Content Menu

● Introduction

● What Are Carbide Edge Blocks?

● Why Source from France?

● The Leading Carbide Edge Block Manufacturers in France

>> Agir Technologies

>> POLICARBURE and SPM

>> RTC Industrie

>> Gardette

>> ArcelorMittal France

>> Pedersen, Pisten Tool, and Other Custom Suppliers

● OEM/ODM Services and International Logistics

● Key Applications of Carbide Edge Blocks

● How to Choose a Carbide Edge Block Supplier in France

● Sustainability and Environmental Impact

● Innovations and Future Trends

● French Carbide Edge Blocks in International Markets

● The Procurement Journey: From Inquiry to Delivery

● Making the Most of French OEM Advantages

● Conclusion

● FAQ on Carbide Edge Block Manufacturers and Suppliers in France

>> 1. What industries most frequently use French carbide edge blocks?

>> 2. Can French suppliers deliver custom and OEM carbide edge blocks for unique projects?

>> 3. How can global buyers ensure the quality of French carbide edge blocks before placing bulk orders?

>> 4. Are French companies equipped for international shipping and export compliance?

>> 5. What distinguishes French carbide edge block manufacturers in the global marketplace?

Introduction

The global manufacturing landscape increasingly relies on advanced materials—and among these, carbide edge blocks stand as critical components for industries demanding longevity, durability, and exceptional performance under rigorous conditions. France, with its blend of technical innovation, industrial know-how, and commitment to both quality and sustainability, ranks as a top choice for international brands, wholesalers, and manufacturers seeking reliable carbide edge block suppliers. French factories bring together expertise in tungsten carbide processing, custom engineering, and the capacity to handle complex OEM projects for demanding applications. Across sectors ranging from mining and construction to automotive and aerospace, France is setting the benchmark for carbide edge block excellence.

What Are Carbide Edge Blocks?

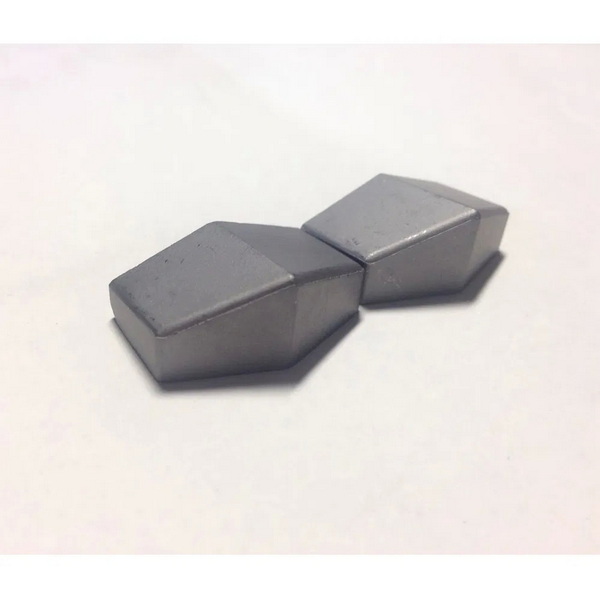

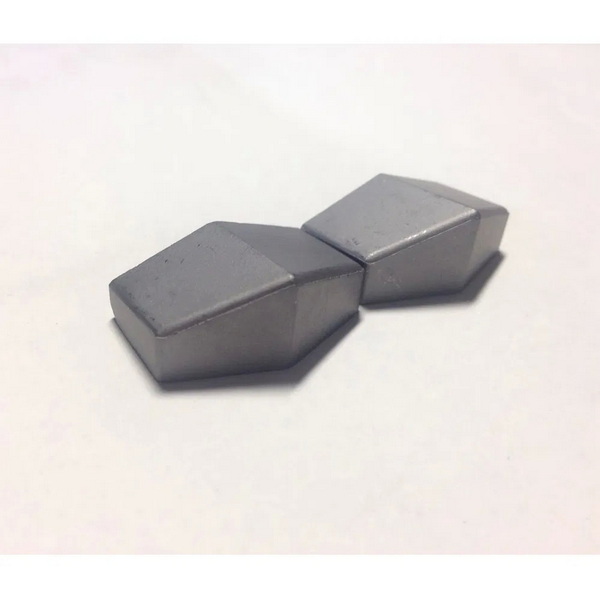

Carbide edge blocks are specialized inserts or segments made from tungsten carbide—a compound favored for its remarkable hardness, wear resistance, and stability under high temperature and pressure. When installed in machines or processes that encounter significant abrasion or impact, these blocks mitigate damage, delay wear, and prolong the operational life of critical tools and equipment. Tungsten carbide, the primary material for these blocks, rivals diamond in hardness and boasts a high melting point, making it ideal where steel and conventional alloys fall short. As such, carbide edge blocks are essential in forging dies, mining crushers, high-pressure grinding rolls (HPGRs), construction machinery, and metal forming operations.

