Content Menu

● Understanding Cemented Carbide

>> Properties of Cemented Carbide Plates

● Factors to Consider When Choosing Cemented Carbide Plates

>> 1. Application Requirements

>> 2. Grade Selection

>> 3. Size and Thickness

>> 4. Surface Finish

>> 5. Supplier Reliability

● Cost Considerations

● Maintenance and Care

● Conclusion

● Related Questions

>> 1. What are the typical costs associated with different cemented carbide grades?

>> 2. How do surface finishes affect the performance of cemented carbide plates in specific applications?

>> 3. What are the best practices for storing and handling cemented carbide plates to prevent damage?

>> 4. How can I determine the right grade of cemented carbide for my application?

>> 5. What industries commonly use cemented carbide plates?

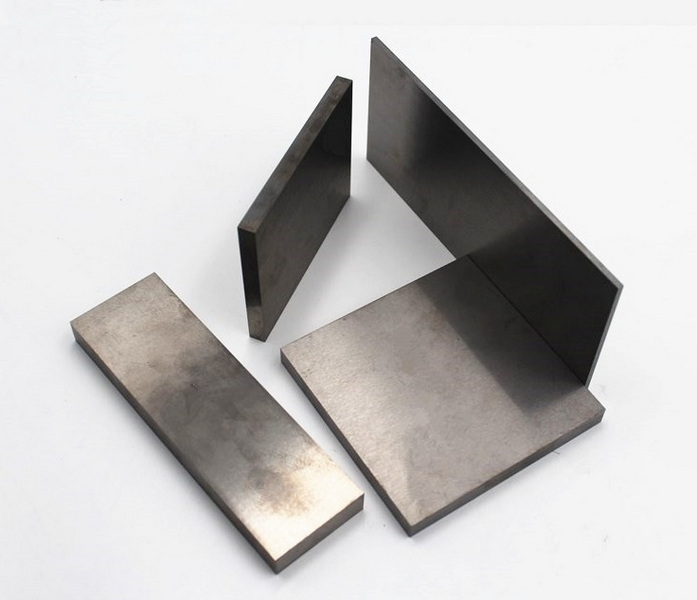

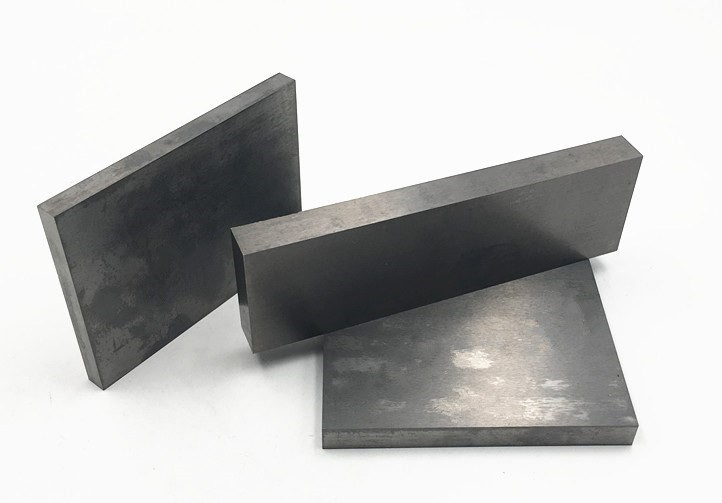

Cemented carbide plates are essential components in various industrial applications due to their exceptional hardness, wear resistance, and durability. Choosing the right wholesale cemented carbide plates can significantly impact the efficiency and longevity of your operations. This article will guide you through the critical factors to consider when selecting these plates, ensuring you make an informed decision that meets your specific needs.

Understanding Cemented Carbide

Cemented carbide, also known as hard metal, is a composite material made from tungsten carbide (WC) and a metal binder, typically cobalt (Co). The combination of these materials results in a product that is incredibly hard and resistant to wear, making it ideal for cutting tools, mining equipment, and various industrial applications.

Properties of Cemented Carbide Plates

1. Hardness: Cemented carbide plates are known for their high hardness, which allows them to withstand significant wear and tear. This property is crucial in applications where materials are subjected to abrasive conditions.

2. Toughness: While cemented carbide is hard, it also possesses a degree of toughness, which helps prevent chipping and cracking under stress.

3. Heat Resistance: These plates can maintain their properties at elevated temperatures, making them suitable for high-speed machining and other heat-intensive applications.

4. Corrosion Resistance: Depending on the binder used, cemented carbide can exhibit good resistance to corrosion, which is essential in certain environments.

