Content Menu

● Introduction

● Understanding Carbide Edge Blocks

● The Value of Russian Manufacturers and Suppliers

● Key Players in Russia's Carbide Edge Block Industry

>> Microbor

>> VakTec

>> Haltec

>> ISCAR Russia

>> Zhongbo Carbide Russia

● The Carbide Edge Block Manufacturing Process

>> Raw Material Selection

>> Blending and Mixing

>> Pressing and Compacting

>> Sintering

>> Finishing and Inspection

>> Customization and Branding

>> Logistics and Export Preparation

● Industry Applications and Expansion

>> Mining and Mineral Processing

>> Metalworking and Tooling

>> Construction and Infrastructure

>> Electronics and Medical Devices

● Technical Innovations and R&D Advancements

● Sourcing Tips for International Buyers

● Market Perspective: Russia's Advantage and Challenges

● Conclusion

● FAQ

>> Q1: How do Russian carbide edge block manufacturers ensure product quality?

>> Q2: Can Russian suppliers accommodate custom OEM or ODM requests?

>> Q3: Which industries most frequently use Russian carbide edge blocks?

>> Q4: How are carbide edge blocks exported from Russia?

>> Q5: What are the latest innovations in Russian carbide edge block production?

Introduction

Russia is renowned for its innovation and expertise in advanced metallurgy, especially in producing precision-engineered components such as carbide edge blocks. These products are foundational across heavy industry, mining, machining, and high-pressure processing. Global demand continues to rise for reliable carbide edge block manufacturers and suppliers capable of delivering value, consistency, and technical support. Russian suppliers have earned global attention, providing OEM and branded solutions for brands, wholesalers, and OEM production enterprises around the world. This article will comprehensively discuss vital aspects of sourcing carbide edge blocks in Russia, the industrial landscape, the manufacturing process, key players, export logistics, and best practices for global buyers.

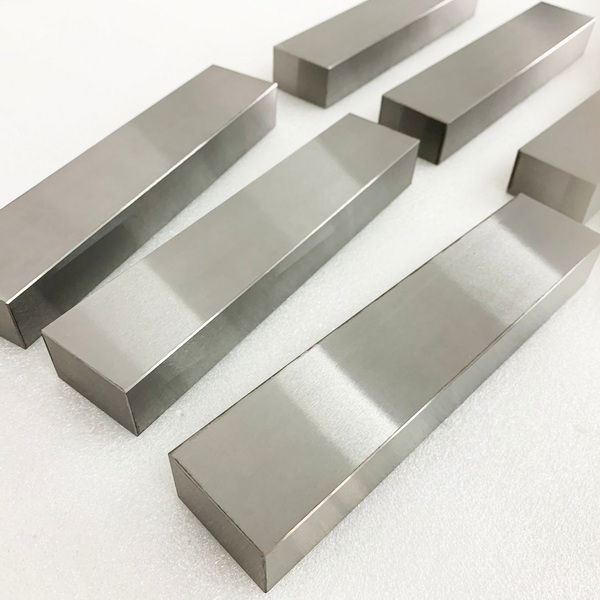

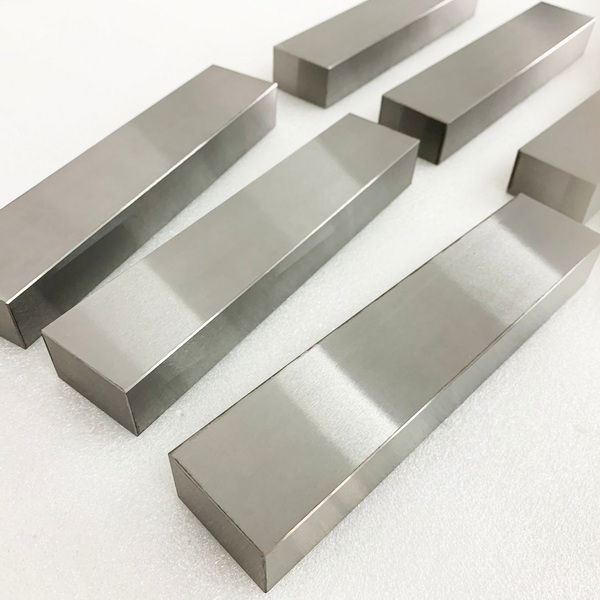

Understanding Carbide Edge Blocks

Carbide edge blocks serve as critical wear-resistant components across various industrial applications. Most are made from tungsten carbide—a material prized for its extreme hardness, reliability, and resistance to abrasion. The combination of carbide and a bonding element enhances durability and prolongs service life, especially under intense mechanical and thermal stress.

