Content Menu

● Understanding Tungsten Carbide

● What is Tensile Strength?

● Tensile Strength of Tungsten Carbide

● Why is Tensile Strength Important for Tungsten Carbide?

● Factors Affecting the Tensile Strength of Tungsten Carbide

>> 1. Composition and Binder Content

>> 2. Grain Size and Microstructure

>> 3. Sintering Process

>> 4. Heat Treatment

>> 5. Surface Treatments and Coatings

● How is Tensile Strength Measured?

● Comparing Tungsten Carbide's Tensile Strength

● Practical Implications in Industry

● Enhancing Tensile Strength in Tungsten Carbide

● Recent Advancements in Tungsten Carbide Technology

● Applications Benefiting from Enhanced Tensile Strength

● Environmental and Economic Considerations

● Conclusion

● FAQ: Tungsten Carbide Tensile Strength

>> 1. What is the typical tensile strength range for tungsten carbide?

>> 2. Why is tungsten carbide's tensile strength lower than its compressive strength?

>> 3. How does the binder metal (like cobalt) affect tensile strength?

>> 4. Can tungsten carbide be used in applications involving high tensile loads?

>> 5. How can manufacturers improve the tensile strength of tungsten carbide components?

Tungsten carbide is renowned for its exceptional hardness and durability, making it a staple in demanding industrial applications. Yet, while its resistance to wear and deformation is legendary, its tensile strength is a more nuanced property that often surprises engineers and designers. This article explores the tensile strength of tungsten carbide in depth, examining its significance, influencing factors, measurement methods, and practical implications for industry.

Understanding Tungsten Carbide

Tungsten carbide is a composite material formed by combining tungsten and carbon atoms in a dense, hexagonal crystal structure. This structure grants the material its remarkable mechanical properties, including:

- Extreme hardness (Mohs scale 9–9.5)

- High compressive strength

- Significant stiffness (Young's modulus 530–700 GPa)

- Excellent wear resistance

- High melting point (around 2,870°C)

These characteristics make tungsten carbide a top choice for cutting tools, mining equipment, and wear-resistant components.

What is Tensile Strength?

Tensile strength measures a material's ability to resist being pulled apart. It is defined as the maximum amount of tensile stress a material can withstand before failure. In practical terms, it indicates how much pulling force a material can endure without snapping.

Tensile Strength of Tungsten Carbide

Tungsten carbide's tensile strength typically ranges from 350 to 700 MPa, depending on its composition, grain size, and manufacturing process. Most commonly used grades fall between 350 and 500 MPa. This value is moderate compared to its compressive strength, which can exceed 2,700 MPa, and is much lower than the tensile strength of many metals such as steel.

The relatively low tensile strength is due to the brittle nature of tungsten carbide. While it resists compression and abrasion extremely well, it is more susceptible to cracking under tensile or bending forces.

Why is Tensile Strength Important for Tungsten Carbide?

While tungsten carbide excels in hardness and compressive strength, its tensile strength is a critical consideration for applications involving pulling or bending loads. Understanding this property helps engineers:

- Select appropriate materials for specific mechanical stresses

- Design tools and components that avoid failure under tension

- Optimize manufacturing processes for improved durability

Factors Affecting the Tensile Strength of Tungsten Carbide

Several key factors influence the tensile strength of tungsten carbide:

1. Composition and Binder Content

Tungsten carbide is often combined with a binder metal, typically cobalt, to improve toughness. The ratio of tungsten carbide to binder affects both hardness and tensile strength. Higher binder content generally increases toughness and tensile strength but may slightly reduce hardness.

