Content Menu

● Introduction

● The Role and Function of Carbide Edge Blocks

● UK Market Advantages for Carbide Edge Block Buyers

● Manufacturing Processes of Carbide Edge Blocks

● Innovations in Carbide Edge Block Production

● Customization and OEM/ODM Services

● Key Product Segments

● Quality Assurance and Certifications

● Export Logistics and Global Reach

● Major Application Industries

● Challenges and Industry Trends

● How to Choose the Right Carbide Edge Block Supplier

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What materials are used in premium UK carbide edge blocks?

>> 2. Can overseas buyers order custom-shaped carbide edge blocks from the UK?

>> 3. Are UK-made carbide edge blocks certified for export?

>> 4. Which industries benefit most from UK carbide edge blocks?

>> 5. How do UK suppliers guarantee product quality?

Introduction

Carbide edge blocks are at the core of precision machining, manufacturing efficiency, and product durability across an array of industries. As global supply chains prioritize longer lifecycle and higher technical performance, Carbide Edge Block Manufacturers and Suppliers in the UK have gained international acclaim for combining material innovation with rigorous quality standards. This comprehensive article explores the capabilities, strengths, and product diversity of the leading UK carbide edge block suppliers, providing insights for overseas brands, OEM/ODM factories, wholesalers, and engineering professionals seeking reliable industrial partners.

The Role and Function of Carbide Edge Blocks

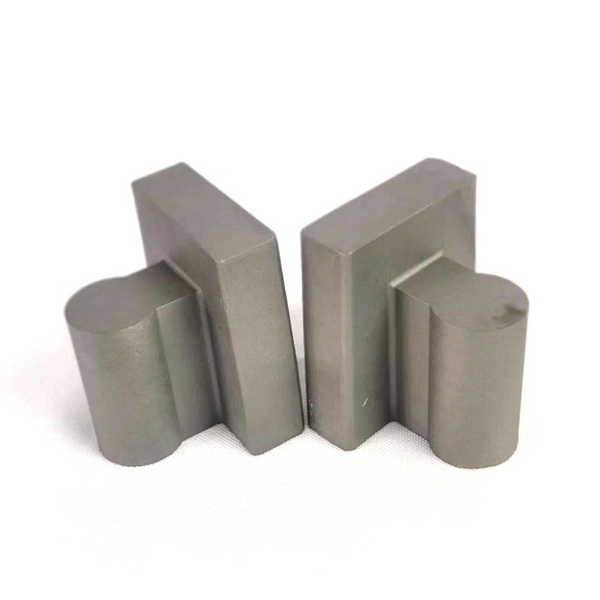

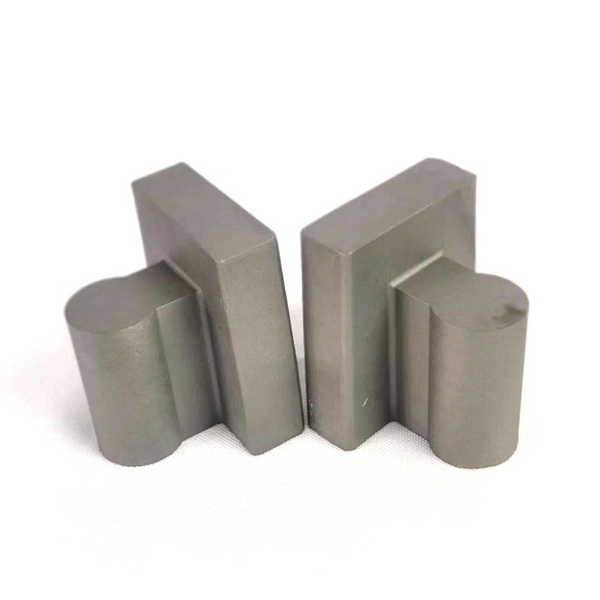

Carbide edge blocks are integral tools designed to provide high resistance to abrasion, deformation, and thermal stress. Produced predominantly from tungsten carbide with cobalt or nickel binders, these blocks outlast and outperform traditional steel in challenging industrial environments. Their hardness, high melting point, and structural stability enable them to maintain sharp edges and dimensional accuracy through prolonged, heavy-duty use.

In addition to tool longevity and wear resistance, these blocks deliver tight engineering tolerances necessary for modern automation and CNC systems. Their use spans automotive, aerospace, bridge construction, metalworking, woodworking, electronics, and composite manufacturing—wherever exacting standards and robust operational cycles are paramount.

UK Market Advantages for Carbide Edge Block Buyers

The UK has established itself as a leading destination for carbide edge block manufacturing, built on a foundation of:

- Precision engineering history, blending advanced CNC technologies with experienced craftsmanship.

