Content Menu

● The Manufacturing Process: A Step-by-Step Guide

>> 1. Powder Preparation

>> 2. Mixing and Milling

>> 3. Pressing and Shaping

>> 4. Pre-Sintering (Optional)

>> 5. Sintering

>> 6. Hot Isostatic Pressing (HIP) (Optional)

>> 7. Finishing

● Applications of Tungsten Carbide Inserts

● Advantages of Tungsten Carbide Inserts

● Conclusion

● FAQ

>> 1. What are the primary raw materials used in making carbide inserts?

>> 2. Why is sintering such a crucial step in the manufacturing process?

>> 3. What is the purpose of Hot Isostatic Pressing (HIP)?

>> 4. How does milling affect quality?

>> 5. What types of quality control measures are taken during manufacturing?

● Citations:

Tungsten carbide inserts are essential components in modern machining, offering exceptional hardness and wear resistance for various cutting applications. Understanding how these inserts are manufactured reveals the intricate processes involved in producing these high-performance tools. This article delves into the step-by-step manufacturing of carbide inserts, from raw material selection to the finished product.

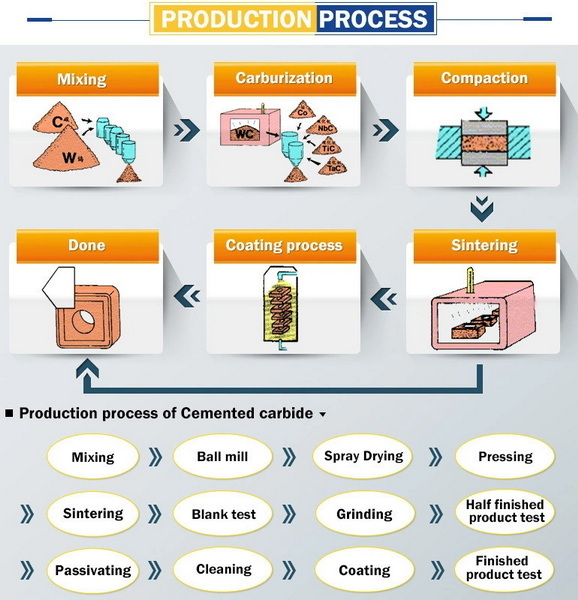

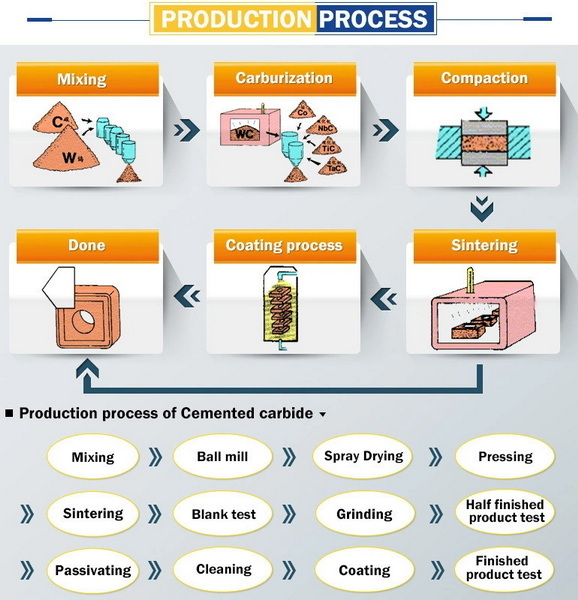

The Manufacturing Process: A Step-by-Step Guide

The creation of tungsten carbide inserts involves several key stages, each demanding precision and expertise. These steps include powder preparation, mixing and milling, pressing and shaping, pre-sintering (optional), sintering, hot isostatic pressing (HIP) (optional), and finishing.

