Content Menu

● Introduction to Carbide Saws

● Advantages of Carbide Saws: A Technical Deep Dive

>> 1. Material Science Behind Durability

>> 2. Thermal Management

>> 3. Cutting Force Optimization

● Advanced Applications of Carbide Production Saws

>> Aerospace: Titanium Turbine Blade Machining

>> Automotive: EV Battery Tray Production

>> Energy: Wind Turbine Component Fabrication

● Carbide Production Saw Manufacturing Innovations

>> 1. Additive Manufacturing

>> 2. Nanostructured Carbides

● Maintenance Best Practices for Carbide Saws

>> 1. Cleaning Protocols

>> 2. Sharpening Techniques

● Global Market Trends (2025–2030)

>> 1. Growth Projections

>> 2. Sustainability Initiatives

● Conclusion

● Frequently Asked Questions

>> 1. Can Carbide Saws Cut Hardened Steel (HRC 60+)?

>> 2. What's the Maximum Diameter for Carbide Circular Saws?

>> 3. How Does Tooth Rake Angle Affect Cutting?

>> 4. Are Laser-Cut Carbide Teeth Better Than Brazed?

>> 5. What's the Future of Carbide Saw Technology?

● Citations:

Carbide saws have become the gold standard in industrial cutting, offering unparalleled performance in precision, durability, and efficiency. This article explores the science, economics, and real-world applications driving their dominance, with a focus on advancements in carbide production saw technology.

Introduction to Carbide Saws

Carbide saws use teeth made from tungsten carbide (WC), a compound of tungsten and carbon atoms in a lattice structure. This material ranks second only to diamond in hardness (2,200 HV vs. diamond's 10,000 HV), making it ideal for abrasive applications. Modern carbide production saw blades combine these teeth with advanced steel alloys (e.g., M42 cobalt steel) for optimal flexibility and heat dissipation.

Advantages of Carbide Saws: A Technical Deep Dive

1. Material Science Behind Durability

Carbide's wear resistance stems from its unique composition:

- 90% Tungsten Carbide: Provides hardness through covalent WC bonds.

- 10% Cobalt Binder: Adds toughness by filling interstitial spaces.

This structure allows carbide production saw blades to withstand 3–5 GPa of cutting pressure without deformation, compared to 1–2 GPa for high-speed steel (HSS).

2. Thermal Management

During cutting, temperatures at the blade edge can reach 800°C (1,472°F). Carbide's low thermal expansion coefficient (5.5 µm/m·K vs. steel's 12 µm/m·K) minimizes warping. Advanced coatings like AlTiN (aluminum titanium nitride) reflect heat, reducing edge temperature by 200°C in tests.

3. Cutting Force Optimization

A study by the International Journal of Machine Tools and Manufacture found carbide saws require 30% less cutting force than HSS when machining 304 stainless steel. This reduces machine wear and energy consumption by 15–20%.

Advanced Applications of Carbide Production Saws

Aerospace: Titanium Turbine Blade Machining

Boeing's South Carolina plant uses carbide production saws with 80-tooth TCG (triple-chip grind) blades to cut Ti-6Al-4V alloy. Key parameters:

- Speed: 120 m/min

- Feed: 0.08 mm/tooth

- Accuracy: ±0.025 mm

This process reduces post-processing time by 40% compared to abrasive cutting.

Automotive: EV Battery Tray Production

Tesla's Gigafactory employs 350mm diameter carbide circular saws to cut aluminum battery enclosures. The blades feature:

- Kerf: 3.2 mm

- Tooth Count: 72

- Coating: DLC (diamond-like carbon)

This setup achieves 500 cuts per hour with ≤0.1mm dimensional variance.

Energy: Wind Turbine Component Fabrication

Vestas uses carbide production saws with PVD-coated blades to cut G10 fiberglass composites for turbine blades. Benefits include:

- Cut Speed: 2x faster than diamond blades

- Dust Reduction: 60% less particulate emissions

- Blade Life: 8,000 linear meters per sharpening

Carbide Production Saw Manufacturing Innovations

1. Additive Manufacturing

3D-printed carbide teeth using binder jet technology allow complex geometries unachievable with traditional sintering. Sandvik's new CoroMill® 316 blades feature:

- Internal Cooling Channels: Reduce temperature by 35%

- Custom Tooth Profiles: Optimized for vibration damping

2. Nanostructured Carbides

Nano-grained tungsten carbide (200nm particle size) developed by Kennametal increases hardness by 15% while maintaining toughness. Applications include:

- Micro-Drilling: 0.3mm carbide bits for PCB manufacturing

- Medical: Bone saw blades with 0.05mm cutting width

Maintenance Best Practices for Carbide Saws

1. Cleaning Protocols

Use alkaline solutions (pH 9–11) to remove pitch and resin buildup without corroding carbide. Avoid chlorine-based cleaners which can embrittle cobalt binders.

