Content Menu

● Understanding Tungsten Carbide Coatings

>> What is Tungsten Carbide?

>> Properties of Tungsten Carbide Coatings

● How Are Tungsten Carbide Coatings Applied?

>> Thermal Spray Processes

>> Advantages of HVOF Coating

● Industrial Applications of Tungsten Carbide Coatings

>> 1. Oil and Gas Industry

>> 2. Aerospace and Aviation

>> 3. Manufacturing and Metalworking

>> 4. Power Generation

>> 5. Paper and Textile Industries

>> 6. Automotive and Heavy Machinery

>> 7. Mining and Construction Equipment

>> 8. Food Processing Industry

● Benefits of Tungsten Carbide Coatings

● Technical Insights: Why Tungsten Carbide Coatings Excel

>> Microstructure and Composition

>> Wear Mechanisms Addressed

>> Coating Thickness and Surface Finish

● Environmental and Economic Impact

>> Environmental Benefits

>> Economic Advantages

● Maintenance and Repair Considerations

>> Inspection and Monitoring

>> Repair and Recoating

● Conclusion

● FAQ

>> 1. What industries benefit most from tungsten carbide coatings?

>> 2. How does tungsten carbide coating compare to hard chrome plating?

>> 3. What are the common methods for applying tungsten carbide coatings?

>> 4. Can tungsten carbide coatings withstand high temperatures?

>> 5. Are tungsten carbide coatings resistant to corrosion?

● Citations:

Tungsten carbide coatings are among the most durable and wear-resistant surface treatments available today. They are widely used across various industries to enhance the lifespan, performance, and reliability of components exposed to extreme wear, abrasion, corrosion, and high temperatures. This article explores the properties, application methods, industrial uses, and benefits of tungsten carbide coatings, supported by illustrative images and detailed explanations.

Understanding Tungsten Carbide Coatings

What is Tungsten Carbide?

Tungsten carbide (WC) is a chemical compound composed of tungsten and carbon atoms arranged in a hexagonal crystal structure. It is an ultra-hard ceramic material often combined with metallic binders such as cobalt, nickel, or chromium to form a cermet (ceramic-metal composite). This combination provides exceptional hardness, wear resistance, and toughness, making it ideal for protective coatings.

Properties of Tungsten Carbide Coatings

- Extreme Hardness: Tungsten carbide coatings can reach hardness levels above 70 HRC (Rockwell scale), surpassing many other industrial materials.

- Wear and Abrasion Resistance: The coatings protect surfaces from sliding wear, fretting, and erosion, significantly extending component life.

- Thermal Stability: With a melting point around 2,870°C, tungsten carbide maintains structural integrity under high temperatures.

- Corrosion Resistance: When combined with binders like nickel or chromium, the coatings offer good resistance to corrosion in harsh environments.

- Low Porosity and High Bond Strength: Advanced application methods produce dense coatings with porosity less than 1%, ensuring strong adhesion to substrates.

How Are Tungsten Carbide Coatings Applied?