- Robust quality control systems and international certifications (ISO, BS) to ensure consistent global export standards.

- Strong focus on research and development, with several manufacturers pioneering advances in carbide composition, tooling geometries, and surface finishing.

- Excellent OEM/ODM service orientation, offering custom formulations, block shapes, and branding options suited for international market demands.

UK suppliers emphasize responsiveness, comprehensive after-sales support, and technical collaboration—critical for global buyers optimizing supply chains.

Manufacturing Processes of Carbide Edge Blocks

The manufacturing of carbide edge blocks is a multi-stage process demanding attention to material science, design accuracy, and surface quality:

1. Powder Preparation and Mixing: Manufacturing begins with the preparation of tungsten carbide, which is ground to a precise powder and mixed with a binder such as cobalt or nickel. This blend provides both hardness and necessary toughness in the final product.

2. Compaction and Shaping: The prepared mixture is compacted under high pressure into molds that define the edge block's geometry.

3. Pre-sintering and Sintering: Green compacts (pre-shaped blocks) are heated in a controlled environment to bind the particles and remove any binding agents. Final sintering occurs at extremely high temperatures, resulting in a dense, highly durable material.

4. Machining and Grinding: Post-sintering, blocks undergo diamond grinding or EDM (Electrical Discharge Machining) to achieve precise dimensions, flatness, edge sharpness, and required surface finish.

5. Finishing and Lapping: Surfaces may be lapped or polished for ultra-flat edges, especially in applications such as gauge blocks or high-precision dies. Surface coating or passivation may be added for extra corrosion resistance.

6. Quality Inspection: Throughout production, manufacturers utilize advanced metrology and non-destructive testing (NDT) systems to ensure each block meets exact specifications.

7. Customizations: Many UK suppliers offer part engraving, serialization, and customized packaging to fulfill OEM or brand-specific requirements.

This rigorous process ensures that every carbide edge block can withstand intense operational conditions and deliver repeatable, accurate performances.

Innovations in Carbide Edge Block Production

UK Carbide Edge Block Manufacturers and Suppliers continually push the envelope in materials and processes:

- Adoption of nano-grain carbide powder to maximize fine-grain structure and deliver improved edge retention.

- Integration of advanced CAD/CAM modeling for rapid prototyping and customer-driven R&D projects.

- Use of high-precision robotic handling and computer-controlled grinders to achieve ultra-flatness below micron levels.

- Environmentally friendly machining techniques, optimizing coolant recycling and minimizing waste.

- Introduction of hybrid carbide grades, blending tungsten carbide with additional elements for specialty industry applications.

These advances enable UK suppliers to serve highly specialized needs within industries like semiconductor production, aerospace, and next-generation energy infrastructure.

Customization and OEM/ODM Services

One of the strongest draws for international buyers is the customized production and OEM capabilities offered by top UK carbide edge block suppliers. Buyers benefit from:

- The ability to specify block dimensions, material grade, and tolerance according to unique project requirements.

- Quick-turn prototyping based on detailed CAD files or sample drawings.

- Integrated private labeling and brand packaging, streamlining entry into overseas markets.

- Flexible order quantities, accommodating both short and large batch runs with responsive lead times.

- Full documentation, including certificates of compliance, test reports, and export paperwork for smooth global logistics.

Key Product Segments

UK Carbide Edge Block Manufacturers and Suppliers provide an extensive product portfolio covering:

- Precision gauge blocks and calibration tools for metrology laboratories and high-accuracy production lines.

- Cutting and wear blocks for metal forming, electronics stamping, bridge and large-scale construction, and tool and die shops.

- Router and edge bander blocks for woodworking machinery, ensuring clean, accurate panel cutting and edge finishing.

- Application-specific shapes and inserts engineered for custom industrial machinery or proprietary assembly processes.

By offering both standardized and bespoke products, UK companies support varied client sectors and technical goals.

Quality Assurance and Certifications

Elevating global buyer confidence, UK suppliers adhere to the strictest quality standards. Leading producers operate under:

- ISO 9001: Quality management systems

- BS 4311 and EN ISO 3650: Calibration and gauge block quality

- UKAS accreditation: Third-party validation for laboratory-grade measurements

- Traceability systems: Digital records for each batch, supporting continuous improvement and rapid recall if ever necessary

Facilities use state-of-the-art CMM (Coordinate Measuring Machines), optical comparators, and hardness testers to verify every block. Many companies offer detailed inspection reports and guarantee product conformance.

