Content Menu

● Material Properties and Composition

>> Carbide: Tungsten Carbide-Cobalt Alloys

>> High-Speed Steel (HSS)

● Key Advantages of Carbide in Drilling

>> Hardness and Wear Resistance

>> Heat Resistance and Thermal Stability

>> Efficiency and Productivity

● Role of Steel in Modern Drilling Applications

>> Flexibility and Cost-Effectiveness

>> Hybrid Designs: Carbide-Tipped Steel Drills

● Industrial Applications of Production Carbide and Steel

>> Oil & Gas Industry

>> Aerospace Manufacturing

>> Construction Sector

● Comparative Analysis: Carbide vs. Steel Drills

● Innovations in Carbide-Steel Drill Technology

>> Geometric Optimization

>> Advanced Coatings

>> Smart Tooling Systems

● Environmental and Economic Impact

>> Waste Reduction

>> Energy Efficiency

● Practical Considerations for Optimal Use

>> Machine Setup

>> Operating Parameters

>> Maintenance Tips

● Conclusion

● FAQs

>> 1. What is the primary advantage of carbide over HSS drills?

>> 2. Are carbide drills cost-effective despite higher initial costs?

>> 3. Can carbide and steel be combined in drill design?

>> 4. What industries benefit most from carbide drills?

>> 5. How does heat treatment affect drill performance?

● Citations:

Drilling technologies have evolved significantly with the introduction of advanced materials like production carbide and steel, which deliver unparalleled performance in industrial, military, aerospace, and construction applications. Carbide, composed primarily of tungsten carbide and cobalt, offers exceptional hardness and heat resistance, while high-speed steel (HSS) provides flexibility and cost-effectiveness. Together, these materials address the challenges of modern machining, enabling faster, more precise, and durable drilling solutions. This article explores their unique properties, synergistic benefits, and applications across industries.

Material Properties and Composition

Carbide: Tungsten Carbide-Cobalt Alloys

Carbide drills are manufactured from a composite of tungsten carbide (WC) particles bonded with a cobalt matrix through sintering at 1,400–1,600°C. This combination achieves:

- Hardness: 9–9.5 on the Mohs scale (nearly as hard as diamond), surpassing most metals.

- Heat Resistance: Maintains structural integrity at temperatures exceeding 1,000°C.

- Wear Resistance: 5x longer lifespan than steel in abrasive environments like sandstone or fiberglass composites.

High-Speed Steel (HSS)

HSS drills, alloyed with tungsten (14–18%), chromium (4%), vanadium (1–5%), and cobalt (5–10%), excel in:

- Toughness: Absorbs vibrations and resists chipping during interrupted cuts.

- Cost-Efficiency: 30–50% lower upfront costs for moderate drilling tasks.

- Versatility: Suitable for wood, plastic, and non-ferrous metals like aluminum.

Key Advantages of Carbide in Drilling

Hardness and Wear Resistance

Carbide's extreme hardness allows it to drill through hardened steel (HRC 60+), stainless steel (ISO M-group), and titanium (Grade 5) without rapid wear. For example:

- Mining Industry: Carbide-tipped roof bolting drills reduce tool replacement frequency by 70% in iron ore operations.

- Automotive: Carbide twist drills achieve 10,000+ holes in cast iron engine blocks vs. HSS's 2,000.

Heat Resistance and Thermal Stability

Carbide's low thermal expansion coefficient (5.5 µm/m·K) minimizes deformation under heat. Inner cooling channels in tools like Dormer Pramet's Force X series reduce cutting temperatures by 200°C, enabling 3–5x faster drilling than HSS.

Efficiency and Productivity

- Faster Feed Rates: Carbide drills operate at 80–120 m/min in steel vs. HSS's 20–30 m/min.

- Precision: Achieves ±0.05 mm tolerances in aerospace wing spar components.

Role of Steel in Modern Drilling Applications

Flexibility and Cost-Effectiveness

HSS drills remain ideal for low-to-medium demand tasks:

- Woodworking: Reduced risk of splintering in oak or maple.

- Aluminum Machining: M35 HSS drills last 2x longer than standard HSS in 6061-T6 aluminum.

