Content Menu

● The Fundamentals of Tungsten Carbide Powder

● Tungsten Carbide Powder Production Process

>> 1. Ingredient Calculation

>> 2. Mixing

>> 3. Carbonization

>> 4. Milling

>> 5. Sieving and Granulation

>> 6. Quality Control

● Hardmetal Manufacturing: From Powder to Product

>> 1. Mixing

>> 2. Granulation

>> 3. Pressing

>> 4. Sintering

>> 5. Finishing

● Applications of Tungsten Carbide Powder in Hardmetal Products

>> 1. Industrial Cutting Tools

>> 2. Mining and Oil Drilling Equipment

>> 3. Military and Defense

>> 4. Aerospace and Automotive

>> 5. Metallurgical and Construction

>> 6. Medical Instruments

>> 7. Electronics and Semiconductor Manufacturing

● Tungsten Carbide Powder in Advanced Manufacturing

>> 1. Additive Manufacturing

>> 2. Thermal Spray Coatings

● Quality Control and Innovation in Tungsten Carbide Powder Production

>> 1. Advanced Analytical Techniques

>> 2. Process Optimization

>> 3. Environmental Considerations

● Global Trends and Future Outlook

>> 1. Technological Advancements

>> 2. Sustainability and Recycling

>> 3. Customization and Digitalization

● Conclusion

● Frequently Asked Questions

>> 1. What is tungsten carbide powder?

>> 2. How is tungsten carbide powder produced?

>> 3. What are the main uses of tungsten carbide powder in hardmetal manufacturing?

>> 4. What are the advantages of using tungsten carbide powder in hardmetal products?

>> 5. How does tungsten carbide powder contribute to advanced manufacturing techniques?

Tungsten carbide powder is universally recognized as the backbone of hardmetal manufacturing—a process that bridges advanced materials science and practical industrial applications. Its unique combination of hardness, wear resistance, and thermal stability has made it an indispensable material across a broad spectrum of sectors, including industrial machining, military defense, metallurgy, oil drilling, mining, construction, and even medical technology. This article explores the journey of tungsten carbide powder from raw material to finished hardmetal product, highlighting its production, applications, and the cutting-edge innovations shaping its future.

The Fundamentals of Tungsten Carbide Powder

At its core, tungsten carbide powder is a fine, gray material synthesized by chemically bonding tungsten with carbon. The resulting compound (WC) is renowned for its extraordinary hardness—second only to diamond in some forms—and remarkable density, which surpasses that of most traditional metals and alloys. Tungsten carbide powder is approximately four times stiffer than steel and can only be polished using diamond tools or compounds, underscoring its superior mechanical characteristics.

The production of tungsten carbide powder is a meticulous, multi-stage process that demands precision at every step to ensure the final product meets the stringent requirements of hardmetal manufacturing. This process is not only foundational to the quality of hardmetal products but also to their performance in the most demanding environments.

Tungsten Carbide Powder Production Process

The transformation from raw materials to finished tungsten carbide powder is both complex and precise. Here, we delve deeper into each stage of the production process:

1. Ingredient Calculation

Precise measurements of tungsten powder and carbon are essential. Modern production facilities use advanced analytical tools to determine the exact ratios needed, accounting for factors such as oxygen content and the optimal level of carbonization. The purity of the starting materials is critical, as impurities can negatively impact the mechanical properties of the final product.

2. Mixing

Tungsten powder and carbon are thoroughly mixed, often in a ball mill or other high-energy mixing equipment. This step is crucial for achieving a homogenous blend, which helps prevent defects and ensures uniform properties throughout the powder. The mixing process may also include the addition of small amounts of other elements to tailor the powder's characteristics for specific applications.

3. Carbonization

The mixed powder is then subjected to high temperatures in a controlled atmosphere furnace. The carbonization process typically occurs between 1,300°C and 1,800°C, depending on the desired particle size and application. During this stage, tungsten and carbon react to form tungsten carbide (WC). The reaction must be carefully controlled to avoid over- or under-carbonization, both of which can degrade the powder's quality.

4. Milling

After carbonization, the resulting material is ground into fine particles. Milling is usually performed in a ball mill, with the particle size carefully monitored and adjusted to meet specific application requirements. Advanced milling techniques, such as jet milling or attritor milling, may be used to achieve ultra-fine or nano-sized powders for specialized applications.

5. Sieving and Granulation

The milled powder is sieved to achieve the desired particle size distribution. Sieving ensures consistency and performance in subsequent manufacturing processes. Granulation may also be employed to improve the powder's flowability and handling characteristics, which is especially important for automated production systems.

6. Quality Control

Throughout the production process, rigorous quality control measures are implemented. These include chemical analysis, particle size measurement, and microscopic examination to ensure the powder meets the required standards. Advanced analytical techniques, such as X-ray diffraction (XRD) and scanning electron microscopy (SEM), are often used to verify the powder's composition and microstructure.

