Content Menu

● Introduction: Why Carbide Chisel Tips Dominate Tooling in Canada

● What Makes Carbide Chisel Tips Superior?

● Key Types of Carbide Chisel Tips

>> Woodturning and Woodworking Tips

>> Stone and Masonry Chisel Tips

>> Metalworking and Industrial Tips

● Leading Carbide Chisel Tips Manufacturers and Suppliers in Canada

>> Kilian Tools

>> Hunter Tool Systems

>> Masonry- and Stone-Focused Suppliers

>> Retailers and Distributors Serving B2B Markets

● The Carbide Chisel Tip Manufacturing Process

>> 1. Powder Preparation

>> 2. Mixing and Milling

>> 3. Pressing and Forming

>> 4. Presintering and Green Machining

>> 5. Final Sintering

>> 6. Grinding and Finishing

>> 7. Coating and Surface Treatment (Optional)

>> 8. Inspection and Quality Assurance

● OEM and Custom Services from Canadian Suppliers

>> White-Label and Private Branding

>> Custom Geometry and Material Combinations

>> Flexible Batch Sizes and Logistics Support

● Applications Across Canadian and Global Industries

>> Woodworking and Furniture Production

>> Stone, Masonry, and Landscaping

>> Metalworking, Mining, and Heavy Industry

● Trends and Innovations in Carbide Chisel Tips

>> Nano-Structured Carbides

>> Advanced Coatings and Surface Engineering

>> Automation and Smart Quality Control

● How to Choose the Right Canadian Carbide Chisel Tip Partner

● Conclusion

● FAQ

>> 1. What are the main advantages of carbide chisel tips compared with traditional steel chisels?

>> 2. Can Canadian suppliers provide OEM and private-label carbide chisel tips?

>> 3. How should I specify carbide chisel tips for a new project?

>> 4. What quality checks are important when evaluating carbide chisel tips?

>> 5. Are carbide chisel tips suitable for both professional and hobbyist users?

Introduction: Why Carbide Chisel Tips Dominate Tooling in Canada

Carbide chisel tips are essential for industries ranging from woodworking and stone carving to mining and metalworking. Their exceptional hardness, wear resistance, and longevity make them the tool of choice for professionals and hobbyists across Canada. In such a competitive market, choosing reliable carbide chisel tips manufacturers and suppliers is critical for brands, wholesalers, and production plants that want stable quality and long-term cost savings.

Canada has built a solid reputation for producing precision tooling and engineered components. Within this ecosystem, Canadian carbide chisel tips manufacturers and suppliers provide high-performance products that meet strict quality standards and support OEM projects worldwide. For overseas buyers, these suppliers offer a reliable bridge between advanced materials technology and real-world productivity.

What Makes Carbide Chisel Tips Superior?

Carbide chisel tips are typically made from tungsten carbide bonded with cobalt or similar binders. This composite structure creates a cutting edge that is far harder than standard tool steel and able to withstand extreme temperatures. For woodworkers, stonemasons, and metal fabricators, this translates into consistently sharp tools that can cut, carve, and shape materials with minimal downtime.

The main advantages of carbide chisel tips include long tool life, dimensional stability under load, and the ability to maintain sharpness even under severe working conditions. Unlike traditional steel tools that require frequent sharpening, carbide chisel tips maintain their geometry for long production runs. This improves surface finish, reduces rework, and increases throughput, especially when sourced from professional carbide chisel tips manufacturers and suppliers with robust quality systems.

