Content Menu

● Introduction

>> Overview of Tungsten Carbide

>> Overview of Silicon Carbide

● Composition and Material Properties

>> Composition of Tungsten Carbide

>> Composition of Silicon Carbide

>> Hardness Comparison

>> Other Mechanical Properties

>> Physical Properties

● Thermal and Chemical Resistance

>> Thermal Resistance

>> Chemical Resistance

● Applications of Tungsten Carbide

>> Cutting Tools

>> Mining and Construction

>> Wear-Resistant Coatings

>> Other Industrial Applications

● Applications of Silicon Carbide

>> Abrasives

>> High-Temperature Semiconductors

>> Wear-Resistant Parts

>> Refractory Materials

>> Other Applications

● Advantages and Disadvantages

>> Tungsten Carbide

>> Silicon Carbide

● Cost Considerations

● Conclusion

● FAQ

>> 1. What is the major difference between silicon carbide and tungsten carbide?

>> 2. Is tungsten carbide harder than silicon carbide?

>> 3. When would I choose silicon carbide over tungsten carbide for a mechanical seal?

>> 4. Are tungsten carbide seals suitable for corrosive environments?

>> 5. What is the cost comparison between silicon carbide and tungsten carbide?

● Citations:

Tungsten carbide (WC) and silicon carbide (SiC) are both recognized for their exceptional hardness and wear resistance, making them suitable for a wide array of industrial applications[7]. Determining which is harder requires a detailed comparison of their material properties, manufacturing processes, and application-specific performance. This article explores the in-depth comparison of tungsten carbide and silicon carbide, covering their hardness, composition, thermal and chemical resistance, applications, and frequently asked questions to provide a comprehensive understanding.

Introduction

The quest for materials that can withstand extreme conditions has driven significant advancements in material science. Among these materials, tungsten carbide and silicon carbide stand out due to their superior hardness and durability[5]. Tungsten carbide, an alloy of tungsten and carbon, is renowned for its toughness and resistance to deformation[1]. Silicon carbide, a compound of silicon and carbon, is celebrated for its exceptional hardness, high thermal conductivity, and chemical inertness[1].

