Content Menu

● Introduction

● What is Tungsten Carbide?

>> Properties of Tungsten Carbide

>> Applications of Tungsten Carbide

● How Hard is Tungsten Carbide?

>> Comparison with Other Materials

● Factors Affecting Hardness

>> Types of Tungsten Carbide

● Advantages of Using Tungsten Carbide

>> 1. Longevity

>> 2. Precision

>> 3. Versatility

>> 4. Aesthetic Appeal

● Challenges Associated with Tungsten Carbide

>> 1. Brittle Nature

>> 2. Cost

>> 3. Machining Difficulties

● Conclusion

● FAQ

>> 1. What is the Mohs hardness scale?

>> 2. How does tungsten carbide compare to steel?

>> 3. Can tungsten carbide be used in high-temperature environments?

>> 4. Is tungsten carbide corrosion-resistant?

>> 5. What industries commonly use tungsten carbide?

Introduction

Tungsten carbide is a remarkable material known for its exceptional hardness and durability. With a Mohs hardness rating of 9, it is second only to diamond, making it an ideal choice for various industrial applications, including cutting tools, mining equipment, and jewelry. This article explores the properties of tungsten carbide, its applications, and answers some frequently asked questions about its hardness and other characteristics.

What is Tungsten Carbide?

Tungsten carbide (WC) is a chemical compound comprised of tungsten and carbon atoms. It is created by heating tungsten powder with carbon black in a hydrogen atmosphere at high temperatures (approximately 1,400°–1,600° C). The resulting material is dense, with a light gray color and a bluish tinge. Unlike many materials that melt, tungsten carbide decomposes at around 2,600° C (4,700° F).

Properties of Tungsten Carbide

Tungsten carbide possesses several notable properties that contribute to its widespread use:

- Hardness: With a Mohs hardness of 9, tungsten carbide is extremely hard and resistant to scratching.

- Strength: It exhibits high compressive strength (up to 4780 MPa) and rigidity, making it suitable for heavy-duty applications.

- Wear Resistance: Tungsten carbide can wear up to 100 times longer than steel under abrasive conditions.

- Thermal Stability: It maintains its hardness at elevated temperatures (up to approximately 1,000°F in oxidizing environments).

- Corrosion Resistance: Certain grades of tungsten carbide offer corrosion resistance comparable to noble metals.

Applications of Tungsten Carbide

Tungsten carbide's unique properties make it valuable across various industries:

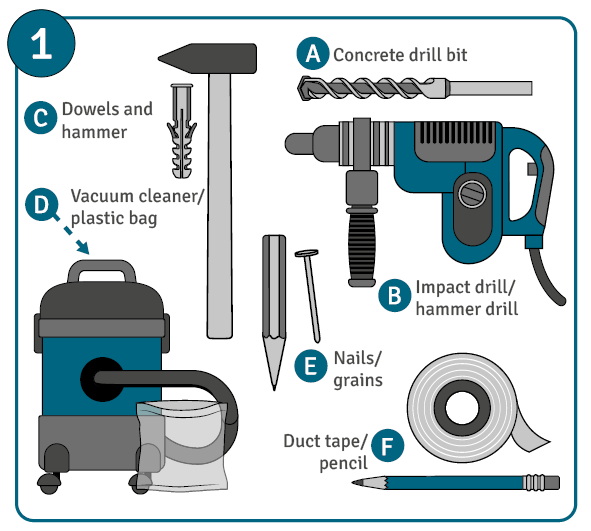

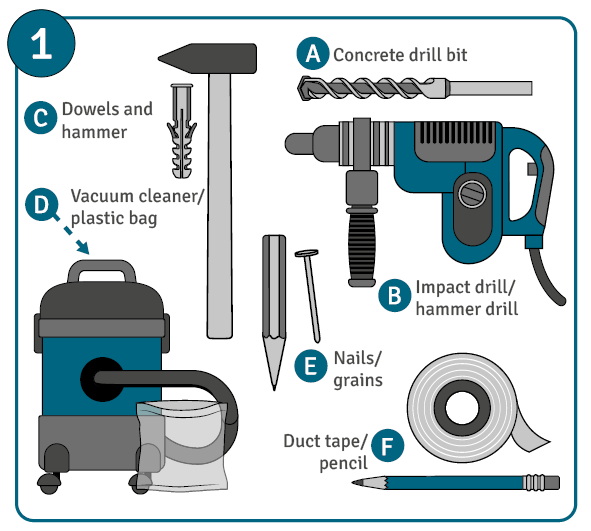

- Cutting Tools: Used in drills, saw blades, and milling tools due to its hardness and wear resistance. Tungsten carbide cutting tools are preferred for their ability to maintain sharp edges longer than traditional steel tools.

Tungsten Carbide Cutting Tools

- Mining Equipment: Employed in drill bits and other mining tools that require durability. The toughness of tungsten carbide allows it to withstand the extreme conditions found in mining operations.