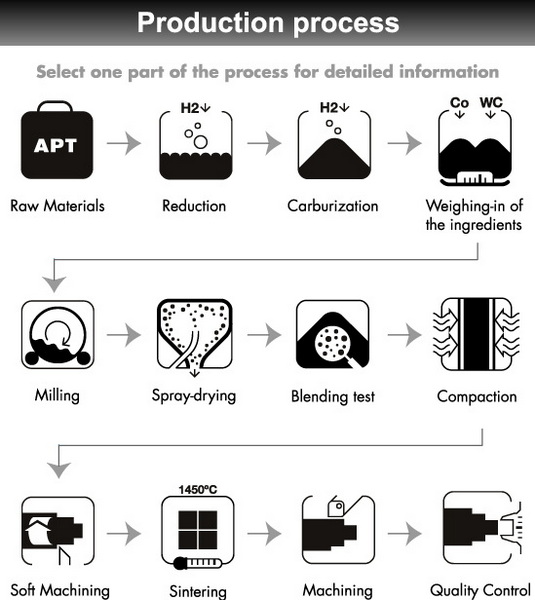

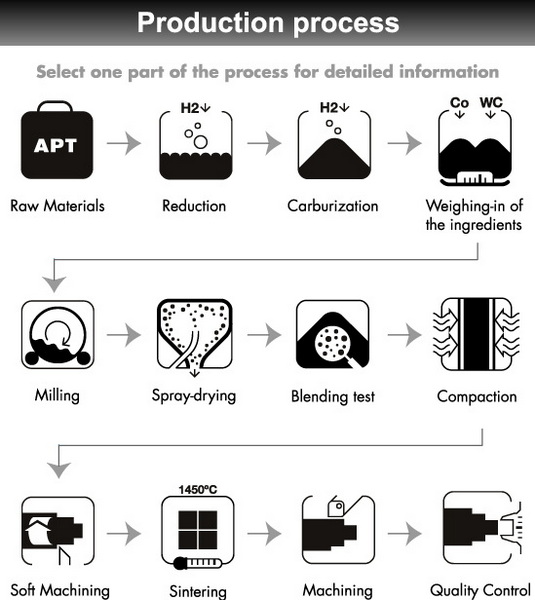

1. Powder Preparation

The journey of a carbide insert begins with the careful selection and preparation of raw materials.

- Raw Material Selection: High-purity tungsten carbide and cobalt powders are sourced. The quality of these raw materials directly influences the final insert's performance.

- Powder Analysis: The powders undergo analysis to determine particle size distribution, purity, and chemical composition. Advanced techniques such as laser diffraction or scanning electron microscopy (SEM) may be employed for accurate measurements.

- Weighing and Proportioning: Precise amounts of tungsten carbide and cobalt powders are weighed according to the desired grade specifications. The cobalt content typically ranges from 6% to 30%, depending on the intended application of the insert.

- Additive Incorporation: Additional carbides like titanium carbide or tantalum carbide are added to enhance specific properties such as toughness or thermal stability.

2. Mixing and Milling

This stage ensures the homogeneity of the materials.

- Initial Mixing: The measured powders are mixed in a V-blender or turbula mixer to ensure a uniform distribution of all components.

- Ball Milling: The mixture is transferred to a ball mill, which uses hard, wear-resistant balls (often made of tungsten carbide) to further mix and grind the powder.

- Wet Milling: A liquid medium, typically alcohol and water, is added to facilitate the milling process and prevent oxidation.

- Milling Duration: The milling process can last from 24 to 72 hours, depending on the desired particle size and grade characteristics.

- Particle Size Reduction: Milling reduces the powder particles to submicron sizes, typically ranging from 0.5 to 5 micrometers.

- Drying: After milling, the slurry is dried using spray drying or vacuum drying techniques to remove the liquid medium.

3. Pressing and Shaping

The powder is formed into the desired shape during this phase.

- Powder Lubrication: A small amount of organic binder (often paraffin wax) is added to the powder to improve its flowability and compressibility.

- Die Preparation: A die with the shape of the desired insert is prepared. The die cavity is often slightly larger to account for shrinkage during sintering.

- Powder Filling: The prepared powder mixture is poured into the die cavity. The powder is transported in 100 kg barrels in the pressing machines to make the inserts. The operator inputs the order number, pressing tool, and mold.

- Compaction: The powder is compressed under high pressure, typically between 10 and 30 tons per square inch, using hydraulic or mechanical presses.

- Green Compact Formation: The result is a "green compact," which has the basic shape of the final insert but is still relatively soft and fragile.

- Ejection: The green compact is carefully ejected from the die.

4. Pre-Sintering (Optional)

This step is included by some manufacturers.

- Low-Temperature Heating: The green compacts are heated to a temperature between 500°C and 900°C.

- Binder Removal: This process removes the organic binder used in the pressing stage.

- Strength Increase: Pre-sintering slightly increases the strength of the compact, making it easier to handle in subsequent steps.

5. Sintering

Sintering transforms the fragile green compact into a dense, hard carbide insert.

- Furnace Loading: The green compacts (or pre-sintered parts) are loaded into a sintering furnace. There are at least a hundred thousand inserts that can be placed together at the same time.

- Atmosphere Control: The furnace atmosphere is carefully controlled, often using vacuum or an inert gas like argon to prevent oxidation.

- Temperature Ramp-Up: The temperature is gradually increased to around 1400°C (near the melting point of cobalt). The powder of cemented carbide is heated to about 1,500 degrees Celsius for 13 hours before it is fused into a material known as cemented carbide, which has extreme hardness.

- Holding Period: The temperature is maintained for a specific period, typically 1-3 hours, allowing cobalt to melt and flow between tungsten carbide particles.

- Liquid Phase Sintering: The molten cobalt acts as a binder, filling spaces between carbide particles.

- Cooling: The furnace is slowly cooled, allowing cobalt to solidify and bind tungsten carbide particles together.

- Shrinkage: During sintering, the insert shrinks by about 17-25% due to pore elimination and structure consolidation.

6. Hot Isostatic Pressing (HIP) (Optional)

Some high-performance inserts undergo this additional step.

