Content Menu

● Introduction to Tungsten Carbide

● Natural Raw Materials for Tungsten Carbide Production

>> 1. Tungsten Ores

>> 2. Ammonium Paratungstate (APT)

>> 3. Tungsten Oxide (WO3)

>> 4. Carbon Sources

● Manufacturing Process Overview

>> 1. Extraction and Refining of Tungsten

>> 2. Mixing Tungsten and Carbon

>> 3. Carburization

>> 4. Powder Processing

>> 5. Shaping and Sintering

● Characteristics of Tungsten Carbide

● Additional Properties of Tungsten Carbide

● Industrial and Commercial Applications

● Environmental and Sustainability Considerations

● Recent Advancements and Innovations

● Global Market and Economic Importance

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What natural ores are the main sources of tungsten for tungsten carbide production?

>> 2. How is ammonium paratungstate related to tungsten carbide production?

>> 3. What types of carbon are used to make tungsten carbide?

>> 4. Why is cobalt commonly used in tungsten carbide products?

>> 5. What determines the hardness and toughness of tungsten carbide?

Tungsten carbide is a highly durable and hard material widely used in industrial applications such as cutting tools, mining machinery, abrasives, and wear-resistant parts. Understanding the natural materials that go into making tungsten carbide helps appreciate its unique properties and the sophisticated processes involved in its production. This article explores the natural raw materials used, the manufacturing process, and the characteristics of tungsten carbide.

Introduction to Tungsten Carbide

Tungsten carbide (chemical formula WC) is a compound consisting of equal parts tungsten and carbon atoms. It is known for its exceptional hardness—comparable to diamond—and excellent wear resistance. Tungsten carbide is typically produced as a fine gray powder that can be pressed and sintered into various shapes for industrial use.

Natural Raw Materials for Tungsten Carbide Production

1. Tungsten Ores

The primary natural source of tungsten is tungsten ore, mainly found in two mineral forms:

- Wolframite (FeMnWO4): A dense, iron-manganese tungstate mineral.

- Scheelite (CaWO4): A calcium tungstate mineral, often found in hydrothermal veins.

Both ores contain tungsten in oxidized forms and are mined from natural deposits worldwide. Scheelite is notable for its use not only as a tungsten source but also as a gemstone and scintillator material.

2. Ammonium Paratungstate (APT)

Ammonium paratungstate is a purified intermediate compound derived from tungsten ore. It is a white crystalline salt with the chemical formula (NH4)10(W12O41)·5H2O. APT is produced by digesting tungsten ore in acid, precipitating tungstic acid, and then crystallizing ammonium tungstate compounds. It serves as a key starting material for producing tungsten metal powders and tungsten carbide.

3. Tungsten Oxide (WO3)

By calcining ammonium paratungstate at high temperatures (above 600°C), tungsten trioxide (WO3) is obtained. Tungsten oxide is a critical intermediate that can be reduced to metallic tungsten powder under a hydrogen atmosphere.

4. Carbon Sources

Carbon is the second essential natural material used to make tungsten carbide. The carbon sources include:

- Graphite: A natural form of crystalline carbon.

- Carbon black: A fine carbon powder derived from incomplete combustion of hydrocarbons.

- Soot: Another form of carbon used in carburization.

These carbon materials react with tungsten metal powder at high temperatures to form tungsten carbide.

Manufacturing Process Overview

The production of tungsten carbide involves several key steps, starting from natural raw materials:

1. Extraction and Refining of Tungsten

- Tungsten ore is mined and chemically processed to produce ammonium paratungstate.

- APT is calcined to tungsten oxide and then reduced in a hydrogen atmosphere to produce pure tungsten metal powder.

