Content Menu

● Introduction to Tungsten Carbide

>> Historical Background

>> Synthesis Methods

● Chemical Structure and Bonding

>> Crystal Structure

>> Ionic vs. Covalent Bonding: A Comparative Analysis

● Properties of Tungsten Carbide

>> Mechanical Properties

>> Thermal and Electrical Properties

>> Chemical Resistance

● Advanced Applications of Tungsten Carbide

>> Industrial and Consumer Uses

>> Emerging Technologies

● Health, Safety, and Environmental Considerations

>> Occupational Hazards

>> Environmental Impact

● Conclusion

● Frequently Asked Questions

>> 1. Why isn't tungsten carbide considered ionic?

>> 2. Can tungsten carbide rust or corrode?

>> 3. How does cobalt improve tungsten carbide's properties?

>> 4. Is tungsten carbide used in consumer electronics?

>> 5. What's the future of tungsten carbide in green energy?

● Citations:

Tungsten carbide (WC) is a compound of tungsten and carbon renowned for its extraordinary hardness, high melting point, and diverse industrial applications. While its physical properties are well-documented, the nature of its chemical bonding—ionic or covalent—remains a topic of scientific inquiry. This article explores the structure, bonding, properties, applications, and implications of tungsten carbide while addressing its ionic or covalent character.

Introduction to Tungsten Carbide

Historical Background

Tungsten carbide was first synthesized in the late 19th century by French chemist Henri Moissan, who also discovered synthetic diamonds. However, its industrial potential wasn't realized until the 1920s, when German engineers developed cemented carbide tools by combining WC with cobalt binders. This innovation revolutionized machining processes, enabling faster and more durable cutting tools.

Synthesis Methods

Tungsten carbide is produced by reacting tungsten powder with carbon at temperatures between 1,500°C and 2,000°C in a hydrogen or vacuum environment. The reaction follows:

W+C→WC

Modern techniques include:

- Carbothermal Reduction: Using tungsten oxide (WO₃) and carbon in a high-temperature furnace.

- Chemical Vapor Deposition (CVD): For creating thin coatings of WC on substrates.

- Mechanical Alloying: Ball-milling tungsten and carbon powders to achieve nanoscale structures.

Chemical Structure and Bonding

Crystal Structure

Tungsten carbide crystallizes in two primary forms:

1. Hexagonal (α-WC): Stable at room temperature, with tungsten atoms in a hexagonal close-packed (HCP) lattice and carbon occupying half the octahedral interstitial sites.

2. Cubic (β-WC): Forms at temperatures above 2,600°C, adopting a rock-salt structure (B1 type).

The bond length between tungsten and carbon is ~220 pm, shorter than typical ionic bonds (e.g., NaCl: ~280 pm), suggesting strong covalent interactions.

Ionic vs. Covalent Bonding: A Comparative Analysis

| Property | Ionic Bond (e.g., NaCl) | Covalent Bond (WC) |

| Electronegativity | High difference (Δχ = 2.23) | Low difference (Δχ = 0.8) |

| Melting Point | ~800°C | ~2,870°C |

| Electrical Conductivity | Poor (insulator) | High (metallic conductor) |

| Bond Directionality | Non-directional | Directional (localized) |

The small electronegativity difference between tungsten (χ = 2.36) and carbon (χ = 2.55) and the metallic conductivity of WC confirm covalent bonding with metallic characteristics.

Properties of Tungsten Carbide

Mechanical Properties

Hardness:

- Mohs Scale: 9.0–9.5 (diamond = 10).

- Vickers Hardness: 2,200–2,400 HV, outperforming titanium and steel.

- Fracture Toughness: ~6–8 MPa√m, lower than steel but mitigated by cobalt binders in composites.

- Density: 15.6 g/cm³, comparable to uranium and gold.

Thermal and Electrical Properties

- Melting Point: 2,870°C, making it suitable for high-temperature environments.

- Thermal Conductivity: 110 W/m·K, similar to aluminum.

- Electrical Resistivity: ~20 μΩ·cm, enabling use in electrical contacts.

Chemical Resistance

- Resistant to acids (except HNO₃/HF mixtures) and oxidation up to 600°C.

- Vulnerable to molten salts and alkaline solutions.

