Content Menu

● Understanding Carbide Edge Blocks

● Why Japan Leads in Carbide Technology

● Top Japanese Carbide Edge Block Manufacturers and Suppliers

>> 1 DIJET INDUSTRIAL CO., LTD.

>> 2. Fuji Die Co., Ltd.

>> 3. NIPPON CARBIDE INDUSTRIES CO., INC. (NCI)

>> 4. Everloy Co., Ltd.

>> 5. Muteki Japan

>> 6. Mitsubishi Materials Corporation

>> 7. Sumitomo Electric Hardmetal

>> 8. Sanalloy Industry Co., Ltd.

>> 9. Yatech Materials (Japan)

>> 10. Obishi Keiki Seisakusho

● Applications of Carbide Edge Blocks

● Japan's Competitive Edge in Carbide Supply Chain

● Choosing the Right Japanese Carbide Edge Block Partner

● Applications Across Industries

● Quality Assurance and Certification Landscape

● The Global OEM Advantage

● Choosing the Right Partner: Practical Guidance

● Industry Trends and Outlook

● Integrating with Your Supply Chain

>> Customer Support Scenarios

>> Ethics, Compliance, and Sustainability

>> Tooling and Machining Considerations

● Conclusion

● FAQ

>> 1. What is a carbide edge block used for?

>> 2. Are Japanese carbide manufacturers ISO certified?

>> 3. How long can a carbide edge block last?

>> 4. Can carbide edge blocks be customized for OEM production?

>> 5. What industries use carbide edge blocks?

Japan is globally recognized for its technical precision, advanced material engineering, and superior metalworking technologies. Among them, Carbide Edge Block Manufacturers and Suppliers play a crucial role in shaping industries like automotive, aerospace, mold manufacturing, and electronics assembly. These manufacturers have mastered tungsten and cemented carbide processing to deliver unrivaled wear resistance, precision, and consistency.