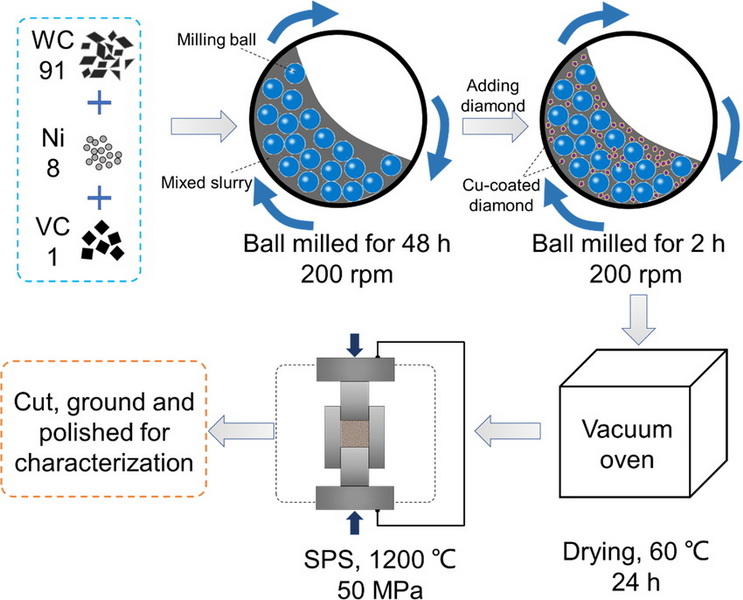

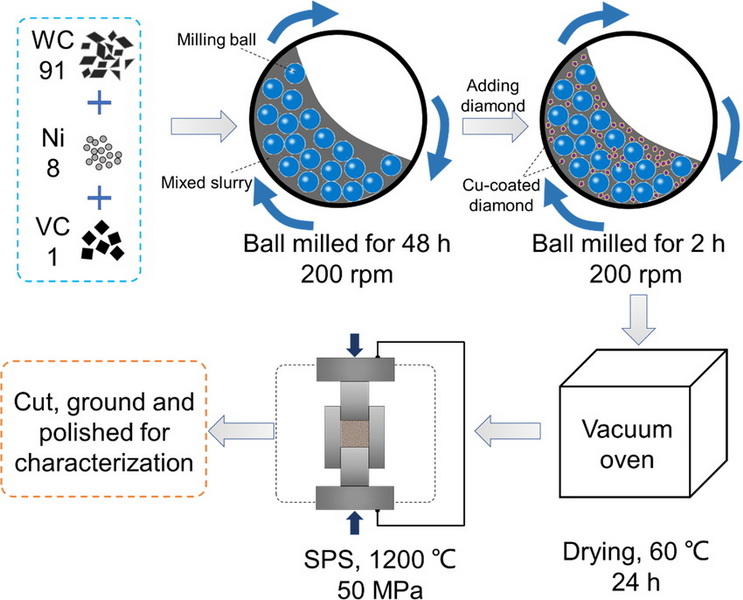

2. Mixing Tungsten and Carbon

- Tungsten powder is uniformly mixed with carbon powder (graphite or carbon black).

- The mixture must be homogeneous to avoid unreacted tungsten cores and ensure consistent carbide formation.

3. Carburization

- The tungsten-carbon mixture is heated in a furnace at temperatures between 1300°C and 1800°C.

- This high-temperature process causes carbon atoms to diffuse into tungsten particles, forming tungsten carbide (WC).

- The reaction proceeds through intermediate phases such as tungsten semicarbide (W2C) before forming the final WC phase.

4. Powder Processing

- The resultant tungsten carbide powder is milled and sieved to achieve the desired particle size.

- Additives such as cobalt powder are mixed with WC powder to act as a binder in the final composite.

5. Shaping and Sintering

- The powder mixture is pressed into desired shapes.

- Sintering at temperatures around 1400°C to 1600°C fuses the particles, with the binder metal melting and binding the carbide grains together.

- The grain size and binder content influence the hardness and toughness of the final product.

Characteristics of Tungsten Carbide

- Hardness: Comparable to diamond, making it ideal for cutting and wear-resistant tools.

- Density: Approximately 15.6 g/cm³, much denser than other carbides like silicon carbide.

- High Melting Point: Around 2780°C to 2830°C.

- Wear Resistance: Excellent resistance to abrasion and deformation.

- Binder Metals: Typically cobalt is used; nickel or nickel/chromium can be used for corrosion resistance.

Additional Properties of Tungsten Carbide

Beyond its hardness and wear resistance, tungsten carbide exhibits excellent thermal conductivity and resistance to thermal shock. This makes it suitable for applications involving rapid temperature changes. Its chemical stability also allows it to resist corrosion in many harsh environments, including acidic and alkaline conditions. These properties contribute to its widespread use in demanding industrial settings.

Tungsten carbide also demonstrates high compressive strength, which is crucial for tools subjected to heavy loads. Its electrical conductivity, although lower than metals, is sufficient for some specialized electronic applications. The combination of these physical and chemical properties makes tungsten carbide a versatile material in various technological fields.

Industrial and Commercial Applications

Tungsten carbide is extensively used in the manufacturing of cutting tools such as drills, milling cutters, and saw blades due to its ability to maintain a sharp edge under high stress. It is also used in mining equipment, where its wear resistance extends the life of drill bits and excavation tools. In the automotive industry, tungsten carbide components are used in fuel injection systems and turbochargers. Additionally, it finds applications in jewelry as a durable and scratch-resistant material for rings and watches.