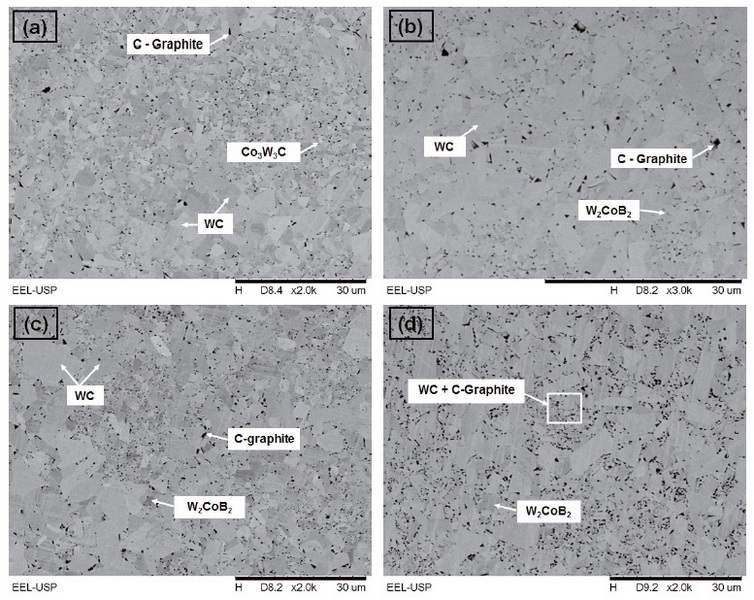

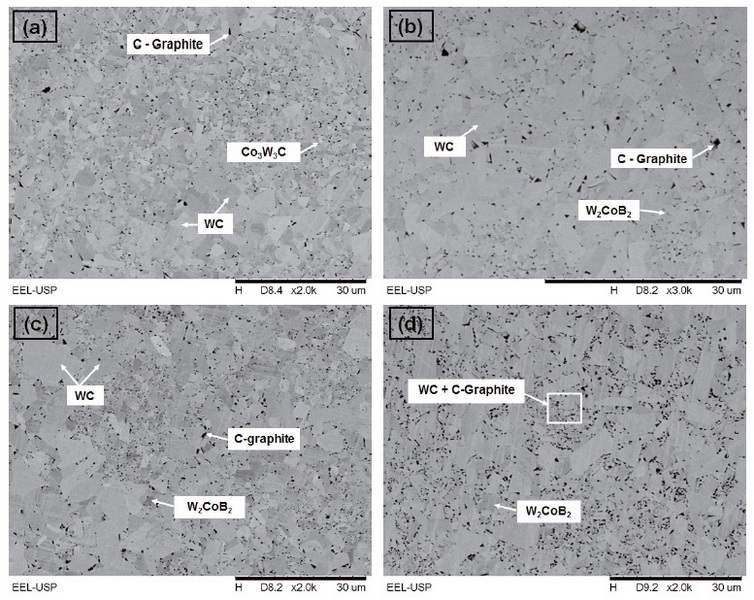

2. Grain Size and Microstructure

Finer grain sizes usually enhance tensile strength by impeding crack propagation. A uniform microstructure with minimal porosity also contributes to higher tensile strength.

3. Sintering Process

The temperature, pressure, and atmosphere during sintering determine the density and bonding quality of the composite, directly impacting tensile strength.

4. Heat Treatment

Post-sintering heat treatments can relieve internal stresses and optimize binder distribution, further improving tensile strength.

5. Surface Treatments and Coatings

Surface flaws can initiate cracks under tensile stress. Polishing and applying protective coatings can help reduce surface defects and enhance tensile performance.

How is Tensile Strength Measured?

Tensile strength is determined using standardized tests, typically involving a universal testing machine (UTM). The process involves:

- Preparing standardized specimens with specific dimensions

- Applying a controlled tensile force until the specimen fractures

- Recording the maximum stress endured before failure

The results are plotted on a stress-strain curve, revealing key points such as yield strength, ultimate tensile strength, and elongation at break.

Comparing Tungsten Carbide's Tensile Strength

| Property | Tungsten Carbide | Steel (High-Strength) | Titanium Alloy |

| Tensile Strength (MPa) | 350–700 | 800–2,000 | 900–1,200 |

| Compressive Strength (MPa) | 2,700+ | 250–1,000 | 800–1,100 |

| Hardness (Mohs) | 9–9.5 | 4–4.5 | 6 |

| Young's Modulus (GPa) | 530–700 | 200–210 | 110 |

Tungsten carbide's tensile strength is lower than that of many metals, but its hardness and compressive strength are significantly higher.