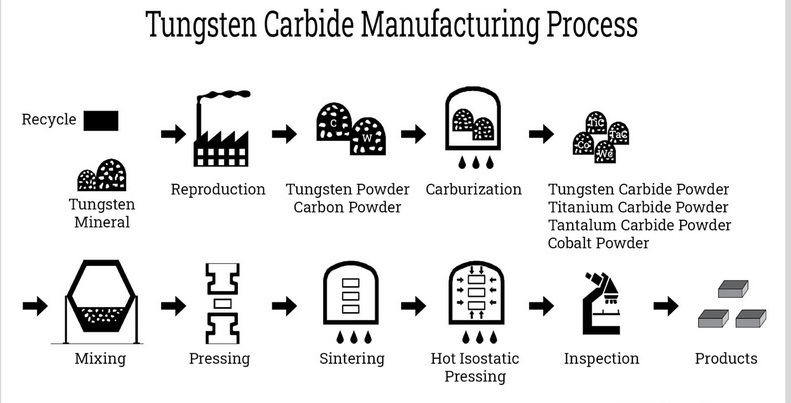

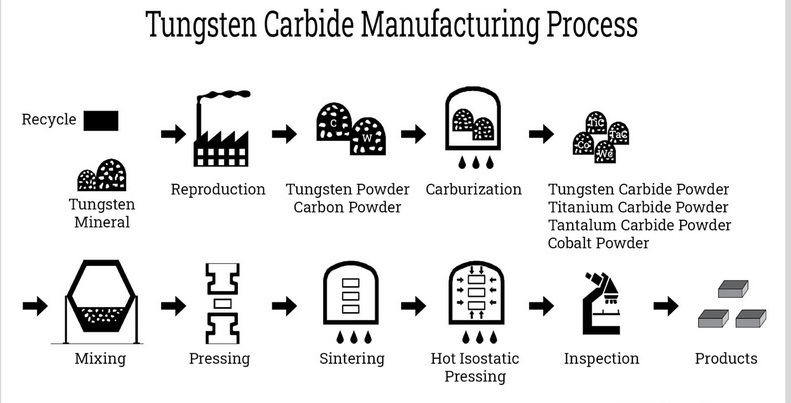

Overview of Tungsten Carbide

Tungsten carbide is a composite material consisting of tungsten and carbon atoms[1]. It is often combined with other metals like cobalt or nickel to enhance its toughness[5]. This material is widely used in applications requiring high wear resistance and mechanical strength, such as cutting tools, mining equipment, and wear-resistant coatings[1].

Overview of Silicon Carbide

Silicon carbide (SiC), also known as carborundum, is a semiconductor material composed of silicon and carbon[4]. It is produced through the Acheson process, which involves heating silica sand and carbon to high temperatures[1]. Silicon carbide is prized for its extreme hardness, thermal conductivity, and chemical inertness, making it suitable for abrasives, high-temperature semiconductors, and wear-resistant parts[1].

Composition and Material Properties

Understanding the composition and properties of tungsten carbide and silicon carbide is crucial for determining their suitability for different applications.

Composition of Tungsten Carbide

Tungsten carbide is primarily composed of tungsten and carbon, typically in a 1:1 ratio (WC)[1]. The addition of other metals, such as cobalt (Co) or nickel (Ni), serves as a binder to improve its toughness and reduce brittleness[5]. The resulting composite combines the hardness of tungsten carbide with the enhanced mechanical properties of the binder metal.

Composition of Silicon Carbide

Silicon carbide consists of silicon and carbon atoms bonded in a crystal lattice structure[1]. It exists in several polytypes, each with slightly different crystal structures and properties[4]. The most common polytype is alpha-silicon carbide (α-SiC), which has a hexagonal crystal structure and is widely used in industrial applications.

Hardness Comparison

Both tungsten carbide and silicon carbide are exceptionally hard materials, but silicon carbide is generally considered harder[7].

- Tungsten Carbide Hardness: Tungsten carbide typically has a Mohs hardness of around 9, and its hardness can range from 89 to 95 HRA (Rockwell A scale), which corresponds to approximately 69 to 81 HRC (Rockwell C scale)[2][1]. Its Vickers hardness is approximately 2400 Hv[2].

- Silicon Carbide Hardness: Silicon carbide has a Mohs hardness of 9 to 9.5[1]. Its Knoop hardness can range from 2800 to 3300 kg/mm², which is higher than that of tungsten carbide.

While both materials exhibit excellent hardness, silicon carbide's slightly higher values make it more suitable for applications requiring extreme abrasion resistance[7].

Other Mechanical Properties

Besides hardness, other mechanical properties such as toughness, wear resistance, and compressive strength are important considerations.

- Tungsten Carbide: Tungsten carbide is known for its high compressive and tensile strength[1]. It is a very tough ceramic material highly resistant to deformation and breakage[1].

- Silicon Carbide: Silicon carbide is a moderately tough material but is more brittle than tungsten carbide[1]. It has excellent wear resistance and high thermal conductivity, making it suitable for high-temperature applications.

Physical Properties

- Density: Tungsten carbide is much denser than silicon carbide. The density of WC typically ranges from 15.6 to 15.8 g/cm³[1], while SiC has a density of 3.1 to 3.2 g/cm³[1].

- Thermal Conductivity: Silicon carbide has a higher thermal conductivity (120-160 W/m-K) compared to tungsten carbide (110 W/m-K)[1].

- Melting Point: The melting point of tungsten carbide is approximately 2870°C, while silicon carbide melts at around 2730°C[1].

Thermal and Chemical Resistance

Thermal Resistance

- Tungsten Carbide: Tungsten carbide has good thermal shock resistance, meaning it can withstand sudden temperature changes without cracking[5]. It is suitable for applications involving high-speed rotations and heavy loads.

