Content Menu

● Overview of Silicon Carbide Production Methods

● The Acheson Process: Step-by-Step Breakdown

>> 1. Raw Material Preparation

>> 2. Furnace Loading and Configuration

>> 3. High-Temperature Reaction

>> 4. Cooling and Extraction

>> 5. Crushing and Grading

>> 6. Purification and Quality Control

● Advanced Manufacturing Techniques

>> Physical Vapor Transport (PVT)

>> Chemical Vapor Deposition (CVD)

● Post-Processing and Shaping

>> Forming Technologies

>> Sintering Advancements

● Industrial Applications

>> Sector-Specific Requirements

● Environmental and Economic Considerations

>> Energy Optimization

>> Recycling Initiatives

● Future Trends in SiC Manufacturing

● Conclusion

● FAQs

>> 1. Why does the Acheson process use sawdust?

>> 2. What's the typical purity of Acheson-process SiC?

>> 3. How long does a full production cycle take?

>> 4. Can SiC be recycled?

>> 5. Why is CVD preferred for electronics?

● Citations:

Silicon carbide (SiC) has become indispensable across industries ranging from aerospace to semiconductors due to its extreme hardness, thermal stability, and chemical resistance. This article explores the industrial production methods, focusing on the Acheson process, while also covering advanced techniques like Physical Vapor Transport (PVT) and Chemical Vapor Deposition (CVD).

Overview of Silicon Carbide Production Methods

Two primary methods dominate SiC manufacturing:

1. Acheson Process: The traditional, large-scale method for producing abrasive-grade SiC.

2. Physical Vapor Transport (PVT): Used for high-purity single crystals in electronics.

3. Chemical Vapor Deposition (CVD): Specialized for thin-film semiconductor applications.

This article focuses on the Acheson process, which accounts for over 90% of industrial SiC production.

The Acheson Process: Step-by-Step Breakdown

1. Raw Material Preparation

The silicon carbide production process begins with meticulous raw material selection:

- Silica sand: Sourced from quartz deposits, requiring ≥99.5% SiO₂ purity.

- Carbon sources: Petroleum coke (preferred for low ash content) or anthracite coal.

- Additives:

- Sawdust (5–10% by weight) to create gas escape channels.

- Sodium chloride (2–3%) lowers reaction temperature from 2,600°C to 2,400°C.

Modern facilities use laser-induced breakdown spectroscopy (LIBS) for real-time composition analysis of raw materials.

2. Furnace Loading and Configuration

The heart of silicon carbide production lies in the electric resistance furnace:

- Design: Rectangular steel shell with 500–1,000mm thick refractory lining.

- Electrodes: Graphite rods (300–500mm diameter) deliver 100–200V DC power.

- Core assembly: Carbon black mixed with 10% binder forms the conductive core.

A typical production batch uses:

| Component | Quantity | Purpose |

| SiO₂/C mixture | 50–100 tons | Reaction mass |

| Salt additive | 1–2 tons | Flux agent |

| Sawdust | 3–5 tons | Porosity control |

3. High-Temperature Reaction

The carbothermal reduction occurs in three phases:

1. Preheating (0–1,800°C): 12–18 hours to drive off volatiles.

2. Reaction phase (2,100–2,500°C):

SiO2+3C→SiC+2CO↑

CO gas emission peaks at 2.5 tons per batch.

3. Crystal growth (2,500–2,700°C): α-SiC hexagonal platelets form.

Advanced thermal imaging systems monitor temperature gradients within ±25°C.

4. Cooling and Extraction

Post-reaction handling requires precision:

- Controlled cooling: Nitrogen purging accelerates cooling to 5–7 days.

- Zonal extraction: The boule contains distinct regions:

- Inner core: High-purity green SiC (Mohs 9.5).

- Middle layer: Black SiC with 1–3% free carbon.

- Outer crust: Unreacted material (15–25% of total mass).

5. Crushing and Grading

Modern silicon carbide production lines employ:

- HPGR crushers: High-pressure grinding rolls reduce energy use by 30% vs jaw crushers.

- Air classification: Achieves particle size distributions of:

- Coarse grits: 12–240 mesh (1,680–53 μm).

- Micron powders: D97 ≤ 10 μm.

6. Purification and Quality Control

Post-processing ensures material consistency:

- Acid leaching:

- Hydrofluoric acid (5–15%) removes SiO₂.

- Sulfuric acid (20%) eliminates metallic impurities.

- Laser diffraction: Verifies particle size distribution.

