Content Menu

● Introduction

● The Role of Carbide Edge Blocks in Industry

● Top Carbide Edge Block Manufacturers and Suppliers in Germany

● Manufacturing Process of Carbide Edge Blocks in Germany

>> Powder Preparation

>> Mixing and Blending

>> Compaction

>> Sintering

>> Machining

>> Finishing and Quality Assurance

● Why German Carbide Edge Blocks Lead the Market

● Applications Across Industries

● Factors to Consider When Choosing a Supplier

● OEM Collaboration Benefits

● Innovation and Sustainability in Carbide Manufacturing

● Quality Assurance and Standards

● Conclusion

● FAQ

>> 1. What are carbide edge blocks used for?

>> 2. How are German carbide edge blocks manufactured?

>> 3. What materials are used in producing carbide edge blocks?

>> 4. Why choose German manufacturers for carbide edge blocks?

>> 5. Are there sustainable practices in carbide edge block production?

Introduction

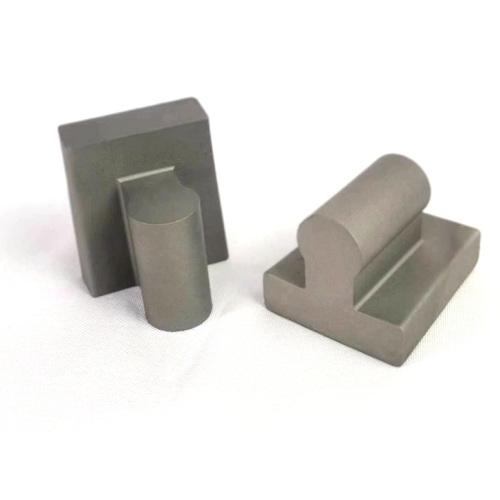

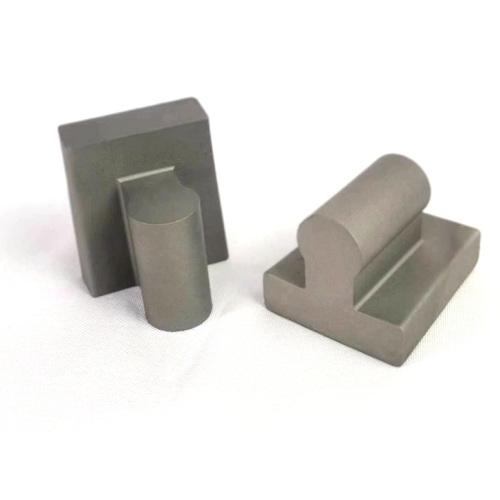

Carbide edge blocks are specialized tungsten carbide components designed for use in high-pressure grinding rolls (HPGR), electrical discharge machining (EDM), and various industrial cutting and forming systems. Owing to their exceptional strength and hardness, these blocks provide enhanced wear resistance and dimensional stability, which directly translates into improved process uptime, consistent output quality, and lower maintenance costs.

Germany's carbide industry benefits from advanced R&D, automation, and extensive OEM experience. Many German suppliers not only produce standard carbide edge blocks but also offer complete custom fabrication, surface coating, and prototyping services. They cater to international markets where precision, durability, and long service life are critical.

The Role of Carbide Edge Blocks in Industry

Carbide edge blocks are crucial wherever extreme loads, wear, and deformation risk exist. The unique combination of tungsten carbide grains bonded with cobalt or nickel provides superior hardness while maintaining sufficient toughness. Applications include:

- Edge protection for HPGRs in mineral processing.

- Guide and support components in heavy machinery.

- Precision inserts in EDM and CNC tooling.

- Wear surfaces for cutting, grinding, and forming dies.

These components are often custom-made depending on pressure, load, and temperature conditions. German manufacturers excel at creating tailor-made carbide solutions through advanced design, testing, and high-purity material sourcing.