- High-Pressure Environment: The sintered inserts are placed in a special chamber filled with inert gas at very high pressure (up to 30,000 psi).

- Elevated Temperature: The chamber is heated to temperatures close to sintering temperatures.

- Pore Elimination: This combination eliminates remaining porosity, resulting in a fully dense structure.

7. Finishing

The finishing stage ensures that inserts meet required specifications.

- Grinding: Cemented carbide is ground with industrial diamond—the hardest material in the world—to achieve perfect geometry and size for each insert.

- Quality Check: Inserts undergo laboratory quality checks during grinding processes to ensure they meet stringent standards for hardness, toughness, wear resistance, and dimensional accuracy.

- Coating (Optional): Some inserts may receive surface coatings such as titanium nitride (TiN) or aluminum oxide (Al2O3) for enhanced performance in specific applications. These coatings can improve hardness further while reducing friction during cutting operations.

Applications of Tungsten Carbide Inserts

Tungsten carbide cutting tool inserts have diverse applications across various industries:

1. Machining Operations:

- Used extensively in turning tools for lathes where they cut metal into desired shapes with precision.

- Employed in milling machines for creating complex geometries on metal workpieces.

2. Mining Industry:

- Utilized in drill bits for extracting minerals due to their exceptional wear resistance against abrasive materials.

3. Construction Sector:

- Found in tools used for concrete drilling or cutting due to their durability against hard surfaces.

4. Automotive Industry:

- Applied in manufacturing parts such as brake rotors where high heat resistance is crucial.

5. Woodworking Tools:

- Used in router bits or saw blades designed for cutting hardwoods effectively without dulling quickly.

Advantages of Tungsten Carbide Inserts

Tungsten carbide inserts offer numerous advantages that make them highly sought after in various applications:

- Exceptional Hardness: Tungsten carbide ranks second only to diamond on the Mohs scale of hardness. This characteristic allows it to maintain sharp cutting edges for extended periods without significant wear.

- High Wear Resistance: Inserts made from tungsten carbide resist abrasion effectively when machining tough materials like stainless steel or cast iron.

- Thermal Stability: They can withstand high temperatures generated during machining processes without losing their structural integrity.

- Versatility: Tungsten carbide inserts can be manufactured in various shapes and sizes tailored for specific machining tasks—making them suitable across multiple industries.

- Cost Efficiency: Although initial costs may be higher than traditional tool materials like high-speed steel (HSS), their longevity leads to lower overall tool costs over time due to reduced replacement frequency.

Conclusion

The manufacturing of tungsten carbide inserts is a complex process that requires careful control over each stage—from powder preparation through finishing. Each step contributes significantly towards achieving high-performance tools capable of meeting demanding machining requirements across various industries. With their exceptional hardness and wear resistance properties combined with versatility across applications—tungsten carbide inserts remain indispensable components within modern manufacturing environments.

FAQ

1. What are the primary raw materials used in making carbide inserts?

The primary raw materials are high-purity tungsten carbide and cobalt powders. Additional carbides like titanium carbide or tantalum carbide may be added to enhance specific properties.

2. Why is sintering such a crucial step in the manufacturing process?

Sintering transforms fragile "green compacts" into dense hard carbide inserts by heating them at high temperatures—allowing cobalt binder material flow between tungsten carbides resulting in strong bonds that enhance durability during use.

3. What is the purpose of Hot Isostatic Pressing (HIP)?

HIP eliminates any remaining porosity within sintered inserts by applying both high pressure & temperature—leading towards fully dense structures that exhibit superior performance characteristics under operational conditions compared with non-HIP processed counterparts.

4. How does milling affect quality?

Milling reduces powder particles down into submicron sizes ensuring uniform distribution throughout mixtures—which directly impacts final product homogeneity influencing performance metrics like toughness & wear resistance during actual usage scenarios later on after production completion phases have concluded successfully!

5. What types of quality control measures are taken during manufacturing?

Quality control measures include thorough analyses regarding particle size distributions/chemical compositions; laboratory tests conducted periodically throughout production cycles; grinding processes ensuring dimensional accuracy; optional coatings applied post-manufacturing enhancing overall performance metrics based upon specific end-user requirements identified beforehand!

Citations:

[1] https://onmytoolings.com/how-are-carbide-inserts-made/

[2] https://www.ee.cityu.edu.hk/~gchen/pdf/Writing.pdf

[3] https://www.zgcccarbide.com/news/The-Manufacturing-Process-of-Cemented-Carbide-Inserts:-A-Comprehensive-Guide-39.html

[4] https://www.163.com/dy/article/EDIGQUV605370K28.html

[5] https://www.hjcarbide.com/new/How-Tungsten-Carbide-Inserts-are-made.html

[6] https://blog.csdn.net/qq_34917728/article/details/125122327

[7] https://huanatools.com/what-are-carbide-inserts-and-how-are-carbide-inserts-made/

[8] https://jphe.amegroups.org/article/view/4265/10863