Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

● What Are Heavy Metals?

● Applications of Tungsten Carbide

● Environmental and Health Considerations

● Production Process

● Recycling of Tungsten Carbide

● Comparison with Other Materials

● Future Developments

● Economic Impact

● Conclusion

● FAQs

>> 1. What is Tungsten Carbide Used For?

>> 2. Is Tungsten Carbide Toxic?

>> 3. Can Tungsten Carbide Be Recycled?

>> 4. How Hard is Tungsten Carbide?

>> 5. What is the Difference Between Tungsten and Tungsten Carbide?

● Citations:

Tungsten carbide, often referred to as "hard metal," is a compound made from tungsten and carbon, renowned for its exceptional hardness and wear resistance. It is widely used in industrial applications, including cutting tools, wear-resistant parts, and even consumer goods like wedding rings. However, the question of whether tungsten carbide is considered a "heavy metal" requires a closer examination of its properties and characteristics.

Introduction to Tungsten Carbide

Tungsten carbide is a chemical compound with the formula WC, consisting of tungsten and carbon atoms in a 1:1 ratio. It is produced through a powder metallurgy process, where tungsten carbide powder is mixed with a binder, typically cobalt or nickel, and then sintered at high temperatures to form a dense, hard composite material. The addition of these binders enhances the material's toughness and helps to prevent cracking under stress.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide is extremely hard, ranking about 9.0–9.5 on the Mohs scale, making it one of the hardest substances known, second only to diamond. This property makes it ideal for applications where wear resistance is crucial.

- Density: It is twice as dense as steel, with a density ranging from 15.6 to 15.8 g/cm³, which is slightly less than pure tungsten but still significantly dense. This density contributes to its classification as a heavy material.

- Thermal Properties: Tungsten carbide has a high melting point of approximately 2,870°C and excellent thermal conductivity, making it suitable for high-temperature applications such as rocket nozzles and jet engine components.

- Chemical Stability: It is chemically inert and resistant to corrosion, except when exposed to certain acids like hydrofluoric acid. This stability ensures that it maintains its properties over time in various environments.

What Are Heavy Metals?

Heavy metals are typically defined as metals with relatively high densities and atomic weights. They are often associated with toxicity and environmental concerns. Examples include lead, mercury, and cadmium. However, tungsten, the primary component of tungsten carbide, is not classified as a toxic heavy metal in the same category as these elements. Instead, it is a refractory metal known for its high melting point and density.

Applications of Tungsten Carbide

Tungsten carbide's unique properties make it indispensable in various industries:

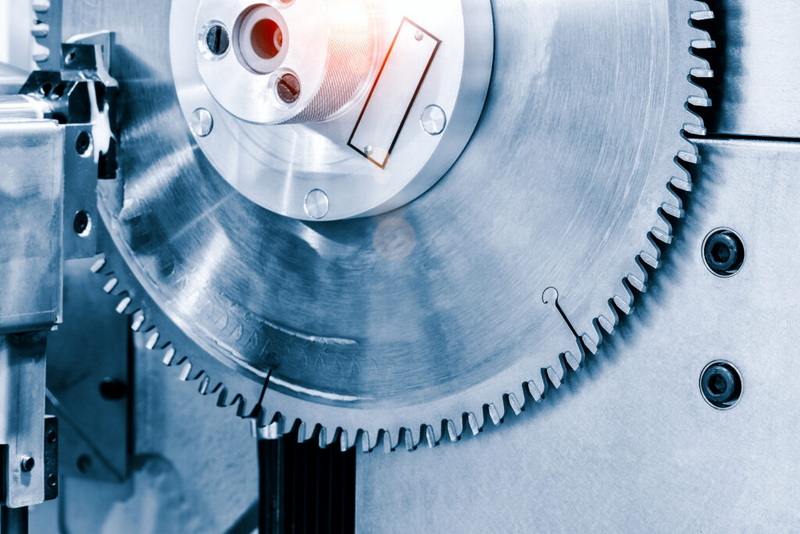

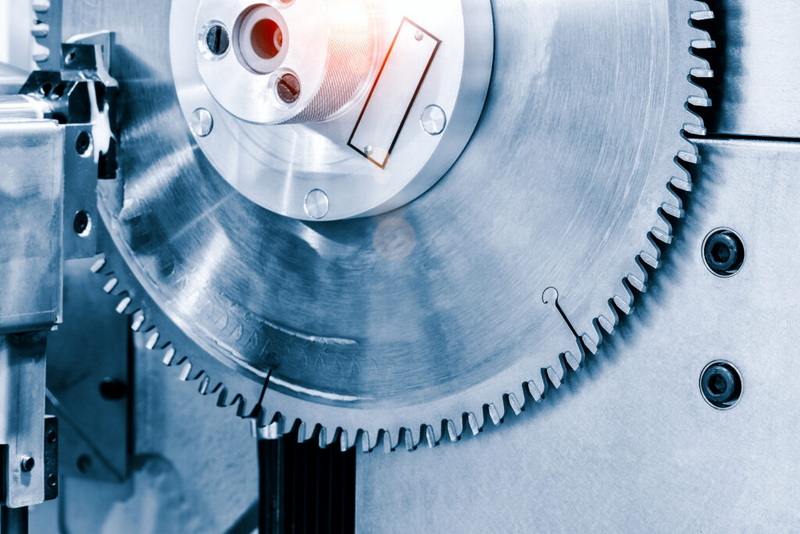

- Industrial Tools: It is used in cutting tools, drill bits, and saw blades due to its hardness and wear resistance. These tools are essential in manufacturing processes where precision and durability are required.