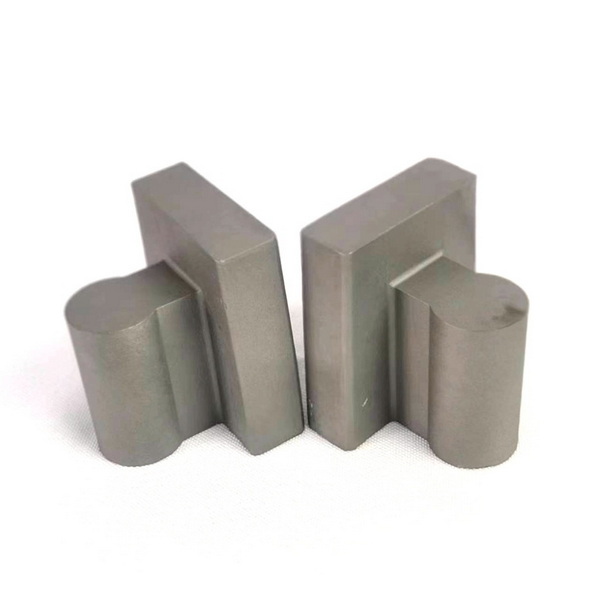

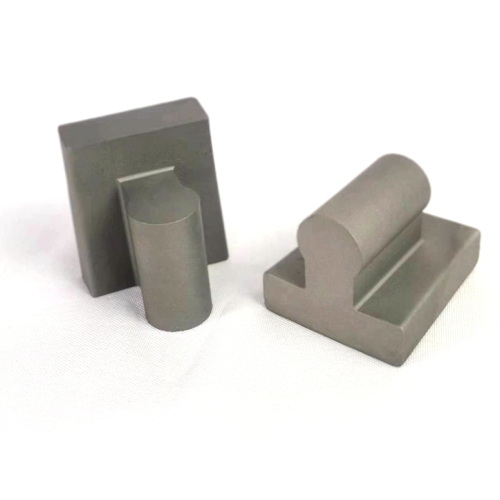

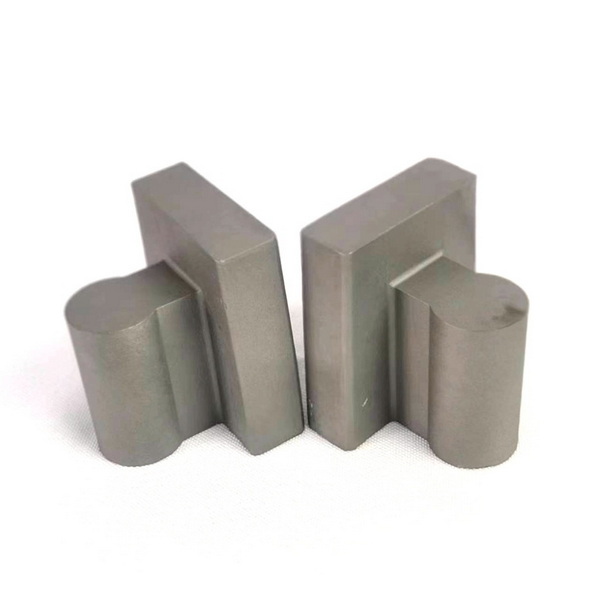

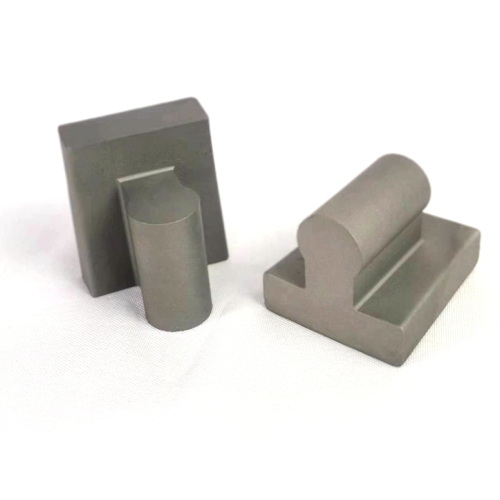

Understanding Carbide Edge Blocks

Carbide edge blocks are components typically made of tungsten carbide or cemented carbide materials, designed to withstand high friction, temperature, and wear. They're used in industrial dies, cutting blades, and high-load machinery where ordinary steel cannot compete.

Carbide edge blocks offer several performance advantages:

- Extreme hardness and dimensional stability

- Resistance to deformation under heat

- Longer lifespan than tool steel

- Custom machining for specific mold or press applications

Why Japan Leads in Carbide Technology

Japan's industrial philosophy centers on material science and manufacturing perfection. From powder metallurgy to sintering and finishing, Japanese Carbide Edge Block Manufacturers and Suppliers maintain exacting quality control. These companies integrate high-precision grinding, CNC shaping, and mirror polishing under ISO standards to ensure consistency for global clients.

Key factors that make Japanese manufacturers stand out:

- Full vertical integration from powder to finished product

- In-house R&D for tungsten and cobalt binder optimization

- Continuous investment in vacuum furnaces and HIP systems

- Global OEM partnerships providing custom carbide parts

Top Japanese Carbide Edge Block Manufacturers and Suppliers

Below is a curated list of the top Carbide Edge Block Manufacturers and Suppliers in Japan, renowned for their precision, innovation, and export quality.

1 DIJET INDUSTRIAL CO., LTD.

Founded in 1938, DIJET Industrial Co., Ltd. is one of Japan's oldest carbide tool producers. Headquartered in Osaka, the company specializes in cemented carbide tools, coated carbide, and CBN products. They are celebrated for their complete in-house manufacturing chain—from powder mixture to final inspection—ensuring unmatched reliability in carbide edge block production.

Key Highlights:

- ISO-certified production facilities

- Custom precision carbide shapes for dies and molds

- Serving global automotive, mold, and construction industries

2. Fuji Die Co., Ltd.

Established in 1949, Fuji Die Co., Ltd. operates multiple sintering plants across Japan equipped with HIP units and a broad furnace capacity. Fuji Die standardizes every manufacturing process under Fuji Die Standards, aligning with ISO9001, delivering dense, durable carbide edge blocks for heavy-duty wear-resistant applications.

Key Strengths:

- Mastery in vacuum sintering and hot press compaction

- World-class wear-resistant carbide parts

- Strong export network covering ASEAN and China

3. NIPPON CARBIDE INDUSTRIES CO., INC. (NCI)

Nippon Carbide Industries (NCI) is a leading manufacturer of carbide edge materials and precision parts. Their production facilities focus on sintered carbide block fabrication, ensuring tight dimensional accuracy for molds, blades, and industrial tools. NCI's high-purity powder metallurgy techniques contribute to durability in precision cutting applications.