Hardmetal Manufacturing: From Powder to Product

Hardmetal, also known as cemented carbide, is produced by combining tungsten carbide powder with a metallic binder—most commonly cobalt or nickel. The resulting composite material is renowned for its exceptional hardness, toughness, and resistance to deformation at high temperatures.

1. Mixing

Tungsten carbide powder is blended with a binder metal powder (typically cobalt or nickel) and sometimes additional alloying elements to enhance specific properties. The mixing process is critical for achieving a uniform distribution of the binder, which is essential for the material's mechanical performance.

2. Granulation

The mixture is granulated to improve flowability and ensure uniform compaction during pressing. Granulation may involve the addition of a temporary binder or lubricant to facilitate the shaping process.

3. Pressing

The granulated powder is pressed into the desired shape using uniaxial or isostatic pressing techniques. Uniaxial pressing is suitable for simple geometries, while isostatic pressing is used for more complex shapes. This step forms a "green" part with sufficient strength for handling.

4. Sintering

The pressed parts are sintered in a controlled atmosphere at temperatures around 1,400°C to 1,600°C. During sintering, the binder metal melts and bonds the tungsten carbide particles, resulting in a dense, hard, and wear-resistant material. The sintering process may also include a pre-sintering stage to remove any temporary binders or lubricants.

5. Finishing

The sintered parts are machined, ground, or polished to achieve the required dimensions and surface finish. Advanced finishing techniques, such as electrical discharge machining (EDM) or laser machining, may be used for complex geometries or tight tolerances.

Applications of Tungsten Carbide Powder in Hardmetal Products

Tungsten carbide powder is the backbone of hardmetal manufacturing, enabling the creation of products that excel in the most challenging environments. Here, we explore its diverse applications in greater depth:

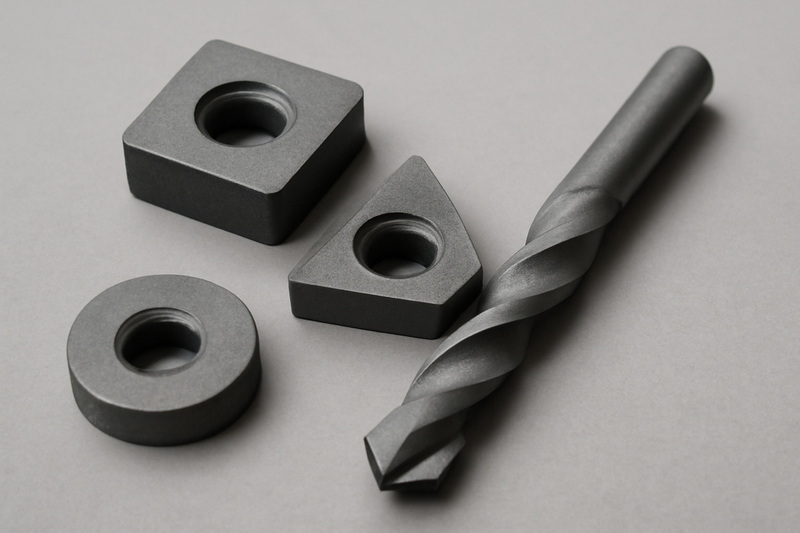

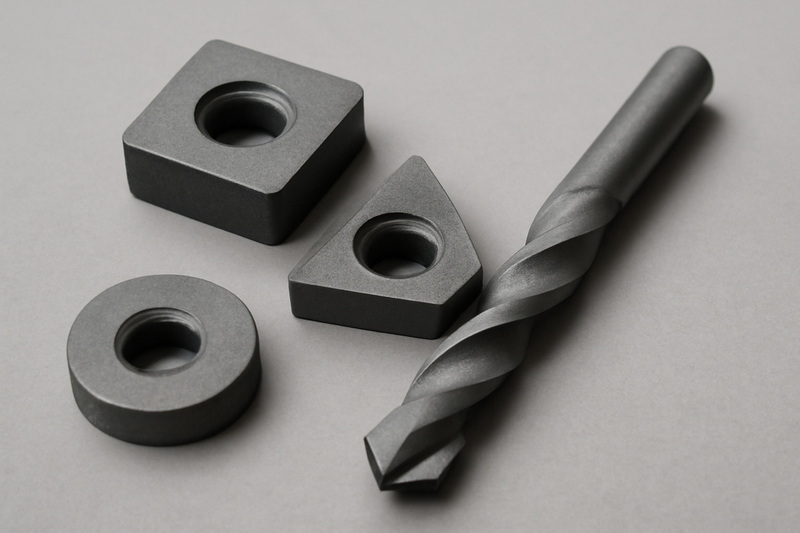

1. Industrial Cutting Tools

Tungsten carbide-based cutting tools are widely used in metalworking, machining, and manufacturing. These tools offer superior performance, longer life, and the ability to withstand high temperatures and abrasive conditions. Examples include inserts for turning, milling, and drilling operations, as well as wear parts for industrial machinery.