Top Carbide Edge Block Manufacturers and Suppliers in Germany

1. BETEK GmbH & Co. KG – A leading name in carbide production, BETEK specializes in high-quality, pore-free carbide materials combined with advanced steel joining. Integrated automation, precision brazing, and ISO-certified quality systems make BETEK a top OEM partner for tooling and construction applications.

2. DURIT GmbH – Known for its ability to manufacture complex carbide geometries, DURIT provides carbide edge blocks and wear parts with exceptional consistency. Their engineering team offers complete design-to-delivery control for custom projects.

3. Ziehstein-Friedrich GmbH – Renowned for its high-precision polishing, grinding, and dimensional accuracy. Their carbide edge blocks are widely used in demanding metal forming and surface finishing industries.

4. DeMa Tools GmbH – Focuses on CAD/CAM-enabled carbide tooling and die systems, offering OEM customizations, prototypes, and comprehensive project documentation.

5. Boeck GmbH – Though primarily a specialist in deburring and edge-rounding technology, Boeck works closely with carbide tooling suppliers to deliver integrated metal edge solutions that improve surface quality and longevity.

These manufacturers share one common trait—precision through process control, ensuring every carbide edge block maintains consistent hardness, grain size distribution, and dimensional integrity.

Manufacturing Process of Carbide Edge Blocks in Germany

German carbide edge block manufacturing is a meticulous process involving several controlled stages that ensure microscopic uniformity and macroscopic strength.

Powder Preparation

Tungsten carbide begins as tungsten ore, reduced in a hydrogen atmosphere to yield tungsten metal powder. This powder is then carburized at high temperatures (1400°C–2000°C) to react with carbon and form tungsten carbide particles. The granular structure of this powder determines the block's final mechanical properties.

Mixing and Blending

The tungsten carbide powder is blended with a metallic binder (usually cobalt or nickel) inside ball mills or attritors. Additives are introduced to refine toughness or improve green strength. Proper mixing ensures consistent structural density and performance.

Compaction

Once homogeneous, the powder mixture is pressed into desired shapes using methods such as uniaxial pressing or cold isostatic pressing. Fiducial “green” blocks are strong enough to handle but not yet fully dense.

Sintering

This step fuses the material through high-temperature vacuum sintering (1400–1600°C). The cobalt binder melts and distributes between tungsten carbide particles, producing a dense and cohesive structure. German plants—such as those of BETEK and HMTG Hartmetall—use fully monitored sintering programs ensuring minimal porosity and maximum strength retention.

Machining

Post-sintering, each carbide edge block undergoes fine grinding, EDM cutting, and polishing. High-precision CNC machines achieve the necessary tolerances for OEM clients. Some manufacturers introduce diamond or multilayer coatings at this stage to enhance surface wear resistance.

Finishing and Quality Assurance

Surface finishing, brazing onto steel bases, and coating are completed in climate-controlled environments. Each batch passes through dimensional verification, density measurement, and metallographic inspection to ensure ISO 9001 compliance.

Why German Carbide Edge Blocks Lead the Market

The global recognition of German precision manufacturing is not accidental—it comes from rigorous process integration, skilled craftsmanship, and leading-edge automation. Advantages of sourcing from German carbide edge block suppliers include:

- Superior material consistency: Use of high-purity tungsten and controlled carbon reactions prevents flaws and ensures uniform grain size.

- Process integrity: Automated sintering and brazing lines maintain traceability and repeatability.

- Customization capacity: OEM clients can specify geometry, grain size, binder ratio, coatings, and tolerances.

- Sustainability and waste minimization: Manufacturers employ carbide recycling programs and energy-efficient sintering technologies.

Additionally, German suppliers provide detailed CAD assistance, prototype validation, and training to international clients—ensuring seamless integration into production lines.

Applications Across Industries

Carbide edge blocks serve multiple heavy and precision industries:

- Mining & Cement: HPGR edge protection to reduce equipment wear.

