Content Menu

● Cemented Carbide Production Process: An Overview

>> 1. Raw Material Preparation

>> 2. Powder Blending & Milling

>> 3. Forming

>> 4. Sintering

>> 5. Post-Processing

● The Science of Sintering: A Stage-by-Stage Breakdown

>> Stage 1: Debinding & Pre-Sintering (400°C–800°C)

>> Stage 2: Solid-Phase Sintering (800°C–1300°C)

>> Stage 3: Liquid-Phase Sintering (1400°C–1500°C)

>> Stage 4: Controlled Cooling

● Advanced Sintering Technologies

>> 1. Vacuum Sintering vs Hydrogen Sintering

>> 2. Sinter-HIP Integration

● Cemented Carbide Quality Control

>> Common Sintering Defects & Solutions

● Conclusion

● FAQ

>> 1. What temperature is used for liquid-phase sintering of WC-Co?

>> 2. How long does the entire sintering cycle take?

>> 3. Why is vacuum used instead of ambient air?

>> 4. What's the role of cobalt in cemented carbide?

>> 5. How much shrinkage occurs during sintering?

● Citations:

Cemented carbide production relies heavily on sintering – a thermal consolidation process that transforms powdered tungsten carbide and metallic binders into ultra-hard, wear-resistant components. This article explores the science behind sintering, its critical stages, and how it integrates into modern cemented carbide manufacturing workflows.

Cemented Carbide Production Process: An Overview

The manufacturing of cemented carbide involves five interconnected stages:

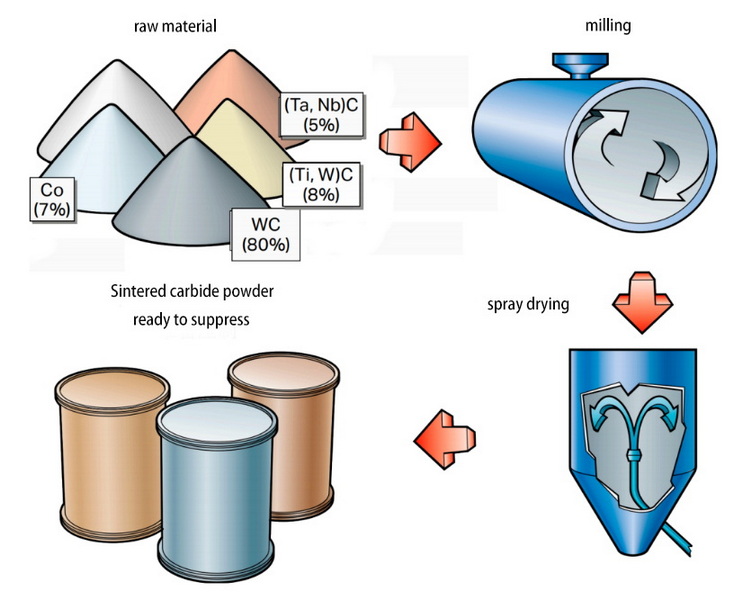

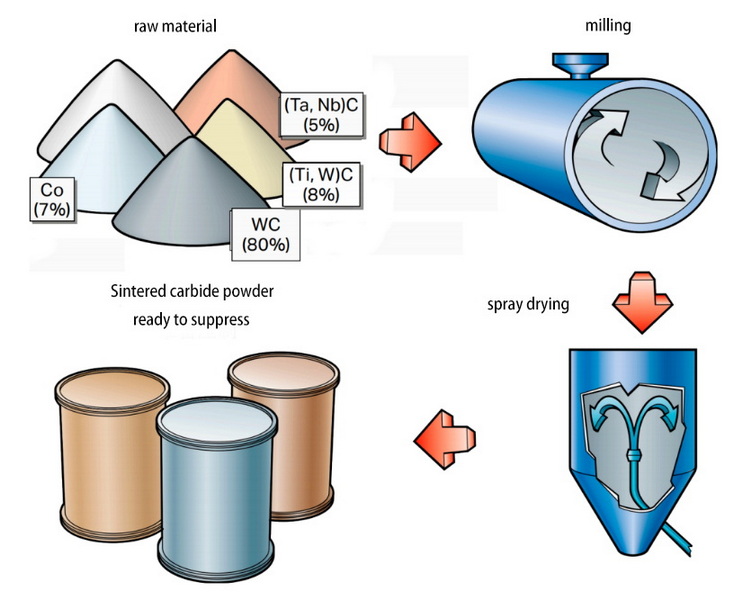

1. Raw Material Preparation

- Tungsten carbide powder (WC) and cobalt (Co) binder are precisely weighed in ratios ranging from 3% to 25% cobalt[6][9].

