Content Menu

● Introduction

● What Are Carbide Edge Blocks and Why They Matter

● Quality, Standards, and OEM Capabilities in Canada

● Key Manufacturing Capabilities in Canadian Facilities

● Profiles of Notable Canadian Manufacturers and Suppliers

>> 1. Ontario-based specialists with a long heritage in carbide blanks and custom tooling

>> 2. Midwestern Canada firms focused on precision cutting tools and edge blocks

>> 3. West Coast metalworking groups offering integrated carbide solutions

>> 4. Specialty firms with coating technology and wear-resistance expertise

>> 5. Firms with strong OEM collaboration records

● Choosing the Right Canadian Partner for Carbide Edge Blocks

● Applications Across Industries

● Driving Factors for Global Buyers

● Sample Procurement Scenarios

● Regulatory and Trade Considerations

● Sustainability and Corporate Responsibility

● Innovations and Trends in Canadian Carbide Production

● Vendor Evaluation Checklist (Practical Steps)

● Measuring Success and Value for Buyers

● Global Sourcing Considerations

● Case Integration for a Complete Article

● Conclusion

● FAQ

>> 1. What are carbide edge blocks, and why are they essential in Canadian manufacturing?

>> 2. Which industries in Canada most frequently use carbide edge blocks?

>> 3. How do Canadian manufacturers ensure quality across international orders?

>> 4. What should international buyers look for when evaluating a Canadian supplier?

>> 5. How can buyers optimize total cost of ownership when sourcing carbide edge blocks from Canada?

Introduction

Canada's advanced manufacturing sector hosts a dynamic ecosystem for carbide edge blocks, cemented carbide blanks, and related tooling components. For international brands, distributors, and OEMs seeking reliable suppliers with strong design capability, Canada offers a compelling mix of technical expertise, rigorous quality control, and responsive service. This extended guide surveys leading Canadian carbide edge block manufacturers and suppliers, outlines core production capabilities, discusses OEM/ODM strengths, and provides practical guidance for evaluating and engaging with Canadian partners. The emphasis on carbide edge blocks reflects their critical role in high-worce applications such as mining, heavy construction, metalworking, and energy industries. Global buyers will appreciate the breadth of product lines, customization options, and the robust export infrastructure that Canada maintains to support international trade.

