Content Menu

● Introduction

● Why carbide edge blocks matter in the supply chain

● Top carbide edge block manufacturers and suppliers in the United States

>> Hydro Carbide Tool Company

>> ZCC America

>> Zhuzhou Better Tungsten Carbide

>> Yatech Materials

● OEM and ODM readiness for international buyers

● Material science aspects to consider

● How to choose the right partner

● Practical recommendations for international buyers

>> Case notes: industry examples and references

● What to include in your OEM proposal

● About your manufacturing setup

● Conclusion

● FAQ

>> 1. What are carbide edge blocks and what is their primary use in tooling?

>> 2. How do I choose between EDM blocks and ground-surface carbide blocks for a project?

>> 3. What certifications should an OEM supplier provide for carbide edge blocks?

>> 4. What grain structures are offered for carbide edge blocks and why do they matter?

>> 5. What logistics considerations are important when sourcing carbide edge blocks from the US for international buyers?

Introduction

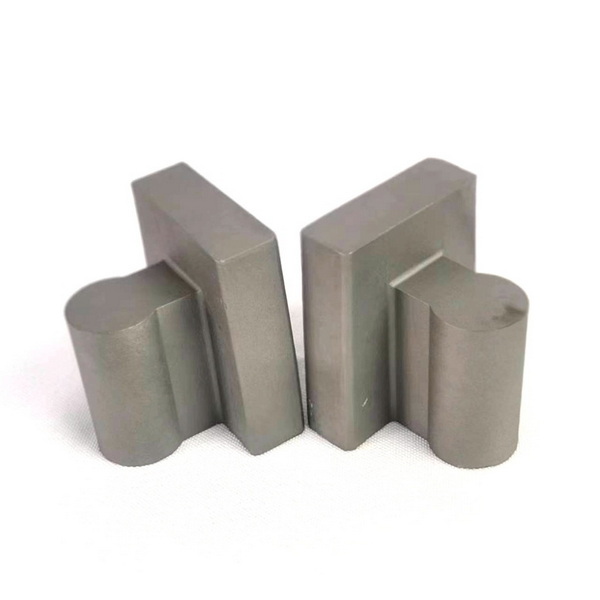

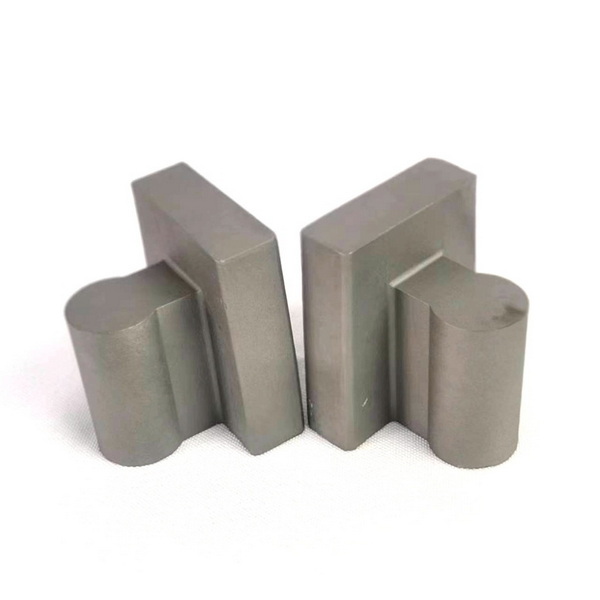

Carbide edge blocks are essential wear-resistant components used in high-pressure grinding, stamping, die work, and various mining and manufacturing applications. For international brands, distributors, and manufacturers seeking reliable supply chains, identifying top carbide edge block manufacturers and suppliers in the United States enables better quality control, consistent performance, and smoother collaboration with OEM-focused factories. This article examines the U.S. and North American supply ecosystem, highlighting capabilities, OEM/ODM readiness, material grades, and what to consider when selecting a partner. While many U.S. buyers source through national suppliers, a strong global network remains critical, as international buyers often pair U.S. distribution with offshore manufacturing to meet scale, customization, and lead-time demands. The discussion also reflects the broader supplier landscape that international buyers monitor for edge-block wear parts used in HPGRs, stamping dies, and tooling platforms. The emphasis is on practical decision-guides, data-driven supplier evaluation, and how a Chinese OEM supplier of stainless steel capillary and coil materials can align its strengths with the needs of carbide edge block manufacturers and their international customers.