- Silicon Carbide: Silicon carbide excels in high-temperature environments due to its structural stability and resistance to thermal degradation[5]. It is often used in applications where high thermal conductivity is essential for heat dissipation.

Chemical Resistance

- Tungsten Carbide: Tungsten carbide is moderately resistant to corrosion but can be susceptible to oxidation in harsh chemical environments[5]. It may require coatings for protection in aggressive chemical applications.

- Silicon Carbide: Silicon carbide offers excellent resistance to chemical corrosion, making it suitable for applications involving corrosive chemicals and fluids[5]. Its inert nature ensures it remains stable in harsh environments.

Applications of Tungsten Carbide

Tungsten carbide's unique properties make it ideal for various demanding applications across multiple industries[5].

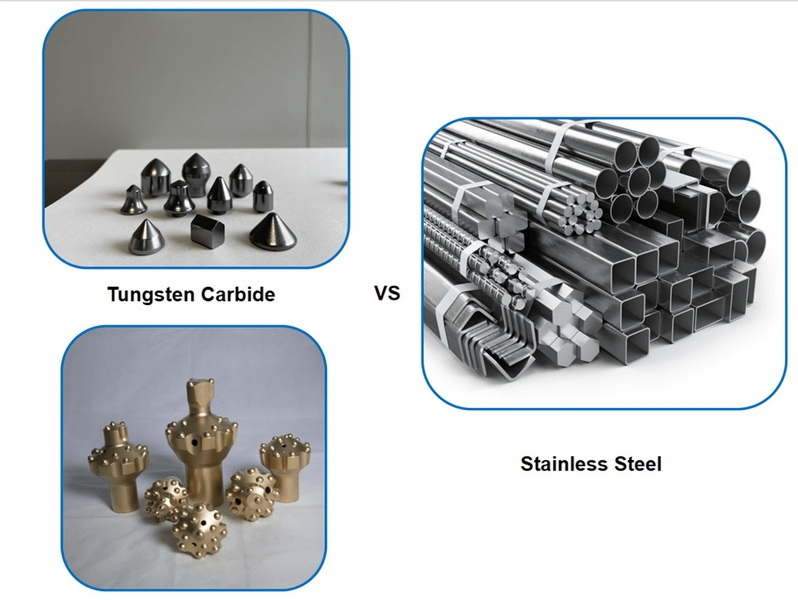

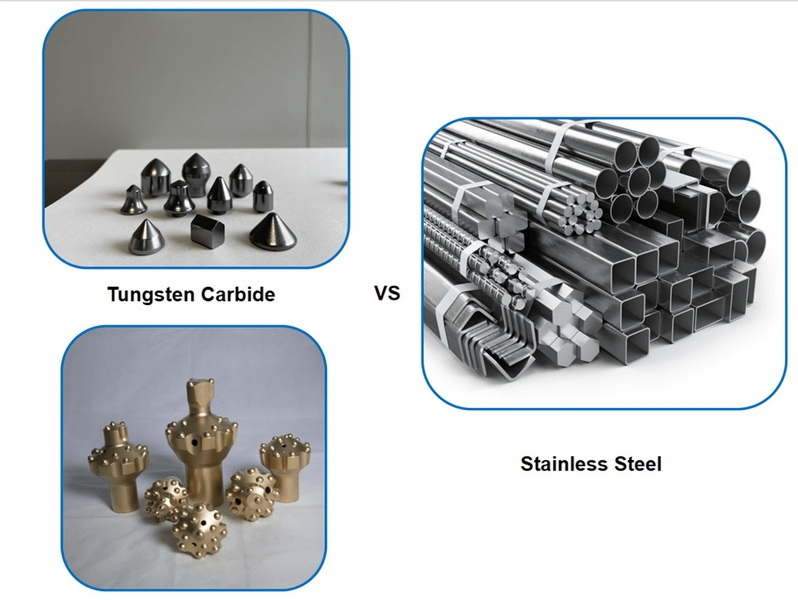

Cutting Tools

Tungsten carbide is extensively used in the manufacture of cutting tools for machining metals, wood, and plastics[1]. Its hardness and wear resistance ensure long tool life and precise cutting performance.

