Content Menu

● Introduction

● Why carbide edge blocks matter

● Leading carbide edge block manufacturers and suppliers in Arabia

● What to look for in a carbide edge block supplier

● How to choose a partner for OEM and international sales

● Practical deployment: selecting an edge block supplier for Arabian projects

● Media-forward approach: visuals that support technical decisions

● Global market view

● About OEM/ODM services

● Best practices for procurement and collaboration

● Conclusion

● FAQ (single consolidated section)

>> 1.What is a carbide edge block and why is it used in HPGR systems?

>> 2.Which grades of tungsten carbide are commonly used for edge blocks?

>> 3.What should be considered when choosing an OEM supplier for edge blocks in Arabia?

>> 4.How does tungsten carbide edge block cost compare to alternative wear parts?

>> 5.How can media assets (images/videos) support procurement decisions?

Introduction

In today's industrial landscape, carbide edge blocks and related carbide components play a pivotal role in high-pressure grinding, mining, cement production, and metalforming. For foreign brands, distributors, and manufacturers seeking reliable OEM partnerships in Arabia, understanding who the leading carbide edge block manufacturers and suppliers are—and what they offer—can drive smarter sourcing decisions, longer equipment life, and lower total cost of ownership. This article provides a detailed panorama of top carbide edge block players, their capabilities, markets, and how to engage them effectively. It also highlights the value of tungsten carbide edge blocks in HPGR (high-pressure grinding roll) applications and other wear-intensive contexts, with guidance on selection, QA, and collaboration models.

In the Arabian region, the demand for robust wear parts is closely tied to mining, cement, and metalforming sectors. Edge blocks sit at critical contact points on grinding equipment, absorbing and distributing extreme forces while resisting abrasion, impact, and thermal cycling. Choosing the right partner for edge blocks—one that blends technical expertise, reliable supply chains, and responsive after-sales service—can translate into fewer unplanned downtimes, steadier production, and clearer lifecycle economics. This article brings clarity to buyers, engineers, procurement specialists, and brand owners navigating the Gulf markets, offering practical criteria, case-based reasoning, and actionable steps for effective supplier engagement.

Carbide edge blocks, forged from cemented tungsten carbide, deliver exceptional hardness and fracture toughness compared with conventional steel components. They enable longer service intervals, improved material throughput, and enhanced wear resistance under harsh operating conditions. Across HPGR systems and allied processing lines, edge blocks and related wear parts contribute to consistent particle size distribution, reduced energy losses due to inefficiencies, and more stable crusher and grinder performance. For OEMs and distributors, the ability to source reliable carbide edge blocks with consistent geometry, coatings, and traceable material properties is a differentiator in competitive bidding and project delivery timelines. This extended narrative offers a structured guide to the landscape, with emphasis on the practical realities of sourcing, quality assurance, and long-term performance.

Why carbide edge blocks matter

Edge blocks are purpose-built wear parts designed to tolerate severe abrasion, impact, and high compressive forces. In high-pressure grinding rolls, the blocks sit at the interface between the roller and the material stream, where intense contact forces and dynamic loading occur. Tungsten carbide's celebrated hardness and toughness enable extended service life, stable grinding action, and improved process reliability. Beyond HPGR, edge blocks find relevance in other heavy-duty contexts such as roll presses, cement mills, mining conveyors, and ore-dressing circuits, where consistent wear resistance translates into fewer maintenance interruptions and more predictable throughput. The combination of tailored grades, precise tolerances, and surface finishes allows engineers to optimize performance for specific ore compositions and processing temperatures.

- Performance benefits include enhanced wear resistance, stable dimensional tolerances, and compatibility with standard HPGR roll geometries. These attributes support longer operating windows between interventions and more efficient material reduction.

- Economic benefits arise from longer block life, reduced maintenance cycles, and potentially lower energy consumption through steadier grinding dynamics and lower resistance losses.

In practice, choosing a carbide edge block involves balancing hardness, toughness, and resistance to particular wear mechanisms (abrasive wear, impact wear, and thermal fatigue). Grade selection (for example, a family of tungsten carbide grades with varying cobalt binder content) is essential to align with ore hardness, moisture, and the presence of abrasive minerals. Surface finishing choices—grinding, polishing, or protective coatings—also influence friction, heat dissipation, and ease of inspection during maintenance. This nuanced selection process underpins reliable long-term performance in demanding Arabian processing facilities.

Leading carbide edge block manufacturers and suppliers in Arabia

The market for carbide edge blocks in Arabia is characterized by a global supply ecosystem, where Gulf-region buyers frequently engage with international manufacturers and leverage regional distributors for local service. The following profiles illustrate a cross-section of credible players known for carbide edge blocks, HPGR wear parts, and related cemented carbide components. While some manufacturers are headquartered outside the region, their Arabian market presence is established through regional distributors, technical support infrastructure, and OEM collaboration programs.

