Content Menu

● Introduction

● What Carbide Edge Blocks Are and Why They Matter

● Manufacturing Excellence: How Carbide Edge Blocks Are Made

● Applications Across Industries

● Choosing the Right Carbide Edge Block Partner

● Emerging Trends and the European Advantage

● Material Science Insights: What Sets European Blocks Apart

● Practical Considerations for OEMs and Distributors

● Visual and Video Integration: Enhancing Comprehension (Illustrative Strategy)

● Case Study: Real-World Impact in European Operations

● Global Relevance: Export and Logistics Considerations

● Updated Perspectives on Quality Assurance

● Conclusion

● FAQ

>> 1. What makes European carbide edge blocks stand out in the global market?

>> 2. How are carbide edge blocks customized for specific applications?

>> 3. Is OEM support available for international brands?

>> 4. What industries benefit most from carbide edge blocks?

>> 5. What should buyers look for in supplier quality assurance?

Introduction

Carbide edge blocks stand as a cornerstone in modern industrial manufacturing, enabling precise cutting, grinding, and shaping while delivering exceptional wear resistance in demanding environments. Europe's industrial base hosts一carbide edge block manufacturers and suppliers, with deep expertise in metallurgy, precision engineering, and custom OEM capabilities. For brand owners, wholesalers, and OEMs seeking reliable partners, understanding the landscape, production methodologies, and application contexts is vital to choosing the right collaborator. The topic “Carbide Edge Block Manufacturers and Suppliers” captures a broad spectrum of entities—from established carbide houses to innovative engineering shops—each contributing to safer, more efficient, and longer-lasting tooling solutions across mining, cement, woodworking, metalworking, and beyond.

What Carbide Edge Blocks Are and Why They Matter

Carbide edge blocks are precisely engineered components fabricated from tungsten carbide or cemented carbide. They feature hardened edge geometries designed to withstand extreme wear, high temperatures, and significant mechanical loads. These blocks often serve as critical wear parts or replaceable edges in equipment such as high-pressure grinding rolls (HPGR), mining crushers, woodworking machinery, metal forming lines, and die tooling. The inherent hardness and toughness of carbide, combined with engineered coatings and tailored grain sizes, translate into longer tool life, higher uptime, and improved process stability. As a result, Carbide Edge Block Manufacturers and Suppliers emphasize material science, surface engineering, and application-specific designs to meet diverse performance requirements.

Manufacturing Excellence: How Carbide Edge Blocks Are Made

A clear view of the production chain helps buyers evaluate supplier capability and quality assurance. The typical manufacturing pathway combines powder metallurgy with precision forming, high-temperature processing, and finishing steps that define final performance.

- Powder preparation: The process begins with tungsten carbide powder formation from tungsten and carbon sources, often blended with trace elements to tune hardness and toughness. Cobalt binder powder is integrated to form a dense, cohesive material. Meticulous control of particle size distribution and impurities sets the foundation for predictable performance.

- Pressing and shaping: Powder mixtures are compacted under high pressure using precision presses to create green bodies that approximate final geometry. Consistency at this stage determines dimensional tolerances and internal density.

- Sintering: Green bodies undergo high-temperature sintering, typically around 1500°C, to fuse particles into a dense, hard matrix. This step induces shrinkage and demands tight process control to achieve the target density and mechanical properties.

- Grinding and finishing: Post-sintering grinding refines tolerances, flatness, and edge geometry. Diamond tooling is commonly used to achieve the exact profiles required for high-performance applications.

- Coating and edge treatment: Many carbide edge blocks receive protective coatings or surface treatments to bolster wear resistance, reduce friction, and improve corrosion performance. Final inspection verifies dimensional accuracy, surface integrity, and coating adherence.

- Quality assurance: Throughout the process, in-line and end-of-line testing—such as hardness, density, microstructure assessment, and dimensional checks—ensure conformity to specifications. ISO certifications and supplier quality programs underpin long-term reliability.