Other notable applications include:

- Aerospace: Tungsten carbide is used in turbine blades and other components that require high strength and temperature resistance.

- Metalworking: It is employed in dies, punches, and molds for shaping metals.

- Oil and Gas Industry: Tungsten carbide is used in drilling bits and wear-resistant parts exposed to harsh subterranean conditions.

- Medical Devices: Its biocompatibility and hardness make it suitable for surgical instruments and implants.

Environmental and Sustainability Considerations

The production of tungsten carbide involves energy-intensive processes, including high-temperature sintering and chemical reduction. These processes contribute to a significant carbon footprint. However, efforts are ongoing to improve the sustainability of tungsten carbide manufacturing by optimizing energy use and recycling tungsten scrap.

Recycling tungsten carbide from used tools and components helps reduce the demand for raw tungsten ore, conserving natural resources and minimizing environmental impact. The recycling process involves crushing, magnetic separation, and chemical treatment to recover tungsten and cobalt for reuse. This circular approach not only lowers environmental harm but also reduces costs and dependence on mining.

Additionally, research is underway to develop greener synthesis methods, such as lower-temperature carburization and alternative binder materials that are less toxic than cobalt.

Recent Advancements and Innovations

Research in tungsten carbide materials continues to evolve, focusing on enhancing toughness and reducing brittleness. Innovations include the development of nanostructured tungsten carbide composites, which exhibit improved mechanical properties due to their fine grain sizes and homogeneous microstructures.

Alternative binder metals such as nickel, iron, and high-entropy alloys are being explored to improve corrosion resistance and reduce reliance on cobalt, which has supply chain and health concerns.

Advances in additive manufacturing (3D printing) techniques also enable the production of complex tungsten carbide parts with tailored properties. This technology opens new possibilities in aerospace, medical devices, and custom tooling by allowing intricate geometries and functionally graded materials.

Furthermore, surface coating technologies are being developed to enhance the wear resistance and lifespan of tungsten carbide tools, further expanding their industrial applications.

Global Market and Economic Importance

Tungsten carbide holds a significant position in the global market due to its critical role in manufacturing and industrial sectors. The demand for tungsten carbide products continues to grow, driven by advancements in technology and infrastructure development worldwide. Countries rich in tungsten resources, such as China, Russia, and Canada, play a vital role in the supply chain.

The economic impact of tungsten carbide extends beyond raw material extraction to include manufacturing, recycling, and end-user industries. Its applications in automotive, aerospace, mining, and electronics sectors contribute substantially to global industrial productivity. As technology evolves, the demand for high-performance materials like tungsten carbide is expected to increase, reinforcing its importance in the global economy.

Conclusion

Tungsten carbide is a remarkable material produced from natural raw materials including tungsten ores (wolframite and scheelite), ammonium paratungstate, tungsten oxide, and carbon sources such as graphite and carbon black. The transformation from these natural materials to a high-performance industrial product involves complex chemical and thermal processes like carburization and sintering. The resulting tungsten carbide exhibits exceptional hardness, wear resistance, thermal stability, and chemical durability.

Its wide-ranging industrial applications—from cutting tools and mining equipment to aerospace components and jewelry—underscore its versatility and importance. Sustainability efforts and recent technological advancements continue to improve the production efficiency and performance of tungsten carbide, ensuring its relevance in future industrial innovations.

Frequently Asked Questions (FAQ)

1. What natural ores are the main sources of tungsten for tungsten carbide production?

The main natural ores are wolframite (iron-manganese tungstate) and scheelite (calcium tungstate), both mined for their tungsten content used in tungsten carbide manufacturing.

2. How is ammonium paratungstate related to tungsten carbide production?

Ammonium paratungstate is an intermediate chemical compound derived from tungsten ore. It is processed to produce tungsten oxide and then tungsten metal powder, which is essential for making tungsten carbide.

3. What types of carbon are used to make tungsten carbide?

Natural carbon sources such as graphite and carbon black are used to carburize tungsten powder at high temperatures, forming tungsten carbide.

4. Why is cobalt commonly used in tungsten carbide products?

Cobalt acts as a binder metal in tungsten carbide composites, providing toughness and binding the hard tungsten carbide grains together during sintering.

5. What determines the hardness and toughness of tungsten carbide?

The grain size of tungsten carbide particles and the amount of binder metal (usually cobalt) influence the hardness and toughness. Finer grains increase hardness, while higher binder content improves toughness.