Content Menu

● Introduction

● Understanding Carbide Edge Blocks

● Spain's Market Leadership in Carbide Manufacturing

● Key Industry Drivers

● Customization and OEM Support

● Spain's Leading Carbide Edge Block Manufacturers and Suppliers

>> Mitsubishi Materials España, S.A.U

>> Graf Hartmetall

>> Esteves DWD Spain

>> Trasteel Blades

>> Hyperion Materials & Technologies

● Modern Manufacturing Technologies

● OEM and ODM Services for Global Clients

● Market Trends and Future Prospects

● Applications of Carbide Edge Blocks

● How to Choose the Best Carbide Edge Block Supplier in Spain

● Conclusion

● FAQ: Carbide Edge Block Manufacturers and Suppliers in Spain

>> 1. What distinguishes Spanish carbide edge block manufacturers from others?

>> 2. Are custom orders and OEM services readily available from Spanish suppliers?

>> 3. Which sectors most frequently use Spanish carbide edge blocks?

>> 4. How do Spanish suppliers ensure consistent product quality?

>> 5. What is the outlook for Spain's carbide edge block industry?

Introduction

Spain stands at the forefront of precision engineering in Europe, with a robust manufacturing base that specializes in groundbreaking carbide edge block production. Over the last decade, Spanish suppliers have secured their place as essential partners to global industries, serving OEMs in automotive, aerospace, metalworking, construction, and energy. These manufacturers offer advanced technologies, rigorous quality control, and customized service for international clients demanding top-tier chemical and physical durability from their carbide edge blocks. This article explores the competitive edge of Spain's carbide edge block sector, introduces the top players, and provides practical insight into the manufacturing process, OEM services, and applications that set Spanish suppliers apart.

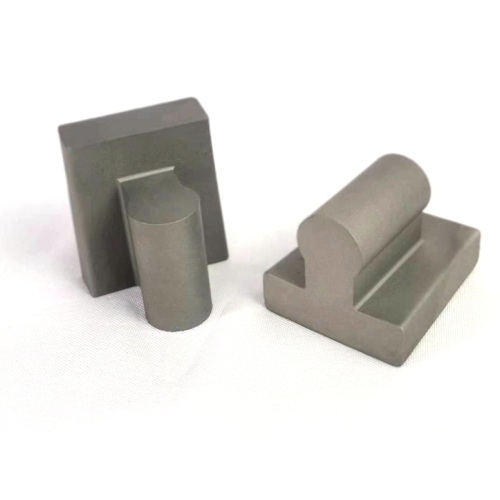

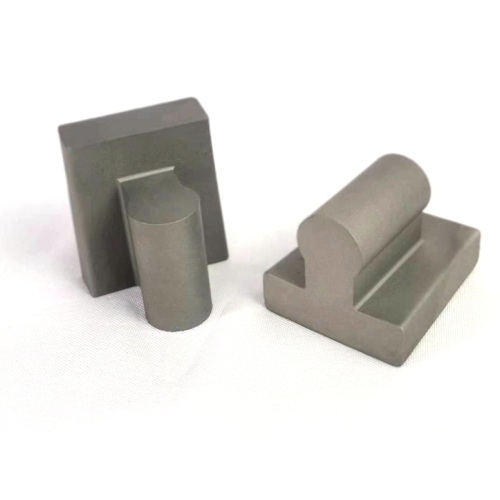

Understanding Carbide Edge Blocks

Carbide edge blocks are critical wear-resistant components widely used in heavy industry. Made primarily from tungsten carbide and cobalt, these blocks display exceptional hardness, resistance to deformation, and longevity in harsh working environments. These characteristics make them invaluable in stamping dies, wire electrical discharge machining (EDM), cutting tool fabrication, and forming processes. As industries progress toward higher speeds, tighter tolerances, and complex geometries, carbide edge blocks have become indispensable in ensuring efficiency, consistency, and quality across production cycles.

The Spanish manufacturing sector distinguishes itself through its focus on innovative metallurgy, integration of computer-aided design, and extensive OEM support. By offering precision-ground surfaces, customized geometries, and fast turnaround for prototyping or volume orders, Spanish carbide edge block manufacturers and suppliers have become reliable partners for both local and global customers.

Spain's Market Leadership in Carbide Manufacturing

Spanish carbide manufacturers are recognized worldwide for combining advanced investments in machinery with a tradition of technical excellence. The domestic market is fueled by high standards for quality and reliability, while a significant percentage of production is exported throughout Europe and beyond. Plants in Valencia, Barcelona, and Madrid use state-of-the-art powder preparation, automated pressing, and robotic sintering lines to deliver high-performance carbide edge blocks at scale.