Factors to Consider When Choosing Cemented Carbide Plates

1. Application Requirements

The first step in selecting the right cemented carbide plates is to understand the specific requirements of your application. Different industries may have varying needs based on the materials being processed, the operating environment, and the desired outcomes. For instance, plates used in mining may require different properties compared to those used in manufacturing.

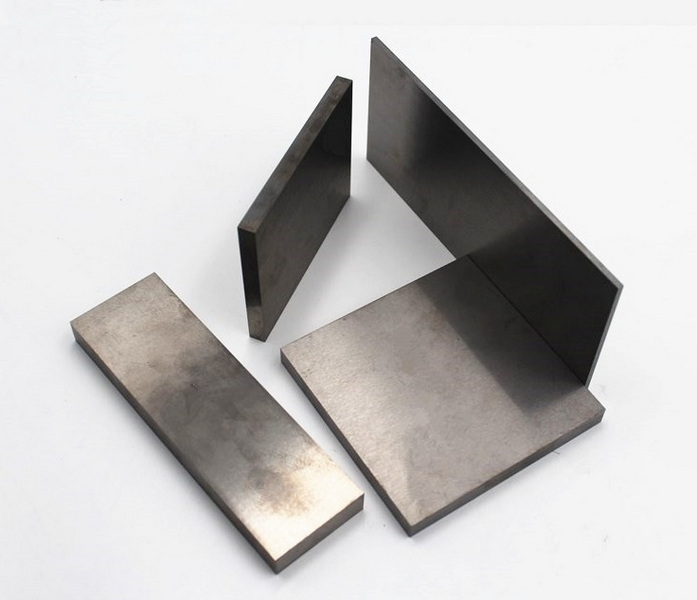

2. Grade Selection

Cemented carbide comes in various grades, each designed for specific applications. The grade is determined by the composition of the carbide and the binder. Common grades include:

- WC-Co: This is the most common type, offering a good balance of hardness and toughness.

- WC-Ni: Nickel-bonded carbide is often used in applications requiring higher corrosion resistance.

- WC-Cr: Chromium-bonded carbide is suitable for high-temperature applications.

Selecting the appropriate grade is crucial for ensuring optimal performance in your specific application.

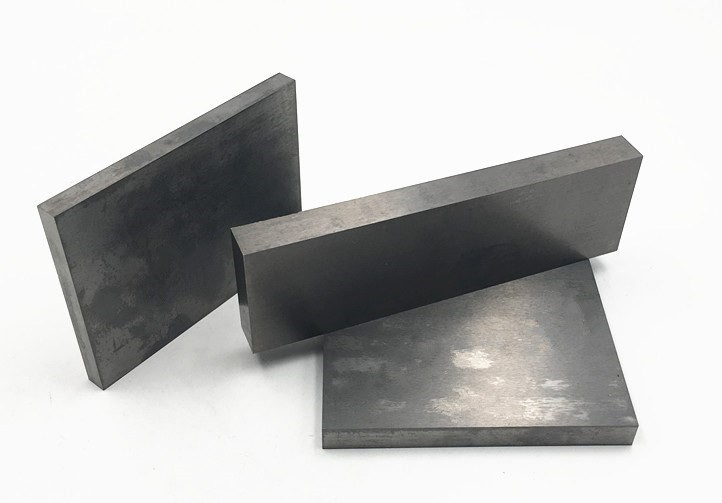

3. Size and Thickness

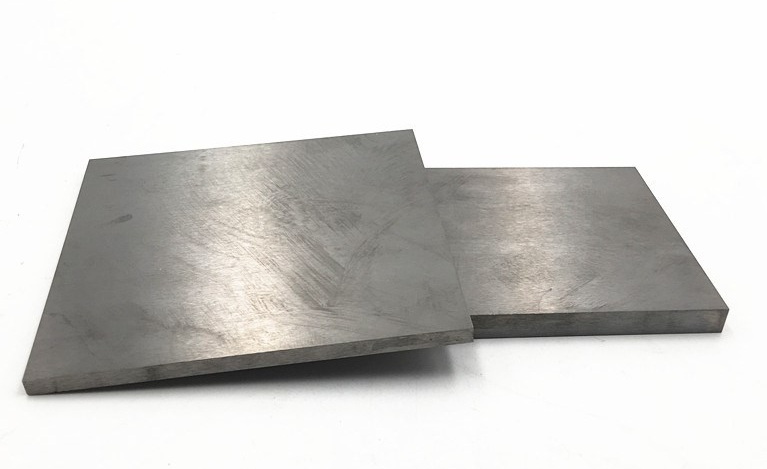

The size and thickness of the cemented carbide plates are also important considerations. Depending on your application, you may need plates of varying dimensions. Ensure that the supplier can provide the specific sizes you require, as this can affect the performance and fit of the plates in your machinery.