Core Competence:

- Proprietary powders for carbide edge blocks

- Strong R&D and ISO-certified testing labs

- Ongoing innovation in low-defect carbide materials

4. Everloy Co., Ltd.

Everloy specializes in cemented carbide technology, developing customized carbide blocks and components for global industries. Their strengths lie in precision processing and product shaping for high-speed cutting and injection molding applications.

Product Portfolio:

- Carbide and tungsten alloy edge blocks

- Electronic component machining inserts

- Powder metallurgy R&D for special alloys

5. Muteki Japan

Muteki Japan manufactures carbide inserts, circular edge blocks, and wear-resistant components. They combine traditional toolmaking craftsmanship with modern automation technologies to deliver reliable OEM services.

Manufacturing Features:

- Computer vision for quality assurance

- OEM services for carbide cutting and forming tools

- Focus on sustainability and reduced material waste

6. Mitsubishi Materials Corporation

Mitsubishi Materials is among the most globally recognized Japanese brands in carbide manufacturing. Its carbide blocks, cutting inserts, and milling tools feature proprietary cemented carbide formulations. The company's advanced binder design supports maximum rigidity and impact resistance.

Advantages:

- High-performance carbide microstructure

- Global distribution and technical support

- Excellent tool life in extreme machining conditions

7. Sumitomo Electric Hardmetal

A unit of Sumitomo Electric Industries, this brand supplies carbide materials optimized for edge block production, drills, reamers, and milling inserts. Its precision is well-regarded in aerospace and mold industries.

Special Features:

- Multiple grades for custom hardness

- Enhanced thermal shock resistance

- Strong R&D for micro-grain cemented materials

8. Sanalloy Industry Co., Ltd.

Sanalloy Industry offers carbide tips, rolls, die plugs, and specialized edge blocks for construction and tooling, backed by strict quality assurance protocols. They export to many countries worldwide.

Core Offerings:

- Wear-resistant cemented carbide components

- Edge block customization for OEM clients

- Broad international export network

9. Yatech Materials (Japan)

Yatech Materials provides high-grade tungsten carbide EDM blocks with corrosion resistance and long service life in stamping dies. They offer full customization with precision finishing to ensure total flatness and wear resistance.

Key Applications:

- EDM blocks for stamping die molds

- Corrosion-resistant grades for chemical environments

- OEM service with custom dimensioning options

10. Obishi Keiki Seisakusho

Obishi Keiki Seisakusho specializes in precision measuring instruments but also produces carbide V-blocks and testing jigs. Their metrology-grade carbide blocks maintain micron-level tolerances for inspection setups.

Primary Segment:

- Carbide precision measuring blocks

- Custom grinding and calibration tooling

Applications of Carbide Edge Blocks

Modern industry relies on carbide edge blocks more than ever. The unique material properties of tungsten carbide allow these blocks to be used in:

- Cold forming dies

- Punching and drawing tools

- Molds for aluminum and stainless parts

- Precision cutting and EDM electrodes

- High-speed stamping dies

Their unparalleled hardness ensures low tool wear and reduced maintenance cycles, delivering superior cost efficiency for manufacturers worldwide.

Japan's Competitive Edge in Carbide Supply Chain

Japanese Carbide Edge Block Manufacturers and Suppliers emphasize not just production but collaboration. The local ecosystem includes powder suppliers, furnace manufacturers, and inspection system developers that enable seamless process control.

Advantages of sourcing from Japan include:

- Consistent batch purity in tungsten/cobalt blends

- Seamless OEM support for customized geometries

- Strong R&D-to-production communication loops

- Long-term supply reliability for global markets

Choosing the Right Japanese Carbide Edge Block Partner

When selecting a supplier, consider aspects such as:

- Sintering technology and HIP treatment capabilities

- Machining precision (micron-level tolerance)

- Material performance certificates (ISO, JIS, FDS)

- Lead time and OEM customization flexibility

- After-sales technical support and export logistics

Japan's commitment to precision engineering ensures that clients partnering with Japanese carbide producers receive high-value, long-service tools that outperform low-cost alternatives.

