Content Menu

● Introduction

● What Carbide Edge Blocks Deliver

● Key properties and performance drivers

● Why Italy Is a Strategic Source for Carbide Edge Blocks

● OEM and Customization Capabilities in Italy

● How to Select the Right Italian Carbide Edge Block Supplier

● Profiles of Notable Italian Players

>> 1. Sarmec SNC (Schio, Vicenza)

>> 2. Gleason Cutting Tools S.r.l. (Viganò, Lecco)

>> 3. Eurolame Commerciale S.r.l. (Italy)

>> 4. Freud (Martignacco, Udine)

>> 5. Carbitalia S.r.l. (Italy)

>> 6. Br Meccanica Italy (Cemented carbide components)

>> 7. Yatech Materials and similar tungsten carbide suppliers

● Manufacturing Technologies and Process Insights

● Industry Trends and Market Dynamics

● Practical Guidance for Buyers

● Integrated Visuals and Media Strategy (placement suggestions)

● Conclusion

● Frequently Asked Questions (FAQ)

>> What are the main applications of carbide edge blocks in industry?

>> How does Italy stand out as a source for carbide edge blocks?

>> What quality controls do Italian carbide block suppliers typically implement?

>> Can a supplier accommodate custom geometries and branding?

>> What is a typical lead time for custom carbide edge blocks?

Introduction

Carbide edge blocks play a pivotal role in high-precision tooling across metalworking, woodworking, automotive, aerospace, electronics, and general manufacturing. Italy—renowned for its engineering heritage, rigorous quality standards, and strong OEM/ODM capabilities—offers a dense ecosystem of carbide edge block manufacturers and suppliers. This article provides an in-depth look at leading Italian players, their technical strengths, customization capabilities, and how they serve international brands, wholesalers, and manufacturers through end-to-end OEM solutions. It combines market context, technology insights, supplier profiles, and practical guidance to help international buyers select the right partner for bespoke carbide edge block requirements.

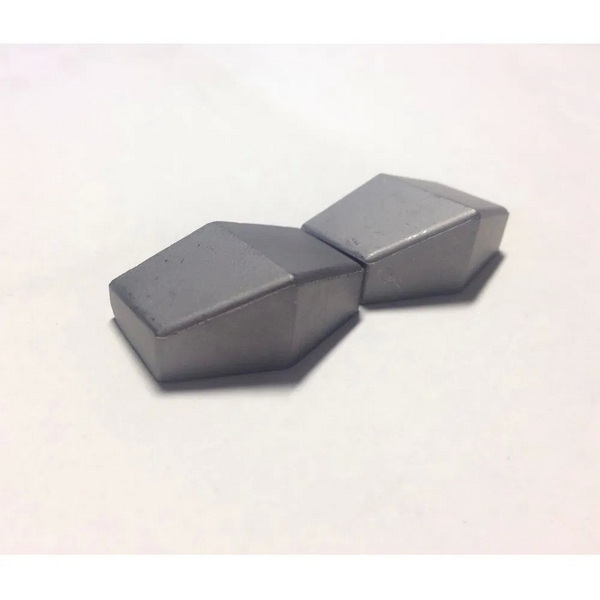

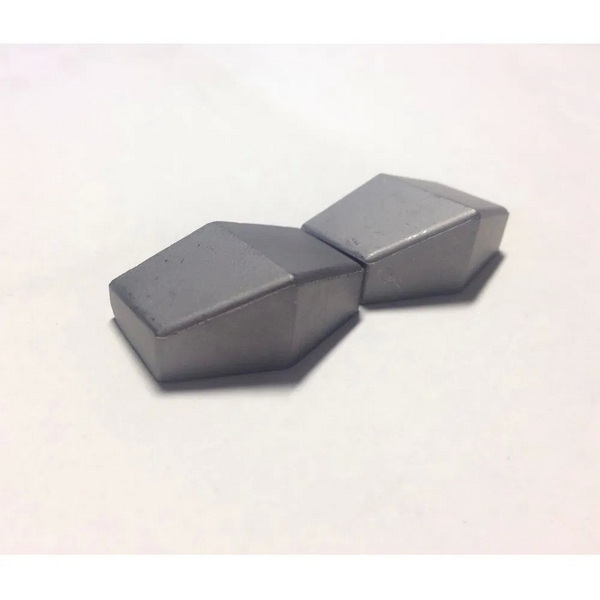

What Carbide Edge Blocks Deliver

Carbide edge blocks are engineered to offer extreme hardness, wear resistance, and dimensional stability under demanding cutting and forming conditions. The primary material—tungsten carbide—combines a ceramic-like hardness with metallic binders to achieve toughness. These blocks support applications such as cutting, stamping, slitting, and precision machining, where consistent edge retention and thermal management are critical. For Italian manufacturers, the emphasis often extends beyond base material properties to include coatings, heat treatments, surface finishing, and compatibility with bespoke tooling geometries and production workflows.

