Content Menu

● Understanding Tungsten Carbide and Steel

● Common Methods for Joining Tungsten Carbide to Steel

>> 1. Brazing

>> 2. Inertial Welding

>> 3. Laser Welding

>> 4. Tungsten Carbide Hardfacing

● Best Practices for Welding Tungsten Carbide to Steel

● Applications of Tungsten Carbide-Steel Joints

● Challenges and Considerations

● Emerging Technologies and Future Trends

● Conclusion

● FAQ

>> 1. What is the most common method for joining tungsten carbide to steel?

>> 2. Can tungsten carbide be directly welded to steel using traditional fusion welding methods?

>> What are the key considerations when preparing surfaces for welding tungsten carbide to steel?

>> 4. How does inertial welding work for joining tungsten carbide to steel?

>> 5. What are some emerging technologies for improving tungsten carbide to steel joints?

● Citations:

Welding tungsten carbide to steel is a specialized process that requires careful consideration of materials, techniques, and equipment. This comprehensive guide will explore the various methods and best practices for joining these dissimilar materials, providing valuable insights for engineers, welders, and fabricators working with tungsten carbide and steel components.

Understanding Tungsten Carbide and Steel

Before delving into the welding processes, it's essential to understand the properties of tungsten carbide and steel:

Tungsten Carbide:

- Extremely hard and wear-resistant

- Brittle and sensitive to thermal shock

- High melting point (2,870°C / 5,198°F)

- Often used as a composite material with cobalt as a binder

Steel:

- Relatively softer than tungsten carbide

- More ductile and impact-resistant

- Lower melting point (1,370-1,530°C / 2,500-2,786°F)

- Widely used in structural applications

These differences in properties make direct fusion welding challenging, necessitating specialized joining techniques.

Common Methods for Joining Tungsten Carbide to Steel

1. Brazing

Brazing is the most widely used method for joining tungsten carbide to steel due to its effectiveness and relatively low heat input[1][2].

Process:

1. Clean and prepare surfaces

2. Apply flux to prevent oxidation

3. Heat the joint area to brazing temperature (600-900°C)

4. Introduce filler metal (usually silver or copper-based alloy)

5. Allow the joint to cool slowly

Advantages:

- Lower heat input, reducing the risk of thermal damage

- Strong, reliable joints

- Suitable for various joint geometries

Considerations:

- Proper surface preparation is crucial

- Filler metal selection impacts joint strength and performance

2. Inertial Welding

Inertial welding, also known as friction welding, is an innovative method for joining tungsten carbide to steel[5].

Process:

1. Clamp one workpiece (usually steel) in a rotating chuck

2. Secure the other workpiece (tungsten carbide) in a stationary chuck

3. Accelerate the rotating workpiece to a predetermined velocity

4. Bring the workpieces into contact under pressure

5. Allow friction to generate heat and form a bond

Advantages:

- No filler material required

- Rapid process with minimal heat-affected zone

- Suitable for cylindrical components

Considerations:

- Limited to specific geometries

- Requires specialized equipment

3. Laser Welding

Laser welding offers precise control and localized heating for joining tungsten carbide to steel[3].

Process:

1. Align workpieces in the welding fixture

2. Focus laser beam on the joint interface

3. Apply filler material if needed

4. Control laser parameters to achieve optimal weld

Advantages:

- Minimal heat input and distortion

- High precision and repeatability

- Suitable for thin materials and complex geometries

Considerations:

- Expensive equipment

- Requires skilled operators

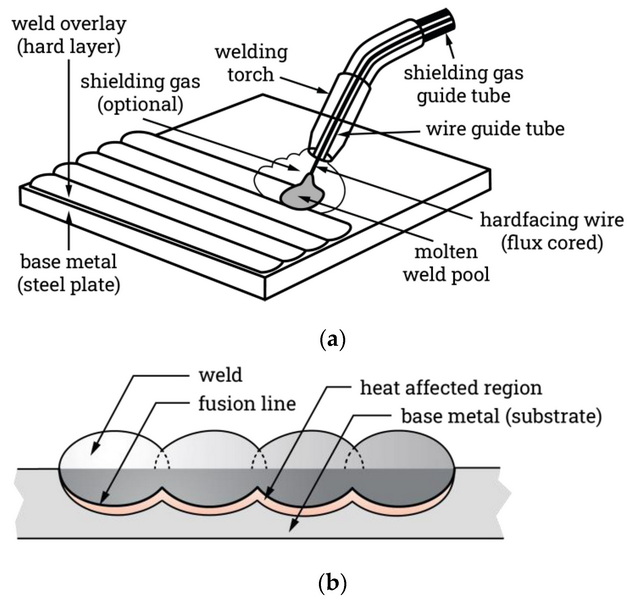

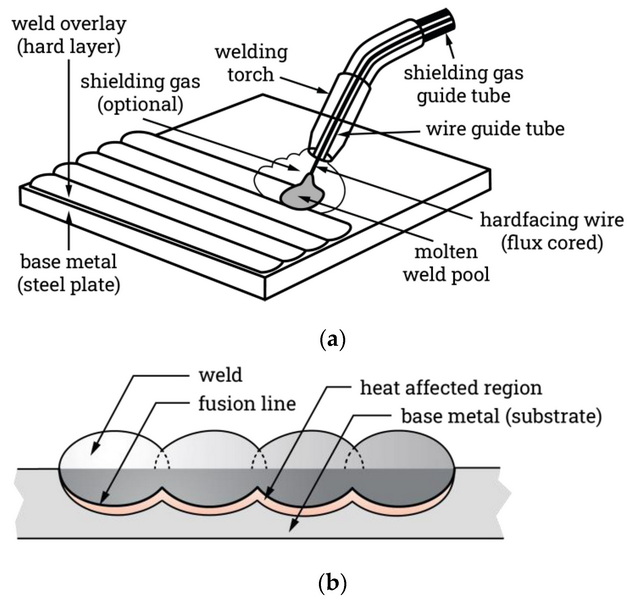

4. Tungsten Carbide Hardfacing

While not a direct welding method, hardfacing with tungsten carbide particles is a popular technique for applying wear-resistant coatings to steel substrates[7].

Process:

1. Clean and prepare the steel surface

2. Apply tungsten carbide-filled welding rod or wire

3. Use oxy-acetylene or other suitable heat source

4. Control heat input to preserve tungsten carbide integrity

Advantages:

- Excellent wear resistance

- Customizable coating thickness and composition

- Suitable for large surface areas

Considerations:

- Not suitable for joining pre-formed tungsten carbide components

- Requires careful control of heat input

Best Practices for Welding Tungsten Carbide to Steel

To achieve successful joints between tungsten carbide and steel, consider the following best practices:

1. Surface Preparation: Thoroughly clean both surfaces to remove contaminants and ensure proper bonding[2].

2. Temperature Control: Minimize heat input to prevent thermal damage to the tungsten carbide[4].

3. Filler Material Selection: Choose appropriate filler metals or alloys compatible with both materials[2].

4. Stress Management: Design joints to minimize stress concentrations and accommodate thermal expansion differences.

5. Post-Weld Treatment: Allow for slow cooling and consider stress-relieving heat treatments when appropriate.

6. Quality Control: Implement rigorous inspection procedures to ensure joint integrity and performance.

Applications of Tungsten Carbide-Steel Joints

The ability to join tungsten carbide to steel opens up numerous applications across various industries:

- Mining and Drilling: Wear-resistant drill bits and cutting tools

- Manufacturing: Cutting inserts and forming dies

- Automotive: Engine components and exhaust systems

- Aerospace: Turbine blade tips and abrasion-resistant coatings

- Military: Armor plating and penetrator cores

Challenges and Considerations

While various methods exist for joining tungsten carbide to steel, several challenges remain:

1. Thermal Expansion Mismatch: The difference in thermal expansion coefficients can lead to residual stresses and potential joint failure.

2. Brittle Nature of Tungsten Carbide: Care must be taken to avoid cracking or chipping during the joining process.

3. Interfacial Reactions: High temperatures can cause undesirable reactions between tungsten carbide and steel, potentially weakening the joint.

4. Cost Considerations: Some joining methods require specialized equipment, increasing production costs.

5. Quality Assurance: Non-destructive testing of tungsten carbide-steel joints can be challenging due to the dissimilar materials.

Emerging Technologies and Future Trends

As materials science and welding technologies advance, new possibilities for joining tungsten carbide to steel are emerging:

1. Hybrid Welding Processes: Combining multiple welding techniques to optimize joint properties.

2. Nanomaterial Interlayers: Using nanostructured materials to improve bonding and reduce thermal stresses.

3. Additive Manufacturing: Exploring 3D printing techniques for creating tungsten carbide-steel composite structures.

4. Advanced Simulation Tools: Developing sophisticated modeling software to predict joint behavior and optimize process parameters.