Export Logistics and Global Reach

Serving clients worldwide, UK Carbide Edge Block Manufacturers and Suppliers excel in managing robust export processes:

- Secure packaging that protects blocks from corrosion, dust, and mechanical shock during transit.

- Documentation support for customs, export certification, and insurance policies to minimize delays.

- Flexible transportation arrangements, including sea, air, express courier, and bonded warehouse services where required.

- Multilingual sales and technical teams familiar with regulatory nuances in Europe, North America, the Middle East, and Southeast Asia.

Their expertise ensures that even highly regulated and sensitive deliveries—such as aerospace-grade or metrology blocks—arrive safely and on time at their destinations.

Major Application Industries

UK-produced carbide edge blocks are integral to:

- Automotive and Aerospace: Used in precision metal forming, engine assembly, component stamping, and gear manufacturing where tool longevity and repeatability are paramount.

- Construction and Infrastructure: Essential for bridge bearing shims, wear-resistant inserts, and heavy-duty tooling required in large-scale modular construction.

- Wood and Furniture Manufacturing: Employed in high-speed routings, edge banding, and complex contour shaping where close tolerances and minimized wear lead to cost efficiency.

- Electronics and Micro-Machining: Critical for small component precision, such as circuit board tooling or semiconductor die mounting, where consistency at the micron level is essential.

- General Industrial Fabrication: Deployed in wear parts, punches, dies, and bespoke tooling for CNC and automated systems across the manufacturing spectrum.

Challenges and Industry Trends

Modern carbide edge block production faces several emerging challenges:

- Rising Raw Material Costs: Fluctuations in tungsten and cobalt pricing prompt suppliers to invest in cost-efficient processes and maximize material yield.

- Demand for Sustainability: Environmental regulations urge manufacturers to reduce energy consumption, adopt green machining fluids, and recycle scrap carbide.

- Technological Complexity: With increasing demands for micro-precision and non-standard block shapes, suppliers must continually upgrade equipment and invest in technical training.

- Global Competition: Navigating tariffs, logistics disruptions, and international certification requires experienced export teams and agile supply chain management.

Nonetheless, UK companies distinguish themselves through relentless innovation and collaborative problem-solving, ensuring clients receive tailored solutions and strong post-sales support.

How to Choose the Right Carbide Edge Block Supplier

When evaluating potential suppliers in the UK or beyond, consider:

- The supplier's certifications, quality records, and track record serving international clientele.

- Willingness to accommodate unique technical requests, provide prototypes, and collaborate on new development.

- Evidence of investment in modern equipment and process automation.

- Clarity and transparency in communication, pricing, and export logistics.

- Solid after-sales technical support, ensuring long-term customer satisfaction.

Requesting samples, visiting factory sites (onsite or virtual), and reviewing customer case studies can also aid in supplier selection and build confidence in large procurement decisions.

Conclusion

The United Kingdom stands as a beacon for precision engineering and technical advancement in the field of carbide tooling. Carbide Edge Block Manufacturers and Suppliers in the UK have earned their global reputation by blending reliable supply, advanced manufacturing, cutting-edge R&D, and a strong service ethic—whether serving a global OEM, specialist distributor, or end-user. Buyers benefit not only from the technical superiority of UK-made carbide blocks, but from a holistic partner relationship that starts at product conception and continues through lifetime technical support. As both established industries and high-growth sectors demand ever-greater precision and efficiency, choosing a UK supplier remains a wise strategic investment for international enterprises seeking premium results.

Frequently Asked Questions (FAQ)

1. What materials are used in premium UK carbide edge blocks?

Premium UK carbide edge blocks are primarily made of tungsten carbide blended with binders such as cobalt or nickel to deliver the optimal balance of hardness and toughness.

2. Can overseas buyers order custom-shaped carbide edge blocks from the UK?

Yes, top UK manufacturers provide custom dimensioning, shaping, OEM branding, and private-label packaging. Buyers can submit CAD drawings or collaborate with supplier R&D teams to develop bespoke solutions.

3. Are UK-made carbide edge blocks certified for export?

Reputable suppliers deliver blocks with all required certifications, inspection reports, and compliance documentation, ensuring smooth global exports and acceptance across industry sectors.

4. Which industries benefit most from UK carbide edge blocks?

Industries such as automotive, aerospace, bridge and infrastructure construction, woodworking, electronics, and industrial fabrication regularly rely on UK-made carbide edge blocks for their superior wear resistance and precision.

5. How do UK suppliers guarantee product quality?

They employ advanced CNC machinery, rigorous in-line and post-production inspections, and full traceability for each batch produced. Many maintain ISO and UKAS accreditation for ongoing reliability and trust.