Mining and Construction

In the mining and construction industries, tungsten carbide is used in drill bits, wear plates, and other components that require exceptional durability and abrasion resistance[5]. These parts withstand the harsh conditions and extend the lifespan of equipment.

Wear-Resistant Coatings

Tungsten carbide coatings are applied to surfaces to improve their wear resistance and extend their service life[1]. These coatings are used in automotive parts, industrial machinery, and other components subjected to high wear.

Other Industrial Applications

Other applications of tungsten carbide include:

- Dies and molds for metal forming.

- Nozzles for abrasive blasting.

- Balls and seats for valves.

- Tires for improved traction on icy roads.

Applications of Silicon Carbide

Silicon carbide's properties make it suitable for a wide range of high-performance applications[5].

Abrasives

Silicon carbide is widely used as an abrasive material in grinding wheels, sandpaper, and cutting tools[7]. Its hardness and sharp cutting edges make it effective for grinding, cutting, and polishing various materials.

High-Temperature Semiconductors

Silicon carbide is used in high-temperature semiconductor devices, such as diodes, transistors, and power modules[1]. Its high thermal conductivity and wide bandgap make it suitable for applications requiring high power and high-temperature operation.

Wear-Resistant Parts

Silicon carbide is used to manufacture wear-resistant parts such as bearings, seals, and pump components[5]. Its hardness and chemical inertness ensure reliable performance in demanding environments.

Refractory Materials

Silicon carbide is used as a refractory material in high-temperature furnaces and kilns[1]. Its high melting point and thermal stability make it suitable for lining furnace walls and other high-temperature components.

Other Applications

- LED lighting: As a heat sink material.

- Brake pads: In automotive brake systems.

- Body armor: Due to its high hardness and impact resistance.

Advantages and Disadvantages

Tungsten Carbide

Advantages:

- High Hardness and Wear Resistance: Suitable for demanding applications[5].

- Excellent Toughness: Resistant to deformation and breakage[1].

- Good Compressive Strength: Capable of withstanding high loads[1].

- Thermal Shock Resistance: Can withstand sudden temperature changes[5].

Disadvantages:

- Lower Thermal Conductivity: Less effective at dissipating heat compared to silicon carbide[1].

- Susceptible to Chemical Corrosion: Can be attacked by harsh chemicals[5].

- High Density: Can be a disadvantage in weight-sensitive applications[1].

- Cost: Generally more expensive than silicon carbide[1].

Silicon Carbide

Advantages:

- Extreme Hardness: Excellent abrasion resistance[7].

- High Thermal Conductivity: Effective at dissipating heat[1].

- Excellent Chemical Resistance: Inert to most chemicals[5].

- Lightweight: Lower density compared to tungsten carbide[1].

Disadvantages:

- Brittle: More prone to cracking under impact[1].

- Lower Toughness: Less resistant to deformation compared to tungsten carbide[1].

- Difficult to Machine: Requires specialized techniques for shaping and finishing.

- Cost: Can be expensive for certain high-purity grades.

Cost Considerations

The cost of tungsten carbide and silicon carbide varies depending on factors such as purity, grain size, and manufacturing process. Generally, tungsten carbide is more expensive than standard grades of silicon carbide[1]. However, high-purity or specialized silicon carbide grades can be equally or more costly.

Conclusion

Both tungsten carbide and silicon carbide are exceptional materials with unique properties that make them suitable for a wide range of applications. While silicon carbide is generally harder and offers better thermal and chemical resistance, tungsten carbide provides superior toughness and compressive strength. The choice between the two depends on the specific requirements of the application, considering factors such as hardness, wear resistance, thermal properties, chemical inertness, and cost.

Industries must carefully evaluate their needs and select the material that best meets their performance criteria to ensure optimal results. Understanding the differences between these materials is essential for making informed decisions and achieving success in demanding applications.