Conclusion

Welding tungsten carbide to steel presents unique challenges due to the dissimilar properties of these materials. While traditional fusion welding methods are generally unsuitable, techniques such as brazing, inertial welding, laser welding, and hardfacing offer viable solutions for creating strong and durable joints. By understanding the characteristics of both materials and following best practices, engineers and welders can successfully join tungsten carbide to steel for a wide range of industrial applications.

As technology continues to advance, new methods and materials will likely emerge, further expanding the possibilities for creating high-performance tungsten carbide-steel components. Ongoing research and development in this field will undoubtedly lead to improved joining techniques, enhanced joint properties, and novel applications across various industries.

FAQ

1. What is the most common method for joining tungsten carbide to steel?

The most common method for joining tungsten carbide to steel is brazing. This process involves using a filler metal with a lower melting point than both tungsten carbide and steel to create a strong bond between the two materials. Brazing offers several advantages, including lower heat input, which reduces the risk of thermal damage to the tungsten carbide, and the ability to join components with different geometries[1][2].

2. Can tungsten carbide be directly welded to steel using traditional fusion welding methods?

Direct fusion welding of tungsten carbide to steel is generally not recommended due to the significant differences in their properties, such as melting points and thermal expansion coefficients. Traditional fusion welding methods typically generate too much heat, which can cause cracking or degradation of the tungsten carbide. Instead, specialized joining techniques like brazing, inertial welding, or laser welding are preferred for creating strong and reliable joints between these dissimilar materials[3][5].

What are the key considerations when preparing surfaces for welding tungsten carbide to steel?

Surface preparation is crucial for achieving strong bonds between tungsten carbide and steel. Key considerations include:

1. Thorough cleaning to remove any contaminants, oils, or oxides

2. Roughening the surfaces to increase bonding area and mechanical interlocking

3. Ensuring proper fit-up and alignment of the components

4. Applying appropriate flux or protective atmosphere to prevent oxidation during the joining process

5. Handling the materials carefully to avoid damaging the brittle tungsten carbide[2][4]

4. How does inertial welding work for joining tungsten carbide to steel?

Inertial welding, also known as friction welding, is a solid-state joining process that uses rotational motion and friction to generate heat at the interface between tungsten carbide and steel. The process involves the following steps:

1. One workpiece (usually steel) is clamped in a rotating chuck and accelerated to a predetermined velocity

2. The other workpiece (tungsten carbide) is held stationary

3. The rotating piece is brought into contact with the stationary piece under pressure

4. Friction generates heat, plasticizing the materials at the interface

5. Rotation is stopped, and additional pressure is applied to form a solid-state bond

This method offers advantages such as minimal heat-affected zone and the ability to join materials with significantly different melting points[5].

5. What are some emerging technologies for improving tungsten carbide to steel joints?

Several emerging technologies show promise for enhancing the joining of tungsten carbide to steel:

1. Hybrid welding processes that combine multiple techniques (e.g., laser-assisted brazing)

2. Use of nanostructured interlayers to improve bonding and reduce thermal stresses

3. Additive manufacturing methods for creating composite structures

4. Advanced simulation and modeling tools for optimizing joint design and process parameters

5. Development of new filler materials specifically tailored for tungsten carbide-steel joints

These technologies aim to address current challenges and improve the strength, durability, and performance of tungsten carbide-steel components across various industries.

Citations:

[1] https://carbideprocessors.com/pages/brazing-carbide/welding-tungsten-carbide.html

[2] https://passionblade.com/how-can-you-weld-tungsten-carbide/

[3] https://www.mdpi.com/2075-4701/9/11/1161

[4] http://www.metalspiping.com/tungsten-carbides-for-hardfacing.html

[5] https://patents.google.com/patent/US3497942A/en

[6] https://shop.machinemfg.com/how-does-gas-tungsten-arc-welding-work-a-step-by-step-guide/

[7] https://www.alloysint.com.au/tungsten-carbide-hardfacing/

[8] https://hup-pietz.de/en/beschichtungen/wolfram-karbid-schweissung/

[9] https://www.linkedin.com/pulse/how-use-tungsten-carbide-composite-rod-ye-yi

[10] https://forum.weldingtipsandtricks.com/viewtopic.php?t=9273

[11] https://www.linkedin.com/pulse/welding-tungsten-carbide-strips-shijin-lei

[12] https://www.pexels.com/search/tungsten%20carbide%20welding/

[13] https://www.db-thueringen.de/servlets/MCRFileNodeServlet/dbt_derivate_00039282/978-3-7315-0612-6_p99-107.pdf

[14] https://unimig.com.au/the-ultimate-guide-to-tig-welding/

[15] https://hup-pietz.de/en/beschichtungen/wolfram-karbid-schweissung/