Thermal Spray Processes

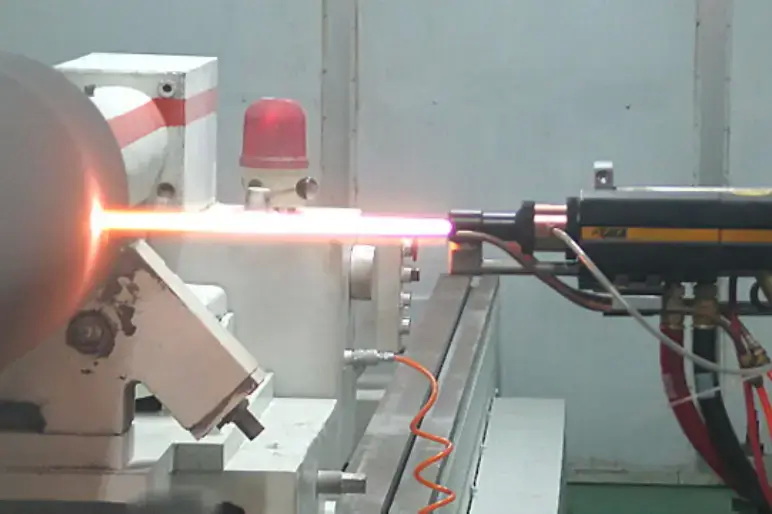

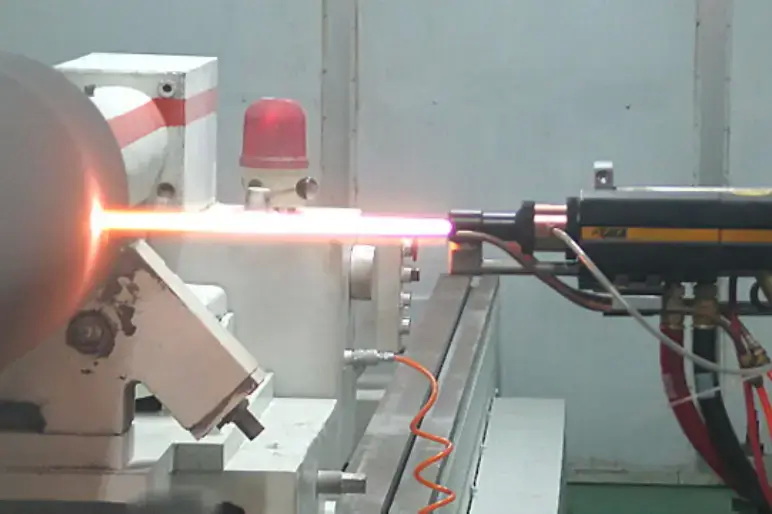

The most common method for applying tungsten carbide coatings is thermal spraying, particularly the High Velocity Oxygen Fuel (HVOF) process. This technique involves:

- Mixing and igniting fuel and oxygen to create a high-velocity gas stream.

- Injecting tungsten carbide powder into this stream, accelerating particles toward the substrate.

- Particles impact the surface at high speed, bonding instantly and forming a dense, uniform coating.

Other methods include plasma spraying, detonation gun spraying, and chemical vapor deposition, each offering different coating characteristics tailored to specific applications.

Advantages of HVOF Coating

- Produces coatings with very low porosity (80 MPa).

- Results in smooth surfaces that reduce friction and wear.

- Faster application compared to traditional hard chrome plating.

Industrial Applications of Tungsten Carbide Coatings

1. Oil and Gas Industry

Tungsten carbide coatings protect drilling equipment such as drill bits, valve stems, and pump components from abrasive wear and corrosion in high-pressure, harsh environments. This extends equipment life and reduces costly downtime.

2. Aerospace and Aviation

Critical engine parts like turbine blades, compressor seals, and landing gear components are coated to resist erosion, abrasion, and impact damage. The coatings maintain strength under severe stress and high temperatures, ensuring safety and reliability.

3. Manufacturing and Metalworking

Cutting tools, stamping dies, and forming rolls benefit from tungsten carbide coatings due to their hardness and wear resistance. This leads to longer tool life, improved precision, and reduced maintenance costs.

4. Power Generation

Turbine components in steam and gas power plants are coated to withstand erosion from particulates and high-temperature gases, maintaining efficiency and reducing repair frequency.

5. Paper and Textile Industries

Rollers and process equipment in paper mills use tungsten carbide coatings to provide durable grip surfaces and resist abrasive wear. In textiles, specialized needles and weaving tools are coated to enhance durability.

6. Automotive and Heavy Machinery

Components exposed to friction and wear, such as shafts, gears, and impellers, are coated to improve lifespan and performance under demanding conditions.

7. Mining and Construction Equipment

Mining tools like drill bits, crusher parts, and excavator buckets are coated with tungsten carbide to resist abrasive wear from rocks and minerals. This reduces replacement frequency and improves operational uptime.

