Content Menu

● Introduction: The Growing Significance of Carbide Buttons

● Understanding Carbide Buttons: Composition and Uses

>> Key Properties

● Why Choose Arabian Carbide Button Manufacturers and Suppliers?

● Leading Manufacturers and Suppliers in Arabia

● The Manufacturing Process: Precision and Expertise

>> 1. Raw Material Preparation

>> 2. Powder Mixing and Ball Milling

>> 3. Wet Milling and Spray Drying

>> 4. Pressing and Molding

>> 5. Sintering and Hot Isostatic Pressing

>> 6. Machining and Finishing

>> 7. Quality Assurance

● Insertion Techniques: Integrating Carbide Buttons into Tools

>> Copper Brazing

>> Cold Pressing

>> Hot Pressing

● Application Areas for Arabian Carbide Buttons

● Customization and OEM Support: Meeting Clients' Specific Needs

● Logistics and Bulk Ordering Capabilities

● Selection Tips: How to Choose the Best Supplier

● Innovations and Market Trends in Arabia

● Conclusion

● FAQs

>> 1. What industries commonly use Arabian carbide buttons?

>> 2. How do Arabian manufacturers assure product quality?

>> 3. Can clients request custom designs and OEM services?

>> 4. What are popular surface treatments offered?

>> 5. Do Arabian suppliers support bulk orders and international shipping?

Introduction: The Growing Significance of Carbide Buttons

Carbide buttons are essential components across mining, drilling, construction, oil and gas, and automotive sectors. In Arabia, the surge in infrastructure projects and energy exploration has driven a remarkable demand for high-performance carbide buttons. This dynamic industrial climate has fostered the rise of numerous carbide button manufacturers and suppliers capable of serving international brands, OEM clients, and regional distributors with quality, innovation, and reliability.

Arabia's carbide button manufacturers and suppliers are renowned for their advanced production capabilities, adherence to international standards, and robust supply chains. By leveraging superior raw materials, skilled labor, and innovative engineering, they deliver products that meet stringent requirements in both domestic and global markets.

Understanding Carbide Buttons: Composition and Uses

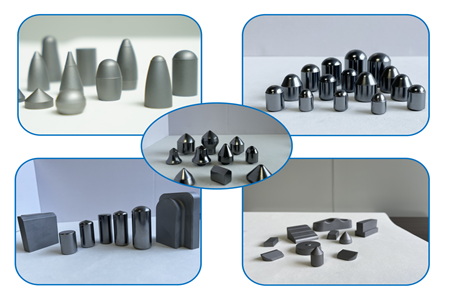

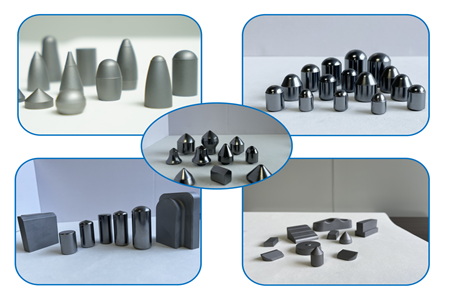

Carbide buttons are typically produced from tungsten carbide—a composite renowned for its exceptional hardness and resistance to abrasion, heat, and mechanical stress. These properties make carbide buttons especially suitable for the most demanding operational environments. Their robust composition allows them to perform effectively in drilling heads, mining bits, construction equipment, and various wear parts.

Key Properties

- Exceptional hardness and longevity

- Superior abrasion and impact resistance

- Excellent thermal stability and corrosion resistance

- Precise dimensional accuracy and customizable geometries

Carbide button manufacturers and suppliers in Arabia offer numerous variants designed for specific applications, such as conical, spherical, and parabolic heads. Their engineering teams work alongside buyers to tailor products for maximum performance.

Why Choose Arabian Carbide Button Manufacturers and Suppliers?

Arabia has become a preferred destination for sourcing carbide buttons for several reasons:

- Ready access to top-grade raw materials, including tungsten and binders

- Advanced technical infrastructure and manufacturing expertise

- Stringent quality assurance procedures guaranteeing reliability

- Strong OEM capabilities allowing for customized solutions and branding partnerships

- Competitive prices, efficient logistics, and international trade know-how

Arabian suppliers are uniquely positioned to serve global markets, ensuring timely delivery and customization for international standards.