Key properties and performance drivers

- Hardness and wear resistance that extend tool life and reduce downtime

- Thermal stability to maintain tolerances under high-speed or high-temperature operations

- Precision tolerances and surface finish control to minimize secondary processing

- Customizable weight, density, and coating options to fit specific machine tools and processes

- Traceability and quality documentation to support regulatory and customer requirements

Why Italy Is a Strategic Source for Carbide Edge Blocks

Italy's ecosystem blends long-standing metalworking traditions with modern manufacturing technologies. The country's carbide suppliers commonly offer robust OEM/ODM capabilities, enabling brands to source customized blocks with precise dimensions, coatings, and branding. Italian firms often emphasize technical consultation, rapid prototyping, and reliable after-sales support, which is essential for aerospace, automotive, and medical device sectors that demand strict quality controls and documentation. Additionally, Italy's export-oriented suppliers maintain established logistics networks for international shipments and documentation aligned with global trade standards.

OEM and Customization Capabilities in Italy

Italian carbide edge block manufacturers typically provide:

- Custom geometries and tolerances to match exact machine tool interfaces

- Grade options for carbide (and binder compositions) to tailor hardness and toughness

- Surface treatments and coatings (e.g., TiN, TiCN, AlTiN) to improve wear resistance and reduce galling

- Marking, branding, and packaging to support OEM/branding requirements

- Prototyping runs and scalable mass production with dedicated QA regimes

- Documentation packages including material certifications, test reports, and traceability data

- Technical collaboration with international brands for design optimization, process integration, and lifecycle management

How to Select the Right Italian Carbide Edge Block Supplier

When evaluating suppliers, consider:

- Certification and quality systems (ISO 9001, ISO/TS, CE, etc.)

- Proven export experience and ability to support global customers

- Engineering capabilities to translate complex requirements into manufacturable designs

- Lead times, capacity, and flexibility for ramp-up or urgent orders

- After-sales support, including replacement policies, service tooling, and technical advice

- Transparent pricing, clear terms, and consistent delivery performance

- Documentation quality, including material data sheets, coating specs, and traceability records

Profiles of Notable Italian Players

1. Sarmec SNC (Schio, Vicenza)

- Strengths: Deep expertise in solid carbide tooling and carbide-tipped solutions, with a strong emphasis on customized tool design, including carbide edge blocks for niche applications. Their export network supports international brands with tailored tooling solutions.

- Why it matters: For buyers needing high-performance blocks designed around unique operations, Sarmec offers engineering support and flexible production scales.

2. Gleason Cutting Tools S.r.l. (Viganò, Lecco)

- Strengths: A legacy in high-precision tooling with strong capabilities in carbide tool systems and bespoke tooling solutions. Known for reliability and service excellence, including expedited pathways for urgent projects.

- Why it matters: International brands requiring scalable carbide tooling ecosystems can leverage Gleason's integrated approach to design, manufacture, and delivery.

3. Eurolame Commerciale S.r.l. (Italy)

- Strengths: Specializes in high-quality blades and carbide-based tooling components suited for cutting lines and slitting processes. Precision tolerances and material-grade control are central to their offerings.

- Why it matters: For buyers seeking blade-block and edge-block compatibility with advanced slitting and trimming lines, Eurolame's precision standards provide confidence in performance and interchangeability.

4. Freud (Martignacco, Udine)

- Strengths: Notable for 100% in-house carbide production, enabling tight control over the entire value chain and the ability to customize carbide grades and geometries. Proprietary MicroGrain technology and rigorous in-house testing underpin their quality.

- Why it matters: For international brands prioritizing full traceability, meticulous quality control, and the ability to request specialized carbide grades for demanding applications, Freud is a compelling partner.

5. Carbitalia S.r.l. (Italy)

- Strengths: Focused on advanced carbide solutions with both standard and custom geometries, backed by a strong R&D orientation to address niche tooling requirements.

- Why it matters: For customers with unique design specifications or niche industrial applications, Carbitalia's customization and research capabilities help realize optimized performance.

6. Br Meccanica Italy (Cemented carbide components)

- Strengths: Specializes in cemented carbide components and related tooling parts, with precise tolerances and OEM readiness for toolmakers and manufacturing lines.

- Why it matters: For buyers seeking integrated carbide components that fit into broader tooling systems or modular tooling assemblies, Br Meccanica can offer end-to-end support.

7. Yatech Materials and similar tungsten carbide suppliers

- Strengths: Provide tungsten carbide blocks and EDM blocks with a focus on high-precision tooling components and compatibility with complex tooling systems.

- Why it matters: For international buyers requiring tungsten carbide blocks with tight tolerances and compatibility with EDM processes, these suppliers present reliable options.