Hybrid Designs: Carbide-Tipped Steel Drills

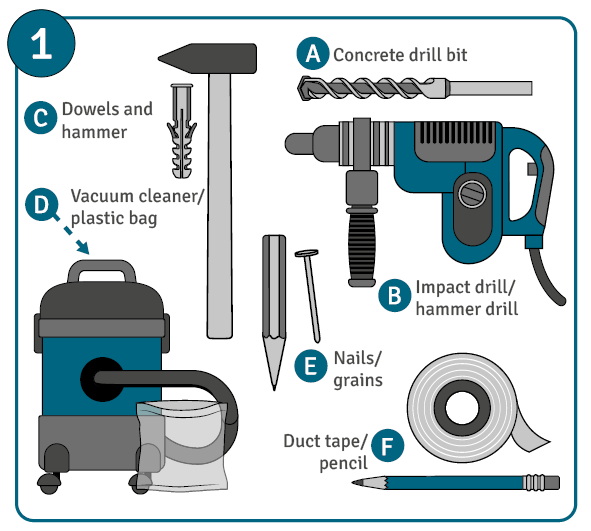

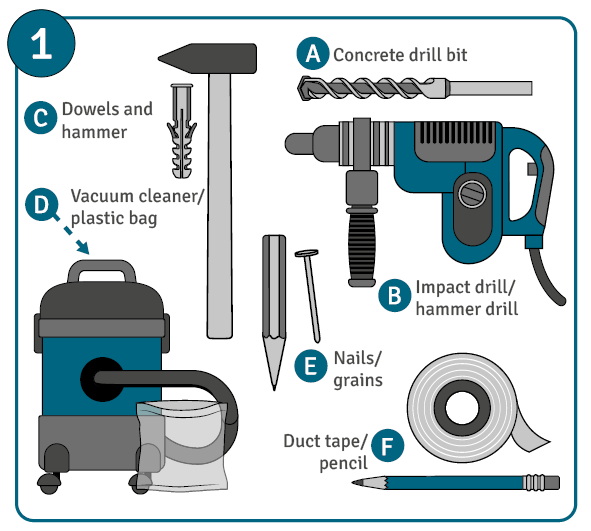

Combining a carbide cutting edge (5–15% of tool mass) with a steel shank balances durability and shock absorption. Applications include:

- Construction: Bosch's X5L carbide-tipped drills penetrate rebar-reinforced concrete at 30% higher speed than full HSS.

- Composite Materials: Steel bodies dampen vibrations when drilling carbon fiber/epoxy laminates.

Industrial Applications of Production Carbide and Steel

Oil & Gas Industry

- Carbide: Used in PDC (polycrystalline diamond compact) drill bits for shale formations, achieving ROP (rate of penetration) of 50 m/hr.

- Steel: HSS tools machine temporary blowout preventer components with 20% cost savings.

Aerospace Manufacturing

- Carbide: 8-flute carbide end mills machine Inconel 718 turbine disks at 12,000 RPM, reducing cycle time by 40%.

- Steel: M42 cobalt HSS drills create pilot holes in aluminum fuselage frames.

Construction Sector

- Carbide: Diamond-coated carbide core drills cut through granite at 100 mm/min with water cooling.

- Steel: HSS step drills install electrical conduits in wooden beams.

Comparative Analysis: Carbide vs. Steel Drills

| Metric | Carbide Drills | HSS Drills |

| Hardness | 1,500–2,000 HV30 | 800–900 HV30 |

| Max Temperature | 1,200°C (with coolant) | 600°C (tempering limit) |

| Cost per Hole | $0.03 (long-term) | $0.10 (short-term) |

| Typical Use Case | Stainless steel, composites | Aluminum, plastic |

Innovations in Carbide-Steel Drill Technology

Geometric Optimization

- Helical Flute Designs: Ruwag's 45° helix carbide drills improve chip evacuation, reducing downtime by 40%.

- Variable Pitch: Kennametal's Beyond™ drills reduce harmonics in deep-hole drilling (>10xD).

Advanced Coatings

- AlTiN (Aluminum Titanium Nitride): Increases carbide tool life by 300% in hardened steels.

- TiSiN (Titanium Silicon Nitride): Enhances HSS performance in stainless steel up to 45 HRC.

Smart Tooling Systems

Wireless sensors in Sandvik Coromant's Connected Tools monitor carbide insert wear in real-time, reducing unplanned downtime by 25%.

Environmental and Economic Impact

Waste Reduction

Carbide's extended lifespan decreases insert disposal by 60% vs. HSS. Recycling programs recover 95% of tungsten content.

Energy Efficiency

High-speed carbide machining reduces energy consumption per part by 18% in automotive production.

Practical Considerations for Optimal Use

Machine Setup

- Rigidity: Use ISO CAT50 tool holders with <3 µm runout for carbide.

- Coolant Pressure: Minimum 70 bar for deep-hole carbide drilling.