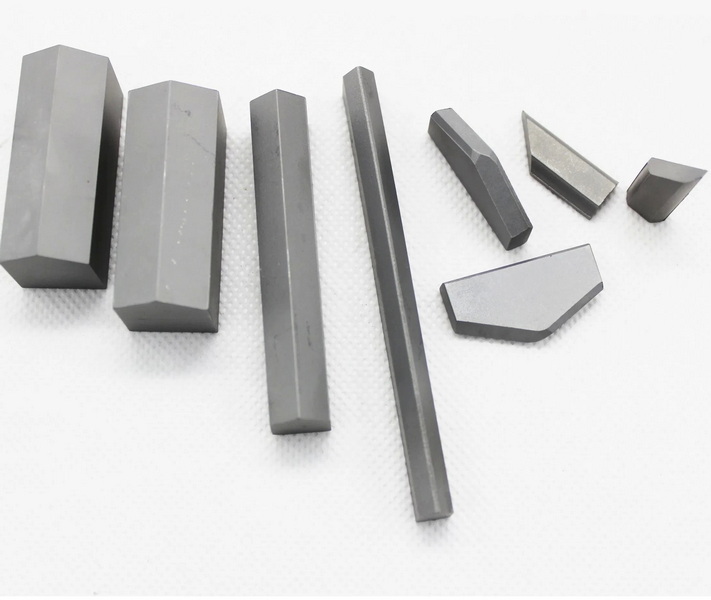

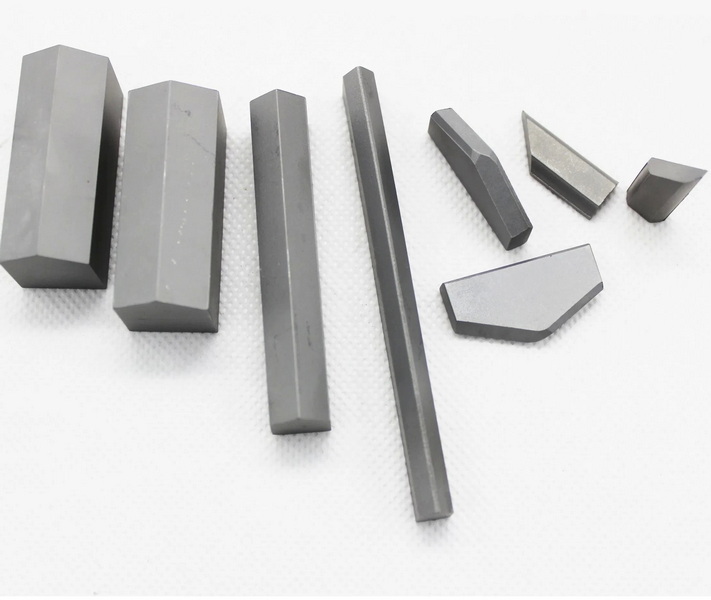

Key Types of Carbide Chisel Tips

Carbide chisel tips appear in multiple formats to suit different industries and cutting styles. Understanding these categories helps buyers specify the right product when working with Canadian carbide chisel tips manufacturers and suppliers.

Woodturning and Woodworking Tips

For woodturning applications, tips usually come in round, square, and diamond shapes. Round tips excel at smooth finishing, square tips at roughing and rapid material removal, and diamond tips at detail work. These tips are often mounted on lathe chisels with interchangeable inserts, making them attractive to both hobbyists and professional workshops.

Stone and Masonry Chisel Tips

In masonry, carbide chisel tips are designed to split, shape, and texture stone, brick, and concrete. Pitching tools, hand tracers, and point chisels often use wide, flat or tapered tips optimized for impact and abrasion. Such tools are expected to survive repeated hammer blows against extremely hard mineral surfaces, which is why reliable carbide chisel tips manufacturers and suppliers focus heavily on toughness and edge retention.

Metalworking and Industrial Tips

In metalworking and manufacturing, carbide chisel tips are used for deburring, grooving, and impact cutting in harsh environments. These tips must resist chipping and micro-fracture at high speeds or under shock loading. Some designs resemble small inserts similar to those used on indexable cutting tools, while others are brazed onto custom shanks for niche industrial processes.

Leading Carbide Chisel Tips Manufacturers and Suppliers in Canada

Canada's landscape of carbide chisel tips manufacturers and suppliers includes both specialized tooling brands and larger distribution networks that connect domestic producers with global buyers. While each company has unique strengths, they commonly emphasize precision, consistency, and support for OEM or custom designs.

Kilian Tools

Kilian Tools is widely recognized for its high-performance carbide woodturning solutions. Focused on nanograin carbide, the company produces chisel tips that provide exceptionally smooth finishes and long service life on the lathe. This precision is attractive for pen turners, bowl turners, and fine wood artists who demand consistent results. As a Canadian-based operation, Kilian Tools understands local needs and can respond quickly to domestic and export orders.

Hunter Tool Systems

Hunter Tool Systems specializes in handcrafted carbide woodturning tools that pair engineered inserts with ergonomic handles. Their tooling concept focuses on simplicity and control, using razor-sharp carbide inserts shaped for clean, efficient cuts rather than aggressive scraping. Many overseas buyers appreciate Hunter's balance between artisan craftsmanship and industrial-grade materials, and the company is a strong example of how Canadian carbide chisel tips manufacturers and suppliers can compete globally.

Masonry- and Stone-Focused Suppliers

Canadian stone supply and landscape tool companies offer carbide hand chisels, hand tracers, and other stone tools designed for masonry professionals. These firms emphasize impact-resistant carbide tips, robust steel bodies, and designs that suit stone fabrication, carving, and architectural restoration. For buyers in construction and landscaping, such suppliers act as both manufacturers and technical advisors on selecting the right carbide chisel tips for granite, marble, sandstone, and concrete.

