Contentus menu

● Intellectus Tungsten Carbide et Steel

● Commune modi ad juncto Tungsten carbide ad ferro

>> I. Brazing

>> II. Inertia Welding

>> III. Laser Welding

>> IV. Tungsten Carbide Hardfacing

● Optimus exercitia enim Welding Tungsten Carbide ad Steel

● Applications of Tungsten Carbide, Steel Articipes

● Provocationes et considerations

● Emerging technologiae et futurum trends

● Conclusio

● Faq

>> I. Quid est maxime commune methodus ad coniungens Tungsten carbide ad ferro?

>> II. Potest Tungsten carbide sit directe welded ad ferro per traditional eget turpis modi?

>> Quid est clavis considerations cum parat superficies ad Welding Tungsten carbide ad ferro?

>> IV. Quomodo enim inertia welding opus ad junctam Tungsten carbide ad ferro?

>> V. Quid sunt aliqui emergentes technologies ad meliorem tangsten carbide ad ferro articulis?

● Citations:

LIBELLUS Tungsten carbide ad Steel est specialized processum quod requirit diligenter consideratione materiae, artes et apparatu. Hoc comprehensive dux et explorandum variis modi et optimum exercitia ad conjunctionem haec dissimiles materiae, providing valuable insights ad engineers, welders, et fabricators operantes cum Tungsten carbide et ferro components.

Intellectus Tungsten Carbide et Steel

Antequam Delving in WELDING processus, suus 'essentiale intelligere proprietatibus Tungsten carbide et ferro:

Tungsten Carbide:

- maxime difficile et gerunt, repugnans

- fragilis et sensitivo ad scelerisque inpulsa

- Altus liquescens Point (2,870 ° F / 5,198 ° F)

- Saepe usus est compositum materia cum Cobalt ut ligans

Steel:

- relative mollior quam Tungsten carbide

- Magis Ductile et Impact-repugnans

- minus liquescens punctum (1,370-1,530 ° C / 2,500-2,786 ° F)

- late in structural applications

Hae differentias in proprietatibus directe fusione welding provocantes, necessitating specialized joining techniques.

Commune modi ad juncto Tungsten carbide ad ferro

I. Brazing

Brazing est maxime late solebat methodus ad joining Tungsten carbide ad ferro ex eius efficaciam et relative humilis calor initus [I] [II].

Processus:

I. Mundare et parare superficiebus

II. Applicare fluxu ad ne oxidatio

III. Calor in iuncturam area ad Cerens Temperature (600-900 ° F)

IV. Inducere filler metallum (plerumque argentum aut aeris, secundum Alloy)

V. Patitur iuncturam ad refrigescant lente

Commoda:

- minus calor initus, reducendo periculum scelerisque damnum

- fortis, certa articulis

- Apta variis iuncturam geometries

Considerations:

- propriis superficiem praeparatio est crucial

- Filler Metal Electio Confacts iuncturam vires et perficientur

II. Inertia Welding

Inertia Welding, etiam notum est friction welding, est innovative modum ad juncturam Tungsten carbide ad ferro [V].

Processus:

I. Fibulae unus workpiece (plerumque ferro) in rotating Chuck

II. Secure altera workpiece (Tungsten carbide) in stabilem Paul

III. Accelerate rotating workpiece ad praefinitum velocitatis

IV. Afferte workpieces in contactu sub pressura

V. Patitur friction ad generare calor et formare vinculum

Commoda:

- non filler materia requiratur

- celeri processus cum minimal calor, affectus zone

- apta cylindricis components

Considerations:

- limited ad specifica geometries

- requirit specialized apparatu

III. Laser Welding

Laser Welding offert praecise imperium et localized calefactio pro jungendo Tungsten carbide ad ferro [III].