Advanced Applications of Tungsten Carbide

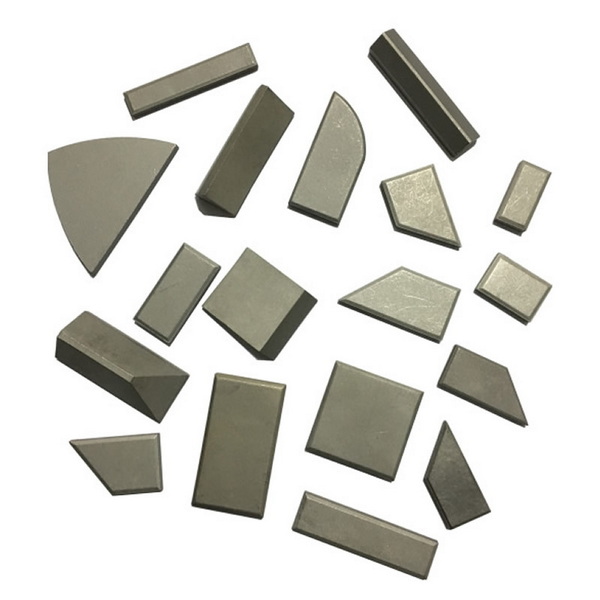

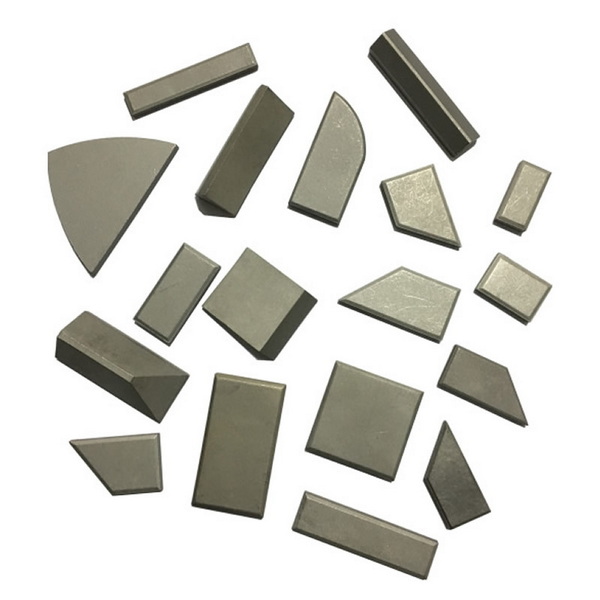

Industrial and Consumer Uses

1. Machining Tools:

- WC-Co composites dominate the cutting tool market (e.g., end mills, inserts).

- Example: Sandvik Coromant's “GC4325” inserts for aerospace alloys.

2. Aerospace:

- Turbine blade coatings and heat shields in rocket nozzles.

3. Medical:

- Surgical tools (e.g., osteotomes) and prosthetics due to biocompatibility.

Emerging Technologies

1. Additive Manufacturing:

- WC powders are used in 3D-printed tools with complex geometries.

2. Nuclear Fusion:

- Investigated as a plasma-facing material in tokamak reactors.

3. Nanotechnology:

- WC nanoparticles enhance catalytic reactions, such as hydrogen evolution.

Health, Safety, and Environmental Considerations

Occupational Hazards

- Pulmonary Effects: Inhalation of WC dust may cause “hard metal lung disease,” a form of pneumoconiosis.

- Carcinogenicity: Classified as a Group 2B carcinogen (possibly carcinogenic) by the IARC.

- Regulations: OSHA mandates workplace exposure limits (<5 mg/m³ for respirable dust).

Environmental Impact

- Mining: Tungsten extraction often involves open-pit mining, leading to habitat destruction.

- Recycling: Up to 95% of WC scrap is recycled via zinc-reclamation processes.

- Sustainability Initiatives: Companies like Kennametal promote closed-loop recycling systems.

Conclusion

Tungsten carbide's covalent bonding underpins its exceptional hardness, thermal stability, and electrical conductivity. Its applications span traditional industries (mining, aerospace) and cutting-edge fields (nuclear fusion, nanotechnology). While challenges like health risks and environmental impact persist, advancements in recycling and additive manufacturing promise a sustainable future for WC utilization.

Frequently Asked Questions

1. Why isn't tungsten carbide considered ionic?

Tungsten carbide lacks the large electronegativity difference required for ionic bonding. Its conductivity and directional bonds align with covalent/metallic characteristics.

2. Can tungsten carbide rust or corrode?

WC is highly corrosion-resistant but degrades in oxidizing acids (e.g., nitric acid) or alkaline solutions.

3. How does cobalt improve tungsten carbide's properties?

Cobalt acts as a binder, enhancing toughness by filling gaps between WC grains.

4. Is tungsten carbide used in consumer electronics?

Yes! It's found in smartphone vibration motors and watch casings for scratch resistance.

5. What's the future of tungsten carbide in green energy?

WC is being studied for hydrogen fuel cell catalysts and wind turbine bearings, supporting renewable energy systems.

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten_carbide

[2] https://chem.libretexts.org/Bookshelves/General_Chemistry/Map:_A_Molecular_Approach_(Tro)/23:_Chemistry_of_the_Nonmetals/23.05:_Carbon_Carbides_and_Carbonates

[3] https://softschools.com/formulas/chemistry/tungsten_iv_carbide_formula/462/

[4] https://www.alamy.com/stock-photo/tungsten-carbide.html

[5] https://www.refractorymetal.org/tungsten-carbide-uses-properties.html

[6] https://www.chemicalbook.com/article/crystal-structure-and-uses-of-tungsten-carbide.htm

[7] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide?page=2

[8] https://en.wikipedia.org/wiki/File:-Alpha_tungsten_carbide_crystal_structure.jpg

[9] https://create.vista.com/photos/tungsten-carbide/

[10] https://www.reddit.com/r/askscience/comments/f26est/how_does_tungsten_bond_with_carbon_to_produce/

[11] https://en.wikipedia.org/wiki/Carbide

[12] https://pubchem.ncbi.nlm.nih.gov/compound/Tungsten-carbide

[13] https://www.freepik.com/free-photos-vectors/tungsten

[14] https://www.shutterstock.com/search/tungsten-metal

[15] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide

[16] https://www.istockphoto.com/photos/tungsten-carbide

[17] https://www.atomic-scale-physics.de/lattice/struk/bh.html

[18] https://en.wikipedia.org/wiki/Tungsten

[19] https://www.vedantu.com/chemistry/carbide