8. Food Processing Industry

Certain food processing equipment benefits from tungsten carbide coatings to resist wear and corrosion caused by abrasive food materials and cleaning chemicals, ensuring hygiene and durability.

Benefits of Tungsten Carbide Coatings

| Benefit | Description |

| Extended Service Life | Significantly increases durability of tools and components under abrasive and erosive wear. |

| Reduced Friction | Smooth coating surfaces lower friction, improving operational efficiency. |

| Corrosion Resistance | Protects against chemical and environmental damage, especially with appropriate binders. |

| High Temperature Resistance | Maintains hardness and structural integrity in extreme heat conditions. |

| Cost Efficiency | Reduces maintenance, downtime, and replacement costs over the component lifecycle. |

| Versatility | Applicable to a wide range of substrates and complex geometries. |

Technical Insights: Why Tungsten Carbide Coatings Excel

Microstructure and Composition

Tungsten carbide coatings typically consist of WC particles embedded in a metallic binder matrix, often cobalt or nickel. The hard WC particles provide wear resistance, while the metallic binder offers toughness and adhesion to the substrate. The microstructure is engineered to balance hardness and toughness, preventing brittle failure.

Wear Mechanisms Addressed

- Abrasive Wear: Hard particles in the coating resist scratching and gouging by hard contaminants.

- Erosive Wear: The coating withstands high-velocity particle impacts that would otherwise erode the surface.

- Adhesive Wear: Low friction surfaces reduce material transfer and galling.

- Corrosive Wear: Protective binders shield the substrate from chemical attack.

Coating Thickness and Surface Finish

Typical tungsten carbide coatings range from 100 to 500 microns in thickness. Thicker coatings provide longer wear life but may increase residual stresses. Surface finish after coating is usually smooth, with roughness values (Ra) below 1 micron, which helps reduce friction and improve component performance.

Environmental and Economic Impact

Environmental Benefits

Tungsten carbide coatings can replace environmentally harmful processes such as hard chrome plating, which involves toxic hexavalent chromium compounds. HVOF and other thermal spray methods are cleaner, producing less hazardous waste and emissions.

Economic Advantages

Though the initial cost of tungsten carbide coating application is higher than some alternatives, the extended service life and reduced downtime lead to significant cost savings over time. This makes tungsten carbide coatings a cost-effective solution for critical components.

Maintenance and Repair Considerations

Inspection and Monitoring

Components coated with tungsten carbide should be regularly inspected for wear, cracking, or delamination. Non-destructive testing methods such as ultrasonic testing or dye penetrant inspection can detect coating defects early.

Repair and Recoating

Damaged coatings can often be repaired by grit blasting the worn area and reapplying the coating using the same thermal spray process. Proper surface preparation is essential to ensure good adhesion of the repair layer.

Conclusion

Tungsten carbide coatings are a critical technology for industries requiring superior wear resistance, corrosion protection, and thermal stability. Their application through advanced thermal spray processes like HVOF results in dense, hard, and durable coatings that extend the life of components exposed to extreme conditions. From aerospace to oil and gas, manufacturing to power generation, tungsten carbide coatings enhance performance, reduce maintenance costs, and improve operational efficiency. As industries continue to demand higher durability and reliability, tungsten carbide coatings remain an indispensable solution that balances technical excellence with environmental and economic benefits.

FAQ

1. What industries benefit most from tungsten carbide coatings?

Tungsten carbide coatings are widely used in oil and gas, aerospace, manufacturing, power generation, paper, textile, automotive, mining, and food processing industries due to their exceptional wear and corrosion resistance.

2. How does tungsten carbide coating compare to hard chrome plating?

Tungsten carbide coatings offer higher hardness (>70 HRC vs. 60-70 HRC), lower porosity, better corrosion resistance, and faster application times compared to hard chrome plating.

3. What are the common methods for applying tungsten carbide coatings?

The primary methods include High Velocity Oxygen Fuel (HVOF) spraying, plasma spraying, detonation gun spraying, and chemical vapor deposition, with HVOF being the most popular for its dense, strong coatings.

