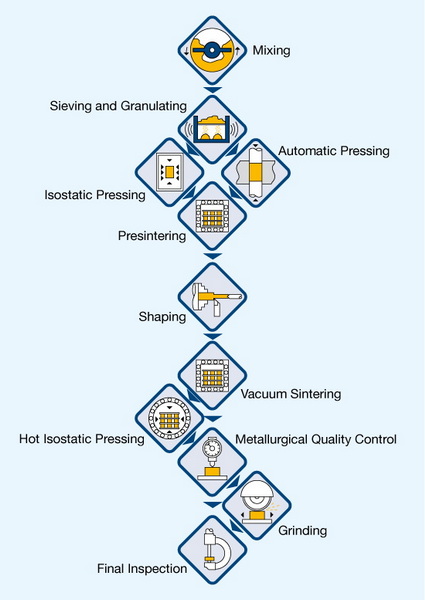

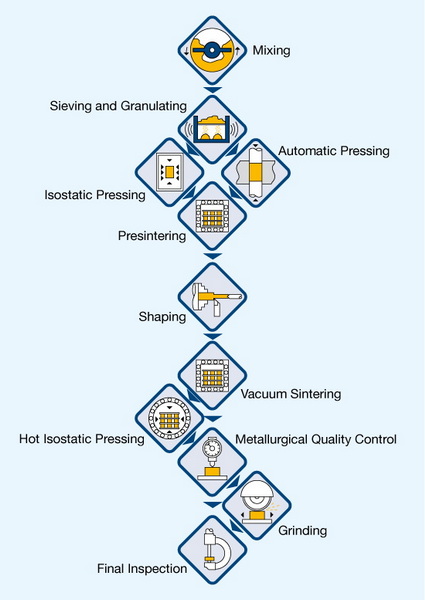

The manufacturing of tungsten carbide involves powder metallurgy, a process that starts with the mixing of tungsten carbide powder and a metallic binder, usually cobalt. This mixture is then compacted into the desired shape and sintered at high temperatures ranging from 1300 to 1600 degrees Celsius. The sintering process causes the powder particles to bond together, creating a dense and extremely hard material. Advanced techniques such as hot isostatic pressing (HIP) may also be used to improve the density and mechanical properties of the final product.

Expanded Applications

Medical Industry

Tungsten carbide is increasingly used in the medical field for surgical instruments and dental tools due to its exceptional hardness and biocompatibility. Its wear resistance ensures that cutting edges remain sharp during delicate procedures, improving precision and patient outcomes. For example, carbide-tipped scalpels and dental burs provide longevity and reduce the frequency of tool replacement.

Electronics and Electrical Industry

Tungsten steel components are used in electrical contacts and connectors because of their excellent conductivity and resistance to electrical erosion. These properties make tungsten steel ideal for high-performance electronic devices and industrial electrical equipment. Tungsten steel's ability to withstand arcing and high temperatures extends the lifespan of electrical switches and relays.

Mining and Construction

Tungsten carbide is extensively used in mining and construction equipment, such as drill bits, cutting heads, and wear plates, due to its superior abrasion resistance. Its ability to withstand harsh environments and maintain cutting efficiency reduces downtime and maintenance costs in heavy machinery.

Jewelry and Fashion

Tungsten carbide has gained popularity in jewelry, particularly for rings and watches, because of its scratch resistance and aesthetic appeal. Unlike traditional metals, tungsten carbide jewelry maintains its polish and resists deformation, making it a durable choice for everyday wear.

Environmental and Recycling Considerations

Both tungsten steel and tungsten carbide are recyclable materials, which is critical given the environmental impact of tungsten mining. Recycling tungsten carbide involves crushing used tools and components, separating the binder metal from the carbide particles, and then reprocessing the materials to produce new carbide powder. This recycling process reduces the need for mining raw tungsten, conserving natural resources and reducing environmental impact.

Tungsten steel can also be recycled by remelting and refining, allowing tungsten and other alloying elements to be recovered and reused. Recycling not only conserves resources but also reduces energy consumption and greenhouse gas emissions compared to primary production.

Future Trends and Innovations

Research in material science continues to improve the properties of tungsten steel and tungsten carbide. Innovations include the development of nano-structured carbides that offer even greater hardness and toughness, as well as coatings that enhance wear resistance and reduce friction. These coatings, such as titanium nitride (TiN) or diamond-like carbon (DLC), extend tool life and improve performance in extreme conditions.

Additive manufacturing techniques such as 3D printing are being explored to create complex tungsten carbide components with customized properties. This technology allows for the production of intricate shapes that are difficult or impossible to achieve with traditional manufacturing methods, opening new possibilities in aerospace, medical devices, and precision tooling.

Conclusion

Tungsten steel and tungsten carbide are both indispensable materials in modern industry, each with unique advantages. Tungsten steel offers a balance of hardness and toughness, making it suitable for tools requiring impact resistance and moderate wear resistance. Tungsten carbide, with its exceptional hardness and wear resistance, excels in abrasive environments and precision cutting applications but is more brittle and difficult to machine. Understanding these differences helps industries choose the right material for specific applications, optimizing performance and cost-effectiveness.

Advancements in manufacturing, recycling, and material science continue to enhance the capabilities and sustainability of both materials, ensuring their relevance in future industrial and technological developments.

FAQ

1. What is the main difference between tungsten steel and tungsten carbide?

Tungsten steel is a steel alloy with 15-25% tungsten, produced by steelmaking, while tungsten carbide is a compound of tungsten and carbon with over 80% tungsten, made by powder metallurgy. Tungsten carbide is harder and more wear-resistant but more brittle than tungsten steel.