Leading Manufacturers and Suppliers in Arabia

The region is home to several industry leaders who have distinguished themselves with consistent quality, innovation, and customer service. Some notable manufacturers and suppliers include:

- Companies specializing in drilling, mining, and construction carbide buttons, with long-standing histories of international exports.

- Firms offering comprehensive OEM support, allowing clients to customize button geometry, surface finish, and packaging.

- Suppliers certified under ISO, ASTM, and other quality standards, ensuring their products meet global benchmarks.

- Distributors with established networks across the Middle East, Europe, and Asia, and the capability to fulfill bulk orders for both standard and custom products.

These manufacturers and suppliers leverage state-of-the-art technology to produce carbide buttons with precise tolerances and extended lifespans, successfully serving high-impact industries worldwide.

The Manufacturing Process: Precision and Expertise

The manufacturing of carbide buttons is both advanced and meticulous, combining material science, high-precision engineering, and thorough inspections. The following key stages exemplify the detailed workflow:

1. Raw Material Preparation

Manufacturing begins with the selection of high-purity tungsten ore, which is refined and mixed with a suitable carbon source. Binder metals such as cobalt or nickel are added to increase toughness and binding efficiency. This forms the basis of the powder metallurgy process.

2. Powder Mixing and Ball Milling

Tungsten carbide powder is blended with binder metals and other additives in a ball mill to achieve uniformity. Consistent grain size during mixing is vital for optimal product hardness and performance.

3. Wet Milling and Spray Drying

The mixed powder is sometimes wet milled using water or ethanol to ensure even finer grain distribution. It is then dried—either in a vacuum dryer or spray drying tower—to produce granulated powder, which is ready for forming.

4. Pressing and Molding

Special molds are used to press the powder into specific button shapes. Depending on specifications, pressing may be done via uniaxial, isostatic, or hydraulic methods. Precise molding enables manufacturers to create conical, spherical, or parabolic heads in accordance with client requirements.

5. Sintering and Hot Isostatic Pressing

Pressed buttons are placed in high-temperature sintering furnaces, sometimes employing hot isostatic pressing (HIP) technology. The buttons are heated in vacuum or inert atmospheres at temperatures above 1400°C. This consolidates the powder, maximizing density, hardness, and durability.

6. Machining and Finishing

Post-sintering, buttons undergo CNC machining, grinding, and sometimes electrical discharge machining to achieve exact dimensions and smooth surfaces. Polishing and additional coatings—such as galvanization or PVD—further enhance wear resistance.

7. Quality Assurance

Strict inspection protocols are enforced: hardness testing, microstructure analysis, and dimensional checks. Only products meeting rigorous standards are packaged, labeled, and readied for shipping.

Insertion Techniques: Integrating Carbide Buttons into Tools

Arabian carbide button manufacturers and suppliers offer several methods for integrating buttons into industrial tools, ensuring optimal performance and durability.

Copper Brazing

This traditional method involves welding carbide buttons into tool bodies using copper or silver alloys. While impact resistance is enhanced, high temperatures may introduce thermal stresses that affect button hardness.

Cold Pressing

Cold pressing utilizes mechanical force to fit carbide buttons into predrilled holes. It's suitable for applications requiring minimal thermal impact, but may not achieve the strongest bond compared to hot methods.

Hot Pressing

Now regarded as the mainstream method, hot pressing heats the tool body to expand button holes. Carbide buttons are inserted and, as the material cools, it contracts tightly around the button, minimizing stress and maximizing retention. This delivers superior wear resistance and longevity in challenging conditions.

Application Areas for Arabian Carbide Buttons

Across Arabia, manufacturers supply carbide buttons to diverse industries:

- Mining and Exploration: Used in bit inserts, cutting heads, and percussion drilling tools.

- Oil and Gas: Deployed in downhole drilling, completion, and servicing equipment.

