Content Menu

● Understanding Stiffness: The Basics

● Tungsten Carbide: Composition and Structure

● Atomic Structure and Bonding in Tungsten Carbide

● Stiffness of Tungsten Carbide: Key Figures

>> Young's Modulus

>> Other Moduli

● Why Is Tungsten Carbide So Stiff?

● Manufacturing Processes and Their Impact on Stiffness

● Comparison Table: Stiffness of Common Materials

● Mechanical Properties of Tungsten Carbide

● Applications Leveraging Stiffness

● Expanded Applications of Tungsten Carbide

● How Does Stiffness Affect Performance?

● Limitations of Tungsten Carbide's Stiffness

● Recent Research and Advancements

● Environmental and Economic Considerations

● Visualizing Stiffness: Deflection Comparison

● Material Science Behind the Numbers

>> Young's Modulus Calculation

● Stiffness in Real-World Applications

● Summary Table: Key Stiffness Properties of Tungsten Carbide

● Conclusion

● FAQ: Frequently Asked Questions About the Stiffness of Tungsten Carbide

>> 1. What is the Young's modulus of tungsten carbide?

>> 2. How does tungsten carbide's stiffness compare to steel?

>> 3. Why is tungsten carbide so stiff?

>> 4. Does tungsten carbide maintain its stiffness at high temperatures?

>> 5. What are the main applications that benefit from tungsten carbide's stiffness?

Tungsten carbide is renowned for its exceptional mechanical properties, particularly its remarkable stiffness, which has made it indispensable in demanding industrial applications. This article provides an in-depth exploration of the stiffness of tungsten carbide, comparing it with other materials, explaining the underlying science, and illustrating its real-world impact.

Understanding Stiffness: The Basics

Stiffness is a material's resistance to deformation under an applied force. In engineering, it is commonly quantified by Young's modulus (also called the elastic modulus), which measures the ratio of stress (force per unit area) to strain (proportional deformation) in a material. The higher the Young's modulus, the stiffer the material.

Tungsten Carbide: Composition and Structure

Tungsten carbide (WC) is a compound composed of equal parts tungsten and carbon atoms. It forms a dense, hard, and brittle material that is typically manufactured through powder metallurgy, often with a metallic binder like cobalt for added toughness.

Atomic Structure and Bonding in Tungsten Carbide

Tungsten carbide's remarkable stiffness is fundamentally rooted in its atomic structure and the nature of the bonds between its constituent atoms. The compound consists of tungsten atoms bonded covalently to carbon atoms in a hexagonal crystal lattice. This strong covalent bonding is much stronger than metallic bonding found in many other engineering materials, which contributes significantly to its high Young's modulus. The dense packing of atoms in the crystal lattice also minimizes the space for atomic movement, making deformation under stress very difficult.

The tungsten atoms provide a heavy, dense framework, while the carbon atoms fill interstitial spaces, creating a rigid and stable structure. This combination results in a material that is not only stiff but also extremely hard and resistant to wear.

Stiffness of Tungsten Carbide: Key Figures

Young's Modulus

- Range: 530–700 GPa (gigapascals)

- Typical Value: ~550–630 GPa is most frequently cited

- Comparison:

- Steel: ~200 GPa

- Titanium: ~110 GPa

- Diamond: ~1,000 GPa

This means tungsten carbide is approximately three times as stiff as steel and second only to diamond among common engineering materials.

Other Moduli

- Bulk modulus (resistance to uniform compression): 379–381 GPa

- Shear modulus (resistance to shearing): 274 GPa

Why Is Tungsten Carbide So Stiff?

The stiffness of tungsten carbide arises from its strong covalent bonding between tungsten and carbon atoms and its dense, hexagonal crystal structure. These atomic arrangements resist deformation, even under high stresses.

Manufacturing Processes and Their Impact on Stiffness

The stiffness of tungsten carbide can be influenced by the manufacturing process used to produce it. Typically, tungsten carbide is produced through powder metallurgy, where tungsten and carbon powders are mixed and then sintered at high temperatures. The sintering process causes the powders to bond together, forming a dense, solid material.

