Content Menu

● Understanding Tungsten Carbide: Composition and Structure

>> Chemical Composition

>> Physical and Chemical Properties

● Manufacturing Process of Tungsten Carbide

● Key Properties of Tungsten Carbide

>> Hardness and Wear Resistance

>> High Temperature Stability

>> Toughness and Strength

>> Chemical Stability

● Applications of Tungsten Carbide

>> Industrial and Manufacturing

>> Medical Field

>> Jewelry

>> Aerospace and Automotive

>> Everyday Tools and Consumer Products

● Advanced Applications of Tungsten Carbide

● Recent Innovations in Tungsten Carbide Manufacturing

● Environmental Impact and Sustainability of Tungsten Carbide

● Comparative Analysis with Other Hard Materials

● Future Trends in Tungsten Carbide Usage

● Conclusion

● FAQ About Tungsten Carbide

>> 1. What is tungsten carbide made of?

>> 2. How hard is tungsten carbide compared to steel?

>> 3. What industries use tungsten carbide tools?

>> 4. Can tungsten carbide be recycled?

>> 5. Why is cobalt used as a binder in tungsten carbide?

● Citations:

Tungsten carbide, often simply called carbide, is a remarkable chemical compound composed of equal parts tungsten and carbon atoms. It is renowned for its exceptional hardness, durability, and resistance to heat and wear, making it a critical material in many industrial, medical, and consumer applications. This article explores the nature, properties, manufacturing, applications, and advantages of tungsten carbide, providing a comprehensive understanding of why it is so widely used and valued.

Understanding Tungsten Carbide: Composition and Structure

Tungsten carbide (chemical formula WC) is a dense, grayish compound formed by fusing tungsten (W) and carbon (C) atoms in a precise 1:1 ratio. The atoms arrange themselves in a hexagonal crystal structure, which contributes to the material's extraordinary hardness and stability.

Chemical Composition

- Tungsten (W): A heavy metal with a very high melting point and density.

- Carbon (C): A non-metal that bonds with tungsten to form a ceramic-like compound.

In industrial applications, tungsten carbide powder is often mixed with a metallic binder such as cobalt or nickel to create a composite material known as cemented carbide or cermet. This binder enhances toughness and ductility while maintaining the hardness of the ceramic tungsten carbide.

Physical and Chemical Properties

- Hardness: Tungsten carbide ranks about 9 to 9.5 on the Mohs scale, second only to diamond.

- Density: Approximately 15.6 g/cm³, about twice that of steel.

- Melting Point: Around 2,870 °C (5,200 °F), decomposes rather than melts.

- Young's Modulus: Approximately 530–700 GPa, indicating extreme stiffness.

- Thermal Conductivity: High, allowing efficient heat dissipation in high-temperature environments.

- Corrosion Resistance: Resistant to acids and oxidation at normal temperatures, though it reacts with certain chemicals at elevated temperatures.