- Construction: Integrated into rotary hammers, demolition tools, and milling bits for rock and concrete operations.

- Automotive and Transportation: Utilized in tire studs, snow chains, and wear-resistant components for vehicles.

- Agricultural and Sports Equipment: Ensuring longevity and efficiency in machinery subject to constant abrasive wear.

Arabia's strategic location and advanced production facilities allow its suppliers to deliver these products globally, supporting both new infrastructure projects and routine industrial operations.

Customization and OEM Support: Meeting Clients' Specific Needs

Arabian carbide button manufacturers and suppliers excel in providing tailored solutions. They offer extensive options for:

- Button shapes: conical, spherical, parabolic, spoon head, or hybrid designs.

- Surface treatments: galvanization, zinc plating, black oxide, copper plating, PVD coating, or painting.

- Thread variants and dimensions: Metric, UNC, UNF, and other international standards.

- Branding and packaging: Private-label support for international clients, including box design, logo printing, and documentation.

Manufacturers collaborate directly with clients to understand operational requirements, suggest design improvements, and rapidly prototype customized buttons, ensuring every product meets the rigorous demands of the end application.

Logistics and Bulk Ordering Capabilities

Arabian manufacturers offer robust logistics solutions, adept at managing bulk orders and international shipments. They maintain modern warehouses, streamlined supply chains, and dedicated export teams familiar with global trade compliance. These strengths allow them to reliably deliver on-time, cost-effective orders for major distributors and OEM partners worldwide.

Selection Tips: How to Choose the Best Supplier

To maximize performance and value, buyers should examine several factors when choosing Arabian carbide button manufacturers and suppliers:

- Certification: Look for ISO, ASTM, or equivalent endorsements ensuring quality and compliance.

- Customization: Confirm the supplier offers broad engineering and OEM support.

- Production Capacity: Evaluate their ability to fulfill large orders and sustain quick turnaround times.

- Experience: Consider years in business, export history, and presence in relevant industries.

- Technical Support: Assess their ability to provide installation guides, documentation, and after-sales service.

By focusing on these criteria, buyers can partner confidently with Arabian suppliers and achieve optimal performance in their target applications.

Innovations and Market Trends in Arabia

Arabian carbide button manufacturers and suppliers continuously invest in modern technologies and process improvements. Current trends include:

- Adoption of automation and smart manufacturing for increased output and reduced defects.

- Application of advanced coatings to enhance wear and corrosion resistance.

- Use of digital platforms for client collaboration, order management, and supply chain visibility.

- Research into nanostructured carbides and new composite materials for next-generation tools.

These innovations ensure Arabian suppliers remain competitive, responsive, and aligned with client expectations worldwide.

Conclusion

Arabia's carbide button manufacturing sector stands at the forefront of quality, technology, and customization. The region's suppliers offer comprehensive solutions to international brands, OEMs, and distributors, spanning mining, construction, oil and gas, and automotive markets. Through advanced processes, robust logistics, and ongoing innovation, Arabian carbide button manufacturers and suppliers set global benchmarks for performance, reliability, and value. Partnering with these industry leaders ensures access to world-class products engineered for the most demanding applications.

FAQs

1. What industries commonly use Arabian carbide buttons?

Carbide buttons are extensively used in mining, construction, oil and gas, automotive, and agricultural equipment due to their unmatched durability and wear resistance.

2. How do Arabian manufacturers assure product quality?

Suppliers enforce strict quality checks—hardness testing, microstructure analysis, and dimensional inspections—while complying with ISO, ASTM, and other international standards.

3. Can clients request custom designs and OEM services?

Yes. Most Arabian carbide button manufacturers and suppliers provide extensive customization services, including shape, dimensions, coatings, branding, and packaging.

4. What are popular surface treatments offered?

Common treatments include galvanization, zinc plating, black oxide, copper plating, PVD coatings, and painting, all designed to boost corrosion and wear resistance.

5. Do Arabian suppliers support bulk orders and international shipping?

Absolutely. The region's suppliers maintain modern warehousing and logistics networks, facilitating bulk orders and timely global deliveries for international clients.