4. Can tungsten carbide coatings withstand high temperatures?

Yes, tungsten carbide coatings maintain their hardness and structural integrity at temperatures up to approximately 1025°F (550°C) or higher, depending on the binder and application method.

5. Are tungsten carbide coatings resistant to corrosion?

While pure tungsten carbide is not highly corrosion resistant, coatings combined with binders like nickel or chromium provide good corrosion resistance suitable for many industrial environments.

Citations:

[1] https://www.industrialplating.com/materials/tungsten-carbide-coatings

[2] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[3] https://www.paganoni.it/en/articles-blog/tungsten-carbide-coating-why-is-it-recommended/

[4] https://www.asbindustries.com/coating-materials/carbide-coating-materials/tungsten-carbide-coatings

[5] https://htscoatings.com/blogs/our-craft-our-culture/three-tungsten-carbide-thermal-spray-coatings-and-their-uses

[6] http://www.wococarbide.com/Uploads/2017-07-31/597edb1697a16.pdf

[7] https://shop.machinemfg.com/tungsten-carbide-coating-comprehensive-guide/

[8] https://www.haydencorp.com/tungsten-carbide-coatings

[9] https://www.thermalspray.com/need-tungsten-carbide-coatings/

[10] https://kermetico.com/coating-materials/tungsten-carbide-wc-co-coatings

[11] https://htscoatings.com/pages/tungsten-carbide

[12] https://www.ep-coatings.com/news/applications-of-tungsten-carbide-coatings-in-the-aerospace-industry.html

[13] https://www.samaterials.com/content/how-does-the-new-tungsten-carbide-coating-strengthen-aircraft-parts.html

[14] https://www.thermalspray.com/how-can-tungsten-carbide-coatings-strengthen-aircraft-parts/

[15] https://westernmachine.com/machine-shop-services/tungsten-carbide-coatings/

[16] https://flamespray.org/newsEN-17-HVOF-Tungsten-Carbide-Coatings-A-Superior-Alternative-to-Chrome-Plating

[17] https://www.precisioncoatings.com/capabilities/coatings/carbide/

[18] https://www.eng-tips.com/threads/tungsten-carbide-coating-basic-information-required.69809/

[19] https://www.oerlikon.com/metco/en/products-services/materials/carbides/

[20] https://cdn.shopify.com/s/files/1/0282/3821/7250/files/web-0016_480x480.jpg?v=1677019896&sa=X&ved=2ahUKEwiD0-blr9qMAxXYlYkEHQNyFbAQ_B16BAgKEAI

[21] https://assets.linde.com/-/media/celum-connect/2025/01/16/14/05/tungsten_carbide_calendar_roll_193694.jpg?impolicy=focal-point&cw=1200&ch=630&fx=576&fy=150&r=7acca83058&sa=X&ved=2ahUKEwisyeHlr9qMAxULRjABHZj7PDMQ_B16BAgBEAI

[22] https://www.shutterstock.com/image-photo/spalling-tungsten-carbide-coating-on-plunger-1434824276

[23] https://www.instagram.com/quali.tech/reel/C9-VWrMOWEG/

[24] https://www.nbcbearings.com/tungsten-carbide-carbon-coating-in-ldb/

[25] https://www.pcimag.com/articles/113102-new-tungsten-carbide-powders-for-hvof-applications

[26] https://www.gordonengland.co.uk/microphotographs.htm

[27] https://www.instagram.com/keystoneindonesia/p/DIGYte7Syks/

[28] https://www.cybertruckownersclub.com/musk-tungsten-carbide-coating-may-be-offered-to-scratch-proof-cybertruck/

[29] https://www.carbinite.com

[30] https://www.istockphoto.com/photos/tungsten-carbide?page=2

[31] https://kermetico.com/applications/hvaf-tungsten-carbide-wear-resistant-coating-bends-elbows-sleeves

[32] https://www.thehulltruth.com/boating-forum/739745-tungsten-carbide-coating.html

[33] https://hardide.com/wp-content/uploads/2020/05/Corrosion_20101.pdf