Applications Across Industries

- Automotive and aerospace tooling where high-temperature stability and wear resistance are critical

- Mold and die scenarios and metal forming where tight tolerances are essential

- Electronics and semiconductor packaging that demand clean, burr-free surfaces

- Tooling for glass and ceramic processing where abrasive wear is common

Quality Assurance and Certification Landscape

- ISO 9001 quality management for production control

- Industry-specific standards and compliance, including automotive and aerospace quality schemes

- In-house metrology labs employing coordinate measuring machines (CMM), laser scanning, and advanced microscopy

- Ongoing process validation through statistical process control (SPC) and failure mode effect analysis (FMEA)

The Global OEM Advantage

European and American brands seeking carbide edge blocks for high-stakes tooling often favor Japanese suppliers for:

- Predictable performance under demanding conditions

- Strong technical support with troubleshooting and optimization guidance

- Flexible customization options that align with complex mold and die geometries

- Reliable supply chains and documentation for international shipping and compliance

Choosing the Right Partner: Practical Guidance

- Request a full material data sheet (MDS) and test report for each grade

- Verify sintering technology and HIP capabilities, and request case studies of similar applications

- Assess lead times, minimum order quantities, and scalable production capacity

- Ensure robust after-sales support, including replacement parts, wear-rated coatings, and technical consulting

- Confirm export logistics, incoterms, and packaging standards that protect carbide blocks in transit

Industry Trends and Outlook

- Growing demand for high-precision carbide blocks in automated assembly lines and high-speed stamping

- Advancements in binder metallurgy to improve toughness without sacrificing hardness

- Development of advanced coatings to extend life in challenging environments (oxidizing atmospheres, chemical exposure)

- Increased emphasis on sustainable manufacturing practices and waste minimization within the carbide supply chain

Integrating with Your Supply Chain

For brand owners and distributors, establishing a reliable supplier relationship with a Japanese carbide edge block producer can reduce overall risk and improve time-to-market. Collaborative engagements often involve:

- Joint development projects to tailor carbide grades for end-use conditions

- Shared testing programs to validate wear resistance and service life

- Long-term supply agreements with defined performance milestones

- Co-branding opportunities and technical documentation support for end customers

Customer Support Scenarios

- On-site technical support for tool installation, alignment, and process optimization

- Regular performance reviews and optimization recommendations based on production data

- Access to spare parts, tooling, and maintenance resources to minimize downtime

Ethics, Compliance, and Sustainability

- Adherence to high ethical standards in supplier relationships, labor practices, and environmental stewardship

- Transparent traceability for raw materials and supplier certifications

- Initiatives to minimize waste in powder processing and reduce energy consumption across sintering cycles

Tooling and Machining Considerations

- Hardness, toughness, and fracture resistance are governed by material composition and microstructure

- Finishing and surface treatment options include polishing, coating, and texturing to improve wear performance

- Machinability of carbide blocks requires specialized tooling and process controls due to extreme hardness

Conclusion

Japan remains a global beacon for carbide edge block manufacturing, driven by precision engineering, robust R&D, and an unwavering commitment to quality. Leading houses like DIJET, Fuji Die, NCI, Everloy, Muteki, Mitsubishi Materials, Sumitomo Electric Hardmetal, Sanalloy, Yatech, and Obishi Keiki Seisakusho exemplify the breadth and depth of Japan's carbide edge block capabilities. By understanding the production processes, material science, and collaborative OEM potential, international brands and distributors can partner with confidence to achieve consistent performance, extended tool life, and reliable supply chains.

FAQ

1. What is a carbide edge block used for?

A carbide edge block is used for wear resistance and shape retention in molds, cutting dies, or punches. It withstands high stress and heat in demanding manufacturing conditions.

2. Are Japanese carbide manufacturers ISO certified?

Yes. Leading companies like DIJET, Fuji Die, and Sumitomo Electric Hardmetal are ISO 9001 certified, ensuring globally recognized quality assurance standards.

3. How long can a carbide edge block last?

The lifespan varies depending on operating conditions but typically ranges from several times longer than steel tools due to superior hardness and thermal stability.

4. Can carbide edge blocks be customized for OEM production?

Yes. Most Japanese manufacturers offer OEM customization, including geometry, grade selection, and tight tolerances according to client specifications.

5. What industries use carbide edge blocks?

They are used in automotive component forming, aerospace machining, mold injection, precision stamping, and electronics assembly industries for durability and precision.