Key application sectors include:

- Metal forming and processing equipment

- Mining tools and high-pressure grinding rolls (HPGRs)

- Milling, turning, and cutting operations

- Die and mold manufacturing

- Heavy machinery and infrastructure projects

Modern edge blocks can be engineered for specific applications, with customizable grades, dimensions, and geometries to suit end-user requirements and optimize efficiency. OEM buyers increasingly demand unique block designs for specialized machinery and consumer products, fueling innovation among Russian carbide edge block manufacturers and suppliers.

The Value of Russian Manufacturers and Suppliers

Russian carbide edge block manufacturers distinguish themselves on the global stage for several reasons:

- Technological heritage: Decades of research in metallurgy and materials science have cultivated world-class expertise and innovation.

- Full-cycle production: Leading suppliers offer complete control over the manufacturing process, from powder selection to final packaging.

- OEM/ODM solutions: Russian manufacturers support private-labeling, custom engineering, and flexible order quantities, making them ideal partners for brands and distributors.

- Quality assurance: Multistage inspection, industry certifications, and adherence to international standards are commonplace.

- Competitive pricing: Lower labor and overhead costs often translate into better value for overseas buyers, without sacrificing product quality.

- Export readiness: Russia's major industrial hubs have streamlined logistics and documentation procedures to support clients in Europe, Asia, and North America.

These advantages enable Russian carbide edge block suppliers to support a diverse range of B2B needs, including technical consultations, custom product development, and after-sales service.

Key Players in Russia's Carbide Edge Block Industry

Several manufacturers have established themselves as reliable sources for high-quality carbide edge blocks in Russia. Below are some notable companies shaping the market:

Microbor

Microbor is a flagship Russian producer specializing in superhard composite materials, carbide edge blocks, and precision metalworking tools. The company provides full-cycle manufacturing, advanced CAD modeling, and proprietary material formulations. Microbor supports global OEM and private-label orders, ensuring rapid turnaround and high consistency.

VakTec

VakTec delivers multi-edge tools and carbide blocks optimized for milling and turning operations. Their production facilities are noted for cutting-edge automation and strict process controls, enabling rapid prototyping and efficient mass production.

Haltec

Haltec is a veteran supplier offering a broad product range that includes carbide edge blocks, wear parts, and metal-cutting inserts. The company maintains technical partnerships with research institutes to drive continuous improvement and innovation.

ISCAR Russia

ISCAR is an international leader with significant Russian manufacturing operations. Their catalog covers carbide edge blocks, cutting inserts, and wear-resistant components for demanding industrial uses. ISCAR's expertise in advanced coating and surface finishing further distinguishes their products.

Zhongbo Carbide Russia

Zhongbo Carbide collaborates with Russian partners on high-performance carbide bars, plates, and edge blocks, leveraging automation, digital process control, and international export experience. The company offers flexible OEM solutions and branded packaging for clients worldwide.

The Carbide Edge Block Manufacturing Process

Russian carbide edge block manufacturers use advanced powder metallurgy, integrated quality control, and precision engineering to produce reliable and durable products. Here is a typical overview of the production process:

Raw Material Selection

Most carbide edge blocks start with high-purity tungsten carbide powder. Binder elements (typically cobalt or nickel) are selected according to the required mechanical properties, including hardness, toughness, and corrosion resistance.

Blending and Mixing

Tungsten carbide powder is carefully blended with the binder in ball mills to ensure a homogeneous distribution. Uniform mixing is essential for consistent hardness and wear resistance throughout the finished product.

Pressing and Compacting

The blended powder is pressed into block-shaped moulds with high precision. Automated pressing equipment monitors parameters such as pressure and density to optimize the internal structure of the block.

Sintering

Press-formed blanks are sintered at extremely high temperatures (1300–1600°C), fusing the particles into a dense, rugged cemented carbide body. This process is meticulously controlled to prevent pore formation and ensure ideal mechanical properties.

Finishing and Inspection

After sintering, the blocks may undergo grinding, polishing, and further machining to achieve exact dimensions, surface finish, and edge sharpness demanded by clients. Multi-stage inspections check particle size uniformity, microstructural integrity, surface roughness, and hardness.

Customization and Branding

Russian manufacturers excel at rapid prototyping and custom engineering. They can produce blocks in an endless variety of shapes, sizes, and grades, tailored to the unique needs of global brands and industrial buyers.

Logistics and Export Preparation

Finished products are packaged, coded, and prepared for export with comprehensive documentation. Efficient logistics hubs in Moscow, St. Petersburg, and Ekaterinburg facilitate timely global delivery.