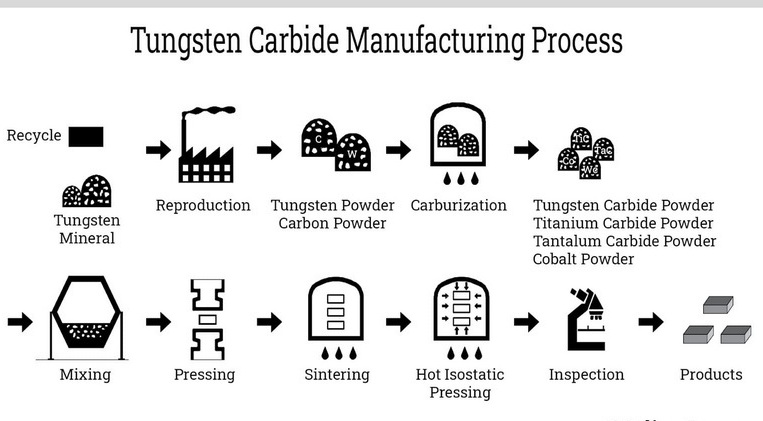

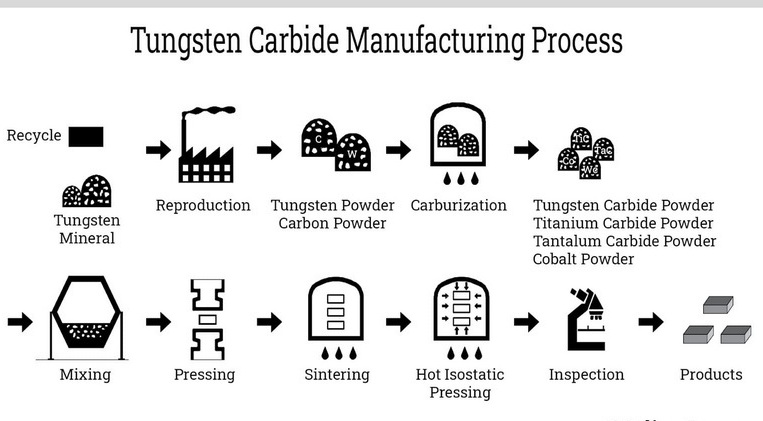

Manufacturing Process of Tungsten Carbide

Tungsten carbide is produced primarily through powder metallurgy techniques developed in the early 20th century. The process involves several key steps:

1. Powder Preparation: Tungsten metal powder is reacted with carbon black at high temperatures (1,400–2,000 °C) to form tungsten carbide powder.

2. Mixing with Binder: The WC powder is mixed with a binder metal powder, usually cobalt, to improve toughness.

3. Compacting: The mixture is pressed into the desired shape.

4. Sintering: The compacted shape is heated to 1,400–1,600 °C, causing the binder to melt and bond the tungsten carbide grains together, forming a dense, hard composite.

This process allows tungsten carbide to be formed into various shapes such as cutting tools, drill bits, wear parts, and jewelry.

Key Properties of Tungsten Carbide

Hardness and Wear Resistance

Tungsten carbide's hardness is its most celebrated property. It is extremely resistant to scratching and wear, making it ideal for cutting tools and industrial machinery parts that must endure abrasive conditions.

High Temperature Stability

With a melting point near 2,870 °C and excellent thermal conductivity, tungsten carbide maintains its strength and shape even under intense heat, which is essential for high-speed machining and aerospace applications.

Toughness and Strength

While ceramic materials are often brittle, the addition of metallic binders like cobalt gives tungsten carbide a balance of hardness and toughness, allowing it to resist fracture and impact better than pure ceramics.

Chemical Stability

Tungsten carbide is chemically stable in many environments, resisting oxidation and corrosion at room temperature. It only reacts with aggressive chemicals like hydrofluoric acid or chlorine at elevated temperatures.

Applications of Tungsten Carbide

Tungsten carbide's unique combination of hardness, toughness, and thermal stability makes it indispensable across many industries.

Industrial and Manufacturing

- Cutting Tools: End mills, drill bits, saw blades, and lathe tools are often tipped or made entirely from tungsten carbide to maintain sharpness and durability during machining.

- Mining and Drilling: Drill bits, cutting picks, and wear-resistant liners in mining and oil drilling equipment use tungsten carbide to withstand abrasive rock and harsh conditions.

- Wear Parts: Components subject to high wear, such as pump impellers, valve seats, and nozzles, benefit from tungsten carbide coatings or parts.

Medical Field

Tungsten carbide is used in surgical instruments due to its corrosion resistance and ability to maintain a sharp edge, improving performance and longevity.

Jewelry

Tungsten carbide is popular in jewelry, especially wedding bands, because it is scratch-resistant, durable, and maintains a polished finish without tarnishing.

Aerospace and Automotive

Its high strength and thermal stability make tungsten carbide suitable for aerospace components and automotive parts that require precision and durability under stress.

Everyday Tools and Consumer Products

High-quality drill bits, woodworking router bits, fishing gear, and sporting equipment often incorporate tungsten carbide for enhanced performance and longevity.

Advanced Applications of Tungsten Carbide

Beyond traditional uses, tungsten carbide is increasingly employed in advanced technological fields:

- Microelectronics: Tungsten carbide coatings are used in microelectromechanical systems (MEMS) for their wear resistance and electrical conductivity.

- Additive Manufacturing: Research into 3D printing tungsten carbide composites is expanding, enabling complex shapes and customized tooling.