- XRD analysis: Confirms β-SiC content <0.5% in α-SiC products.

Advanced Manufacturing Techniques

Physical Vapor Transport (PVT)

Semiconductor-grade SiC requires specialized growth:

1. Seed preparation: 4H-SiC wafers polished to Ra <0.2nm.

2. Growth parameters:

- Temperature gradient: 15–25°C/cm.

- Pressure: 5–50 mbar.

3. Defect mitigation:

- Basal plane dislocation density: <100 cm².

- Micropipe defects: Eliminated in modern 150mm wafers.

Chemical Vapor Deposition (CVD)

For power electronics applications:

Precursor gases:

- Silicon source: SiH₄ (5–10% in H₂).

- Carbon source: C₃H₈ or CH₃SiCl₃.

Growth rates:

- Bulk growth: 0.3–1.0 mm/hr.

- Epitaxial layers: 10–50 μm/hr.

Post-Processing and Shaping

Forming Technologies

| Method | Pressure | Density Achieved | Applications |

| Dry Pressing | 50–200 MPa | 60–75% TD | Refractory bricks |

| Cold Isostatic | 200–400 MPa | 75–85% TD | Armor tiles |

| Injection Molding | 70–150 MPa | 55–65% TD | Complex geometries |

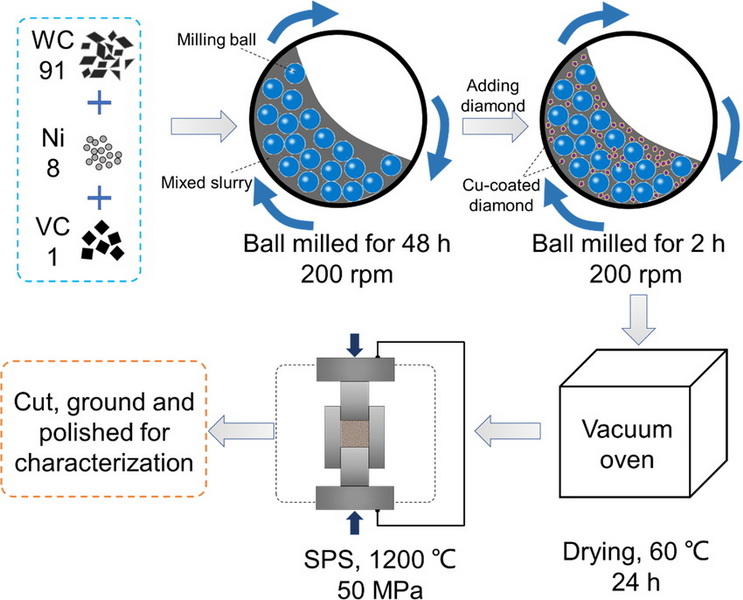

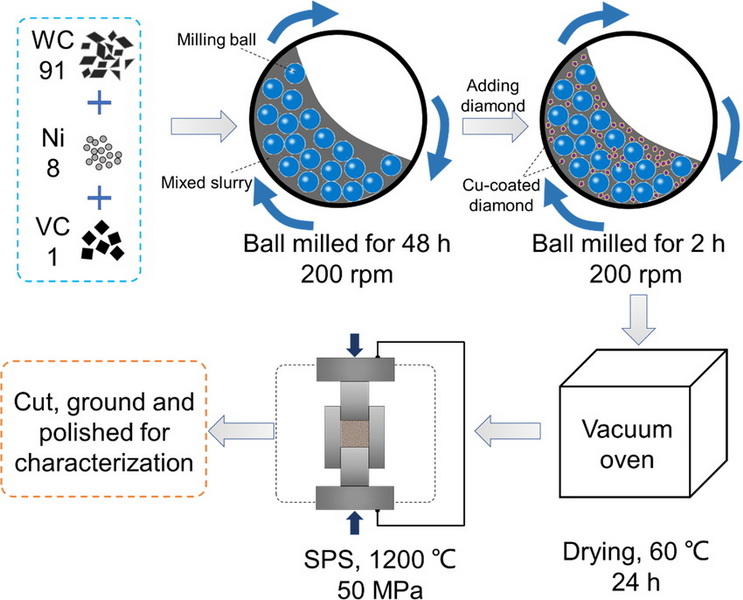

Sintering Advancements

Innovations in silicon carbide production include:

Solid-state sintering:

- Additives: B₄C + C (0.5–2.0%).

- Temperature: 2,100–2,200°C.