Processus:

I. COLIGPIECES in WELDING Fixture

II. Focus laser trabem in iuncturam interface

III. Applicare filler materia si opus

IV. Imperium laser parametri ad consequi optimal weld

Commoda:

- minimal calor input et distortione

- High praecisione et repeatability

- apta tenues materiae et universa geometries

Considerations:

- pretiosa apparatu

- requirit peritos operators

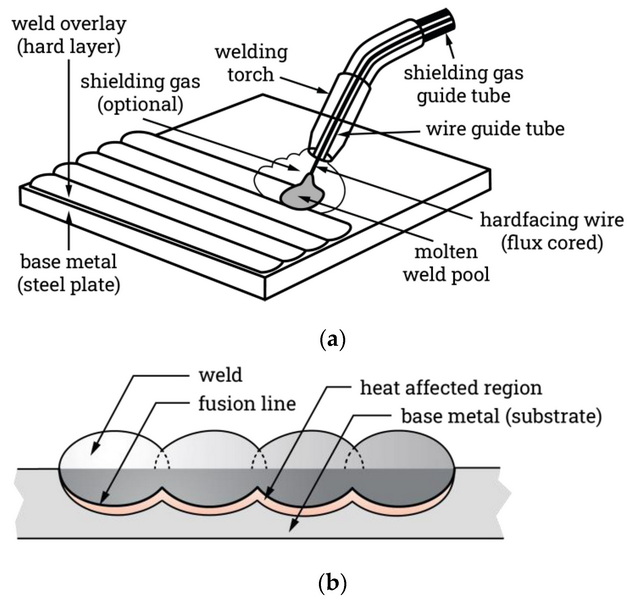

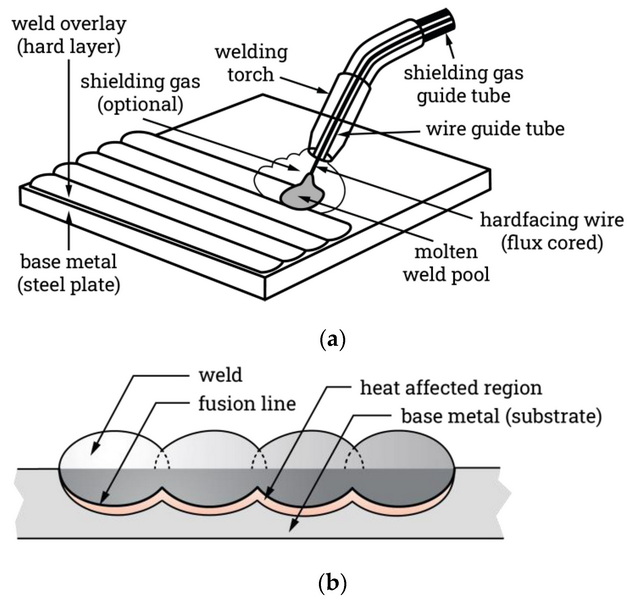

IV. Tungsten Carbide Hardfacing

Dum non recta Welding modum, Hardfacing cum Tungsten carbide particulas est popularis ars ad applicando gerunt, repugnans coatings ad ferro subiecta [VII].

Processus:

I. Mundare et praeparet ferro superficies

II. Applicare Tungsten Carbide-Repleti Welding virga aut filum

III. Usus oxy-acetylene vel idoneam calor fontem

IV. Imperium calor initus ad conservare Tungsten carbide integritas

Commoda:

- optimum gerunt resistentia

- Customizable coating crassitudine et compositionem

- apta ad magnum superficiem areas

Considerations:

- Non idoneam ad conjunctionem pre-formatae Tungsten carbide components

- requirit diligenter imperium calor initus

Optimus exercitia enim Welding Tungsten Carbide ad Steel

Ad consequi felix articulis inter Tungsten carbide et ferro, considerans haec optima exercitia:

I. superficiem praeparatio: mundare utraque superficies ut removendum contaminantium et ensure proper virum vinculum [II].

II. Temperature Control: Minimize calor initus ne scelerisque damnum ad Tungsten carbide [IV].

III. Filler Material Electio: Elige oportet filler metalla aut alloys compatible cum tam materiae [II].

IV. Accentus Management: Design articulis ad minimize accentus concentratione et accommodate scelerisque expansion differentias.