2. Sharpening Techniques

Professional regrinding requires:

- Grinding Wheel: Diamond or CBN (cubic boron nitride)

- Angle Tolerance: ±0.5° for primary bevel

- Coolant Flow: 5–10 L/min to prevent thermal cracking

Global Market Trends (2025–2030)

1. Growth Projections

The carbide tools market is expected to grow at 6.8% CAGR, reaching $15.3B by 2030 (Grand View Research). Key drivers:

- EV Manufacturing: 45% of new demand

- Aerospace Composites: 30% growth in CFRP cutting tools

2. Sustainability Initiatives

- Recycling: 85% of tungsten is now recovered from scrap carbide

- Bio-Based Binders: Cobalt alternatives using lignin show promise in lab tests

Conclusion

From nano-structured teeth to AI-optimized cutting parameters, carbide production saw technology continues to redefine industrial manufacturing. Their unique combination of hardness, thermal stability, and adaptability ensures carbide tools will remain essential in tackling tomorrow's material challenges.

Frequently Asked Questions

1. Can Carbide Saws Cut Hardened Steel (HRC 60+)?

Yes, with proper parameters:

- Speed: 50–80 SFM

- Feed: 0.03–0.05 mm/tooth

- Coolant: High-pressure emulsion (7–10 bar)

2. What's the Maximum Diameter for Carbide Circular Saws?

Standard sizes reach 1,200mm for shipbuilding plate cutting. Custom mills can produce 2,500mm blades for wind tower flange machining.

3. How Does Tooth Rake Angle Affect Cutting?

- Positive Rake (15–20°): Softer materials (aluminum)

- Neutral Rake: Hard alloys (titanium)

- Negative Rake (-5°): Abrasive composites (GFRP)

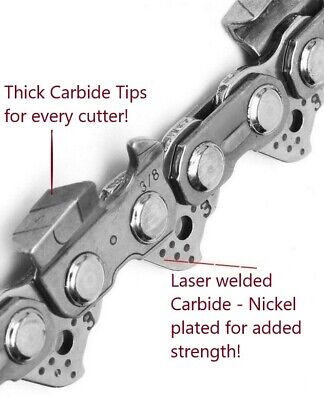

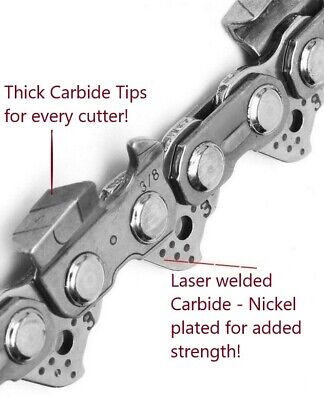

4. Are Laser-Cut Carbide Teeth Better Than Brazed?

Laser welding creates stronger joints (800 MPa vs. 500 MPa for brazing) but increases cost by 30%. Ideal for high-vibration applications like forestry mulching.

5. What's the Future of Carbide Saw Technology?

Emerging trends include:

- Smart Blades: IoT-enabled sensors monitoring tooth wear

- Gradient Carbides: Variable hardness within a single tooth

Citations:

[1] https://rontgensaws.com/understanding-the-advantages-of-carbide-tipped-band-saw-blades/

[2] https://www.baucor.com/blogs/news/carbide-blade-proficiency

[3] https://coldsawshop.com/blogs/cold-saw-blog/10-advantages-of-a-carbide-tipped-saw-blade

[4] https://www.sawblade.com/order-circular-saws.cfm

[5] https://www.istockphoto.com/photos/carbide-tip

[6] https://www.jaybeeenterprises.in/tungsten-carbide-tipped-circular-saw-blade.html

[7] https://www.accusharp.co.in/why-use-carbide-cutting-tools-benefits-of-carbide-cutting-tool-future-of-carbide-cutting-tool

[8] https://caleyron.com/en/blog/advantages-of-circular-saw-cutters/

[9] https://farrisbelt.com/industrial-sharpening-custom-fabrication-blog/key-benefits-of-carbide-tip-saw-blades/

[10] https://www.istockphoto.com/photos/carbide-blade

[11] https://create.vista.com/photos/tungsten-carbide/

[12] https://ukam.com/product/tungsten-carbide-dicing-blades/

[13] https://www.applecarbide.com/article/what-are-the-primary-advantages-of-using-carbide-saw-tips-in-saw-blades-or-cutting-tools.html

[14] https://www.shutterstock.com/search/carbide-saws

[15] https://stock.adobe.com/search/images?k=carbide+cutting

[16] https://www.hdlihuacarbide.com/news/advantages-and-uses-of-carbide-cutting-toolstungsten-carbide-saw-blades

[17] https://en.wikipedia.org/wiki/Carbide_saw

[18] https://www.shutterstock.com/search/carbide-blade

[19] https://stock.adobe.com/search/images?k=saw

[20] https://www.hircotools.com/circular-saw-blades.html