Content Menu

● Understanding Tungsten Carbide

● The Structure of Tungsten Carbide

● Physical Properties of Tungsten Carbide

● Applications of Tungsten Carbide

● Comparison with Other Materials

● Manufacturing Process

● Advantages of Tungsten Carbide

● Limitations of Tungsten Carbide

● Future Trends in Tungsten Carbide Applications

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the hardness range of tungsten carbide?

>> 2. How does tungsten carbide compare to high-speed steel?

>> 3. What are the main applications of tungsten carbide?

>> 4. Is tungsten carbide brittle?

>> 5. What is the manufacturing process for tungsten carbide?

● Citations:

Tungsten carbide is a compound that has gained significant attention in various industries due to its remarkable hardness and durability. This article explores the hardness of tungsten carbide, its properties, applications, and answers some frequently asked questions about this versatile material.

Understanding Tungsten Carbide

Tungsten carbide (WC) is a chemical compound made from equal parts tungsten and carbon atoms. Known for its exceptional hardness, tungsten carbide ranks between 69 and 81 HRC (Rockwell Hardness Scale) under standard conditions, with some formulations exceeding this range. The hardness of tungsten carbide can be attributed to its unique microstructure and the bonding of tungsten and carbon atoms, which form a robust lattice structure.

The Structure of Tungsten Carbide

The microstructure of tungsten carbide consists of a dense arrangement of tungsten atoms surrounded by carbon atoms. This configuration contributes to its hardness and wear resistance. The compound can exist in different forms, including:

- Cubic Tungsten Carbide: This form has a high hardness level and is commonly used in cutting tools.

- Hexagonal Tungsten Carbide: This variant is slightly less hard but offers better toughness.

Understanding these forms helps manufacturers choose the right type for specific applications.

Physical Properties of Tungsten Carbide

- Hardness: Tungsten carbide exhibits hardness levels typically between 69 HRC and 81 HRC. In some cases, it can reach above HRC 90 depending on the composition and manufacturing process.

- Melting Point: The melting point of tungsten carbide is approximately 2,870°C (5,200°F), making it suitable for high-temperature applications.

- Density: Tungsten carbide has a density of about 15.6 g/cm³, which is significantly higher than steel. This high density contributes to its weight and stability in various applications.

- Thermal Conductivity: With a thermal conductivity of around 110 W/m·K, tungsten carbide efficiently dissipates heat, which is crucial in high-speed machining applications.

- Corrosion Resistance: Tungsten carbide exhibits excellent resistance to corrosion and oxidation, making it suitable for harsh environments.

Applications of Tungsten Carbide

Tungsten carbide's hardness and wear resistance make it an ideal material for various applications:

- Cutting Tools: Used in drills, milling cutters, and saw blades, tungsten carbide tools maintain sharpness longer than their high-speed steel counterparts. Their ability to withstand high temperatures and pressures makes them indispensable in manufacturing processes.

- Mining and Drilling: Tungsten carbide is extensively used in drill bits and mining equipment due to its ability to withstand harsh conditions. Its toughness allows it to penetrate hard rock formations effectively.

- Aerospace Components: Coatings made from tungsten carbide protect critical components in aircraft engines from wear and erosion. The aerospace industry values materials that can endure extreme conditions, making tungsten carbide a preferred choice.

Aerospace Components

- Jewelry: Its durability makes tungsten carbide a popular choice for wedding bands and other jewelry items. The material's scratch resistance ensures that jewelry retains its shine over time.