Why carbide edge blocks matter in the supply chain

Carbide edge blocks deliver exceptional hardness, wear resistance, and dimensional stability under demanding service conditions. For OEMs and distributors, this translates to longer tool life, lower downtime, and more predictable performance in high-speed stamping, grinding, and material handling. When sourcing from U.S.-based or U.S.-connected suppliers, buyers often gain advantages in lead times, QA processes, and post-sale support that align with international brands' quality standards. Key considerations include material composition, grain size, binder content, and processing methods such as HIP sintering and post-processing. The choice of grade and processing route directly influences edge retention, resistance to micro-chipping, and the ability to endure repeated thermal and mechanical shocks during operation. Market participants typically categorize edge blocks by material types, hardness ranges, and applicable wear environments, then map these categories to specific customer applications. This alignment ensures that the selected edge blocks perform consistently across different HPGR configurations, tooling lines, and stamping formats. The United States market frequently blends domestic production with imported carbide blocks to achieve optimal price-to-performance ratios while maintaining strict quality oversight and traceability. The discussion below expands on supplier capabilities, OEM readiness, and practical selection criteria that international buyers can apply when evaluating carbide edge block partners.

Top carbide edge block manufacturers and suppliers in the United States

The U.S. market for carbide edge blocks is shaped by specialists in cemented carbide and wear parts, many with strong OEM and ODM capabilities. These players are known for precision, material science expertise, and robust quality management systems. The following profiles summarize core strengths and typical partnerships with international buyers.

Hydro Carbide Tool Company

This U.S.-based producer emphasizes precision carbide products and custom blanks, aligning with the needs of brand owners and OEM partners seeking tailored edge blocks to fit stamping dies and HPGR wear components. The company's processes emphasize stable density, sub-micron surface finishes, and consistent microstructure control, ensuring reliable performance in demanding environments. For international buyers, Hydro Carbide offers a pathway to customized edge-block geometries and post-processing options that support direct integration into existing tooling systems. The company maintains close collaboration with customers to tailor block dimensions, coating options, and inspection protocols that meet global quality expectations. Its approach combines stringent in-process controls with flexible production schedules, enabling rapid prototyping and scalable manufacturing for long-term programs. This alignment makes Hydro Carbide a credible partner for brands seeking consistent supply of high-performance edge blocks that fit a variety of HPGR and stamping configurations.

ZCC America

As part of a global cemented carbide network, ZCC America brings scale, ISO-compliant quality control, and deep material science knowledge to the table. Their edge blocks are designed for demanding service, with an emphasis on traceable batch records, consistent hardness, and reliable supply chains. The North American operation helps bridge language and logistics gaps between Chinese manufacturing and U.S./global customers, enabling smoother OEM collaborations and compliant documentation packages. ZCC America's capabilities extend across multiple carbides, with rigorous acceptance testing, nondestructive evaluation options, and a robust logistics framework that supports international procurement pipelines. This makes them particularly suitable for international brands requiring transparent QA flows and consistent supply commitments.

Zhuzhou Better Tungsten Carbide

Zhuzhou Better and other Zhuzhou-based suppliers specialize in cemented carbide edge blocks and related wear parts, with a track record of serving HPGR components and stamping tooling. They often offer customization options, including tailored binder content, grain size ranges, and surface finishes. Certifications and export experience support international order fulfillment and brand-level procurement programs. These suppliers typically provide detailed datasheets, material certificates, and performance data that help international buyers validate suitability for HPGR wear zones, impact loading, and high-temperature environments. Their global reach often includes distribution partners and regional warehouses to expedite delivery to North American customers.

Yatech Materials

Yatech Materials demonstrates the broader ecosystem's capabilities, including tungsten carbide EDM blocks and related wear parts. While EDM blocks are a distinct product family, the underlying carbide grades and processing know-how translate well to edge-block applications in stamping dies and wear parts with demanding service lives. For buyers seeking an integrated tooling ecosystem, Yatech's capabilities illustrate how carbide solutions can complement other wear components in a brand's product line. Their North American presence helps streamline import processes and provides regional support for technical inquiries, sampling, and trials.

OEM and ODM readiness for international buyers

For brands and distributors outside the United States, OEM/ODM capabilities are a critical decision factor. Key elements to seek include:

- Custom geometry and tolerances aligned with HPGR slot designs or stamping die cavities

- Specific cobalt binder grades and grain-size controls to balance hardness and fracture toughness

- HIP sintering, solution heat treatment, and post-processing to ensure uniform density and surface integrity

- Protective coatings or surface treatments tailored to corrosive environments or high wear resistance

- Documentation packages, including ISO 9001:2015 or equivalent certifications, material traceability, and testing data

- Flexible MOQs and scalable production capacity to accommodate long-term procurement commitments

Material science aspects to consider

Carbide edge blocks are cast from tungsten carbide grades with varied cobalt binder content and grain structure. Grading impacts hardness, wear resistance, and toughness. Buyers should request:

- Grade names, binder percentage, and grain size

- Hardness values (HRA/HV) and fracture toughness (KIC)

- Density, Young's modulus, and compressive strength

- Surface finish quality (ground, polished, or coated)

- Heat treatment steps (HIP, tempering, cryogenic treatment)

- Corrosion resistance and compatibility with relevant media and environments

This information helps buyers map each edge block to specific use cases, such as HPGR wear zones, stamping die cutting edges, or EDM-related wear parts in forming tools.

How to choose the right partner

- Define exact use cases, whether HPGR edge blocks, stamping die blocks, EDM blocks, or other wear parts.