Significant foreign investment in recent years has catalyzed growth and innovation. Local manufacturers are increasingly collaborating with international partners for R&D initiatives, pooling knowledge to create breakthrough materials capable of handling tougher wear scenarios and more demanding OEM specifications. The ability to provide rapid prototyping, small-batch production, and just-in-time deliveries—alongside compliance with ISO and EU industrial standards—reinforces Spain's competitive edge in the global market.

Key Industry Drivers

The explosive demand for advanced material components is propelled by several factors:

- Expansion of the European automotive and aerospace supply chains, which require premium tooling and high-volume parts.

- A well-educated workforce and a culture of continual upskilling among engineers, technicians, and operators.

- The integration of digital automation and smart inspection systems throughout the production process, ensuring repeatable accuracy and swift response times for customer needs.

- Proximity to strategic logistics hubs, enabling rapid, frictionless export to EMEA, Asia, and the Americas.

Customization and OEM Support

Spain's carbide edge block manufacturers and suppliers pride themselves on their flexible OEM/ODM capabilities. International buyers—whether brands, wholesalers, or manufacturing partners—can specify precise material grades, hardness ranges, surface finishes, and dimensional tolerances necessary for their unique applications. This highly responsive approach streamlines product development cycles, accommodates urgent demand spikes, and allows strategic partners to focus on their core business, trusting Spanish suppliers to deliver as promised.

Many Spanish facilities offer full in-house support, including:

- CAD/CAM design for unique part geometries.

- Tooling consultation and failure analysis for process optimization.

- Branding and packaging solutions that support global supply networks.

- Batch traceability, documentation, and compliance services to meet international standards.

Spain's Leading Carbide Edge Block Manufacturers and Suppliers

Mitsubishi Materials España, S.A.U

Mitsubishi Materials operates one of the largest carbide tooling facilities in Spain, leveraging European and Japanese expertise to serve complex and high-volume needs. The company is known for introducing eco-friendly production methods—including resource recycling and energy-saving automation—while maintaining the ability to deliver premium carbide edge blocks, inserts, and end mills. The organization supports OEMs through full customization, integrated logistics, and technical consulting, making it a one-stop partner for international sourcing demands.

Graf Hartmetall

Graf Hartmetall is a specialist in tungsten carbide EDM blocks, meeting the needs of industries ranging from metal stamping and forming to wire and die manufacturing. The company's Spanish operations enable regional customers to tap into global R&D advances in metallurgy while benefiting from personalized service and quick delivery. Graf Hartmetall's reputation for fine and medium grain carbide, combined with versatile customizations, ensures industry partners always have access to optimal wear-resistant solutions.

Esteves DWD Spain

Esteves DWD Spain is a division of a globally recognized tooling brand, renowned for state-of-the-art wire drawing dies, profile shaping tools, and specialty carbide blocks. Their Spanish facility features extensive local engineering and international quality oversight, excelling at quick-turn prototyping, tool refurbishing, and high-precision manufacturing. The company's strength lies in providing bespoke carbide edge blocks for unique production lines and specialty equipment.

Trasteel Blades

Trasteel Blades has become a household name for ground-engaging tools in Europe, thanks to a comprehensive portfolio of carbide edges, blocks, and wear parts for mining, infrastructure construction, and bulk material handling. Their products are engineered to perform under some of the harshest working conditions, thanks to a meticulous approach to materials selection, geometry optimization, and collaboration with end users and OEMs.

Hyperion Materials & Technologies

Hyperion, with a major facility on the outskirts of Barcelona, is a recognized leader in cemented carbide component production. The company invests heavily in R&D and process automation, focusing on new material formulations, high-speed tooling, and value-added OEM integration. Hyperion's Spanish operations epitomize the intersection of technical tradition and contemporary innovation, supporting partners in automotive, aerospace, can tooling, and high-tech industries.

Modern Manufacturing Technologies

The production of carbide edge blocks in Spain benefits from several core technological advantages:

- Computer-numerical control (CNC) systems permit highly intricate cutting, grinding, and finishing of carbide materials to support increasingly complex part designs.

- Sinter-HIP (Hot Isostatic Pressing) processing enables the creation of carbide blocks with optimal density, uniform grain structure, and minimal porosity—ideal for wear resistance and precision tolerances.

- Fully automated powder blending, pressing, and robotic handling systems allow for both high-mix, low-volume orders and mass production with consistency and efficiency.

- Real-time digital inspection tools and smart metrology ensure every block meets or exceeds customer requirements, minimizing rework and waste.

- Advanced periphery rounding and edge stabilization processes further extend the service life of blocks used in high-throughput environments.

These advancements drive both performance and sustainability, enabling rapid scale-up for major projects and tight quality assurance for mission-critical components.

OEM and ODM Services for Global Clients

A hallmark of Spain's carbide edge block industry is its full embrace of OEM and ODM business models. Spanish suppliers work closely with overseas brands, adapting the entire production workflow to support specific market requirements—whether unique raw material sourcing, custom marking, specialized packaging or drop-shipping directly to end users.