Retailers and Distributors Serving B2B Markets

Large Canadian tool retailers and industrial distributors also play a critical role as carbide chisel tips manufacturers and suppliers interface. They stock replacement tips, chisel sets, and related accessories from multiple brands, enabling wholesalers and factories to source standard parts quickly. For overseas buyers, these distributors can consolidate orders, assist with logistics, and often coordinate custom runs with upstream manufacturers.

The Carbide Chisel Tip Manufacturing Process

A deeper understanding of the manufacturing process helps explain why reputable carbide chisel tips manufacturers and suppliers insist on strict quality controls.

1. Powder Preparation

The process begins with tungsten metal and carbon sources, which are combined and heated to form tungsten carbide powder. Precise control over powder composition, grain size, and purity is critical, because it directly affects the tool's hardness, toughness, and wear resistance. Additives such as cobalt powder are also prepared in carefully measured proportions to serve as a metallic binder.

2. Mixing and Milling

The tungsten carbide powder, cobalt, and other additives are mixed thoroughly, often in a ball mill, until a uniform blend is obtained. This step ensures even distribution of the carbide grains and binder. To facilitate pressing, wax or other binders are introduced into the mix, improving flow characteristics and helping the powder compact smoothly into molds.

3. Pressing and Forming

The prepared powder is then pressed into the desired shape under extremely high pressure. Techniques such as uniaxial pressing, isostatic pressing, or extrusion may be used, depending on the complexity of the tip design. The result is a “green” compact that holds its shape but remains relatively fragile and somewhat similar to chalk in its mechanical behavior.

4. Presintering and Green Machining

The green compacts undergo presintering at moderate temperatures in a controlled atmosphere. This stage burns off wax and other temporary binders, while lightly bonding the particles together. At this softened but stable stage, the parts can be machined more easily to refine edges, add features, or correct minor dimensional variations before final hardening.

5. Final Sintering

Final sintering occurs in high-temperature furnaces under inert gas, vacuum, or specialized atmospheres. At this stage, the carbide and binder fuse into a dense solid with minimal porosity. Considerable shrinkage occurs, often up to double-digit percentages in volume, so manufacturers must design tooling and processes that compensate for this change. The resulting carbide body is extremely hard and difficult to machine by conventional methods.

6. Grinding and Finishing

After sintering, the carbide chisel tips are ground and honed using diamond grinding wheels and other superabrasive tools. This step brings each tip to its precise dimensions, tolerance levels, and edge geometry. For carbide chisel tips manufacturers and suppliers, grinding is a major determinant of performance: an accurately ground, finely honed tip cuts cleaner, runs cooler, and lasts longer in the field.

7. Coating and Surface Treatment (Optional)

Some manufacturers apply advanced coatings, such as titanium nitride or titanium carbonitride, to further improve wear resistance and reduce friction. Coatings can also increase oxidation resistance at very high temperatures, which is critical for metal cutting and demanding industrial applications. While not all chisel tips require coating, it can dramatically extend service life in specialized conditions.

8. Inspection and Quality Assurance

Finished carbide chisel tips go through rigorous quality checks, including dimensional inspection, density and hardness tests, and microstructural analysis. Tools may be subjected to cutting or impact testing to verify that they meet the performance claims made by the manufacturer. The best carbide chisel tips manufacturers and suppliers also maintain traceability for raw materials and process parameters, giving B2B clients confidence about consistency across batches.

OEM and Custom Services from Canadian Suppliers

For foreign brands, wholesalers, and manufacturers, the real value of working with Canadian carbide chisel tips manufacturers and suppliers lies in their OEM and customization capabilities.

White-Label and Private Branding

Many Canadian suppliers offer private-label programs in which carbide chisel tips are produced to the buyer's specifications and then packaged under the buyer's brand. This arrangement is ideal for international distributors building their own product lines while relying on experienced manufacturers for design and production.

Custom Geometry and Material Combinations

For niche applications, buyers may request specialized tip shapes, cutting angles, or material combinations. Examples include tips optimized for certain hardwoods, abrasive stone types, or high-strength alloys. Canadian engineering teams can collaborate with customers, running trials and prototypes until the desired cutting performance and tool life are achieved.

Flexible Batch Sizes and Logistics Support

Carbide chisel tips manufacturers and suppliers in Canada often support a range of order sizes, from small development runs to large, ongoing contracts. Combined with established export logistics and documentation expertise, this flexibility makes it simpler for overseas buyers to test the market and then scale up as demand grows.

Applications Across Canadian and Global Industries

Carbide chisel tips find use in a wide variety of sectors.

Woodworking and Furniture Production

In woodturning, cabinetry, and furniture manufacturing, carbide-tipped chisels are prized for maintaining a clean edge through long runs of cutting and shaping. Shops can keep production lines moving without frequent sharpening breaks, making carbide solutions ideal for both high-end custom work and volume manufacturing.

