Content Menu

● Introduction to Tungsten Carbide Inserts

>> Composition of Tungsten Carbide Inserts

● Types of Tungsten Carbide Inserts

● Applications of Tungsten Carbide Inserts

● Manufacturing Process of Tungsten Carbide Inserts

● Benefits of Tungsten Carbide Inserts

● Advanced Applications of Tungsten Carbide Inserts

>> High-Speed Machining

>> Advanced Materials Machining

>> Sustainable Machining Practices

● Latest Innovations in Tungsten Carbide Insert Technology

>> Nanostructured Tungsten Carbide

>> Advanced Coatings

● Tungsten Carbide Inserts vs. Other Materials

● Case Studies on Tungsten Carbide Insert Performance

● Future Trends in Tungsten Carbide Insert Manufacturing

● Conclusion

● Frequently Asked Questions

>> 1. What are tungsten carbide inserts made of?

>> 2. What are the main applications of tungsten carbide inserts?

>> 3. How are tungsten carbide inserts manufactured?

>> 4. What are the benefits of using tungsten carbide inserts?

>> 5. Why are tungsten carbide inserts preferred over traditional steel tools?

● Citations:

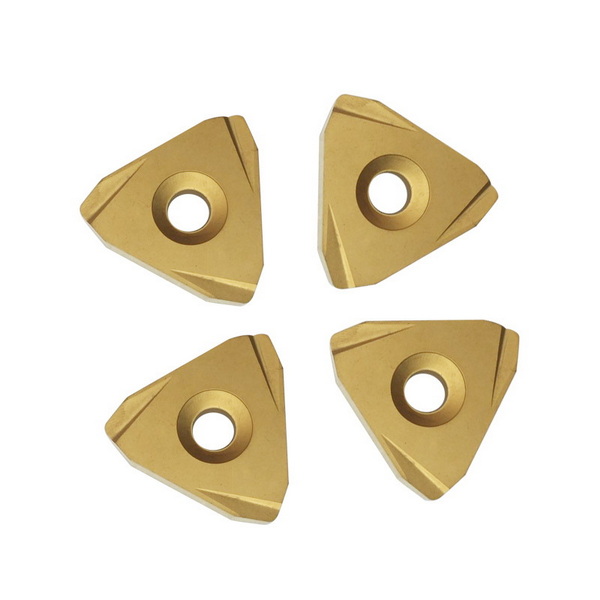

Tungsten carbide inserts are a crucial component in modern machining, offering unparalleled durability and precision for cutting, turning, milling, and boring operations. These inserts are made from tungsten carbide, a compound of tungsten and carbon, known for its exceptional hardness and resistance to wear. In this article, we will delve into the world of tungsten carbide inserts, exploring their types, applications, manufacturing process, benefits, and future trends.

Introduction to Tungsten Carbide Inserts

Tungsten carbide inserts are replaceable cutting tools designed to be easily attached and detached from tool holders, making them versatile and cost-effective. Their composition typically includes tungsten carbide as the primary component, with cobalt acting as a binder. Additional carbides like titanium carbide or tantalum carbide may be added to enhance specific properties such as wear resistance or hot hardness.

Composition of Tungsten Carbide Inserts

The composition of tungsten carbide inserts is a fine balance of different materials to optimize their performance. Here's a breakdown of the typical components and their roles:

- Tungsten Carbide (WC): Provides hardness and wear resistance, typically making up 70-90% of the insert.

- Cobalt (Co): Acts as a binder, enhancing toughness, and usually constitutes 6-15% of the insert.

- Titanium Carbide (TiC): Improves wear resistance and cutting performance, often added in amounts of 2-5%.

- Tantalum Carbide (TaC): Increases hot hardness, typically added in amounts of 1-3%.

- Other Additives: Tailored to specific requirements, such as corrosion resistance, and may constitute up to 2% of the insert.

Types of Tungsten Carbide Inserts

Understanding the various types of tungsten carbide inserts is key to selecting the right one for your application. Here's a table categorizing these inserts based on their geometry and cutting purpose:

| Insert Type | Shape | Application | Examples |

| Turning Inserts | Triangular | General turning, profiling | TNMG, CNMG, DNMG |

| Milling Inserts | Square | Face milling, shoulder milling | APK, SEKT, RDHT |

| Drilling Inserts | Round | Drilling, boring | RCMX, SOMT |

| Grooving Inserts | Special | Grooving, parting | GTN, GCN, GRM |

| Threading Inserts | V-shaped | Internal and external threading | 16ER, 16IR, 11IR |

| Special Purpose Inserts | Custom shapes | Tailored for specific applications | Custom inserts based on needs |

