Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

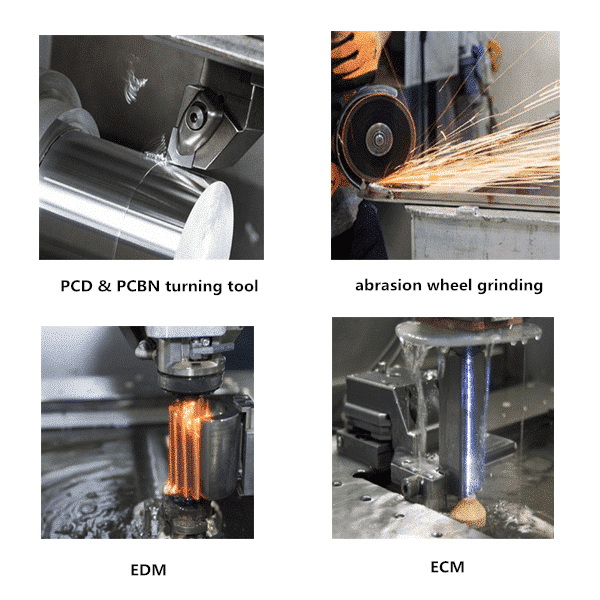

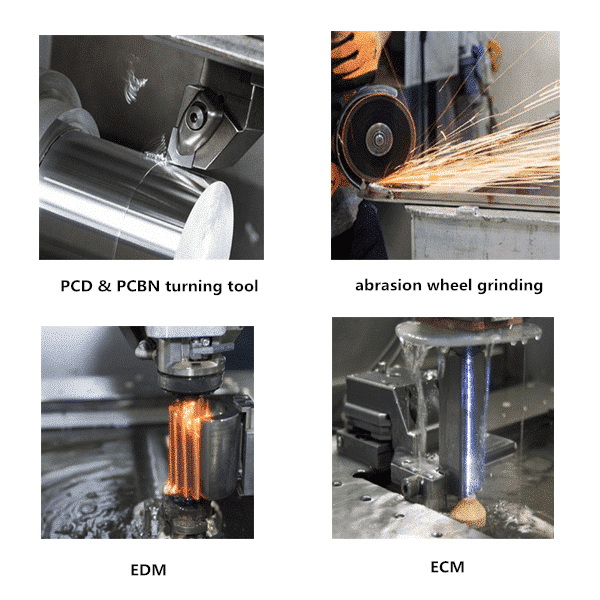

● Methods for Cutting Tungsten Carbide

>> 1. Diamond Saw Blades

>> 2. Carbide-Tipped Tools

>> 3. Wire Cutting

>> 4. Laser Cutting

>> 5. Electric Discharge Machining (EDM)

>> 6. Electrolytic Machining (ECM)

>> 7. Dremel Tool with Carbide Wheel

>> 8. Abrasion Wheels

● Safety Precautions

● Advanced Techniques and Considerations

>> Cooling Systems

>> Tool Maintenance

>> Material Selection

>> Environmental Impact

● Applications of Tungsten Carbide

● Conclusion

● Frequently Asked Questions

>> 1. What is the best tool for cutting tungsten carbide?

>> 2. How do you secure a tungsten carbide rod for cutting?

>> 3. What safety precautions should be taken when cutting tungsten carbide?

>> 4. Can laser cutting be used for tungsten carbide?

>> 5. What are the common applications of tungsten carbide?

● Citations:

Tungsten carbide, known for its exceptional hardness and durability, is a material that poses significant challenges when it comes to cutting. With a hardness ranking of 9 to 9.5 on the Mohs scale, it is surpassed only by diamond and cubic boron nitride in terms of hardness. This makes tungsten carbide an ideal material for applications requiring long-lasting, durable components, such as cutting tools, wear parts, and even jewelry. However, its hardness also means that cutting it requires specialized tools and techniques.

Introduction to Tungsten Carbide

Tungsten carbide is a compound made from equal parts tungsten and carbon, produced by heating tungsten powder with carbon at high temperatures. The resulting material is dense and hard, retaining its properties under extreme conditions. Its exceptional hardness translates into superior wear resistance, making it crucial in many industrial applications.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide ranks 9 to 9.5 on the Mohs scale, with a Vickers hardness of about 2600.

- Durability: It offers superior wear resistance, making it ideal for long-lasting components.

- Brittleness: Despite its hardness, tungsten carbide is brittle and prone to cracking under improper handling.

Methods for Cutting Tungsten Carbide

Cutting tungsten carbide requires specialized tools and techniques due to its hardness and brittleness. Here are some common methods:

1. Diamond Saw Blades

Diamond saw blades are among the most effective tools for cutting tungsten carbide. These blades use high-hardness diamond particles embedded in a metal matrix to grind through the material. Diamond blades are available in various sizes and configurations, making them versatile for different applications.

Diamond saw blades are ideal for precision cutting and can handle the hardness of tungsten carbide efficiently.

2. Carbide-Tipped Tools

Carbide-tipped tools, such as carbide grit blades, are used for rough cuts and shaping. These tools are less precise than diamond blades but are effective for initial shaping or when precision is not critical.

Carbide-tipped tools are widely used in drilling and cutting applications due to their durability.

3. Wire Cutting

Wire cutting, particularly slow wire cutting, offers high precision and is used for intricate shapes. This method involves using a thin wire to erode the material gradually, allowing for complex geometries.

Wire cutting is a precise method suitable for detailed work, especially in applications requiring complex shapes.

4. Laser Cutting

Laser cutting provides non-contact, high-precision results and is ideal for intricate shapes. It uses a high-energy laser beam to vaporize the material, allowing for precise control over the cutting process.

Laser cutting is a versatile method that can handle a variety of materials, including tungsten carbide, with high precision.