The addition of binders such as cobalt can improve toughness but may slightly reduce stiffness. The grain size of the tungsten carbide particles also plays a role; finer grains generally lead to higher stiffness and hardness due to the grain boundary strengthening effect.

Advanced manufacturing techniques, such as hot isostatic pressing and spark plasma sintering, allow for better control over the microstructure, resulting in materials with optimized stiffness and mechanical properties.

Comparison Table: Stiffness of Common Materials

| Material | Young's Modulus (GPa) | Stiffness Relative to Steel |

| Diamond | ~1,000 | ~5x |

| Tungsten Carbide | 530–700 | ~3x |

| Steel | ~200 | 1x |

| Titanium | ~110 | ~0.55x |

| Aluminum | ~70 | ~0.35x |

Mechanical Properties of Tungsten Carbide

Beyond stiffness, tungsten carbide is notable for:

- Hardness: 9–9.5 on the Mohs scale (second only to diamond)

- Compressive strength: ~2,700–4,780 MPa

- Tensile strength: ~344–350 MPa

- Density: ~15.6–15.7 g/cm³ (twice that of steel)

- Thermal conductivity: ~84–110 W/m·K

Applications Leveraging Stiffness

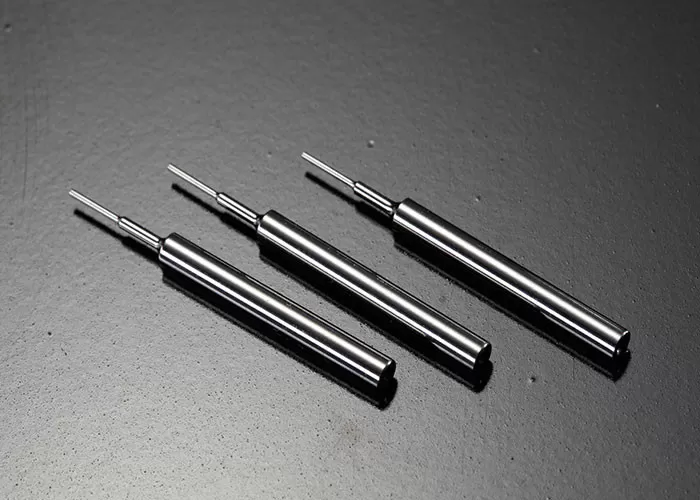

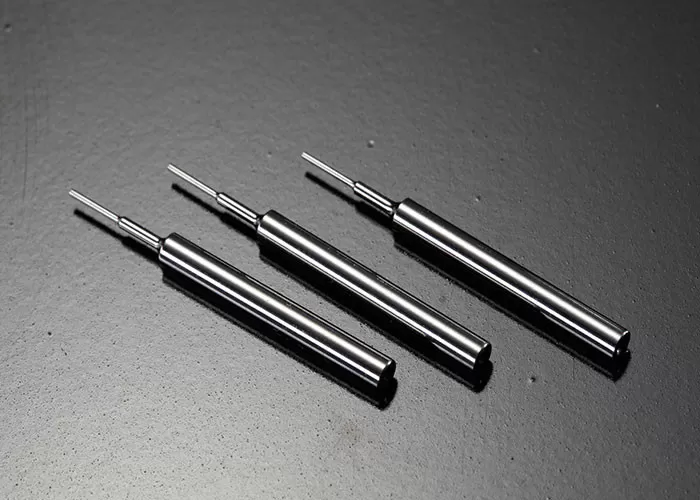

Tungsten carbide's exceptional stiffness and hardness make it ideal for:

- Cutting tools and drill bits: Maintains sharpness and resists deformation under extreme loads

- Wear-resistant parts: Used in mining, oil & gas, and heavy machinery

- Abrasives and dies: For shaping and grinding other hard materials

- Precision instruments: Where minimal deflection is critical (e.g., spindles, measuring devices)

Expanded Applications of Tungsten Carbide

Beyond traditional uses, tungsten carbide's stiffness makes it valuable in emerging fields:

- Electronics: Components in microelectromechanical systems (MEMS) for precision and minimal deformation.

- Automotive: High-performance engine components and fuel injection systems for improved efficiency.

- Aerospace: Turbine blades and structural components exposed to extreme conditions.

How Does Stiffness Affect Performance?