Applications Across Industries

Carbide edge blocks find utility in multiple high-demand sectors, and European manufacturers tailor solutions to specific industry needs:

- Mining and aggregate processing: HPGR edge blocks and wear parts designed to endure abrasive materials and high pressures, contributing to improved throughput and reduced downtime.

- Cement and mineral processing: Grinding rolls and associated tooling demand superb wear resistance and stable dimensional performance across long service intervals.

- Woodworking and metalworking: Replaceable edges, saw tips, dies, and forming tools benefit from sharp retention, reduced need for frequent sharpening, and consistent process outcomes.

- Heavy equipment and machinery: Reinforced wear parts extend service life in challenging environments, supporting maintenance budgets and uptime targets.

- OEM tooling and automation: European providers often offer design-for-manufacture collaboration, co-development of material grades, and value-added services to streamline customers' production lines.

Choosing the Right Carbide Edge Block Partner

Selecting a capable Carbide Edge Block Manufacturer or Supplier hinges on several critical dimensions:

- Technical expertise and track record: Look for a demonstrable history of successful implementations in your sector, with references or case studies that align with your application.

- Customization spectrum: The ability to tailor block geometry, grain size, cobalt binder content, and surface coatings ensures alignment with unique loading conditions and performance targets.

- Quality control and certifications: ISO 9001 or equivalent quality management systems, plus in-house testing and traceability, are essential for consistent results.

- OEM and export readiness: For international buyers, a supplier with established OEM programs and reliable logistics reduces risk and accelerates time-to-market.

- After-sales support: Proactive technical assistance, replacement part availability, and timely communication mitigate downtime and support lifecycle planning.

Emerging Trends and the European Advantage

Europe's carbide ecosystem continues to evolve with advances in materials science, process automation, and integrated supply chains:

- Advanced carbide grades: New formulations balance hardness, toughness, and thermal stability to address ever-harsher service environments.

- Smart manufacturing: Digital twins, process analytics, and automated inspection enhance quality control and shorten iteration cycles.

- Sustainable practices: Recycled feedstock, energy-efficient sintering, and waste minimization are increasingly integrated into supplier operations, aligning with global sustainability goals.

- Global OEM partnerships: European suppliers frequently engage in international collaborations, offering scalable solutions for multinational brands and distributors.

Material Science Insights: What Sets European Blocks Apart

The strength of European carbide edge blocks often stems from a combination of meticulous material selection, refined grain structure, and precision finishing:

- Grain size control: Fine-grain carbides deliver superior hardness and wear resistance, while carefully selected coarser grades may provide improved toughness in certain loads.

- Binder content tuning: The cobalt binder percentage is calibrated to strike the right balance between hardness and toughness, depending on anticipated stress profiles.

- Coating technologies: PVD/CVD coatings, protective ceramic layers, or specialized carbide coatings reduce adhesion, wear, and heat buildup at the cutting edge.

- Surface integrity: Polishing, micro-roughness optimization, and defect minimization translate into smoother tool interactions and more predictable performance.

Practical Considerations for OEMs and Distributors

For brands and distributors sourcing carbide edge blocks, practical questions often include lead times, customization flexibility, and total cost of ownership. Strategic considerations include:

- Material type and grade: Tungsten carbide vs cemented carbide grades, and the corresponding performance envelopes for edge retention and toughness.

- Geometric tolerance and finish: Tolerances affect assembly fit, alignment, and performance in automated lines.

- Coatings and treatments: The choice of coating type impacts tool life under specific coolants, cutting speeds, and workloads.

- Availability of OEM support: Design optimization, material recommendations, and early involvement in product development cycles can yield better outcomes and shorter development timelines.