2. Mining and Oil Drilling Equipment

Hardmetal components are essential in mining, oil drilling, and construction. Tungsten carbide powder is used to manufacture drill bits, inserts, and wear plates that can endure extreme wear and impact. These components are critical for efficient resource extraction and infrastructure development.

3. Military and Defense

The exceptional hardness and density of tungsten carbide make it ideal for armor-piercing ammunition, shrapnel, and protective armor. It is also used in missile components and other critical defense applications, where reliability and performance are paramount.

4. Aerospace and Automotive

Tungsten carbide powder is used to produce high-performance coatings and components for aircraft engines, landing gear, and automotive systems. Its resistance to wear and heat is crucial in these demanding environments, where safety and efficiency are top priorities.

5. Metallurgical and Construction

Hardmetal products are used in grinding, cutting, and shaping operations in the metallurgical and construction industries. Tungsten carbide powder enables the production of durable abrasives and cutting tools for steel, concrete, and other hard materials.

6. Medical Instruments

The biocompatibility and durability of tungsten carbide make it suitable for surgical instruments and specialized medical devices. Its resistance to corrosion and wear ensures long-lasting performance in critical healthcare applications.

7. Electronics and Semiconductor Manufacturing

Tungsten carbide powder is used to create precision tools for drilling circuit boards and manufacturing electronic components. Its electrical conductivity and wear resistance are valuable in these high-tech applications, where precision and reliability are essential.

Tungsten Carbide Powder in Advanced Manufacturing

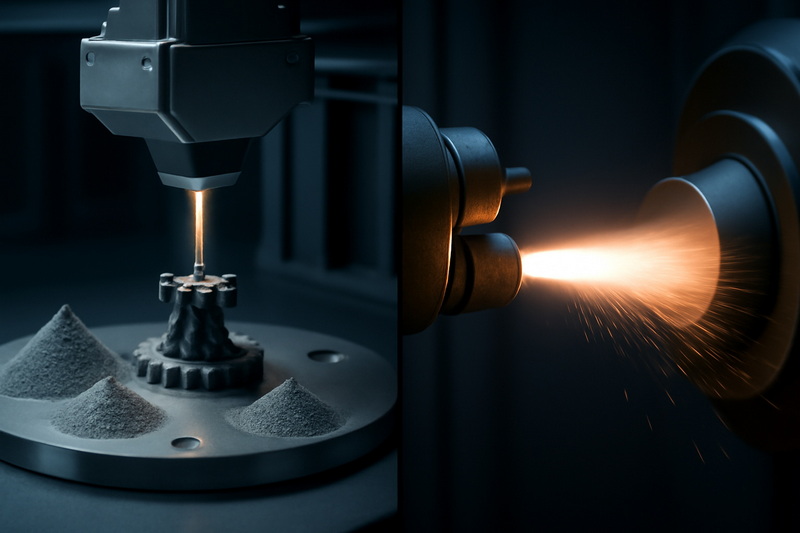

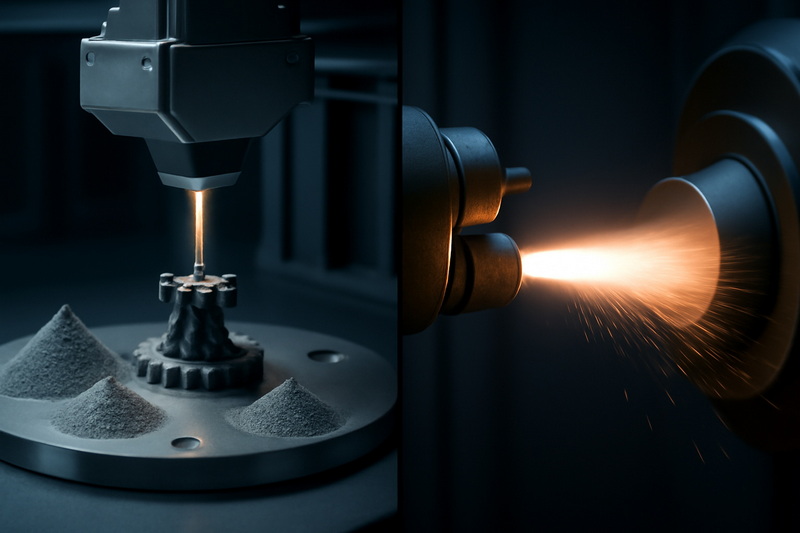

The versatility of tungsten carbide powder extends to advanced manufacturing techniques, including additive manufacturing (3D printing) and thermal spray coatings. These methods allow for the production of complex geometries and the application of wear-resistant coatings to critical components.