Industry Applications and Expansion

Carbide edge blocks produced in Russia power a wide spectrum of industries with escalating technical demands:

Mining and Mineral Processing

Edge blocks are vital components in mining drills, high-pressure grinding rolls (HPGRs), and excavation machinery. Their exceptional resistance to shock and abrasion reduces downtime and prolongs service intervals.

Metalworking and Tooling

Precision carbide edge blocks guarantee longer run times on CNC equipment, cutting dies, and metal-forming presses, enhancing production efficiency across automotive, aerospace, electronics, and consumer goods manufacturing.

Construction and Infrastructure

Carbide blocks are incorporated into bridge construction equipment, tunneling cutters, and other heavy infrastructure tools. Their durability supports the precise and rapid execution of large-scale engineering projects.

Electronics and Medical Devices

Ultrafine carbide edge blocks are indispensable in microelectronics assembly and medical device tooling, where exact surface finish and micron-level accuracy are required.

Technical Innovations and R&D Advancements

Russian carbide edge block manufacturers continue to push the boundaries of powder metallurgy and tooling technologies. Recent innovations include:

- Digital process control for enhanced consistency and traceability

- Automated inspection systems using machine vision for defect detection

- Eco-friendly production initiatives such as powder recycling and energy-efficient sintering

- Advanced composite grades blending carbide, ceramic, and superalloy phases for extreme environments

The ability to prototype quickly and iterate custom solutions, paired with access to deep technical expertise, makes Russian suppliers preferred partners for global OEM and R&D teams.

Sourcing Tips for International Buyers

For overseas brands and procurement professionals, sourcing carbide edge blocks from Russian suppliers offers a balance of quality and value, but it's critical to follow best practices:

- Clarify specifications: Request detailed drawings and standards to ensure alignment on grade, geometry, and required properties.

- Assess certifications: Confirm that suppliers hold relevant ISO or other quality assurance credentials.

- Sample first: Many manufacturers offer rapid prototyping and low-volume trial orders.

- Plan logistics: Consider lead times, export documentation, and local regulations for customs clearance.

- Support and after-sales: Leverage suppliers who provide technical assistance and support for troubleshooting and application optimization.

OEM buyers should seek suppliers specializing in international private-label fulfillment and custom branding, as these capabilities enhance market competitiveness and product differentiation.

Market Perspective: Russia's Advantage and Challenges

Russian carbide edge block manufacturers remain at the forefront of industrial materials innovation, but like all global players, they face several challenges:

- Imported equipment reliance: Some Russian plants still depend on European or Asian machinery for powder refinement and finishing.

- Raw material logistics: While Russia is resource-rich, certain high-purity raw materials are imported for specialty grades.

- Competition: Chinese and German suppliers offer formidable competition in terms of scale and price.

- Domestic market transformation: Russian producers are investing heavily in automation and digital transformation to boost productivity and quality assurance.

Nonetheless, Russia's integrative production networks, growing R&D investment, and strategic export hubs position its carbide edge block industry for continued expansion and evolving technical excellence.

Conclusion

Russian carbide edge block manufacturers and suppliers distinguish themselves by blending deep technical expertise, advanced materials science, and flexible OEM service. As global demand for high-performance carbide components continues to grow, Russian suppliers remain central to delivering engineered solutions for a wide range of industries. For overseas buyers, partnering with Russian factories guarantees access to reliable products, tailored engineering, and comprehensive export support. As manufacturing technologies and market needs evolve, Russian carbide edge block producers will maintain their leadership by integrating innovation with client-focused service.

FAQ

Q1: How do Russian carbide edge block manufacturers ensure product quality?

Russian producers implement rigorous powder selection, automated mixing, precision pressing, and multi-stage inspection to guarantee consistent hardness, toughness, and dimensional accuracy in every block.

Q2: Can Russian suppliers accommodate custom OEM or ODM requests?

Yes, most leading manufacturers offer full-cycle customization, including CAD modeling, rapid prototyping, and branded private-labeling for global brands and projects.

Q3: Which industries most frequently use Russian carbide edge blocks?

Key sectors include mining and metallurgy, automotive, aerospace, electronics, construction, and tooling for heavy industry, each demanding specific block grades and geometries.

Q4: How are carbide edge blocks exported from Russia?

Suppliers operate in major industrial hubs with integrated logistics services, preparing comprehensive documentation, customs, and packaging for seamless international delivery.

Q5: What are the latest innovations in Russian carbide edge block production?

Recent advances include digital process control, machine-vision inspection, eco-friendly sintering, new composite grades, and tailored engineering projects supporting rapid product development.