Mining Equipment

- Jewelry: Popular in wedding bands and fashion jewelry due to its scratch resistance and aesthetic appeal. Tungsten carbide rings are favored for their ability to resist scratches while maintaining a polished appearance.

Tungsten Carbide Jewelry

- Industrial Machinery: Utilized in components that require high strength and low friction. For example, tungsten carbide is often used in bearings and valves where wear resistance is crucial.

How Hard is Tungsten Carbide?

The hardness of tungsten carbide is one of its most defining characteristics. On the Mohs scale of mineral hardness, it scores a 9, which means it can only be scratched by diamond. This level of hardness makes it ideal for applications where wear resistance is critical.

Comparison with Other Materials

To better understand tungsten carbide's hardness, it's helpful to compare it with other materials:

| Material | Mohs Hardness | Applications |

| Diamond | 10 | Cutting tools, industrial applications |

| Tungsten Carbide | 9 | Cutting tools, mining equipment |

| Corundum (Sapphire) | 9 | Abrasives, gemstones |

| Steel | 4-8 | General construction |

As illustrated above, tungsten carbide stands out as one of the hardest materials available.

Factors Affecting Hardness

While tungsten carbide is inherently hard, several factors can influence its performance:

- Composition: The ratio of tungsten to carbon can affect the hardness; different grades may exhibit varying levels of hardness. For instance, increasing the carbon content can enhance certain properties but may also affect toughness.

- Manufacturing Process: The method used to create tungsten carbide—such as sintering—can impact its structural integrity and hardness. Sintering involves compacting the powder into a desired shape and then heating it without melting to form a solid mass.

- Temperature: Exposure to extreme temperatures can alter the material's properties; however, tungsten carbide retains much of its hardness even at elevated temperatures.

Types of Tungsten Carbide

There are various grades of tungsten carbide tailored for specific applications:

1. Cemented Tungsten Carbide: This type combines tungsten carbide with cobalt as a binder. It offers excellent toughness and is commonly used in cutting tools.

2. Metal Matrix Composites: These materials incorporate tungsten carbide particles within a metal matrix (like nickel or cobalt), enhancing wear resistance while maintaining ductility.

3. Ultra-Hard Tungsten Carbide: This variant has been engineered for extreme conditions where maximum hardness and wear resistance are needed.

Advantages of Using Tungsten Carbide

The use of tungsten carbide in various applications comes with several advantages:

1. Longevity

Tungsten carbide tools last significantly longer than their steel counterparts due to their superior wear resistance. This longevity translates into cost savings over time since replacement frequency decreases.

2. Precision

In manufacturing processes where precision is key, tungsten carbide tools provide consistent performance. Their ability to maintain sharp edges ensures high-quality finishes on machined parts.

3. Versatility

Tungsten carbide can be tailored for different uses through adjustments in composition and manufacturing processes. This versatility allows it to fulfill diverse roles across industries.

4. Aesthetic Appeal

In jewelry manufacturing, the scratch-resistant nature of tungsten carbide makes it an attractive option for consumers looking for durable yet stylish pieces.

Challenges Associated with Tungsten Carbide

Despite its many advantages, there are some challenges associated with using tungsten carbide:

1. Brittle Nature

While extremely hard, tungsten carbide can be brittle under certain conditions. This brittleness means that while it resists wear well, it may fracture or chip if subjected to excessive impact or stress.

2. Cost

The initial cost of tungsten carbide products can be higher than those made from other materials like steel. However, considering their longevity and performance benefits, they often prove cost-effective over time.

3. Machining Difficulties

Machining or shaping tungsten carbide can be challenging due to its hardness. Specialized equipment and techniques are required to work with this material effectively.

Conclusion

In summary, tungsten carbide is an exceptionally hard material that plays a crucial role in various industrial applications. Its remarkable properties—such as high strength, wear resistance, thermal stability, and aesthetic appeal—make it an invaluable resource across multiple sectors. Understanding the characteristics and applications of tungsten carbide helps industries leverage this material effectively while also addressing the challenges associated with its use.

FAQ

1. What is the Mohs hardness scale?

The Mohs hardness scale is a qualitative scale used to measure the hardness of minerals based on their ability to scratch one another. It ranges from 1 (talc) to 10 (diamond).

2. How does tungsten carbide compare to steel?

Tungsten carbide is significantly harder than steel; it can wear up to 100 times longer than steel under abrasive conditions.

3. Can tungsten carbide be used in high-temperature environments?

Yes, tungsten carbide retains much of its hardness at high temperatures (up to about 1,000°F in oxidizing atmospheres).

4. Is tungsten carbide corrosion-resistant?

Certain grades of tungsten carbide exhibit corrosion resistance comparable to noble metals.

5. What industries commonly use tungsten carbide?

Tungsten carbide is widely used in cutting tools, mining equipment, jewelry manufacturing, and industrial machinery due to its durability and strength.