What Are Carbide Edge Blocks and Why They Matter

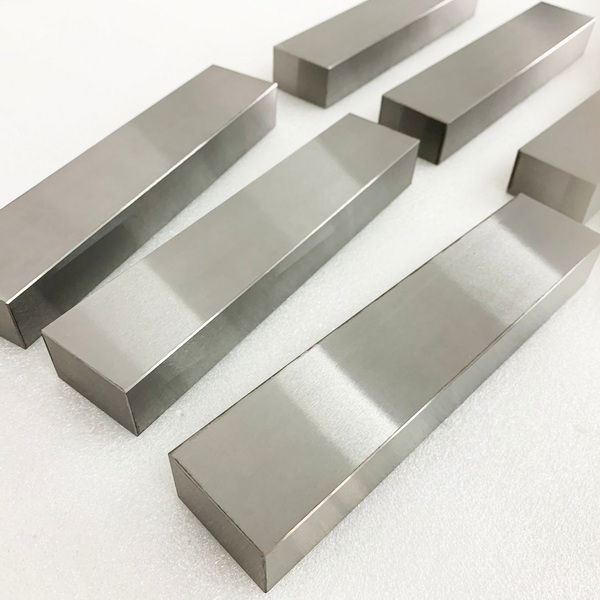

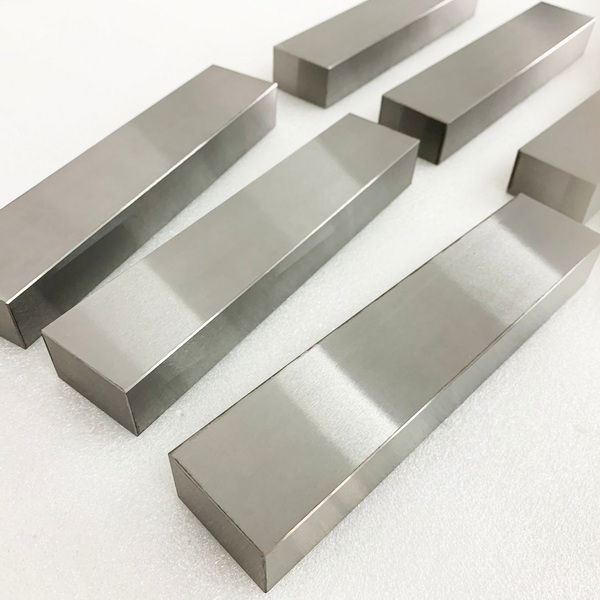

Carbide edge blocks are precision-engineered components produced from tungsten carbide, often combined with a cobalt or nickel binder, designed to withstand extreme wear and high stresses. They are deployed where cutting performance, resistance to abrasion, and stable geometry are essential. In mining equipment, edge blocks serve as key wear-resistant elements in crushers, grinding mills, and rock-breaking tools. In construction and earthmoving, they are used to extend tool life on buckets, teeth, and GETs. In metalworking, carbide edge blocks support high-speed cutting and reliable indexable tooling. The superior hardness and thermal stability of cemented carbide translate into longer service intervals, reduced downtime, and lower total cost of ownership for end users. Canadian manufacturers bring deep process know-how to these applications, including metallurgy, grinding, coating, and testing, all aligned with international quality expectations.

Quality, Standards, and OEM Capabilities in Canada

Canadian carbide edge block suppliers are known for rigorous QA/QC frameworks, often aligned with ISO 9001 and industry-specific standards. This commitment translates into reproducible tolerances, traceable material lots, and documented testing procedures that reassure overseas customers. OEM and ODM collaboration is a common strength, with many Canadian partners offering custom geometry design, prototype validation, coating options, and post-sale refurbishment services. The combination of local engineering talent and access to global supply chains makes Canada a reliable hub for high-precision carbide components. Buyers typically value transparent documentation, clear lead times, and proactive communication—areas in which Canadian suppliers frequently excel.

Key Manufacturing Capabilities in Canadian Facilities

- Powder metallurgy and carbide synthesis: High-purity tungsten carbide powders, binder systems, and grain size control enable tailored performance characteristics for specific applications.

- Forming and shaping: A range of forming methods, including cold isostatic pressing and precision uniaxial pressing, is used to achieve close tolerances and near-net shapes for complex geometries.

- Sintering and densification: Controlled sintering cycles produce dense, uniform cemented carbide with stable microstructures that dictate hardness, toughness, and wear resistance.

- Finishing and coating: Grinding, polishing, spark erosion, and specialized coatings (e.g., TiN, TiAlN, or other wear-resistant coatings) optimize cutting performance and extend edge life.

- Surface integrity and testing: Coordinate measuring machines (CMMs), micro-hardness testing, and inline inspection ensure dimensional accuracy and material properties meet specification.

- Logistics and export readiness: Proximity to major ports, established export procedures, and experience serving international customers streamline overseas fulfillment.

Profiles of Notable Canadian Manufacturers and Suppliers

1. Ontario-based specialists with a long heritage in carbide blanks and custom tooling

- Strengths: deep experience with OEM projects, strong QA culture, reliable supply for end users and toolmakers.

- Ideal partnerships: brands needing consistent supply chains and customization for high-volume manufacturing.

2. Midwestern Canada firms focused on precision cutting tools and edge blocks

- Strengths: advanced grinding capabilities, coating options, and fast prototyping cycles.

- Ideal partnerships: OEMs seeking rapid iteration and short lead times for tool development.

3. West Coast metalworking groups offering integrated carbide solutions

- Strengths: end-to-end service from blank production through finished tools, extensive distribution networks.