- Additives like titanium carbide (TiC) may be included for specialized applications[6].

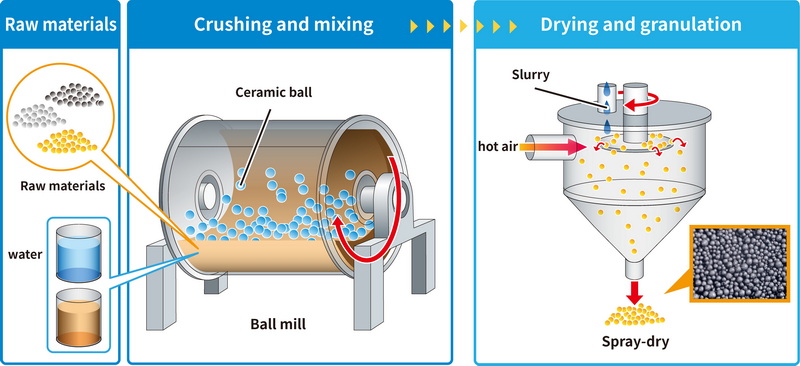

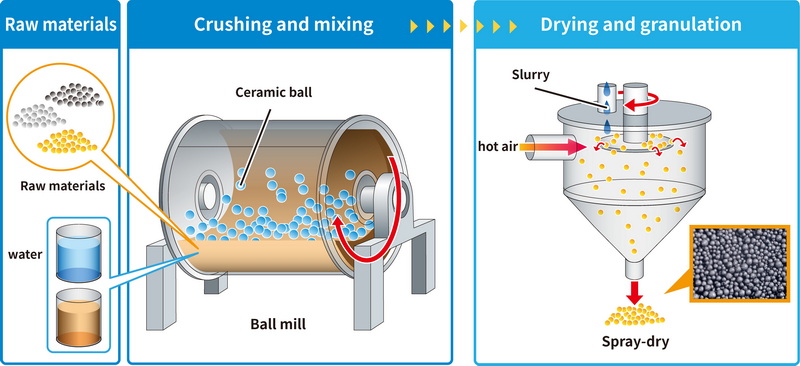

2. Powder Blending & Milling

- Powders undergo wet milling in alcohol for 24-48 hours to achieve homogeneity[9].

- Spray drying creates free-flowing granules ideal for pressing[9].

3. Forming

- Pressing: Hydraulic presses apply 200-400 MPa pressure to create "green" compacts at 50-60% theoretical density[4].

- Injection Molding: Used for complex geometries, requiring 8-15% organic binders[11].

4. Sintering

- The core process achieving full densification through controlled heating cycles[1][3][12].

5. Post-Processing

- Grinding with diamond wheels achieves micron-level tolerances[9].

- Physical vapor deposition (PVD) coatings enhance surface properties[9].

The Science of Sintering: A Stage-by-Stage Breakdown

Stage 1: Debinding & Pre-Sintering (400°C–800°C)

Key Processes:

- Wax Removal: Paraffin/PEG binders decompose into CO₂ and H₂O vapors[4][11].

- Oxide Reduction: Hydrogen atmosphere reduces surface oxides on WC/Co particles[12].

- Carbon Control: Precise atmosphere management prevents η-phase (Co₃W₃C) formation[11].

| Parameter | Typical Value | Impact |

| Heating Rate | 2-5°C/min | Prevents crack formation |

| Hold Time | 1-2 hours | Ensures complete binder removal |

Stage 2: Solid-Phase Sintering (800°C–1300°C)

Material Changes:

- Diffusion Bonding: WC particles develop intergranular necks through surface diffusion[3][5].