Local manufacturers have also invested in digital collaboration platforms, shortening the product development cycle for clients across the world and accommodating last-minute engineering changes. By maintaining robust relationships with logistics companies and compliance consultants, Spanish firms offer turnkey solutions, from engineering and prototyping to fulfillment and post-sale support.

Market Trends and Future Prospects

Spain's carbide edge block sector is on track for continued robust growth, fueled by macro trends such as rapidly expanding electric vehicle production, the proliferation of automation in global factories, and the rise of infrastructure spending across Europe and Africa.

Key trends set to shape the market include:

- Increasing demand for ultra-hard, specialty carbide grades tailored for next-generation timber, composite, and hard-metal cutting.

- The proliferation of smart manufacturing practices, enhancing traceability, production efficiency, and energy management.

- Growth in international strategic alliances, particularly with Asian, American, and other European manufacturers, capitalizing on shared R&D, procurement, and supply chain optimization.

Spanish companies are also taking the lead on sustainability—recycling secondary materials, using energy-efficient kilns, and integrating closed-loop cooling—answering the demands of global OEMs and end-customers aiming for greener manufacturing.

Applications of Carbide Edge Blocks

Spanish-manufactured carbide edge blocks are engineered for a diverse array of applications, demonstrating versatility and reliability in the world's most demanding industrial contexts. They play crucial roles in:

- Metal stamping dies used for precision automotive components, medical devices, and electronic assemblies.

- Wire and pipe EDM processes in tool and mold production, guaranteeing dimensional integrity and smooth finishes.

- Wear plates and cutters for mining equipment, agricultural machinery, and earthmoving vehicles, where downtime from part failure is cost-prohibitive.

- High-strength end bits and blades employed in bridge building, road construction, and structural steelworks, supporting large-scale infrastructure projects under tough operational stresses.

These applications exemplify the adaptability of Spanish carbide block manufacturers, who frequently partner with end users to develop innovative solutions meeting the evolving requirements of global industries.

How to Choose the Best Carbide Edge Block Supplier in Spain

For foreign brands, wholesale distributors, and OEM producers, selecting the right Spanish carbide edge block manufacturer is a critical strategic decision. When evaluating suppliers, consider the following criteria:

- Demonstrated customization and OEM/ODM capacity, evidenced by a proven track record serving international clients across multiple industries.

- Integrated quality control, with investments in digital inspection systems, real-time testing, and compliance with ISO, EU, or industry-specific standards.

- R&D support and willingness to co-develop new grades, geometries, or finishes tailored to unique production processes.

- Flexible logistics and order handling, allowing for efficient fulfillment of both large-scale contracts and urgent, small-batch requests.

- Commitment to sustainability, including responsible sourcing, energy-efficient production, and comprehensive recycling programs.

Spanish suppliers who excel in these domains routinely build long-term relationships with global partners, offering technical support, after-sales services, and partnership models that allow for shared growth.

Conclusion

Spain's carbide edge block manufacturers and suppliers have reached world-class status through their persistent innovation, commitment to quality, and partnership-oriented approach to international business. With broad OEM and customization options, cutting-edge production technologies, and deep-rooted engineering excellence, these companies deliver products that power some of the world's most advanced and demanding manufacturing sectors.

As industries evolve and quality expectations rise, Spain's carbide block manufacturers are ideally positioned to answer the call—serving as adaptable, reliable partners to forward-thinking organizations everywhere.

FAQ: Carbide Edge Block Manufacturers and Suppliers in Spain

1. What distinguishes Spanish carbide edge block manufacturers from others?

Spanish manufacturers stand out for their integration of modern technology, rigorous quality assurance, and highly customizable OEM solutions. Their ability to service international clients with both technical consulting and responsive production sets them apart in the global market.

2. Are custom orders and OEM services readily available from Spanish suppliers?

Yes, leading Spanish carbide edge block manufacturers and suppliers offer extensive OEM and ODM services, including custom dimensions, materials, surface treatments, branding, and packaging, to meet the unique needs of global clients.

3. Which sectors most frequently use Spanish carbide edge blocks?

Major sectors include automotive, aerospace, electronics, mining, construction, and specialized tool manufacturing. Spanish blocks are valued for their resistance to extreme wear, high precision, and adaptability to challenging applications.

4. How do Spanish suppliers ensure consistent product quality?

Many manufacturers employ advanced CNC machinery, Sinter-HIP processing, digital inspection, and real-time data collection to maintain product quality. Compliance with European and global certifications ensures traceability and reliability.

5. What is the outlook for Spain's carbide edge block industry?

The industry is expected to see continued growth, driven by advances in material science, the adoption of smart factory technologies, increased focus on sustainability, and rising demand for custom-engineered wear parts in global markets.