- Ideal partnerships: global distributors serving multiple industries with bundled carbide tooling.

4. Specialty firms with coating technology and wear-resistance expertise

- Strengths: advanced surface engineering, performance-enhancing coatings, and customized wear parts.

- Ideal partnerships: customers requiring coated carbide edges for extended life in challenging materials.

5. Firms with strong OEM collaboration records

- Strengths: co-development of cutting tools and maintenance programs, lifecycle support, and reconditioning services.

- Ideal partnerships: brands needing ongoing engineering support and long-term supplier relationships.

Choosing the Right Canadian Partner for Carbide Edge Blocks

- Technical fit: Ensure the supplier matches required carbide grade, binder system, and grain size for the application, whether mining, construction, or metalworking.

- Customization capability: Confirm availability of design assistance, rapid prototyping, and the ability to deliver complex edge geometries or integrated cutting edges.

- Quality assurance: Look for ISO certifications, documented QA processes, and traceability of raw materials and production batches.

- Manufacturing scale and capacity: Assess the supplier's capacity to meet current demand and potential growth, including lead times for large orders.

- After-sales support: Evaluate warranties, refurbishment services, and technical support for installation and maintenance.

- Logistics and export readiness: Verify packaging, labeling, incoterms, and freight options suitable for international customers.

Applications Across Industries

- Mining and minerals processing: Cemented carbide edge blocks contribute to high abrasion resistance in crushers, grinding media, and HPGR components.

- Construction and earthmoving: Edge blocks improve durability for bucket teeth and digging tools that face aggressive materials.

- Metalworking and tooling: Edge blocks support reliable performance in indexable inserts, end mills, and saw blades.

- Oil and gas and energy sectors: Wear parts designed for downhole and surface equipment benefit from carbide's longevity.

- Automotive and aerospace: Precise tooling components and wear parts drive efficiency in high-volume production lines.

Driving Factors for Global Buyers

- Total cost of ownership: Although carbide tooling may have higher upfront cost, its longer service life reduces downtime and maintenance expenditures over time.

- Performance stability: Consistent hardness, fracture resistance, and wear characteristics translate into predictable machining outcomes.

- Vendor reliability: Strong supplier reliability minimizes the risk of production delays, especially for international programs with strict launch schedules.

- Compliance and documentation: clear material specifications, testing reports, and certifications simplify import and qualification processes.

Sample Procurement Scenarios

- Scenario A: A mid-sized European manufacturer of automotive components seeks a Canadian partner for a new line of high-speed cutting tools, with a preference for coated carbide edges and localized technical support.

- Scenario B: A North American mining contractor requires bulk delivery of cemented carbide blocks for wear parts, with a commitment to long-term supply and simple reordering.

- Scenario C: An Asian tool distributor wants OEM collaboration to develop a line of tailored carbide edge blocks with specific tolerances and coatings for different markets.

Regulatory and Trade Considerations

Canadian carbide edge block suppliers generally align with international export controls and product standards. Buyers should verify that the supplier provides appropriate material data sheets, coating specifications, and compliance documentation. For global buyers, a supplier's ability to support cross-border logistics, invoicing in preferred currencies, and adaptable packaging is often as important as technical capability.

Sustainability and Corporate Responsibility

Many Canadian manufacturers emphasize responsible sourcing of raw materials, energy efficiency in production, and waste reduction through recycling programs. Buyers increasingly seek partners with transparent environmental policies and social governance practices, which can also influence long-term supplier relationships and brand reputation.

Innovations and Trends in Canadian Carbide Production

- Coating developments: Advanced protective coatings that reduce wear and tear in aggressive materials expand the lifespan of carbide edges.

- Microstructure engineering: Tailoring grain size and binder distribution enables optimized combinations of hardness and toughness.

- Additive and hybrid approaches: Integrating carbide with other materials or using additive manufacturing techniques for certain tool components broadens design possibilities.

- Smart tooling: Sensor-enabled tools that monitor wear and performance can inform proactive maintenance schedules.