This list highlights a spectrum of Italian carbide providers—from those with deep in-house carbide production to those specializing in high-precision edge blocks and associated tooling components. Each offers unique strengths in customization, process control, and international service capabilities.

Manufacturing Technologies and Process Insights

Carbide edge blocks are produced through an integrated sequence of powder preparation, blending, compaction, sintering, finishing, and testing. European leaders emphasize the following process capabilities:

- Powder preparation with controlled particle size distribution to influence densification and edge retention

- Precise blending and dispersing of carbide grains with metallic binders to achieve the desired hardness-toughness balance

- Advanced pressing technologies, including uniaxial, isostatic, and HIP-compatible steps, to achieve uniform density and dimensional accuracy

- Sintering in controlled atmospheres, with tailored grain growth and binder migration to meet specification targets

- Post-sintering machining, grinding, and finishing to achieve tight tolerances and smooth surface finishes

- Surface coatings and treatments to enhance wear resistance and reduce friction in cutting and forming operations

- In-process and post-process quality control, including hardness testing, microstructure analysis, and dimensional metrology

In practice, Italian suppliers often align these steps with Industry 4.0 principles: automated data collection at each stage, real-time process monitoring, traceable batch records, and digital interfaces for customers to monitor production status and certification data.

Industry Trends and Market Dynamics

- Customization dominance: OEM and ODM projects drive demand for tailored carbide edge blocks with specific coatings, geometries, and branding.

- Shorter lead times: Global competition and integrated supply chains push suppliers toward agile production models and expedited services.

- Material innovations: New carbide grades and coating technologies extend tool life in challenging materials, enabling higher productivity with consistent quality.

- Sustainability focus: Recyclability of discarded carbide components, efficient sintering processes, and energy management in production are increasingly prioritized.

- Digital integration: Smart manufacturing and predictive maintenance data enable better inventory planning and reduced downtime for end users.

Practical Guidance for Buyers

- Define performance targets early: Clarify hardness, toughness, wear resistance, and edge-holding requirements for the intended application.

- Specify tolerances and finishes: Provide dimensional targets, surface finish standards, and coating types if needed.

- Prioritize traceability: Request full material data sheets, coating specifications, lot numbers, and quality certificates to ensure compliance and after-sales support.

- Consider packaging and labeling: If OEM branding is required, outline labeling, packaging standards, and QA documentation that will accompany each batch.

- Plan for after-sales support: Confirm warranty terms, replacement policies, and access to technical service for ongoing optimization.

Integrated Visuals and Media Strategy (placement suggestions)

- Infographics: Market growth, OEM/ODM capabilities, and supply chain advantages for Italian carbide edge block manufacturing.

- Process diagrams: Powder preparation, compaction, sintering, and finishing steps with labeled process controls.

- Facility images: Factory floors, lab facilities, and machining centers to illustrate capabilities.

- Video features: Facility tours, coating and finishing demonstrations, and interviews with engineering teams discussing customization processes and QA protocols.

- Flow videos: End-to-end order lifecycle from inquiry to delivery, including certifications, packaging, and logistics.

Conclusion

Italy remains at the forefront of carbide tooling innovation in Europe, delivering advanced carbide edge blocks through a blend of deep metallurgical expertise, precise manufacturing capabilities, and robust OEM/ODM partnerships. For international brands, wholesalers, and manufacturers seeking reliable supply chains, technical collaboration, and customized carbide edge block solutions, Italian suppliers offer compelling value, traceable quality, and a proactive approach to meeting evolving market demands. By selecting partners with strong engineering support, transparent documentation, and agile production capabilities, buyers can achieve sustained performance improvements, improved tool lifetimes, and streamlined procurement processes across global operations.

Frequently Asked Questions (FAQ)

What are the main applications of carbide edge blocks in industry?

Carbide edge blocks are central to high-precision cutting, stamping, and forming operations across metalworking, automotive, aerospace, electronics, and tooling industries, delivering edge stability and reliability under demanding conditions.

How does Italy stand out as a source for carbide edge blocks?

Italian manufacturers combine strong metallurgical expertise, rigorous quality systems, and robust OEM/ODM capabilities, enabling tailored solutions and efficient international distribution.

What quality controls do Italian carbide block suppliers typically implement?

Suppliers commonly employ ISO-certified quality systems, material testing (hardness, microstructure, coating integrity), dimensional metrology, and traceability documentation to support compliance and reliability.

Can a supplier accommodate custom geometries and branding?

Yes. Many Italian carbide edge block manufacturers offer custom geometries, coatings, and branding options, supported by prototyping and pilot runs to validate performance before mass production.

What is a typical lead time for custom carbide edge blocks?

Lead times vary by complexity and volume, but competitive Italian suppliers often provide standard turns and express routes for urgent orders, with typical ranges in a few weeks for standard customizations and shorter timelines for expedited services.