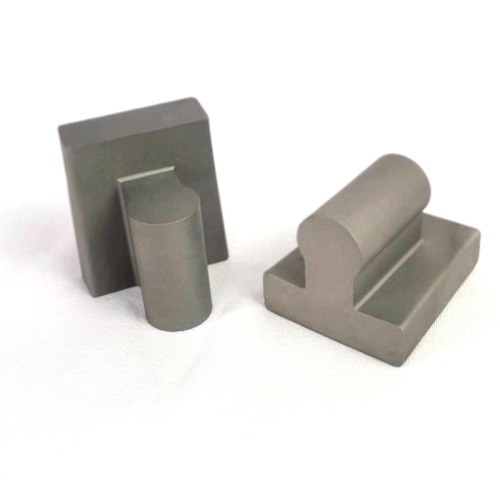

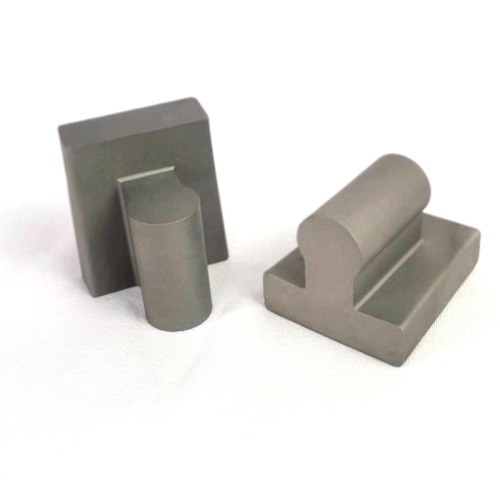

Visual and Video Integration: Enhancing Comprehension (Illustrative Strategy)

To maximize reader comprehension and engagement, embedding visuals without disrupting text flow is essential. Strategically placed diagrams showing the production stages, microstructural photographs, and application schematics, complemented by video tutorials or product demonstrations, can significantly enhance comprehension and retention. Practical usage examples, maintenance tips, and case studies in mining, cement, and woodworking contexts provide tangible value to readers evaluating suppliers.

Case Study: Real-World Impact in European Operations

A hypothetical case study could illustrate how a European carbide edge block supplier collaborated with an OEM in the mining sector to optimize edge geometry, adjust cobalt binder levels for improved toughness, and implement a coating regimen that extended service life by a measurable margin. These outcomes translate to fewer tool changes, reduced downtime, and more predictable maintenance cycles, underscoring the value of a deep supplier collaboration in achieving lifecycle cost reductions.

Global Relevance: Export and Logistics Considerations

For overseas brands and distributors, robust export capabilities and responsive logistics are pivotal. European carbide edge block manufacturers often maintain robust documentation, compliant with international trade standards, and established networks for timely shipment across continents. This reduces risk associated with supply interruptions and ensures continuity in customers' production lines.

Updated Perspectives on Quality Assurance

Quality assurance remains a core differentiator. Beyond passing standard dimensional checks, top suppliers emphasize traceability of raw materials, batch-level testing, and deterministic performance data. Such practices empower downstream users to model performance, schedule maintenance, and optimize production planning with greater confidence.

Conclusion

European Carbide Edge Block Manufacturers and Suppliers combine material science excellence, advanced manufacturing capabilities, and customer-centric service to deliver durable, high-performance edge blocks that meet diverse operating demands. By engaging with a partner that offers deep technical insight, customization options, and reliable OEM support, manufacturers and distributors can achieve longer tool life, higher process stability, and improved total cost of ownership across mining, cement, woodworking, and metalworking environments.

FAQ

1. What makes European carbide edge blocks stand out in the global market?

European providers leverage refined material science, precise processing, and rigorous quality systems, delivering consistent performance and strong OEM collaboration across industries.

2. How are carbide edge blocks customized for specific applications?

Customization typically covers geometry, grain size, binder content, coating choices, and surface finishes, tailored to workload, temperature, and environmental conditions.

3. Is OEM support available for international brands?

Yes, European manufacturers frequently offer comprehensive OEM programs, including design assistance, CTQ parameter specification, and logistics support for global customers.

4. What industries benefit most from carbide edge blocks?

Mining, cement production, woodworking, metalworking, and heavy equipment manufacturing are among the primary beneficiaries due to the high-wear nature of their processes.

5. What should buyers look for in supplier quality assurance?

Key indicators include ISO-certified quality management systems, traceability of raw materials, robust testing protocols, and transparent performance data.