Why Source from France?

French manufacturers have cemented their reputation in the field by blending traditional expertise with cutting-edge technology and a deep commitment to quality assurance. Their strengths include:

- Advanced manufacturing facilities equipped with precision CNC machines, capable of ultra-tight tolerances.

- Robust R&D departments driving product innovation and customization.

- Adherence to international quality protocols, such as ISO certifications, that guarantee consistency and reliability.

- Seamless integration of OEM and ODM services for global clients needing bespoke solutions.

- Dedicated export teams fluent in commercial documentation and international logistics.

French suppliers stand out not just for product quality, but also for their transparent communication, support throughout the procurement process, and willingness to accommodate custom requests and rapid prototyping.

The Leading Carbide Edge Block Manufacturers in France

A number of companies have elevated France's status in the industry, offering wide-ranging options for both standard and custom carbide edge block needs. Here, we detail several of the most esteemed manufacturers and suppliers:

Agir Technologies

Agir Technologies specializes in the production of carbide and diamond dies, focusing on precision-engineered products for industries needing longevity and extreme surface hardness. Their range covers everything from mining tool components to custom wear parts for global OEM clients. With a track record of successful export partnerships, Agir Technologies is trusted for its technical adaptability and rigorous quality control.

POLICARBURE and SPM

POLICARBURE and SPM are major players in France's carbide industry, supplying not only local but also international customers with edge blocks for automotive, aerospace, and heavy engineering. Their flexible manufacturing setups allow for rapid tooling adjustments, and their commitment to innovation has led to the development of edge blocks that perform under the harshest operational stresses.

RTC Industrie

Renowned for ultra-hard carbide rods and forging dies, RTC Industrie uses state-of-the-art manufacturing technologies and quality assurance systems to deliver components that meet stringent demands. Its products are frequently exported for use in mining, material processing, and industrial equipment, where tool life and operational uptime are non-negotiable.

Gardette

Gardette offers an extensive catalog of cold-drawn carbide and steel bars, catering to customers seeking both standard and tailored solutions. Their expertise is reflected in the high consistency of their products, which protect machinery and tools from premature wear even in high-impact environments.

ArcelorMittal France

ArcelorMittal combines deep material science knowledge with advanced forging and forming capabilities. The company is especially suited for large-volume OEM contracts, leveraging its global infrastructure to support complex sourcing needs and rigorous specifications.

Pedersen, Pisten Tool, and Other Custom Suppliers

French suppliers such as Pedersen and Pisten Tool contribute vastly to the industry's diversity. They excel at delivering custom carbide parts, cutting tools, and abrasion-resistant blocks, meeting specialized requirements from international clients in sectors like oil & gas, food processing, and high-speed manufacturing.

OEM/ODM Services and International Logistics

French carbide edge block manufacturers offer world-class OEM and ODM services, guiding buyers from the initial design phase through to prototype approval, quality inspection, and full-scale production. With experience exporting to markets across Europe, North America, and Asia, these companies make use of dedicated export teams to streamline logistics, ensure proper documentation, and support buyers in English and other languages. Many suppliers also provide detailed technical datasheets, factory audit opportunities, and thorough after-sales service—including lifecycle management and tool reconditioning.

Key Applications of Carbide Edge Blocks

The versatility of carbide edge blocks is evident in their widespread adoption:

- Mining operations utilize carbide edge blocks in crushers, HPGRs, and excavation equipment to maximize throughput and reduce maintenance intervals.

- Construction industries deploy these blocks in heavy machinery—such as road cutters, paving equipment, and drilling rigs—to ensure relentless performance in demanding environments.

- Metal forming and forging sectors depend on carbide edge blocks for dies and presses, where surface stability and resistance to deformation are critical.

- Manufacturing lines use carbide edge blocks for stamping, shearing, and cutting tools, particularly in continuous-flow production, where reliability directly impacts profitability.

- Additional sectors, such as automotive, aerospace, and energy, source custom-tailored carbide edge blocks for highly specific applications, including turbine blades, fluid control systems, and high-stress mechanical interfaces.