- ZHONGBO Cemented Carbide Co., Ltd.: A China-based producer with a robust global footprint, ZHONGBO emphasizes customized carbide edge blocks, a wide grade range, and ISO-certified quality processes. Their emphasis on customization and traceability makes them a candidate for large-scale mining and cement projects that require consistent wear-part performance under high-stress conditions. This supplier's outreach to Middle Eastern markets aligns with the region's demand for reliable OEM wear parts and technical documentation suitable for project audits and procurement records.

- Zhuzhou Better Tungsten Carbide Co., Ltd.: Known for durable edge blocks and HPGR-related components, they position themselves as a reliable source for high-stress grinding environments. Their product narratives emphasize long service life and a focus on wear resistance in challenging ore types, which resonates with many Arabian operations featuring hard rock and abrasive minerals.

- Kennametal and other global providers: As a long-standing name in cemented carbide and EDM blocks, Kennametal and similar global brands furnish a broad portfolio of carbide blocks, rods, and blanks. While not Arabia-specific, their global supply networks and established certification programs support consistent quality and supply chain guarantees for Arabian OEMs seeking dependable partners with global service footprints.

- Local distributors and service networks: In the UAE, Saudi Arabia, and neighboring Gulf economies, regional distributors partner with international carbide specialists to deliver edge blocks, inserts, and wear parts. These ecosystems support fast quoting, local stock, and regionally tailored logistics, which are critical for uptime-sensitive mining and cement operations.

Note: The Arabian market often sources carbide edge blocks via international manufacturers, complemented by regional distributors. Prospective buyers should evaluate supplier certifications, traceability, MOQs, and after-sales support, since these factors strongly influence project timelines and total cost of ownership.

What to look for in a carbide edge block supplier

- Product breadth and grade options: The supplier should offer standard and customized edge blocks across multiple grades (YG11C, YG15, YG18, YG20, and comparable equivalents) and finishes (ground, polished). This flexibility supports diverse HPGR configurations and other wear-intensive equipment, enabling optimization for ore composition and process temperature ranges.

- OEM/ODM capabilities: The ideal partner provides design collaboration, custom geometry, coating options, and production ramp-ups to meet exact customer specifications. OEM/ODM alignment reduces integration risk and accelerates time-to-market for new or reconfigured systems.

- Quality management: ISO 9001 or similar certifications, along with robust QA testing (dimensional accuracy, surface finish, hardness, impact resistance), are essential for predictable performance and reliable field operation. Documentation of material certificates and traceability enhances audit readiness for international customers.

- Production scale and delivery: A credible edge block manufacturer demonstrates scalable production capacity and transparent lead times, particularly important for large order quantities typical of mining projects and cement plants.

- Global logistics and support: For Arabian buyers, regional availability, rapid quotes, local stocking, and after-sales support (technical assistance, warranty, field service) materially reduce project risk and downtime. A mature supply chain includes contingency planning for supply disruptions and clear escalation pathways.

How to choose a partner for OEM and international sales

- Alignment with application needs: Confirm the edge block's hardness, toughness, and wear characteristics align with the target ore, cement clinker, or mineral processing environment. Request material certificates and performance data for traceability and validation.

- Customization capabilities: Evaluate whether the supplier can tailor dimensions, tolerances, and surface finishes, including coating selections, to match specific HPGR rollers or machinery. A proven track record in similar OEM partnerships is a strong indicator of capability.

- Supply chain resilience: Inspect lead times, MOQ flexibility, and the ability to scale with project demand, especially for large-scale mining projects in Arabia. A robust supplier should outline production planning, inventory commitments, and alternate sourcing options.

- After-sales support: Confirm warranty terms, spare parts availability, and long-term service for field maintenance, including guidance on replacement cycles and recommended inspection intervals.

Practical deployment: selecting an edge block supplier for Arabian projects

- Engage with cross-functional teams: Procurement, engineering, and operations should collaborate to define grade requirements, service interval targets, and budget impact. Documented criteria and a written supplier short list streamline procurement workflows.

- Request samples and testing: Propose sample blocks to validate fit, stress distribution, and wear resistance under actual process conditions. Access to lab test data, surface finish measurements, and hardness testing supports credible decision-making.

- Consider total cost of ownership: Compare price per block, transport, installation, maintenance, and downtime costs across the asset's life. Tungsten carbide's longer life often yields favorable lifecycle economics despite higher upfront costs, particularly when downtime costs are significant.