- Nuclear Industry: Due to its high density and radiation shielding properties, tungsten carbide is used in nuclear reactors and radiation shielding materials.

- Energy Sector: Tungsten carbide components are critical in turbines and fuel injection systems where high wear resistance and thermal stability are essential.

Recent Innovations in Tungsten Carbide Manufacturing

Manufacturing techniques continue to evolve, improving the performance and sustainability of tungsten carbide products:

- Nanostructured Tungsten Carbide: Advances in nanotechnology allow the production of tungsten carbide with grain sizes in the nanometer range, enhancing hardness and toughness.

- Binderless Tungsten Carbide: Research into eliminating cobalt binders aims to produce purer tungsten carbide with improved corrosion resistance and biocompatibility.

- Advanced Sintering Techniques: Methods like spark plasma sintering reduce sintering time and temperature, improving microstructure and mechanical properties.

- Coating Technologies: Development of advanced chemical vapor deposition (CVD) and physical vapor deposition (PVD) coatings enhances surface hardness and wear resistance.

Environmental Impact and Sustainability of Tungsten Carbide

Tungsten carbide production and use have environmental considerations:

- Resource Intensity: Tungsten mining and processing require significant energy and generate waste, necessitating responsible sourcing.

- Recycling: Tungsten carbide is highly recyclable; scrap materials are collected and reprocessed, reducing the need for virgin tungsten and minimizing environmental footprint.

- Toxicity: Cobalt binders can pose health risks during manufacturing; safer handling and alternative binders are under development.

- Sustainable Manufacturing: Innovations focus on reducing energy consumption and emissions during production, including greener sintering methods and waste recycling.

Comparative Analysis with Other Hard Materials

| Material | Hardness (Mohs) | Toughness | Thermal Stability | Typical Applications |

| Tungsten Carbide | 9 - 9.5 | High (with binder) | Very High | Cutting tools, mining, aerospace |

| Diamond | 10 | Low (brittle) | Moderate | Cutting, polishing, electronics |

| Silicon Carbide | 9 - 9.5 | Moderate | High | Abrasives, semiconductors |

| Cubic Boron Nitride | 9.5 | Moderate | High | Cutting ferrous metals |

| High-Speed Steel | 6.5 - 7 | High | Moderate | Cutting tools |

Tungsten carbide offers a unique balance of hardness and toughness, outperforming many materials in demanding industrial environments.

Future Trends in Tungsten Carbide Usage

- Customization through Additive Manufacturing: 3D printing will enable tailored tungsten carbide tools with complex geometries and optimized performance.

- Eco-friendly Alternatives: Development of binderless or cobalt-free tungsten carbide composites to reduce environmental and health impacts.

- Smart Materials: Integration of sensors and coatings to create self-monitoring tungsten carbide tools for predictive maintenance.

- Expanded Medical Applications: Biocompatible tungsten carbide materials for implants and surgical tools.

- Hybrid Materials: Combining tungsten carbide with other advanced ceramics and metals to enhance multifunctional properties.

Conclusion

Tungsten carbide stands as a cornerstone material in modern technology due to its unparalleled hardness, toughness, and thermal stability. Its versatility spans from traditional cutting tools and mining equipment to cutting-edge applications in microelectronics, aerospace, and medical fields. Continuous innovations in manufacturing and sustainability practices are expanding its potential while addressing environmental concerns. As industries evolve, tungsten carbide's role is set to grow, driven by advances in nanotechnology, additive manufacturing, and eco-friendly materials development. Understanding tungsten carbide's properties, applications, and future trends highlights its indispensable value in both current and emerging technologies.

FAQ About Tungsten Carbide

1. What is tungsten carbide made of?

Tungsten carbide is composed of equal parts tungsten and carbon atoms, often combined with a metallic binder like cobalt to improve toughness.

2. How hard is tungsten carbide compared to steel?

Tungsten carbide is significantly harder than steel, ranking about 9 to 9.5 on the Mohs scale, while steel typically ranges from 4 to 8 depending on the alloy.

3. What industries use tungsten carbide tools?

Industries such as mining, oil and gas, aerospace, automotive, metalworking, medical, and jewelry manufacturing commonly use tungsten carbide tools and components.