Comparison with Other Materials

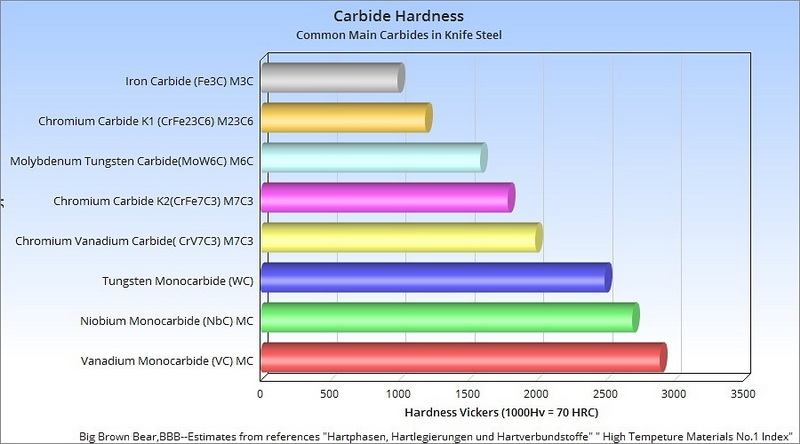

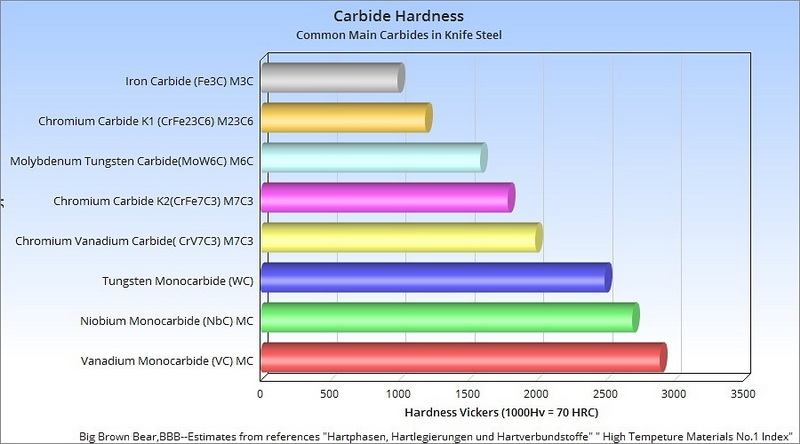

To understand how hard tungsten carbide is compared to other materials, consider the following table:

| Material | Hardness (HRC) |

| Tungsten Carbide | 69 - 81 |

| High-Speed Steel | 60 - 65 |

| Carbon Steel | 50 - 60 |

| Ceramics | 70 - 80 |

This comparison highlights that tungsten carbide is significantly harder than both high-speed steel and carbon steel. Its superior hardness allows it to maintain sharp edges longer, reducing the frequency of tool replacements.

Manufacturing Process

The production of tungsten carbide typically involves the following steps:

1. Powder Production: Tungsten metal powder is mixed with carbon black in a controlled environment to form tungsten carbide powder.

2. Sintering: The powder is compacted into desired shapes and heated at high temperatures to create a solid mass through sintering. This process helps achieve the desired density and hardness.

3. Finishing: The sintered products are then machined to achieve precise dimensions and surface finishes. Various techniques such as grinding or polishing can be employed to enhance surface quality.

Advantages of Tungsten Carbide

The advantages of using tungsten carbide over other materials include:

- Exceptional Hardness: Its hardness allows for longer tool life and reduced wear.

- Versatility: Tungsten carbide can be tailored for various applications by adjusting its composition during manufacturing.

- Heat Resistance: It maintains its hardness even at elevated temperatures, making it suitable for high-speed machining.

- Corrosion Resistance: Its resistance to corrosion extends the lifespan of tools and components used in challenging environments.

Limitations of Tungsten Carbide

Despite its many advantages, tungsten carbide has some limitations:

- Brittleness: While it is extremely hard, tungsten carbide can be brittle under certain conditions, making it susceptible to chipping or cracking if subjected to shock loads.

- Cost: The manufacturing process can be more expensive than other materials like high-speed steel or carbon steel. This cost factor may limit its use in some applications where budget constraints are significant.

- Difficulty in Machining: Due to its hardness, machining tungsten carbide requires specialized equipment and techniques, which can add complexity to production processes.

Future Trends in Tungsten Carbide Applications

As technology advances, the application of tungsten carbide continues to expand. Some emerging trends include:

- 3D Printing: Innovations in additive manufacturing are allowing for the creation of complex shapes using tungsten carbide composites, opening new avenues for design flexibility.

- Nanostructured Materials: Research into nanostructured tungsten carbide aims to enhance properties such as toughness while maintaining hardness levels.

- Sustainable Practices: As industries focus on sustainability, efforts are being made to recycle tungsten carbide tools effectively, reducing waste and conserving resources.

Conclusion

In conclusion, tungsten carbide stands out as one of the hardest materials available today, with hardness levels typically ranging from 69 HRC to over 90 HRC depending on its formulation. Its unique properties make it invaluable across various industries including manufacturing, aerospace, mining, and jewelry. While it offers exceptional wear resistance and durability, considerations regarding brittleness and cost should be taken into account when selecting materials for specific applications.

Frequently Asked Questions (FAQ)

1. What is the hardness range of tungsten carbide?

Tungsten carbide typically has a hardness range between 69 HRC to over 90 HRC depending on its composition and processing methods.

2. How does tungsten carbide compare to high-speed steel?

Tungsten carbide is generally harder than high-speed steel, which has a hardness range of about 60 HRC to 65 HRC.

3. What are the main applications of tungsten carbide?

Tungsten carbide is widely used in cutting tools, mining equipment, aerospace components, and jewelry due to its exceptional hardness and wear resistance.

4. Is tungsten carbide brittle?

Yes, while tungsten carbide is extremely hard, it can be brittle under certain conditions which may lead to chipping or cracking.

5. What is the manufacturing process for tungsten carbide?

The manufacturing process involves producing tungsten powder mixed with carbon black, followed by sintering at high temperatures to form solid products.

Citations:

[1] https://www.carbide-part.com/blog/tungsten-carbide-and-hss/

[2] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[3] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] https://www.vedantu.com/chemistry/tungsten-carbide

[6] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[7] http://www.crucibleservice.com/eselector/general/generalpart1.html

[8] https://stock.adobe.com/search?k=tungsten+carbide

[9] https://www.itia.info/applications-markets/

[10] https://www.carbide-products.com/blog/tungsten-carbide-and-hss/