5. Electric Discharge Machining (EDM)

EDM uses electrical discharges to erode the material, providing precise control over the cutting process. It is particularly useful for complex shapes and fine details.

EDM is a non-contact method that reduces the risk of mechanical stress and cracking, making it suitable for brittle materials like tungsten carbide.

6. Electrolytic Machining (ECM)

ECM uses electrochemical reactions to remove material, offering a non-contact method that reduces the risk of mechanical stress and cracking.

ECM is less commonly used for cutting tungsten carbide but is effective in specific applications requiring minimal mechanical stress.

7. Dremel Tool with Carbide Wheel

For small-scale or intricate tasks, a Dremel tool equipped with a carbide wheel is highly effective. This setup provides the necessary control for precision work.

Dremel tools are versatile and can be used for detailed work, such as cutting small sections or making fine adjustments.

8. Abrasion Wheels

Abrasion wheels, often diamond-coated, are used for grinding and smooth finishing of tungsten carbide rods. These wheels allow for fine control over the final shape and surface finish.

Abrasion wheels are essential for achieving a smooth, polished surface on tungsten carbide components.

Safety Precautions

When cutting tungsten carbide, safety is paramount due to the material's hardness and brittleness. Essential safety gear includes:

- Safety Glasses: To protect against flying particles.

- Gloves: To prevent cuts and abrasions.

- Dust Mask: To avoid inhaling fine particles generated during cutting.

Proper safety equipment is crucial to prevent injuries and maintain efficiency.

Advanced Techniques and Considerations

Cooling Systems

During the cutting process, it is essential to maintain a cooling system to prevent overheating. This can be achieved using water or coolant, which helps extend the life of the cutting tool and prevent damage to the material.

Tool Maintenance

Regular maintenance of cutting tools is crucial. This includes cleaning and sharpening the blades to ensure optimal performance and longevity.

Material Selection

Choosing the right type of tungsten carbide is important. Different grades offer varying levels of hardness and toughness, which should be selected based on the intended application.

Environmental Impact

The environmental impact of cutting tungsten carbide should be considered. Proper disposal of waste materials and adherence to safety protocols help minimize environmental risks.

Applications of Tungsten Carbide

Tungsten carbide is widely used in various industries due to its unique properties:

- Cutting Tools: Tungsten carbide is used in drill bits, saw blades, and other cutting tools due to its durability.

- Wear Parts: It is used in wear-resistant parts such as nozzles and liners.

- Jewelry: Tungsten carbide jewelry is popular for its hardness and durability.

Conclusion

Cutting tungsten carbide requires specialized tools and techniques due to its exceptional hardness and brittleness. Diamond saw blades, carbide-tipped tools, wire cutting, laser cutting, EDM, ECM, Dremel tools, and abrasion wheels are among the methods used to cut this material. Each method has its advantages and is chosen based on the specific requirements of the project, such as precision, complexity, and safety considerations. Understanding the properties of tungsten carbide and employing the right techniques can ensure efficient and safe cutting processes.

Frequently Asked Questions

1. What is the best tool for cutting tungsten carbide?

The best tool for cutting tungsten carbide is often a diamond saw blade due to its ability to handle the material's hardness efficiently.

2. How do you secure a tungsten carbide rod for cutting?

To secure a tungsten carbide rod, use a vise or clamp to hold it firmly in place, ensuring stability and precision. Avoid applying excessive pressure to prevent cracking.

3. What safety precautions should be taken when cutting tungsten carbide?

Essential safety gear includes safety glasses, gloves, and a dust mask. Ensure proper ventilation and manage heat buildup by cooling the blade periodically.

4. Can laser cutting be used for tungsten carbide?

Yes, laser cutting is a suitable method for cutting tungsten carbide, offering high precision and non-contact cutting, which reduces the risk of mechanical stress.

5. What are the common applications of tungsten carbide?

Tungsten carbide is commonly used in cutting tools, wear parts, and jewelry due to its exceptional hardness and durability.

Citations:

[1] https://shop.machinemfg.com/how-to-cut-tungsten-carbide-rods-an-overview/

[2] https://www.carbide-part.com/blog/how-to-cut-carbide/

[3] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[4] https://tronex-tools.com/products/carbide-hard-wire-taper-head-cutters-medium-long-ergonomic-handle

[5] https://globaldiamondpros.com/products/4-1-2

[6] https://www.ideal-tek.com/catalogue/1/cutters-and-pliers/tungsten-carbide-cutters

[7] https://www.alamy.com/stock-photo/tungsten-carbide.html

[8] https://bladesdirect.net/collections/blades-metal-blades/diamond-blade-9

[9] https://ukam.com/product/tungsten-carbide-dicing-blades/

[10] https://www.toptechdiamond.com/all-about-saw-blade/

[11] https://www.betalentcarbide.com/products/carbide-cutting-tools/

[12] https://www.reddit.com/r/Pottery/comments/jir686/tungsten_carbide_trimming_tool_recommendations/

[13] https://www.youtube.com/watch?v=zk3ZiVOvwFg

[14] https://www.gwstoolgroup.com/understanding-the-different-types-of-carbide-in-cutting-tools/

[15] https://www.reddit.com/r/Tools/comments/18yb0p4/whats_the_best_way_to_cut_into_granite_diamond_or/

[16] https://www.shutterstock.com/search/carbide-cutting-tools

[17] https://stock.adobe.com/search?k=tungsten+carbide

[18] https://www.reddit.com/r/toolgifs/comments/17sgnz3/a_tungsten_carbide_tool_cutting_metal_under_a/

[19] https://www.istockphoto.com/photos/tungsten-carbide

[20] http://www.titaniumkay.com/tungsten-rings/can-you-cut-a-tungsten-carbide-ring/