Stone, Masonry, and Landscaping

For stone yards, sculptors, and construction contractors, carbide chisel tips provide the durability needed to cut and shape tough natural stone and concrete. Pitching tools, hand tracers, and lettering chisels with carbide tips last longer and hold their profiles better, which is vital when working on architectural elements, monuments, and decorative facades.

Metalworking, Mining, and Heavy Industry

In heavy industry, mining, and infrastructure development, carbide tips are integral to chisels used for scaling, chipping, and breaking hard surfaces. Their ability to resist deformation and heat makes them suitable for impact tools that operate under massive loads. Many global buyers source such components from established carbide chisel tips manufacturers and suppliers for use in tunneling, demolition, and road construction.

Trends and Innovations in Carbide Chisel Tips

Technology and market demands continuously shape how carbide chisel tips are designed and produced.

Nano-Structured Carbides

The move toward finer, nano-scale grain structures offers impressive improvements in hardness and wear resistance without overly sacrificing toughness. This is particularly attractive in applications where edge integrity is critical, such as fine woodworking and precision stone carving.

Advanced Coatings and Surface Engineering

Ongoing research into multi-layer coatings and surface treatments aims to push cutting speeds higher while reducing tool failure. Better adhesion, smoother surfaces, and more heat-resistant chemistries all come together to extend tool life in demanding industrial contexts.

Automation and Smart Quality Control

Carbide chisel tips manufacturers and suppliers increasingly rely on automated pressing, sintering, and inspection systems. These technologies ensure repeatable quality and improve traceability, which is crucial for global buyers who need consistent performance over long production cycles.

How to Choose the Right Canadian Carbide Chisel Tip Partner

When evaluating Canadian carbide chisel tips manufacturers and suppliers, consider several key factors:

- Technical expertise and ability to advise on material grades and geometries

- ISO or equivalent quality certifications, along with documented process control

- OEM and customization capabilities, including tooling design and packaging

- History of successful export cooperation and stable lead times

- Responsive customer service and technical support

By prioritizing these criteria, international buyers can form long-term partnerships that support both current requirements and future growth.

Conclusion

Canada's carbide chisel tips manufacturers and suppliers form a mature and innovative ecosystem that serves woodworking, stone masonry, metalworking, mining, and many other sectors. From high-end woodturning inserts to heavy-duty stone chisels, Canadian producers combine advanced carbide technology, precise grinding, and thorough quality assurance to deliver tools that perform reliably in demanding conditions. For overseas brands, wholesalers, and manufacturers, partnering with Canadian suppliers offers access to robust OEM services, customized geometries, and consistent global logistics. As material science and coating technologies evolve, these manufacturers are well positioned to keep delivering next-generation carbide chisel tips that improve productivity, surface finish, and total cost of ownership across the entire value chain.

FAQ

1. What are the main advantages of carbide chisel tips compared with traditional steel chisels?

Carbide chisel tips are significantly harder than standard tool steel, which allows them to stay sharp far longer under heavy use. This reduces downtime for sharpening and replacement, improves surface quality on wood, stone, and metal, and ultimately lowers the total cost per unit of work.

2. Can Canadian suppliers provide OEM and private-label carbide chisel tips?

Yes. Many Canadian carbide chisel tips manufacturers and suppliers specialize in OEM services, including custom geometries, branding, labeling, and packaging. Overseas wholesalers and manufacturers can have tools produced to their own specifications and sold under their own brand, while leveraging Canadian expertise in carbide processing.

3. How should I specify carbide chisel tips for a new project?

Start by defining the base material you will be working on, such as hardwood, granite, or high-strength steel. Then determine whether you need roughing, finishing, or detailing performance, and specify the required tip shape, size, and mounting method. Reputable carbide chisel tips manufacturers and suppliers can help refine these parameters, suggest grades, and recommend coatings to match your application.

4. What quality checks are important when evaluating carbide chisel tips?

Key quality checks include verifying hardness, density, and microstructure, as well as confirming that tools meet dimensional tolerances and edge geometry targets. You should also look for consistent brazing or mounting quality, clean grind lines, and any available cutting or impact test data. Suppliers that can document these elements are more likely to provide repeatable performance over time.

5. Are carbide chisel tips suitable for both professional and hobbyist users?

Absolutely. While professionals in woodworking, masonry, and heavy industry rely on carbide for productivity and tool life, hobbyists also benefit from less frequent sharpening and more predictable cutting behavior. Many Canadian carbide chisel tips manufacturers and suppliers offer product lines that cater to both segments, from entry-level kits to high-end, specialized tools.