Operating Parameters

| Material | Carbide Speed (m/min) | HSS Speed (m/min) | Feed (mm/rev) |

| Mild Steel | 80–120 | 20–30 | 0.15–0.25 |

| Stainless Steel | 40–60 | 10–15 | 0.08–0.12 |

| Aluminum | 200–300 | 60–100 | 0.20–0.35 |

Maintenance Tips

1. Carbide: Inspect for thermal cracks after 8 hours of continuous use.

2. HSS: Resharpen at 0.1 mm flank wear to prevent catastrophic failure.

Conclusion

Production carbide and steel drills revolutionize industrial drilling by combining hardness, heat resistance, and cost-efficiency. While carbide excels in high-stress environments like aerospace and oil drilling, HSS remains vital for general-purpose applications. Advances in hybrid designs, coatings, and IoT-enabled tooling further enhance their synergy, making them indispensable in modern manufacturing.

FAQs

1. What is the primary advantage of carbide over HSS drills?

Carbide's superior hardness (1,500–2,000 HV30) allows it to cut hardened materials like stainless steel and titanium, whereas HSS is limited to sub-45 HRC metals.

2. Are carbide drills cost-effective despite higher initial costs?

Yes. Carbide's extended lifespan reduces long-term costs by 60% in high-volume production. For example, a $150 carbide drill replacing five $30 HSS drills pays for itself in 500 holes.

3. Can carbide and steel be combined in drill design?

Absolutely. Carbide-tipped steel drills (e.g., 8% carbide tip mass) leverage carbide's cutting edge and steel's vibration damping for masonry and composites.

4. What industries benefit most from carbide drills?

Aerospace (titanium machining), oil/gas (PDC drill bits), and automotive (cast iron engine blocks) rely on carbide for precision and durability.

5. How does heat treatment affect drill performance?

Carbide's sintering at 1,500°C enhances hardness, while HSS gains 20% toughness through austenitizing at 1,200°C followed by oil quenching.

Citations:

[1] https://www.betalentcarbide.com/advantages-of-carbide-drill-bits-for-steel.html

[2] https://www.kimdrill.com/blog/What-is-the-main-advantage-of-using-carbide-drill-bits-over-other-Consumable-drilling-bit/

[3] https://www.cutwel.co.uk/blog/carbide-vs-hss-drills.html

[4] https://www.alamy.com/stock-photo/metal-drilling.html

[5] https://dormerpramet.com/fr/fr/Solid-carbide-drill-optimum-productivity-and-reliable-performance

[6] https://ruwag.co.za/blogs/news/everything-you-need-to-know-about-carbide-drill-bits

[7] https://www.cnccookbook.com/carbide-drill-bits-ultimate-guide-for-precision-drilling/

[8] https://www.linkedin.com/pulse/advantages-using-carbide-drills-tough-material-machining-debra-cattle-u6k5e

[9] https://www.coinchtools.com/news/drill-bit-manufacturing/

[10] https://hctoolshop.com/which-is-better-hss-or-carbide-drill-bit/

[11] https://www.tivoly.com/en/choose-hss-drill-carbide-drill

[12] https://primatooling.co.uk/breaking-down-the-benefits-of-carbide-drills/

[13] https://www.mazin.tech/en/en-columns/65e9a1ed79e945a5ad5056d8

[14] https://en.vellfire-tools.com/new_detail/1873952464163786752.html

[15] https://www.aimsindustrial.com.au/blog/hss-vs-carbide

[16] https://www.shutterstock.com/search/solid-carbide-drill

[17] https://www.shutterstock.com/search/carbide-drills?page=2

[18] https://www.shutterstock.com/search/drill-bit-carbide

[19] https://cuttingtools.ceratizit.com/ie/en/machining-know-how/drilling/advisor/strategy-for-producing-deep-holes.html

[20] https://www.practicalmachinist.com/forum/threads/drilling-with-a-carbide-bit-question.160889/

[21] https://www.mmc-carbide.com/us/technical_information/trouble_shooting/tec_drilling_trouble_shooting

[22] https://primatooling.co.uk/the-uses-of-carbide-drills-in-engineering/

[23] https://www.istockphoto.com/photos/tungsten-carbide-drill-bits

[24] https://www.istockphoto.com/photos/metal-cutting-drill-bits

[25] https://www.alamy.com/stock-photo/hss-drill-bit.html

[26] https://www.istockphoto.com/photos/carbide-bit

[27] https://www.alamy.com/stock-photo/carbide-drill-and-cnc.html