4. Can tungsten carbide be recycled?

Yes, tungsten carbide is highly recyclable. Recycling reduces the need for new raw materials, lowers energy consumption, and decreases environmental impact.

5. Why is cobalt used as a binder in tungsten carbide?

Cobalt acts as a binder to hold tungsten carbide grains together, providing toughness and resistance to fracture while maintaining hardness.

Citations:

[1] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[2] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[3] https://www.thermalspray.com/understanding-the-unique-characteristics-of-tungsten-carbide/

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] https://create.vista.com/photos/tungsten-carbide/

[6] http://www.carbidetechnologies.com/faqs/

[7] https://rrcarbide.com/understanding-tungsten-carbide-composition-uses-and-expertise/

[8] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[9] https://www.britannica.com/science/tungsten-carbide

[10] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/

[11] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[12] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[13] https://tuncomfg.com/about/faq/

[14] https://www.imetra.com/tungsten-carbide-material-properties/

[15] https://www.azom.com/properties.aspx?ArticleID=1203

[16] https://www.dymetalloys.co.uk/what-is-tungsten-carbide

[17] https://www.youtube.com/watch?v=g_YpNM1FBhs

[18] https://www.linkedin.com/pulse/significance-tungsten-carbide-buttons-mining-shijin-lei

[19] https://www.sciencedirect.com/topics/physics-and-astronomy/tungsten-carbide

[20] https://va-tungsten.co.za/pure-tungsten-vs-tungsten-carbide-whats-the-difference/

[21] https://www.itia.info/applications-markets/

[22] https://www.azom.com/article.aspx?ArticleID=1203

[23] https://www.larsonjewelers.com/pages/the-pros-cons-of-tungsten-carbide-rings

[24] https://upload.wikimedia.org/wikipedia/commons/7/72/Tungsten_carbide_inserts.jpg?sa=X&ved=2ahUKEwjWwoe7t9qMAxVRlokEHS1IJLoQ_B16BAgCEAI

[25] https://www.azom.com/article.aspx?ArticleID=4827

[26] https://stock.adobe.com/search?k=tungsten+carbide

[27] https://www.istockphoto.com/photos/tungsten-carbide

[28] https://periodictable.com/Elements/074/pictures.html

[29] https://stock.adobe.com/search?k=carbide

[30] https://www.shutterstock.com/search/tungsten

[31] https://www.shutterstock.com/search/tungsten-carbide

[32] https://www.istockphoto.com/photos/tungsten-carbide-drill-bits

[33] https://www.freepik.com/free-photos-vectors/tungsten

[34] https://cen.acs.org/materials/Chemistry-Pictures-Tungsten-carbide-slice/103/web/2025/02

[35] https://www.aemmetal.com/news/tungsten-vs-tungsten-carbide-guide.html

[36] https://rrcarbide.com/understanding-tungsten-carbide-composition-uses-and-expertise/

[37] https://consolidatedresources.com/blog/10-facts-about-tungsten-carbide/

[38] https://theartisanrings.com/pages/tungsten-rings-faqs

[39] https://www.reddit.com/r/metallurgy/comments/ub4dg9/question_about_tungsten_carbide_toxicity/

[40] https://www.hpnonline.com/sterile-processing/article/55233008/tungsten-carbide-versus-villains-is-it-rust-or-corrosion

[41] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/

[42] https://www.bladeforums.com/threads/tungsten-carbide-question.524307/

[43] https://www.carbidetek.com/faqs/

[44] https://www.tungstenrepublic.com/Tungsten-Carbide-Rings-FAQ.html

[45] https://eternaltungsten.com/Frequently-Asked-Questions-FAQs

[46] https://www.usgs.gov/centers/national-minerals-information-center/tungsten-statistics-and-information

[47] https://metallicbonds.com/economic-importance-tungsten-carbide-industries/

[48] http://www.tungsten-carbide.com.cn

[49] https://www.alamy.com/stock-photo/tungsten-carbide.html

[50] https://www.istockphoto.com/photos/tungsten-carbide?page=2

[51] https://www.bangerter.com/en/tungsten-carbide

[52] https://en.wikipedia.org/wiki/Tungsten_carbide