- Aerospace: Tungsten carbide is used in jet engine components and rocket nozzles because of its high thermal stability and resistance to erosion.

- Consumer Goods: It is popular for making jewelry, such as wedding rings, due to its durability and scratch resistance. The aesthetic appeal of tungsten carbide, combined with its strength, makes it a preferred choice for couples seeking durable wedding bands.

- Medical Applications: Tungsten carbide is sometimes used in medical implants due to its biocompatibility and resistance to corrosion.

Environmental and Health Considerations

While tungsten carbide itself is not considered a toxic heavy metal, the production process involves handling fine powders, which can pose health risks if not managed properly. Inhalation of these powders can lead to respiratory issues, emphasizing the need for proper ventilation and protective equipment during manufacturing. Additionally, tungsten carbide is recyclable, which helps reduce waste and conserve resources. Recycling also reduces the environmental impact associated with mining and processing raw tungsten.

Production Process

The production of tungsten carbide involves several steps:

1. Raw Material Extraction: Tungsten is typically extracted from wolframite or scheelite ores.

2. Powder Production: Tungsten is converted into tungsten carbide powder through a carburization process.

3. Mixing with Binders: The tungsten carbide powder is mixed with a binder, such as cobalt or nickel, to enhance its toughness.

4. Sintering: The mixture is then sintered at high temperatures to form a dense, hard composite material.

Recycling of Tungsten Carbide

Recycling tungsten carbide is an important aspect of its lifecycle. Worn-out tools and scrap material can be reclaimed and reused, reducing waste and conserving resources. The recycling process involves collecting scrap material, crushing it into smaller pieces, and then separating the tungsten carbide from other materials. The recovered tungsten carbide can be reused in the production of new tools and components.

Comparison with Other Materials

Tungsten carbide is often compared to other hard materials like diamond and cubic boron nitride (CBN). While diamond is the hardest substance known, it is more expensive and less versatile than tungsten carbide. CBN is another hard material used in cutting tools but is less dense and less wear-resistant than tungsten carbide.

Future Developments

Research into improving the properties of tungsten carbide continues, with advancements in nanotechnology and composite materials offering potential for even greater hardness and toughness. Additionally, efforts to reduce the environmental impact of tungsten mining and to develop more efficient recycling processes are ongoing. Innovations in powder metallurgy techniques are also expected to enhance the efficiency and cost-effectiveness of tungsten carbide production.

Economic Impact

The economic impact of tungsten carbide is significant, as it plays a crucial role in maintaining the efficiency and productivity of various industries. The demand for tungsten carbide is driven by its versatility and the need for durable tools and components in manufacturing and construction. Furthermore, the recyclability of tungsten carbide contributes to its economic sustainability by reducing the need for primary raw materials.

Conclusion

Tungsten carbide is not classified as a toxic heavy metal but is indeed a dense and heavy material due to its composition. Its exceptional hardness, wear resistance, and thermal stability make it a crucial material in various industrial and consumer applications. While it poses some environmental and health challenges during production, its recyclability helps mitigate these issues.

FAQs

1. What is Tungsten Carbide Used For?

Tungsten carbide is used in a variety of applications, including cutting tools, wear-resistant parts in mining and oil industries, aerospace components, and consumer goods like wedding rings.

2. Is Tungsten Carbide Toxic?

Tungsten carbide itself is not considered toxic. However, the production process involves handling fine powders that can pose health risks if not managed properly.

3. Can Tungsten Carbide Be Recycled?

Yes, tungsten carbide is recyclable. Worn-out tools and scrap material can be reclaimed and reused, reducing waste and conserving resources.

4. How Hard is Tungsten Carbide?

Tungsten carbide is extremely hard, ranking about 9.0–9.5 on the Mohs scale, making it one of the hardest substances known, second only to diamond.

5. What is the Difference Between Tungsten and Tungsten Carbide?

Tungsten is a pure metal known for its density and high melting point, while tungsten carbide is a compound of tungsten and carbon, offering superior hardness and wear resistance.

Citations:

[1] https://grafhartmetall.com/en/what-is-tungsten-carbide/

[2] https://en.wikipedia.org/wiki/Tungsten

[3] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[4] https://www.istockphoto.com/photos/tungsten-carbide

[5] https://en.wikipedia.org/wiki/Tungsten_carbide

[6] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[7] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[8] https://ewsllp.in/why-to-choose-tungsten-carbide-over-other-metals/

[9] https://www.hit-tw.com/newsdetails.aspx?nid=298

[10] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html

[11] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[12] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[13] https://www.pollen.am/metal_tungsten/

[14] https://www.alamy.com/stock-photo/tungsten-carbide.html

[15] https://periodictable.com/Elements/074/pictures.html

[16] http://www.tungsten-carbide.com.cn

[17] https://www.freepik.com/free-photos-vectors/tungsten-carbide

[18] https://cowseal.com/tungsten-vs-tungsten-carbide/

[19] http://picture.chinatungsten.com/list-18.html