How to Choose a Carbide Edge Block Supplier in France

Selecting the right supplier hinges on several best practices:

- Assess the supplier's certifications, production capacity, and case history.

- Request samples and technical datasheets to confirm fit for intended applications.

- Review testimonials or references from other international buyers.

- Consider the supplier's willingness to conduct site visits, virtual factory tours, or provide video evidence of their process quality.

- Clarify post-purchase support, warranty terms, and maintenance or reconditioning services.

French suppliers are particularly strong in their responsiveness and customer support, making it easier for global buyers to navigate technical complexities and regulatory requirements.

Sustainability and Environmental Impact

French carbide edge block manufacturers are increasingly prioritizing sustainability. Many have instituted recycling processes for tungsten carbide waste, adopted energy-efficient production protocols, and minimized hazardous material usage in their factories. By investing in cleaner technologies and more responsible waste management, suppliers reduce their environmental footprint and provide added assurance for clients with green sourcing mandates.

Innovations and Future Trends

The future of carbide edge block manufacturing in France is marked by ongoing innovation. Companies are developing advanced composites, integrating smart sensors into tooling systems, and embracing automated inspection technologies. The move toward digitalization enables more precise machining, predictive maintenance, and enhanced traceability throughout the supply chain. International buyers should expect ongoing improvements in customization capabilities, cost-competitiveness, and delivery times as French industry evolves in step with global trends.

French Carbide Edge Blocks in International Markets

French suppliers are adept at managing the demands of global buyers, whether for large-scale industrial plants or niche applications. Their experience includes collaborating with partners in North America, the Middle East, Asia, and Europe, providing:

- Multilingual project management and commercial negotiations

- Flexible financing and payment terms

- Packaging and labeling that meets international standards

- Comprehensive export compliance and logistics coordination

The result for global brands and distributors is a smooth, low-risk sourcing process backed by technical leadership and market-tested reliability.

The Procurement Journey: From Inquiry to Delivery

A typical buying cycle for carbide edge blocks from France starts with a technical inquiry, moves through sample production, validation, and factory audits, before mass production and shipment. French manufacturers support buyers at each step, helping them clarify specifications, optimize designs, and anticipate operational risks. Export managers are trained to provide regulatory support for customs, technical translation of datasheets, and troubleshooting for overseas installations.

Making the Most of French OEM Advantages

Working with French carbide edge block suppliers is not just about product acquisition—it is about building a long-term industrial partnership. By leveraging French expertise in engineering, material science, and sustainable production, global clients gain access to high-performance solutions that keep their operations at the forefront of efficiency and reliability. Whether launching new projects or upgrading existing lines, buyers can trust French manufacturers to deliver durability, precision, and dedicated support.

Conclusion

France remains a powerhouse in carbide edge block manufacturing, driven by technical proficiency, robust infrastructure, and a deep culture of engineering excellence. Sourcing from French suppliers unlocks benefits such as superior product quality, world-class OEM services, sustainable production practices, and seamless international logistics. For any brand, wholesaler, or manufacturer seeking reliability in the most demanding industrial environments, French carbide edge block manufacturers and suppliers offer the expertise and support needed for success.

FAQ on Carbide Edge Block Manufacturers and Suppliers in France

1. What industries most frequently use French carbide edge blocks?

French carbide edge blocks are widely adopted in mining, construction, metalworking, automotive, aerospace, and heavy equipment manufacturing. Their high resistance to wear and toughness suit industries that require long-lasting tooling and minimal downtime.

2. Can French suppliers deliver custom and OEM carbide edge blocks for unique projects?

Yes, French manufacturers offer robust OEM and ODM capabilities, including custom design, prototyping, and scaling for specific client requirements. They work closely with buyers to optimize products for unique applications and operational constraints.

3. How can global buyers ensure the quality of French carbide edge blocks before placing bulk orders?

It's recommended to request product samples, technical documentation, and references. Many suppliers perform factory audits (virtual or physical), offer video tours, and provide international certifications that confirm product quality and process reliability.

4. Are French companies equipped for international shipping and export compliance?

French carbide edge block manufacturers are highly experienced in international logistics, offering streamlined documentation, multilingual support, packaging compliant with export regulations, and established channels for global delivery.

5. What distinguishes French carbide edge block manufacturers in the global marketplace?

Their combination of technical excellence, focus on continuous improvement, strong customer service, and dedication to sustainability set them apart. French suppliers regularly invest in R&D and infrastructure to stay ahead of industry trends and deliver lasting value to international clients.