V. Post-Weld Treatment: patitur tardus refrigerationem et considerans accentus-levare calor treatments cum oportet.

VI. Qualitas Imperium: Offends rigorous inspectionem ratio ut iuncturam integritatem et perficientur.

Applications of Tungsten Carbide, Steel Articipes

Et facultatem ad iungere Tullius Carbide ad ferro aperit numerosa applications per varia industries:

- Mining et EXERCITATIO: gere, repugnans terebro bits et secans instrumenta

- Vestibulum: Cutting insertiones et formatam moritur

- Automotive: Engine components et exhauriunt systems

- Aerospace: Turbine Laminas Tips et Abrasion, repugnans coatings

- Military: Armor plating et penetratorium

Provocationes et considerations

Dum variis modi est ad juncturam Tungsten carbide ad ferro, plures challenges manent:

I. Thermal expansion mismatch: differentia in scelerisque expansion coefficientes potest ducere ad residua passiones et potentiale iuncturam defectum.

II. Fortuus natura Tungsten Carbide: curare debet esse capta vitare fregisset vel chipping in joining processus.

III. Interfacial reactiones: altum temperaturis potest facere undesirable reactiones inter Tungsten carbide et ferro, in potentia infirmat iuncturam.

IV. Sumptus considerations: Quidam jungens modi eget specialioribus apparatu, augendae productio costs.

V. Qualitas Fides: Non-perniciosius Testing of Tungsten Carbide, Steel articulis potest provocantes debitum ad dissimilar materiae.

Emerging technologiae et futurum trends

Ut materiae scientiae et Welding Technologies progredi, novum possibilitates ad juncto Tungsten carbide ad ferro sunt emergentes:

I. Hybrid Welding processibus: Combining Multiple Welding Techniques ad optimize iuncturam proprietatibus.

II. Nanomaterial Interlayers: Using Nanostructured Materials ad amplio vinculum et reducere scelerisque passiones.

III. Eminentive vestibulum: exploring 3D printing techniques ad creando Tungsten carbide, ferro compositum structures.

IV. Advanced Simulation Tools: developing sophisticated modeling software praedicere iuncturam mores et optimize processus parametri.

Conclusio

Welding Tungsten Carbide ad Steel Praeses unique challenges debitum ad dissimile proprietatibus harum materiae. Dum traditional eget turpis modi plerumque aliena artes tales ut Brazing, inertia Welding laser Welding et Hardfacing offer viable solutiones creando fortis et oblata articulis. Per intellegendum est characteres et materiae et post optimum exercitia, engineers et welders feliciter iungere Tungsten carbide ad ferro ad amplis industrialis applications.

Ut technology continues ad antecessum, novum modi et materiae erit verisimile emerge, longius expanding ad possibilitates ad creando summus perficientur Tungsten carbide, ferro components. Ongoing investigationis et progressionem in hoc agro et indubitanter plumbum ad emendare junctis techniques, amplitudo iuncturam proprietatibus, et novus applications trans variis industries.

Faq

I. Quid est maxime commune methodus ad coniungens Tungsten carbide ad ferro?

Most commune methodus ad juncturam Tungsten carbide ad ferro est Brazing. Hoc processus involves per filler metallum cum inferioribus liquescens punctum quam tam Tungsten carbide et ferro creare fortis vinculum inter duo materiae. Brazing offert plures commoda, inter minus calor input, quod reduces periculum scelerisque damnum ad Tungsten carbide et facultatem ad iungere components cum diversis geometries [I] [II].

II. Potest Tungsten carbide sit directe welded ad ferro per traditional eget turpis modi?

Direct fusionem Welding of Tungsten carbide ad ferro est plerumque non commendatur ex significant differentias in proprietatibus, ut liquescit puncta et scelerisque expansion coefficientes. Traditum eget Welding modi typically generate nimium calor, quod potest causare fregisset vel degradation of Tungsten carbide. Instead, specialized joining techniques sicut brazing, inertia wellding, aut laser welding sunt maluit ad creando fortis et fideles articulis inter haec dissimilis materiae [III] [III].