- Shrinkage Initiation: Linear dimensional changes reach 10-12%[5].

- Pore Morphology: Open porosity decreases from 25% to <5%[7].

Critical Control Factors:

- Vacuum level: Maintained at 10-2–10-3 mbar to prevent oxidation[8][10]

- Temperature uniformity: ±5°C across furnace hot zone[10]

Stage 3: Liquid-Phase Sintering (1400°C–1500°C)

Process Dynamics:

1. Cobalt melts at 1495°C, forming a metallic matrix[3][10]

2. Capillary forces drive pore elimination through particle rearrangement[5]

3. WC grains grow via Ostwald ripening (average size increases 30-50%)[7]

Performance Outcomes:

| Property | Pre-Sintering | Post-Sintering |

| Hardness | 300 HV | 1400-1800 HV |

| Density | 9-10 g/cm³ | 14-15 g/cm³ |

| TRS* | <200 MPa | 2000-4000 MPa |

Stage 4: Controlled Cooling

Slow Cooling (Furnace Cooling):

- Rate: 5-10°C/min

- Produces coarse-grained structure (better toughness)[7]

Rapid Cooling (Gas Quenching):

- Rate: 50-100°C/min

- Creates fine-grained structure (higher hardness)[10]

Hot Isostatic Pressing (HIP):

- Applies 100 MPa argon pressure during cooling

- Eliminates residual porosity (<0.01%)[8]

Advanced Sintering Technologies

1. Vacuum Sintering vs Hydrogen Sintering

| Parameter | Vacuum Sintering | Hydrogen Sintering |

| Atmosphere | 10-3–10⁻⁴ mbar | H₂ at 1-2 bar |

| Carbon Control | ±0.02% | ±0.05% |

| Surface Finish | Mirror-like | Matte |

| Applications | Precision tools | Mining tools |

2. Sinter-HIP Integration

Combines sintering and hot isostatic pressing in one cycle:

1. Initial vacuum sintering at 1400°C

2. Argon pressurization to 50-100 bar during cooling[8][11]

3. Achieves 99.99% theoretical density

Cemented Carbide Quality Control

Common Sintering Defects & Solutions

| Defect | Causes | Remediation |

| Blisters | Trapped gases | Improve dewaxing, use stepped pre-sintering |

| Cobalt Pooling | Uneven heating | Optimize furnace temperature profile |

| Carbon Loss | Excessive vacuum | Introduce carbon-containing atmosphere |

| η-Phase | Low carbon content | Adjust powder carbon balance |

Conclusion

The sintering process transforms powdered tungsten carbide and cobalt into one of humanity's hardest materials through precise thermal management. From aerospace components to oil drill bits, modern industry relies on this ancient metallurgical technique perfected through vacuum furnaces and computer controls. As additive manufacturing advances, sintering remains the cornerstone of cemented carbide production – a testament to its irreplaceable role in materials engineering.

FAQ

1. What temperature is used for liquid-phase sintering of WC-Co?

The liquid-phase sintering occurs between 1400°C and 1500°C, where cobalt melts to form the binding matrix[3][5][10].

2. How long does the entire sintering cycle take?

Typical cycle times range from 18-36 hours, including heating, sintering, and controlled cooling[4][10].

3. Why is vacuum used instead of ambient air?

Vacuum prevents oxidation and enables precise carbon control through partial pressure adjustments[8][11].

4. What's the role of cobalt in cemented carbide?

Cobalt acts as a metallic binder (6-25% by weight), determining the balance between hardness and toughness[6][9].

5. How much shrinkage occurs during sintering?

Linear shrinkage ranges from 15-25%, requiring careful die design compensation[5][9].