Practical Implications in Industry

Tungsten carbide's unique balance of properties makes it ideal for:

- Cutting tools (drill bits, milling cutters)

- Mining equipment (rock drills, excavation tools)

- Wear-resistant parts (bearings, seals, nozzles)

- Jewelry (rings, watch bands)

However, its brittleness and moderate tensile strength mean it is best suited for applications dominated by compressive and abrasive forces, rather than those involving significant tension or bending.

Enhancing Tensile Strength in Tungsten Carbide

Manufacturers employ several strategies to optimize tensile strength:

- Fine-tuning composition: Adjusting the tungsten carbide-to-binder ratio for the desired balance of hardness and toughness.

- Advanced powder metallurgy: Using high-purity powders and precise sintering to minimize defects.

- Microstructural control: Achieving finer, more uniform grain structures.

- Heat treatment: Relieving internal stresses and optimizing binder distribution.

- Rigorous quality control: Ensuring consistent tensile strength across production batches.

Recent Advancements in Tungsten Carbide Technology

Recent research and development efforts have focused on enhancing the mechanical properties of tungsten carbide, including its tensile strength. Innovations such as nano-structured tungsten carbide composites and the incorporation of alternative binder materials like nickel or iron have shown promising results. These advancements aim to reduce brittleness while maintaining hardness and wear resistance, opening new possibilities for tungsten carbide in more demanding tensile applications.

Applications Benefiting from Enhanced Tensile Strength

With improved tensile strength, tungsten carbide is increasingly being considered for use in aerospace components, high-performance automotive parts, and advanced manufacturing tools. These applications require materials that can withstand complex stress states, including tension, bending, and impact, while retaining durability and precision.

Environmental and Economic Considerations

The production and use of tungsten carbide also involve environmental and economic factors. Recycling tungsten carbide scrap and optimizing manufacturing processes to reduce waste contribute to sustainability. Additionally, the high cost of raw materials and processing necessitates careful design and application to maximize the material's value.

Conclusion

Tungsten carbide's tensile strength, typically in the range of 350–700 MPa, is moderate compared to its extraordinary hardness and compressive strength. This property is shaped by its composition, grain structure, and manufacturing processes. While its brittleness limits its use in tensile applications, tungsten carbide remains indispensable for roles demanding wear resistance, rigidity, and durability under compressive loads. Understanding and optimizing its tensile strength is essential for maximizing performance and reliability in high-stress industrial environments. With ongoing research and technological advancements, the potential for tungsten carbide to be used in even more demanding applications continues to grow, ensuring its relevance in the future of materials engineering.

FAQ: Tungsten Carbide Tensile Strength

1. What is the typical tensile strength range for tungsten carbide?

The tensile strength of tungsten carbide generally falls between 350 and 700 MPa, depending on its composition and processing.

2. Why is tungsten carbide's tensile strength lower than its compressive strength?

Tungsten carbide is a brittle material with a rigid crystal structure, making it much stronger under compression than tension. It resists crushing but is more prone to fracture when pulled apart.

3. How does the binder metal (like cobalt) affect tensile strength?

Adding a binder metal such as cobalt increases the toughness and tensile strength of tungsten carbide by improving its ability to absorb energy and resist crack propagation.

4. Can tungsten carbide be used in applications involving high tensile loads?

Due to its brittleness and moderate tensile strength, tungsten carbide is not ideal for applications dominated by tensile or bending stresses. It is best used in compressive or abrasive environments.

5. How can manufacturers improve the tensile strength of tungsten carbide components?

Manufacturers can enhance tensile strength by optimizing the tungsten carbide-to-binder ratio, refining grain size, using advanced sintering techniques, applying heat treatments, and performing thorough quality control.