4. Surface Finish

The surface finish of cemented carbide plates can significantly impact their performance. A smoother finish can reduce friction and wear, while a rougher finish may be beneficial in certain applications where grip is essential. Discuss your requirements with the supplier to determine the best surface finish for your needs.

5. Supplier Reliability

Choosing a reliable supplier is critical when purchasing wholesale cemented carbide plates. Look for suppliers with a proven track record in the industry, positive customer reviews, and certifications that demonstrate their commitment to quality. A reputable supplier will also provide technical support and guidance in selecting the right products for your application.

Cost Considerations

When purchasing cemented carbide plates, cost is always a factor. Prices can vary significantly based on the grade, size, and supplier. It's essential to balance cost with quality; opting for the cheapest option may lead to higher long-term costs due to premature wear or failure. Request quotes from multiple suppliers and compare not only the prices but also the quality and specifications of the products offered.

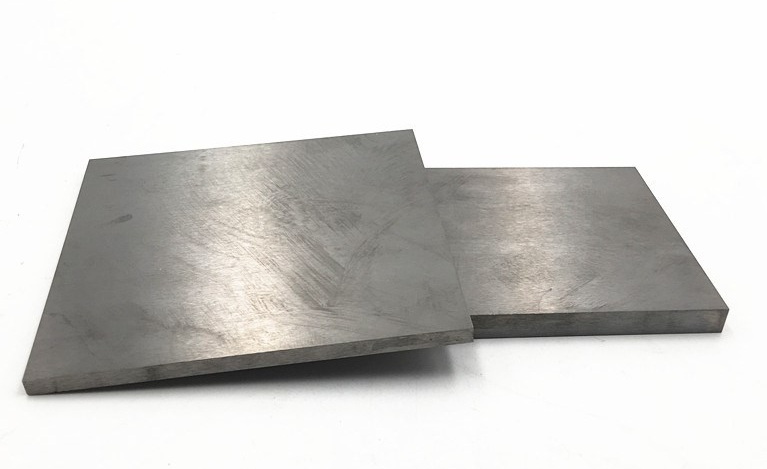

Maintenance and Care

Proper maintenance and care of cemented carbide plates can extend their lifespan and improve performance. Here are some best practices:

- Storage: Store plates in a dry, clean environment to prevent corrosion and damage. Avoid stacking heavy items on top of them.

- Handling: Use appropriate handling techniques to avoid chipping or cracking. Always wear protective gear when handling these materials.

- Cleaning: Regularly clean the plates to remove any debris or contaminants that could affect their performance.

Conclusion

Choosing the best wholesale cemented carbide plates for your industrial applications requires careful consideration of various factors, including application requirements, grade selection, size, surface finish, and supplier reliability. By understanding these elements and conducting thorough research, you can make an informed decision that enhances the efficiency and longevity of your operations.

Related Questions

1. What are the typical costs associated with different cemented carbide grades?

The costs of cemented carbide grades can vary widely based on the composition and manufacturing processes. Generally, higher-grade materials with superior properties will command higher prices. It's essential to compare prices from multiple suppliers and consider the long-term value of the investment.

2. How do surface finishes affect the performance of cemented carbide plates in specific applications?

Surface finishes can significantly impact the performance of cemented carbide plates. A smoother finish can reduce friction and wear, making it ideal for cutting applications, while a rougher finish may provide better grip in applications where traction is necessary.

3. What are the best practices for storing and handling cemented carbide plates to prevent damage?

To prevent damage, store cemented carbide plates in a dry, clean environment and avoid stacking heavy items on top of them. Use appropriate handling techniques and wear protective gear to minimize the risk of chipping or cracking.

4. How can I determine the right grade of cemented carbide for my application?

Determining the right grade involves understanding the specific requirements of your application, including the materials being processed and the operating conditions. Consulting with suppliers and reviewing technical specifications can help you make an informed choice.

5. What industries commonly use cemented carbide plates?

Cemented carbide plates are widely used in industries such as mining, manufacturing, construction, and aerospace. Their exceptional hardness and wear resistance make them suitable for various applications, including cutting tools, wear parts, and industrial machinery.

By considering these factors and questions, you can ensure that you select the best cemented carbide plates for your needs, ultimately enhancing the performance and efficiency of your operations.