Liquid-phase sintering:

- Al₂O₃-Y₂O₃ fluxes enable densification at 1,850–1,950°C.

Industrial Applications

Sector-Specific Requirements

| Industry | Key Properties | SiC Grade |

| Electric Vehicles | Thermal conductivity ≥200 W/mK | 4H-SiC wafers |

| Spacecraft | Radiation hardness | High-purity CVD |

| Metal Cutting | Fracture toughness ≥4 MPa·√m | Sintered α-SiC |

Case Study: Tesla's Model 3 inverter uses 24 SiC MOSFETs, reducing power losses by 75% compared to Si IGBTs.

Environmental and Economic Considerations

Energy Optimization

Modern silicon carbide production facilities implement:

- Waste heat recovery: 40–50% of furnace heat converted to steam power.

- DC arc furnaces: Reduce energy consumption to 6–8 kWh/kg.

Recycling Initiatives

Closed-loop systems recover:

- 92–95% of abrasive grit via hydrocyclone separation.

- 70% furnace off-gas CO for methanol synthesis.

Future Trends in SiC Manufacturing

1. Larger crystal growth: 200mm wafer production by 2026.

2. Additive manufacturing: Binder jetting of SiC components with 99.3% density.

3. AI integration: Machine learning predicts optimal furnace parameters with 94% accuracy.

Conclusion

The silicon carbide production process combines century-old principles with cutting-edge innovations. While the Acheson process remains dominant for bulk production, PVT and CVD enable advanced applications in power electronics. Future advancements in furnace design, recycling, and digitalization will further solidify SiC's role as a critical material for extreme environments, with the global SiC market projected to reach $10.6 billion by 2028.

FAQs

1. Why does the Acheson process use sawdust?

Sawdust burns during heating, creating gas escape channels that prevent pressure buildup and improve reaction uniformity.

2. What's the typical purity of Acheson-process SiC?

Commercial grades reach 98–99.5% purity, while acid-washed variants exceed 99.9%.

3. How long does a full production cycle take?

From raw materials to final powder: 15–20 days (including 7–10 days cooling).

4. Can SiC be recycled?

Yes – up to 40% of grinding wheel waste is reclaimed via crushing and magnetic separation.

5. Why is CVD preferred for electronics?

CVD achieves defect densities <1 cm² versus 10⊃3;–10⁴ cm² in PVT crystals.

Citations:

[1] https://www.linkedin.com/pulse/silicon-carbide-sic-industrial-production-methods-francois-xavier-xqf7e

[2] https://www.ipsceramics.com/how-is-silicon-carbide-made/

[3] https://materials.iisc.ac.in/~govindg/silicon_carbide_manufacture.htm

[4] https://www.linkedin.com/pulse/comprehensive-guide-silicon-carbide-from

[5] https://www.linkedin.com/pulse/production-process-silicon-carbide--wrstc

[6] https://www.domill.com/What-is-the-Silicon-Carbide-Powder-Making-Process-Flow.html

[7] https://www.xinliabrasive.com/Production-process-of-black-silicon-carbide.html

[8] https://www.semi-cera.com/news/silicon-carbide-wafer-production-process/

[9] https://kindle-tech.com/faqs/how-do-you-process-silicon-carbide

[10] https://www.washingtonmills.com/silicon-carbide/sic-production-process

[11] https://www.azom.com/article.aspx?ArticleID=3271

[12] https://patents.google.com/patent/US20140315373A1/en

[13] https://www.linkedin.com/pulse/manufacturing-process-production-flow-silicon-carbide-saggars-l57ic

[14] https://www.crystec.com/crysice.htm

[15] https://en.wikipedia.org/wiki/Acheson_process

[16] https://www.ntnu.no/blogger/teknat/en/2020/12/15/role-of-silicon-carbide-sic-in-silicon-ferro-silicon-si-fesi-process/

[17] https://newsroom.st.com/media-center/press-item.html/c3262.html

[18] https://www.matek.com/en-global/Tech_Article/detail/all/all/202205-IAR

[19] https://www.wolfspeed.com/company/news-events/news/wolfspeed-opens-the-worlds-largest-200mm-silicon-carbide-fab-enabling-highly-anticipated-device-production/

[20] https://wiredspace.wits.ac.za/bitstreams/09da15cb-8cc1-4573-b55e-b4ed15050145/download

[21] https://www.sglcarbon.com/en/newsroom/stories/why-silicon-carbide-semiconductors-have-a-bright-future/