2. Which material is harder, tungsten steel or tungsten carbide?

Tungsten carbide is significantly harder, rating 9-9.5 on the Mohs scale, nearly as hard as diamond. Tungsten steel is hard but less so, with hardness around 85-92 HRC.

3. Can tungsten carbide be machined easily?

No, tungsten carbide is very difficult to machine due to its hardness and brittleness. It usually requires diamond-coated tools and is often shaped in its “green” (soft) state before sintering.

4. What are typical applications for tungsten steel?

Tungsten steel is commonly used for high-speed cutting tools, drill bits, lathe tools, and industrial machinery components where toughness and moderate wear resistance are needed.

5. Is tungsten carbide recyclable?

Yes, tungsten carbide can be recycled effectively without loss of durability, making it environmentally and economically valuable in industrial applications.

Citations:

[1] https://www.cncsparetools.com/new/Difference-between-solid-carbide-and-Tungsten-steel.html

[2] https://be-cu.com/blog/tungsten-steel-vs-tungsten-carbide/

[3] https://www.linkedin.com/pulse/tungsten-vs-carbide-whats-difference-haijun-liu

[4] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[5] https://www.samaterials.com/content/cemented-carbide-vs-tungsten-steel.html

[6] https://www.tungco.com/insights/blog/why-use-tungsten-carbide-over-other-metals/

[7] https://cowseal.com/tungsten-vs-tungsten-carbide/

[8] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[9] https://konecarbide.com/tungsten-vs-tungsten-carbide-differences-explained/

[10] https://cowseal.com/carbide-vs-steel/

[11] https://cncpartsxtj.com/cnc-materials/difference-tungsten-and-tungsten-carbide/

[12] https://www.huaxincarbide.com/news/tungsten-carbide-is-tungsten-steel-i-what-is-the-difference-between-the-two-tungsten-carbide-vs-tungsten-steel/

[13] https://shop.machinemfg.com/the-pros-and-cons-of-tungsten-carbide-a-comprehensive-guide/

[14] https://va-tungsten.co.za/pure-tungsten-vs-tungsten-carbide-whats-the-difference/

[15] https://www.makeitfrom.com/compare/SAE-AISI-4340-SNCM439-G43400-Ni-Cr-Mo-Steel/Tungsten-Carbide-WC

[16] https://www.kenenghardware.com/differences-between-tungsten-steel-and-tungsten-carbide-milling-cutters/

[17] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[18] https://www.carbide-products.com/blog/tungsten-carbide-and-hss/

[19] https://www.hyperionmt.com/en/products/Wear-Parts/carbide-vs-steel/

[20] https://industrialmetalservice.com/metal-university/differentiating-tungsten-carbide-vs-steel-and-other-tooling/

[21] https://www.tungstenman.com/tungsten-carbide-tools-the-pros-and-cons.html

[22] https://www.zzcrcarbide.com/news/whats-the-difference-between-tungsten-carbide-and-tungsten-steel/

[23] https://www.zgjrdcc.com/tungsten-vs-tungsten-carbide/

[24] https://samhotool.com/blog/which-is-stronger-carbide-or-steel/

[25] https://www.carbide-part.com/blog/tungsten-carbide-and-hss/

[26] https://www.istockphoto.com/photos/tungsten-metal

[27] https://www.gettyimages.com/photos/tungsten-metal

[28] https://www.alamy.com/stock-photo/tungsten-metal.html

[29] https://www.shutterstock.com/search/tungsten-metal

[30] https://www.shutterstock.com/search/tungsten-carbide

[31] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[32] https://stock.adobe.com/search/images?k=tungsten

[33] https://www.vecteezy.com/free-photos/carbide

[34] https://cowseal.com/carbide-vs-steel/

[35] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide

[36] https://www.shutterstock.com/search/white-tungsten-steel

[37] https://www.shutterstock.com/search/tungsten

[38] https://www.titanjewellery.co.uk/Mens/Tungsten-FAQ.html

[39] https://unbreakableman.co.za/pages/all-about-tungsten-carbide-faq

[40] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/

[41] https://www.aemmetal.com/news/tungsten-carbide-vs-titanium.html

[42] https://www.tungstenrepublic.com/Tungsten-Carbide-Rings-FAQ.html

[43] https://www.kennametal.com/us/en/resources/blog/metal-cutting/tungsten-carbide-versus-cobalt-drill-bits.html

[44] https://www.tungstenringsco.com/faq

[45] https://tuncomfg.com/about/faq/

[46] https://www.tungstenworld.com/pages/tungsten-news-common-questions-about-tungsten

[47] https://www.thermofisher.com/sg/en/home/materials-science/learning-center/periodic-table/transition-metal/tungsten.html

[48] https://www.zhongbocarbide.com/how-do-tungsten-carbide-ball-bearings-compare-to-traditional-steel-bearings.html

[49] https://en.wikipedia.org/wiki/Tungsten

[50] https://pixabay.com/images/search/carbide/

[51] https://www.alamy.com/stock-photo/tungsten-carbide.html

[52] https://terraformstudio.com.au/shop/uncategorized/tungsten-steel-turning-trimming-tools-20/

[53] https://www.istockphoto.com/photos/tungsten-carbide

[54] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide?page=2

[55] https://www.thermalspray.com/questions-tungsten-carbide/