- Minimal Deflection: High stiffness ensures that tools and components do not bend or flex under load, maintaining accuracy and prolonging tool life.

- High Wear Resistance: Stiffness, combined with hardness, means less surface deformation and slower wear rates.

- Thermal Stability: Retains stiffness at high temperatures, crucial for high-speed machining and cutting operations.

Limitations of Tungsten Carbide's Stiffness

- Brittleness: While stiff, tungsten carbide is also brittle and can fracture under impact or tensile stress.

- Difficult to Machine: Its hardness and stiffness mean that only diamond or cubic boron nitride tools can shape it, often requiring specialized processes.

Recent Research and Advancements

Recent studies have focused on enhancing the stiffness of tungsten carbide composites by incorporating nanomaterials such as graphene and carbon nanotubes. These additives reinforce the matrix and prevent crack propagation. Research into coating technologies has also advanced, with novel coatings designed to enhance surface stiffness without compromising bulk properties. Computational materials science enables atomic-scale simulations to predict and tailor stiffness for next-generation materials.

Environmental and Economic Considerations

While tungsten carbide offers exceptional performance, its production involves energy-intensive processes and critical raw materials like tungsten and cobalt. Recycling and recovery from used tools are becoming increasingly important to reduce environmental impact. Economically, its durability and long service life offset initial costs, making it cost-effective for many applications.

Visualizing Stiffness: Deflection Comparison

Suppose you apply the same force to rods of steel and tungsten carbide of identical dimensions. The tungsten carbide rod will deflect only about one-third as much as the steel rod, illustrating its superior stiffness.

Material Science Behind the Numbers

Young's Modulus Calculation

Young's modulus (E) is calculated as:

E=Strain/Stress

Where:

- Stress = Force per unit area (N/m2)

- Strain = Proportional deformation (dimensionless)

A high Young's modulus means the material stretches or compresses very little under load.

Stiffness in Real-World Applications

- Machining: Tungsten carbide tools cut with higher precision and last longer due to minimal tool deflection.

- Aerospace: Used in components where rigidity is essential for performance and safety.

- Medical Devices: Precision instruments benefit from the material's stability and resistance to deformation.

Summary Table: Key Stiffness Properties of Tungsten Carbide

| Property | Value/Range | Significance |

| Young's Modulus | 530–700 GPa | Extremely high stiffness |

| Bulk Modulus | 379–381 GPa | High resistance to uniform compression |

| Shear Modulus | 274 GPa | High resistance to shearing forces |

| Density | ~15.6 g/cm³ | Twice as dense as steel |

| Hardness (Mohs) | 9–9.5 | Second only to diamond |

Conclusion

Tungsten carbide stands out as one of the stiffest engineering materials available, with a Young's modulus in the range of 530–700 GPa-about three times that of steel and second only to diamond among common materials. This exceptional stiffness, combined with outstanding hardness, compressive strength, and thermal stability, makes tungsten carbide the material of choice for high-performance tools and components in the most demanding industrial environments. Advances in manufacturing and nanotechnology continue to expand its applications, while recycling efforts address sustainability concerns.

FAQ: Frequently Asked Questions About the Stiffness of Tungsten Carbide

1. What is the Young's modulus of tungsten carbide?

The Young's modulus of tungsten carbide ranges from 530 to 700 GPa, making it about three times as stiff as steel and second only to diamond among commonly used materials.

2. How does tungsten carbide's stiffness compare to steel?

Tungsten carbide is roughly three times stiffer than steel. While steel's Young's modulus is around 200 GPa, tungsten carbide's is typically in the 530–700 GPa range.

3. Why is tungsten carbide so stiff?

Its high stiffness is due to strong covalent bonds between tungsten and carbon atoms and a dense, hexagonal crystal structure, which resists deformation even under high loads.

4. Does tungsten carbide maintain its stiffness at high temperatures?

Yes, tungsten carbide retains its stiffness and mechanical properties at elevated temperatures, making it ideal for high-speed machining and other demanding applications.

5. What are the main applications that benefit from tungsten carbide's stiffness?

Applications include cutting and drilling tools, wear-resistant machine parts, precision instruments, and dies-anywhere minimal deflection and high wear resistance are critical.