1. Additive Manufacturing

Tungsten carbide powder is used in additive manufacturing processes to create complex hardmetal parts with intricate internal structures. This technology enables the production of customized tools and components that would be difficult or impossible to manufacture using traditional methods. Additive manufacturing also reduces material waste and allows for rapid prototyping and small-batch production.

2. Thermal Spray Coatings

Tungsten carbide powder is applied as a coating to protect surfaces from wear, corrosion, and high temperatures. This is particularly valuable in the aerospace, oil and gas, and energy sectors, where components are exposed to harsh operating conditions. Thermal spray coatings extend the service life of critical components and reduce maintenance costs.

Quality Control and Innovation in Tungsten Carbide Powder Production

Ensuring the quality and consistency of tungsten carbide powder is essential for the performance and reliability of hardmetal products. Manufacturers employ advanced analytical techniques and strict process controls to monitor particle size, chemical composition, and purity. Innovations in powder production, such as improved mixing and milling technologies, continue to enhance the properties and performance of tungsten carbide-based materials.

1. Advanced Analytical Techniques

Modern production facilities use state-of-the-art analytical tools, such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and laser diffraction, to characterize the powder's properties. These techniques provide detailed information about particle size, shape, and distribution, as well as chemical composition and microstructure.

2. Process Optimization

Continuous process optimization is key to maintaining high quality and efficiency in tungsten carbide powder production. Advanced control systems and automation technologies enable real-time monitoring and adjustment of process parameters, ensuring consistent product quality.

3. Environmental Considerations

The production of tungsten carbide powder also involves environmental considerations. Manufacturers are increasingly adopting sustainable practices, such as recycling of scrap materials and reducing energy consumption, to minimize their environmental footprint.

Global Trends and Future Outlook

The demand for tungsten carbide powder and hardmetal products continues to grow, driven by advancements in industrial technology, defense, and infrastructure development. Emerging markets, particularly in Asia, are experiencing rapid growth in manufacturing and construction, further increasing the need for high-performance materials.

1. Technological Advancements

Ongoing research and development are focused on improving the properties and performance of tungsten carbide powder. Innovations such as nano-sized powders, advanced binder systems, and new manufacturing techniques are expanding the range of applications and enhancing product performance.

2. Sustainability and Recycling

Sustainability is becoming a key focus in the industry. Manufacturers are investing in recycling technologies to recover tungsten and other valuable materials from end-of-life products and production scrap. This not only reduces environmental impact but also helps secure the supply of critical raw materials.

3. Customization and Digitalization

The rise of digital manufacturing and Industry 4.0 is enabling greater customization and flexibility in hardmetal production. Digital tools and data analytics are being used to optimize processes, improve quality control, and accelerate product development.

Conclusion

Tungsten carbide powder is the foundation of hardmetal manufacturing, enabling the creation of products that are critical to modern industry, technology, and defense. Its exceptional hardness, wear resistance, and thermal stability make it indispensable in applications ranging from cutting tools and mining equipment to military armor and aerospace components. The rigorous production process ensures that tungsten carbide powder meets the highest standards of quality and performance, supporting innovation and reliability across a broad spectrum of industries. As manufacturing technologies continue to evolve, tungsten carbide powder will remain at the forefront of materials science, driving progress and enabling new possibilities in hardmetal production. The future of tungsten carbide powder production is bright, with ongoing advancements in technology, sustainability, and customization shaping the industry for years to come.

Frequently Asked Questions

1. What is tungsten carbide powder?

Tungsten carbide powder is a fine gray material created by chemically bonding tungsten with carbon. It is renowned for its exceptional hardness and wear resistance, making it a key ingredient in hardmetal manufacturing.

2. How is tungsten carbide powder produced?

The production process involves precise mixing of tungsten and carbon powders, carbonization at high temperatures, milling to achieve the desired particle size, and sieving for consistency.

3. What are the main uses of tungsten carbide powder in hardmetal manufacturing?

Tungsten carbide powder is used to produce cutting tools, mining and oil drilling equipment, military armor, aerospace components, medical instruments, and electronics manufacturing tools.

4. What are the advantages of using tungsten carbide powder in hardmetal products?

Tungsten carbide powder provides superior hardness, wear resistance, and thermal stability, resulting in longer tool life, better performance, and the ability to withstand extreme conditions.

5. How does tungsten carbide powder contribute to advanced manufacturing techniques?

Tungsten carbide powder enables additive manufacturing and thermal spray coatings, allowing for the production of complex geometries and the application of wear-resistant surfaces to critical components.