- Lifecycle services: Refurbishment, regrinding, and reclamation programs extend tool life and reduce waste.

Vendor Evaluation Checklist (Practical Steps)

- Request a technical brief detailing carbide grade, binder system, grain size, coating options, and heat treatment history.

- Obtain a sample batch for initial evaluation, followed by a pilot run to validate performance under real operating conditions.

- Review QA documentation, including lot traceability, inspection reports, and certifications.

- Confirm logistics, packaging standards, and export terms, including incoterms and lead times.

- Establish a communication plan with a dedicated technical contact and a clear escalation path for issues.

- Discuss after-sales services, regrinding, refurbishment, and replacement policies.

Measuring Success and Value for Buyers

- Reduction in downtime and maintenance costs over the equipment's lifecycle.

- Improved tool life and Machining efficiency leading to higher output per shift.

- Consistent quality across batches, reducing rework and scrap rates.

- Strong supplier partnerships offering reliable scheduling and responsive technical support.

Global Sourcing Considerations

- Proximity vs. cost: While Canada offers logistical advantages for North American markets, international buyers should evaluate total landed cost and delivery timelines relative to alternative suppliers.

- Language and cultural alignment: English and French-speaking regions in Canada provide robust communication channels, reducing the risks associated with misinterpretation of technical requirements.

- Time zone coordination: Overlapping business hours with client teams facilitate smoother project management and faster problem resolution.

- Intellectual property protection: Choose suppliers with clear IP policies for OEM designs and coatings to protect proprietary tooling technology.

Case Integration for a Complete Article

To transform the above content into a single, coherent piece, integrate the background on carbide edge blocks, the profiles of Canadian manufacturers, and the buyer-oriented sections into a seamless narrative. Maintain a consistent voice that emphasizes technical accuracy, practical procurement guidance, and clear value propositions for international buyers. The article should present real-world decision criteria, practical steps for engagement, and a balanced view of advantages and considerations when sourcing carbide edge blocks from Canada. The final piece should be accessible to readers with varying levels of technical expertise while preserving depth for professionals in manufacturing and engineering procurement.

Conclusion

Canada's carbide edge block ecosystem offers a compelling blend of advanced materials science, precision manufacturing, and dependable OEM collaboration. For international brands, distributors, and manufacturers seeking reliable supply, Canadian suppliers bring robust capabilities in powder metallurgy, forming, sintering, finishing, and coating, backed by strong QA programs and lifecycle support. The country's export-readiness, proximity to major markets, and a culture of technical excellence contribute to a favorable sourcing environment. By focusing on certifications, process transparency, and responsive technical service, buyers can establish durable partnerships that translate into consistent performance, predictable lead times, and meaningful cost savings over the long term.

FAQ

1. What are carbide edge blocks, and why are they essential in Canadian manufacturing?

Carbide edge blocks are cemented carbide components designed to resist wear and maintain precise geometry in demanding applications such as mining, construction, and metalworking. They play a critical role in reducing downtime and extending tool life in Canadian and international operations.

2. Which industries in Canada most frequently use carbide edge blocks?

Mining, heavy construction, metalworking, and oil and gas sectors are prominent users, with edge blocks supporting wear-resistant tooling in crushers, excavators, and high-speed cutting equipment.

3. How do Canadian manufacturers ensure quality across international orders?

Manufacturers typically implement ISO-based quality systems, rigorous material traceability, testing protocols, and transparent documentation to meet global standards and customer specifications.

4. What should international buyers look for when evaluating a Canadian supplier?

Look for carbide grade options, coating capabilities, OEM/ODM experience, lead times, sample/testing programs, and robust after-sales support, including refurbishment or regrinding services.

5. How can buyers optimize total cost of ownership when sourcing carbide edge blocks from Canada?

Consider the entire lifecycle: longer edge life reduces downtime, less frequent replacements lowers operating costs, and reliable supplier relationships minimize delays and quality-related issues.