- Request detailed data sheets and material certificates covering composition, density, grain size, and mechanical properties.

- Inquire about lead times, sample policies, and trial runs to validate performance before full-scale orders.

- Assess logistics terms, packaging, and after-sales service levels, including warranty coverage.

- Verify quality systems (ISO 9001 or equivalent) and traceability, plus any applicable standards (RoHS, REACH where relevant).

- Compare total cost of ownership, including wear life, downtime reductions, and maintenance requirements. These criteria ensure that the chosen partner can deliver consistent quality, responsive support, and predictable logistics for ongoing procurement.

Practical recommendations for international buyers

- Prioritize suppliers with clear OEM/ODM pathways, including geometry variations, edge geometries, and packaging compatible with brand standards.

- Favor suppliers with established international distribution networks to minimize lead times and ease regulatory compliance.

- Seek suppliers that provide pre-shipment inspections, testing data, and complete documentation packages suitable for audits and procurement reviews.

- Establish a clear communication cadence for design changes, engineering changes, and quality feedback to maintain alignment with brand specifications.

Case notes: industry examples and references

Suppliers routinely discuss edge blocks used in HPGR and stamping contexts, emphasizing customization in size, hardness, and wear outcomes. The market demonstrates a robust ecosystem where many players offer OEM-aligned statements and the capacity to deliver consistent, traceable product lines for international buyers. Datasheets commonly include hardness, density, and grade families (with binder content and grain size as essential data points) that buyers reference when evaluating options for HPGR wear zones or die components.

What to include in your OEM proposal

- Comprehensive specification sheet detailing material grade, density, grain size, binder content, hardness, and tolerances

- Custom geometry drawings with tolerances and surface finish requirements

- Sample availability and a testing plan for wear or impact performance

- Packaging, labeling, and traceability documentation with batch codes and certifications

- Clear lead times, MOQs, and scalable production capabilities for ongoing collaboration

- After-sales service terms and warranty conditions, plus spare-part availability

A well-structured OEM proposal supports faster evaluation, reduces iteration cycles, and accelerates procurement cycles for international buyers.

About your manufacturing setup

Your factory specializes in stainless steel capillary and coil materials and offers OEM services for international brands, wholesalers, and manufacturers. This alignment with OEM/ODM expectations in the carbide edge block market is meaningful for brands seeking integrated tooling and wear-part solutions. The capacity to deliver consistent material supply, process control, and customization positions the facility to engage confidently with U.S.-connected edge block manufacturers and their global customers. The broader capability in stainless and carbon steel complements edge-block projects by enabling a cohesive offering that covers both raw wear parts and compatible tooling components. This makes the Chinese supplier a compelling partner for comprehensive OEM programs in the carbide edge block space.

Conclusion

The United States hosts a diverse ecosystem of carbide edge block manufacturers and suppliers, with a mix of local capability and strong OEM/ODM partnerships tied to global supply networks. For international buyers and brands, the most effective approach is to work with U.S.-connected suppliers that offer clear customization options, robust quality systems, and dependable logistics, while also leveraging the broader global supplier landscape for specialized grades and forms. By prioritizing detailed material data, traceability, and responsive customization, a Chinese OEM-capable supplier of stainless and carbon steel products can build strategic partnerships with top carbide edge block manufacturers, delivering reliable, high-value components for HPGR wear zones, stamping dies, and other demanding wear-part applications. A well-structured collaboration can yield advantages in lead times, regulatory compliance, and post-sale support, ultimately supporting brands in maintaining competitive performance and uptime across international markets.

FAQ

1. What are carbide edge blocks and what is their primary use in tooling?

Carbide edge blocks are precision blocks made from tungsten carbide or similar hard materials used as reference surfaces, fixtures, or wear-resistant guides in high-precision machining and EDM processes. They help ensure flatness, repeatability, and stability under demanding conditions.

2. How do I choose between EDM blocks and ground-surface carbide blocks for a project?

EDM blocks are typically used for electrical discharge machining environments and may include start holes or specific hole patterns; ground-surface blocks provide improved flatness and reduced surface irregularities for metrology and fixture alignment. The choice depends on the machining method, tolerancing needs, and integration with existing tooling.

3. What certifications should an OEM supplier provide for carbide edge blocks?

ISO 9001 or equivalent quality management certifications are common requirements, ensuring traceability, consistent material properties, and documented quality processes—critical for cross-border OEM engagements.

4. What grain structures are offered for carbide edge blocks and why do they matter?

Carbide blocks can be offered in micrograin, fine grain, or ultra-fine grain formulations; finer grains often improve wear resistance and edge retention, while standard grains can reduce cost and improve toughness. Selection depends on wear demands and machining speeds.

5. What logistics considerations are important when sourcing carbide edge blocks from the US for international buyers?

Key considerations include lead times, stock availability, multi-source options, warehousing or Kanban programs, documentation for export, and reliable post-sales support to ensure smooth cross-border procurement.