FAQ

1. What is the major difference between silicon carbide and tungsten carbide?

The primary difference lies in their composition and properties[5]. Silicon carbide is a compound of silicon and carbon, known for its extreme hardness, high thermal conductivity, and chemical resistance[1]. Tungsten carbide is an alloy of tungsten and carbon, valued for its toughness, wear resistance, and compressive strength[1].

2. Is tungsten carbide harder than silicon carbide?

While both materials are very hard, silicon carbide is generally considered harder than tungsten carbide[7]. Silicon carbide has a Mohs hardness of 9-9.5, while tungsten carbide has a Mohs hardness of around 9[1].

3. When would I choose silicon carbide over tungsten carbide for a mechanical seal?

Silicon carbide is preferred in applications where high thermal conductivity and chemical resistance are critical[5]. It is commonly used in mechanical seals for chemical processing, water treatment, and high-temperature systems.

4. Are tungsten carbide seals suitable for corrosive environments?

Tungsten carbide seals offer good wear resistance but may be susceptible to chemical corrosion in harsh environments[5]. In such cases, silicon carbide seals or specially coated tungsten carbide seals are recommended.

5. What is the cost comparison between silicon carbide and tungsten carbide?

Generally, tungsten carbide is more expensive than silicon carbide[1]. However, the cost can vary depending on the purity, grain size, and specific application requirements.

Citations:

[1] https://ggsceramic.com/news-item/tungsten-carbide-vs-silicon-carbide-differences-explained

[2] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[3] https://create.vista.com/photos/tungsten-carbide/

[4] https://www.alamy.com/stock-photo/silicon-carbide.html

[5] https://www.qmseals.com/differences-between-silicon-carbide-and-tungsten-carbide-mechanical-seals

[6] https://leakpack.com/silicon-carbide-vs-tungsten-carbide-mechanical-seal/

[7] https://kindle-tech.com/faqs/which-is-harder-silicon-carbide-or-tungsten-carbide

[8] https://scholars.cityu.edu.hk/en/publications/publication(46e2533d-91d3-410e-bd8e-2c76fbc4fdf9).html

[9] https://www.eng-tips.com/threads/tungsten-carbide-or-silicon-carbide-which-is-the-better-option.387/

[10] http://www.wococarbide.com/Uploads/2017-09-28/59cc5a321343b.pdf

[11] https://www.shutterstock.com/search/silicon-carbide

[12] https://stock.adobe.com/search?k=siliciumcarbid

[13] https://www.meccanotecnica.us.com/blog/582/silicon-carbide-and-tungsten-carbide-mechanical-seals-a-guide

[14] https://www.preciseceramic.com/blog/silicon-carbide-properties-a-summary.html

[15] https://www.syalons.com/2024/07/08/silicon-carbide-vs-tungsten-carbide-wear-applications/

[16] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[17] https://www.thermalspray.com/questions-tungsten-carbide/

[18] https://carbosystem.com/en/tungsten-carbide/

[19] https://www.gwstoolgroup.com/understanding-the-different-types-of-carbide-in-cutting-tools/

[20] https://www.mechanicalsealindia.com/silicon-carbide-and-tungsten-carbide-mechanical-seal.html

[21] https://www.makeitfrom.com/compare/Silicon-Carbide-SiC/Tungsten-Carbide-WC

[22] https://www.victor-seals.com/news/what-is-the-difference-between-silicon-carbide-and-tungsten-carbide-mechanical-seals/

[23] https://cowseal.com/silicon-carbide-vs-tungsten-carbide-mechanical-seal/

[24] https://www.istockphoto.com/photos/tungsten-carbide-drill-bits

[25] https://www.istockphoto.com/photos/tungsten-carbide

[26] https://periodictable.com/Elements/074/pictures.html

[27] https://ggsceramic.com/news-item/silicon-carbide-vs-tungsten-carbide-in-wear-applications

[28] https://scholars.cityu.edu.hk/files/104840707/materials_15_02061_v3.pdf