Applications of Tungsten Carbide Inserts

Tungsten carbide inserts are versatile and find applications in various industries. Here's a detailed table outlining their primary uses:

| Industry | Application | Description |

| Automotive | Engine components, transmission parts | High precision and durability for critical engine parts |

| Aerospace | Structural components, turbine blades | High performance materials requiring excellent wear resistance |

| Medical | Surgical instruments, implants | Biocompatible and precise machining for medical tools |

| Oil & Gas | Drilling equipment, pipeline components | Toughness and wear resistance for harsh drilling conditions |

| Construction | Heavy machinery, tool bits | Durable and reliable for rough working environments |

| General Manufacturing | Tools, molds, dies | Versatile and cost-effective for everyday |

Manufacturing Process of Tungsten Carbide Inserts

The manufacturing process of tungsten carbide inserts involves several critical steps:

1. Powder Preparation: High-purity tungsten carbide and cobalt powders are sourced and analyzed for particle size distribution, purity, and chemical composition.

2. Mixing and Milling: The powders are mixed and milled to ensure uniform distribution. Ball milling is used to grind the mixture into submicron particles.

3. Shaping: The powder mixture is pressed into the desired shape using a die.

4. Sintering: The green compact is sintered in a furnace at high temperatures (around 1400°C) to create a dense, hard carbide insert.

5. Hot Isostatic Pressing (HIP): Some inserts undergo HIP to eliminate any remaining porosity, resulting in a fully dense structure.

Benefits of Tungsten Carbide Inserts

Tungsten carbide inserts offer several benefits, including:

- Durability: They provide a longer working life compared to traditional steel tools.

- Precision: They maintain a sharp cutting edge, ensuring high-quality finishes.

- Heat Resistance: Suitable for high-speed machining due to their ability to withstand high temperatures.

- Versatility: Can be used with various materials, including metals and composites.

Advanced Applications of Tungsten Carbide Inserts

High-Speed Machining

Tungsten carbide inserts are ideal for high-speed machining due to their excellent heat resistance and wear properties. This allows for faster production rates and improved surface finishes.

Advanced Materials Machining

These inserts are used to machine advanced materials like titanium alloys and composites, which are critical in aerospace and automotive industries. Their ability to withstand high stresses and maintain sharp cutting edges makes them indispensable for these applications.

Sustainable Machining Practices

Tungsten carbide inserts contribute to sustainable machining by reducing tool waste and extending tool life. This reduces the environmental impact of frequent tool replacements and minimizes the need for raw materials.

Latest Innovations in Tungsten Carbide Insert Technology

Recent innovations focus on improving the wear resistance and toughness of tungsten carbide inserts. Techniques such as nanostructuring and advanced coating technologies are being explored to enhance performance.

Nanostructured Tungsten Carbide

Nanostructured tungsten carbide offers improved mechanical properties, including increased hardness and toughness. This is achieved by reducing the grain size of the carbide particles, resulting in a more uniform and robust structure.

Advanced Coatings

Coatings like titanium nitride (TiN) and aluminum oxide (Al2O3) are applied to tungsten carbide inserts to further enhance their wear resistance and thermal stability. These coatings can significantly extend tool life and improve machining efficiency.

Tungsten Carbide Inserts vs. Other Materials

Tungsten carbide inserts are compared to other cutting tool materials based on their hardness, wear resistance, and cost. Here's a comparison with common alternatives:

| Material | Hardness | Wear Resistance | Cost |

| Tungsten Carbide | High | Excellent | Moderate to High |

| High-Speed Steel (HSS) | Medium | Fair | Low |

| Ceramic Inserts | Very High | Excellent | High |

| Diamond-Coated Inserts | Extremely High | Superior | Very High |

Case Studies on Tungsten Carbide Insert Performance

Several case studies highlight the performance benefits of tungsten carbide inserts:

- Automotive Industry: A leading automotive manufacturer reported a 30% increase in tool life by switching to advanced tungsten carbide inserts for engine component machining.

- Aerospace Industry: An aerospace company achieved improved surface finishes and reduced tool wear by using tungsten carbide inserts for machining titanium alloys.

Future Trends in Tungsten Carbide Insert Manufacturing

Future trends in tungsten carbide insert manufacturing include the integration of advanced materials and technologies:

- 3D Printing: The use of 3D printing techniques to produce complex geometries and customized inserts.

- Sustainable Materials: Research into more sustainable binder materials and recycling processes for tungsten carbide.

- Digitalization: Integration of digital tools for optimizing insert design and machining processes.

Conclusion

Tungsten carbide inserts are indispensable in modern machining due to their exceptional hardness, wear resistance, and versatility. Their applications span multiple industries, from automotive to aerospace, and they offer significant benefits in terms of durability and precision. Understanding the types, manufacturing process, benefits, and future trends of these inserts is crucial for selecting the right tool for specific machining needs.