Citations:

[1] https://grafhartmetall.com/en/sinter-process-of-tungsten-carbide/

[2] https://www.notoalloy.co.jp/english/product/ccpp.html

[3] https://kindle-tech.com/faqs/how-do-you-sinter-tungsten-carbide

[4] https://www.carbide-products.com/blog/sintered-tungsten-carbide-components/

[5] https://www.zzbetter.com/new/The-Process-of-Sintering-Tungsten-Carbide.html

[6] https://www.zgcccarbide.com/news/The-Manufacturing-Process-of-Cemented-Carbide-Inserts:-A-Comprehensive-Guide-39.html

[7] https://www.linkedin.com/pulse/common-defects-causes-tungsten-carbide-sintering-nancy-xia

[8] https://www.vacfurnace.com/vacuum-furnace-news/sintering-process-of-cemented-carbide/

[9] https://www.betalentcarbide.com/production-process-of-cemented-carbide-blade.html

[10] https://www.bangerter.com/en/tungsten-carbide/manufacturing-process

[11] https://www.tav-vacuumfurnaces.com/blog/74/en/sintering-of-cemented-carbide-a-user-friendly-overview-pt-1

[12] https://www.linkedin.com/pulse/four-basic-stages-tungsten-carbide-sintering-process-nancy-xia

[13] https://www.sciencedirect.com/topics/chemical-engineering/sintered-carbide

[14] https://www.tav-vacuumfurnaces.com/blog/74/en/sintering-of-cemented-carbide-a-user-friendly-overview-pt-1

[15] https://www.sciencedirect.com/science/article/pii/S027288422401277X

[16] https://www.zgcccarbide.com/news/The-Manufacturing-Process-of-Cemented-Carbide-Inserts:-A-Comprehensive-Guide-39.html

[17] https://video.ceradir.com/what-does-sintering-mean-sintering-process-easily-explained.html

[18] https://www.allied-material.co.jp/en/techinfo/hard-metal/process.html

[19] https://www.youtube.com/watch?v=z5327SSM6G0

[20] https://www.sciencedirect.com/science/article/pii/S026343681830533X

[21] https://allaboutsintering.com/4-sintering-processes-for-silicon-carbide/

[22] https://www.everloy-cemented-carbide.com/en/process

[23] https://www.ceratizit.com/int/en/company/passion-for-cemented-carbide-/production.html

[24] https://www.mmc-carbide.com/permanent/courses/91/cemented-carbides.html

[25] https://www.sciencedirect.com/science/article/abs/pii/S0254058417301712

[26] https://repository.up.ac.za/bitstream/handle/2263/24896/03chapter3.pdf

[27] https://www.sciencedirect.com/science/article/abs/pii/S0263436811000333

[28] https://www.mdpi.com/2073-4352/15/2/146

[29] https://www.shutterstock.com/search/cemented-carbide

[30] https://www.sciencedirect.com/science/article/pii/S2214860423000234

[31] https://www.heattreattoday.com/an-overview-of-cemented-carbide-sintering/

[32] https://www.mmc.co.jp/corporate/en/news/2024/news20240529.html

[33] https://www.sciencedirect.com/science/article/abs/pii/S0032591023008367

[34] https://www.preciseceramic.com/blog/silicon-carbide-reaction-sintering-vs-pressureless-sintering.html

[35] https://www.everloy-cemented-carbide.com/en/column/782/

[36] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[37] https://www.twi-global.com/technical-knowledge/faqs/what-is-sintering

[38] http://www.carbidetechnologies.com/faqs/

[39] https://www.carbide-products.com/blog/sintered-tungsten-carbide-components/

[40] https://www.everloy-cemented-carbide.com/en/knowledge/faq.html

[41] https://www.practicalmachinist.com/forum/threads/carbide-question.86468/post-164612

[42] https://blog.entegris.com/the-future-of-silicon-carbide-manufacturing-innovations-and-techniques

[43] https://en.wikipedia.org/wiki/Sintering

[44] https://www.notoalloy.co.jp/english/product/ccpp.html

[45] https://patents.google.com/patent/WO2003010350A1/en

[46] https://www.linkedin.com/pulse/carbiderod-production-process-forming-cemented-carbide-

[47] https://sumitomoelectric.com/sites/default/files/2020-12/download_documents/73-08.pdf

[48] https://grafhartmetall.com/en/sintering-in-tungsten-carbide-part-manufacturing/

[49] https://www.linkedin.com/pulse/sintering-methods-silicon-carbide-zhiming-peng

[50] https://www.mascera-tec.com/news/common-sintering-processes-for-silicon-carbide-ceramics