- Metalforming & Forging: Preventing die edge deformation under high loads.

- Aerospace & Automotive: Providing high precision during machining operations.

- Electronics Manufacturing: Supporting EDM and high-speed stamping operations requiring micro-level accuracy.

With growing demand in energy, construction, and renewable technology sectors, carbide edge blocks have become foundational components for equipment longevity and operational safety.

Factors to Consider When Choosing a Supplier

Selecting the right supplier is vital for achieving consistent quality and reliable delivery. Key considerations include:

- Proven expertise in carbide metallurgy and sintering.

- Ability to develop CAD/CAM-compatible custom geometries.

- Capacity for providing prototype samples and pilot runs.

- Transparent quality documentation and test certificates.

- Flexible logistics, OEM after-sales service, and on-site support.

Buyers should also assess total cost of ownership—longer-lasting carbide edge blocks can justify higher upfront costs through operational savings and extended maintenance intervals.

OEM Collaboration Benefits

For international buyers, German manufacturers often provide complete OEM integration services that include engineering consultation, rapid prototyping, and contract manufacturing for custom applications. Companies like BETEK and DURIT deliver not only components but comprehensive solutions—from powder synthesis to installed assembly.

OEM benefits include:

- Dedicated support teams for technical communication.

- Detailed 2D/3D modeling and tolerance studies.

- Field service assistance during commissioning.

- Continual improvement through shared data feedback.

Innovation and Sustainability in Carbide Manufacturing

The German carbide sector is transitioning toward greener production, focusing on energy efficiency and materials recycling. Modern manufacturing uses automated furnaces with precise heat control to minimize waste energy, while spent carbide parts undergo reclamation to recover tungsten and cobalt materials.

Recycling not only reduces environmental impact but also stabilizes raw material costs amid global tungsten supply fluctuations. Furthermore, smart factory implementations employ predictive monitoring to maintain consistent sintering results, further ensuring process stability and sustainability.

Quality Assurance and Standards

German carbide manufacturers follow DIN ISO 9001 and DIN EN ISO 14001 standards. Each production step, from raw material verification to final inspection, is fully traceable. This strict adherence to documentation ensures consistent quality globally—a major reason international OEMs prefer German suppliers.

Non-destructive testing, metallographic analysis, and dimensional control ensure that each carbide edge block meets its design intent. Automated quality systems detect any deviation, guaranteeing product uniformity batch after batch.

Conclusion

Germany remains at the forefront of carbide edge block manufacturing, combining deep material science expertise with precision machining and rigorous quality control. For foreign buyers and OEMs, sourcing from German manufacturers means investing in longevity, consistency, and innovation. Whether for HPGR wear parts, EDM inserts, or complex custom components, Carbide Edge Block Manufacturers and Suppliers in Germany deliver unmatched reliability and engineering excellence. Partnering with these producers ensures not just superior components but long-term technical collaboration and performance stability across diverse industrial applications.

FAQ

1. What are carbide edge blocks used for?

Carbide edge blocks serve as wear-resistant components in HPGRs, EDM tooling, and forming dies. They ensure structural integrity under high loads and extreme contact pressure.

2. How are German carbide edge blocks manufactured?

They are made through a process involving tungsten powder preparation, carburization, pressing, sintering, and precision finishing. Each stage is meticulously controlled to yield high-density, durable blocks.

3. What materials are used in producing carbide edge blocks?

Tungsten carbide powder mixed with cobalt or nickel acts as the primary composite. Additives improve grain control and surface finish, enhancing toughness and adhesion resistance.

4. Why choose German manufacturers for carbide edge blocks?

German suppliers are known for their process precision, extensive R&D, quality assurance under ISO standards, and strong OEM support for global buyers.

5. Are there sustainable practices in carbide edge block production?

Yes, many manufacturers now emphasize recycling of used carbide, energy-efficient furnaces, and reduced carbon emissions as part of their sustainability initiatives.