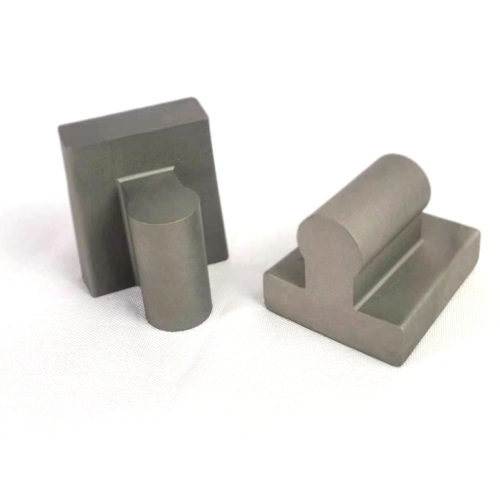

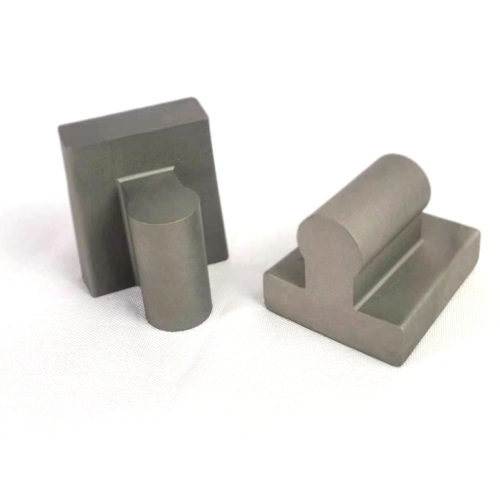

Media-forward approach: visuals that support technical decisions

For technical procurement, media enriches evaluation. The following media assets help engineers and buyers make informed judgments:

- High-resolution product imagery of carbide edge blocks across grades, highlighting surface finish quality and edge geometry.

- 3D exploded views showing how edge blocks interface with HPGR rollers, including alignment tolerances and fitment interfaces.

- Wear and impact testing videos demonstrating performance under simulated or real operating conditions.

- Infographics that compare total cost of ownership across wear-part options, including maintenance schedules and downtime implications.

Note: Each media asset should be captioned, with accessible alt text, and organized in a way that supports quick technical review by procurement teams.

Global market view

Arabia's demand for carbide edge blocks reflects ongoing investment in mining, cement, and metalforming sectors. Suppliers frequently leverage cross-border manufacturing networks and regional distributors to deliver consistent quality and timely delivery. As ISO-certified manufacturers and advanced wear-resistant technologies evolve, Arabian buyers gain access to diversified sourcing options, better pricing clarity, and stronger after-sales support, all of which enhance visibility into long-term asset performance.

About OEM/ODM services

Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) arrangements enable buyers to commission carbide edge blocks with tailored specifications, branding, and documentation. Such partnerships accelerate product deployment and enable brand customization for foreign brands, wholesalers, or manufacturers operating in Arabia or exporting to Gulf markets. Typical OEM/ODM benefits include:

- Custom geometries, coatings, and surface treatments tailored to specific HPGR configurations

- Documented material properties, QA protocols, and traceability records

- Packaging, labeling, and logistics aligned with customer requirements

- Joint development of testing protocols and validation plans

Engaging an experienced carbide edge block supplier with established OEM capabilities reduces development risk and accelerates time-to-market for end-users in the Arabian region.

Best practices for procurement and collaboration

- Prioritize ISO-certified manufacturers with demonstrated edge block offerings and HPGR-related wear parts. Certifications and documented QA workflows provide confidence in long-term performance.

- Seek suppliers with explicit OEM/ODM experience and the ability to tailor geometry and finishes to exact equipment designs.

- Assess total cost of ownership by considering wear life, maintenance cycles, downtime, and transport costs.

- Leverage media assets to support technical evaluation, vendor comparison, and comprehensive training for maintenance teams.

Conclusion

In Arabia's industrial supply chains, carbide edge blocks and HPGR wear parts represent a strategic investment in equipment reliability and process efficiency. By selecting ISO-certified manufacturers with robust OEM programs, favorable lead times, and strong technical support, buyers can achieve durable performance, consistent quality, and clear value over the lifecycle of mining and cement processing assets. The integration of high-quality visuals—images and implementation videos—augments technical evaluation, supplier comparisons, and stakeholder alignment, making the procurement journey more efficient and confident. A thoughtful combination of grade selection, coating options, and process-specific design leads to optimized wear-part performance, reduced downtime, and better predictability in project delivery timelines. Stakeholders should continuously monitor supplier performance through clear KPIs, including on-time delivery, defect rates, and field service response times, to sustain a resilient supply chain and maximize return on investment.

FAQ (single consolidated section)

1.What is a carbide edge block and why is it used in HPGR systems?

A carbide edge block is a cemented tungsten carbide component used on the edges or studs of HPGR rollers to resist wear in high-pressure grinding of ore and cement clinker, extending roller life and improving grinding efficiency.

2.Which grades of tungsten carbide are commonly used for edge blocks?

Common grades include YG11C, YG15, YG18, and YG20, selected based on hardness, toughness, and wear requirements of the target material.

3.What should be considered when choosing an OEM supplier for edge blocks in Arabia?

Consider OEM/ODM capabilities, quality certifications (ISO 9001), traceability, lead times, minimum order quantities, and after-sales support.

4.How does tungsten carbide edge block cost compare to alternative wear parts?

While initial costs are higher, the longer service life and reduced downtime typically yield lower total cost of ownership over the equipment's lifespan.

5.How can media assets (images/videos) support procurement decisions?

Rich media aids technical evaluation by illustrating surface finish, dimensional accuracy, and real-world performance; it supports vendor comparison and training.