Quid est clavis considerations cum parat superficies ad Welding Tungsten carbide ad ferro?

Superficiem praeparatio est crucial ad consequi fortes vincula inter Tungsten carbide et ferro. Key considerations includit:

I. Plus purgatio ad removere aliqua contaminantium, olea, aut oxides

II. Poughening superficiebus ad augendam Bonding area et mechanica Interlocking

III. Cucumque propriis fit, et alignment de components

IV. Applicando oportet fluxu vel tutela atmosphaera ne oxidatio in joining processus

V. tractantem materiae diligenter ad vitare damnosa in fragile Tungsten carbide [II] [IV]:

IV. Quomodo enim inertia welding opus ad junctam Tungsten carbide ad ferro?

Inertia welding, etiam notum est friction welding, est solidum-state joining processus quod usus gyratorius motus et friction ad generate calor ad interface inter Tungsten carbide et ferro. Processus involves haec gradus:

I. Unus workpiece (plerumque ferro) est clamripitur in rotating Paul et accelerated ad praefinitum velocitatem

II. Alii workpiece (Tungsten Carbide) tenuit stabilis

III. Et rotating pars est in contactum cum stationarius pars sub pressura

IV. Friction generat calor, plasticizing materiae ad interface

V. Rotationis cessatur, et additional pressura est applicari ad formare solidum-statum vinculum

Hoc modum praebet commoda ut minimus calor, affectus zonam et facultatem adiungere materiae cum significantly diversis liquescens puncta [V].

V. Quid sunt aliqui emergentes technologies ad meliorem tangsten carbide ad ferro articulis?

Plures emergentes Technologies ostendit promissionem enhancing ad conjunctionem Tungsten carbide ad ferro:

I. Hybrid Welding processibus ut combine multiple techniques (eg, laser-assisted Brazing)

II. Usus Nanostructured interlayers ad amplio vinculum et reducere scelerisque passiones

III. Additive vestibulum modi ad creando compositum structurae

IV. Advanced simulatio et modeling tools pro optimizing iuncturam consilio et processus parametri

V. progressionem novi filler materiae specie tailored pro Tungsten carbide, ferro articulis

Hae technologiae aim ad oratio current provocationes et amplio vires, diuturnitatem, et perficientur Tungsten carbide-ferro components trans variis industries.

Citations:

[I] https://carbideprocessors.com/pages/brazing-carbide/welding-tungsten-carbide.html

[II] https://passsblade.com/how-can-you-weld-tungsten-carbide/

[III] https://www.mdpi.com/2075-4701/9/11/1161

[IV] http://www.metalspiping.com/tungsten-carbides-for-hardfacing.html

[V] https://patents.google.com/patent/us3497942a/en

[VI] https://shop.machinemfg.com/how-does-gas-tungsten-arc-welding-work-sstep-by-step-guide/

[VII] https://www.alloysint.com.au/tungsten-carbide-hardfacing/

[VIII] https://rhup-pietz.de/en/beschichtungen/wolfram-karbid-schweissung/

[IX] https://www.linkedin.com/pulse/how-use-tungsten-carbide-composite-rod-ye-yi

[X] https://forum.weldipstipsandticticks.com/viewtopic.php?t=9273

[XI] https://www.linkedin.com/pulse/welding-thungsten-carbide-strips-shijin-lei

[XII] https://www.pexels.com/search/tungsten%20carbide%20welding/

[XIII] https://www.db-thuaringen.de/servlets/mcrfilenodesvlet/dbt_derivate_00039282/978-3-7315-0612-6_p90-107.pdf

[XIV] https://unimig.com.au/the-ultmate-guide-to-tig-welding/

[XV] https://rhup-pietz.de/en/beschichtungen/wolfram-karbid-schweissung/