Frequently Asked Questions

1. What are tungsten carbide inserts made of?

Tungsten carbide inserts are primarily made from tungsten carbide, with cobalt acting as a binder. Additional carbides like titanium carbide or tantalum carbide may be added to enhance specific properties.

2. What are the main applications of tungsten carbide inserts?

Tungsten carbide inserts are used in various industries, including automotive, aerospace, medical, oil & gas, construction, and general manufacturing. They are essential for cutting, turning, milling, and boring operations.

3. How are tungsten carbide inserts manufactured?

The manufacturing process involves powder preparation, mixing and milling, shaping, sintering, and sometimes hot isostatic pressing (HIP) to create a dense, hard insert.

4. What are the benefits of using tungsten carbide inserts?

The benefits include durability, precision, heat resistance, and versatility. They provide a longer working life, maintain sharp cutting edges, withstand high temperatures, and can be used with various materials.

5. Why are tungsten carbide inserts preferred over traditional steel tools?

Tungsten carbide inserts are preferred due to their exceptional hardness and wear resistance, which results in a longer tool life and better surface finishes compared to traditional steel tools.

Citations:

[1] https://carbideprovider.com/tungsten-carbide-indexable-inserts-202407252/

[2] https://huanatools.com/complete-application-of-carbide-inserts/

[3] https://www.tungco.com/insights/blog/tungsten-carbide-inserts-useful/

[4] https://onmytoolings.com/how-are-carbide-inserts-made/

[5] https://www.alamy.com/stock-photo/carbide-insert.html

[6] https://www.alamy.com/tungsten-carbide-inserts-image8698841.html

[7] http://www.technologydiamond.com/tools/en/carbide-inserts-chart.html

[8] https://jaibros.com/blogs/from-our-blog/what-are-some-common-applications-for-carbide-inserts

[9] https://www.zgcccarbide.com/news/exploring-the-benefits-and-applations-of-tungsten-carbide-inserts-in-metallurgy-172.html

[10] https://jaibros.com/blogs/from-our-blog/decoding-of-insert-size-angel-specification-and-grades

[11] https://www.sandvik.coromant.com/en-us/tools/inserts-grades

[12] https://www.estoolcarbide.com/article/how-to-understand-the-type-of-carbide-inserts-newsinfo-29.html

[13] https://www.wpiinc.com/blog/post/Why-Tungsten-Carbide-Surgical-Instruments-are-Preferred

[14] https://www.ukocarbide.com/blog/what-are-some-common-applications-for-carbide-inserts/

[15] https://www.estoolcarbide.com/article/why-are-tungsten-carbide-inserts-so-beneficial-today--newsinfo-9.html

[16] https://huanatools.com/how-to-make-the-carbide-inserts/

[17] https://www.kennametal.com/au/en/resources/blog/metal-cutting/selecting-carbide-inserts-for-metalworking.html

[18] https://www.zzbetter.com/new/What-Are-Carbide-Inserts.html

[19] https://www.zgcccarbide.com/news/exploring-the-benefits-and-applications-of-tungsten-carbide-inserts-in-metallurgy-172.html

[20] https://primatooling.co.uk/benefits-of-tungsten-carbide-tooling/

[21] https://todaysmachiningworld.com/magazine/how-it-works-making-tungsten-carbide-cutting-tools/

[22] https://toolingonline.com.au/product/tungsten-carbide-inserts/

[23] https://www.shutterstock.com/search/tungsten-carbide

[24] https://www.istockphoto.com/photos/carbide-insert

[25] https://stock.adobe.com/search?k=carbide

[26] https://www.gettyimages.com.au/photos/tungsten-carbide

[27] https://www.carbidedepot.com/formulas-insert-d.htm

[28] https://www.shutterstock.com/search/insert-carbide

[29] https://www.mmc-carbide.com/us/technical_information/tec_turning_tools/tec_turning_insert/guide/tec_turning_identification

[30] https://stock.adobe.com/search?k=tungsten+carbide

[31] https://www.estoolcarbide.com/tag/carbide-insert-identification-chart/

[32] https://www.istockphoto.com/photos/carbide-cutter-insert

[33] https://www.mmc-carbide.com/us/technical_information/tec_turning_tools/tec_turning_insert

[34] https://commons.wikimedia.org/wiki/Category:Tungsten_carbide_insert_tooling

[35] https://huanatools.com/how-to-identify-carbide-inserts-2/

[36] https://cdn.sandvik.coromant.com/files/sitecollectiondocuments/tools/inserts-and-grades/birth-of-an-insert-infographic/birth-of-an-insert-infographic-enu.pdf

[37] https://www.facettestar.ch/changelanguage/1?returnurl=%2Fhartmetall-wendeplatten-rund-geschliffen-und-geschliffen

[38] https://docs.rs-online.com/33c5/0900766b8001b644.pdf

[39] https://insights.am-ind.com/tungaloy-insert-wear-problems-and-solutions-chart