Content Menu

● 1. Composition and Manufacturing of Cobalt-Bonded Cemented Carbides

>> Cobalt's Role in Performance

● 2. Health and Safety Risks of Cobalt Exposure

>> Inhalation Hazards

>> Skin and Eye Contact

>> Long-Term Systemic Effects

● 3. Insights from Cemented Carbide Product with Cobalt SDS

>> Key SDS Warnings

>> First Aid Measures

● 4. Mitigation Strategies for Safe Handling

>> Personal Protective Equipment (PPE)

>> Engineering Controls

>> Workplace Monitoring

● 5. Regulatory and Environmental Compliance

>> Global Standards

>> Waste Management

● 6. Advancements in Cobalt Reduction Technologies

>> Alternative Binders

>> Surface Coatings

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. Are cemented carbide products corrosive?

>> 2. What PPE is required for welding cobalt-containing carbides?

>> 3. How does cobalt content affect grinding parameters?

>> 4. Are cobalt-containing carbides MRI-safe?

>> 5. Can cobalt exposure occur during product use?

● Citations:

Cemented carbide products with cobalt binders are indispensable in industrial, military, and engineering applications due to their exceptional hardness, wear resistance, and high-temperature stability. However, safety concerns surrounding cobalt exposure during manufacturing, grinding, or disposal have sparked rigorous debate. This article examines the risks, regulatory frameworks, and mitigation strategies for handling these materials, with insights from cemented carbide product with cobalt SDS (Safety Data Sheet) documentation.

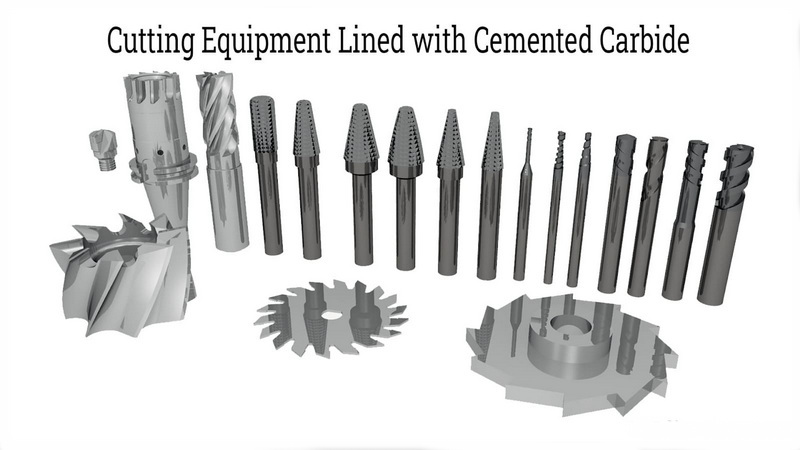

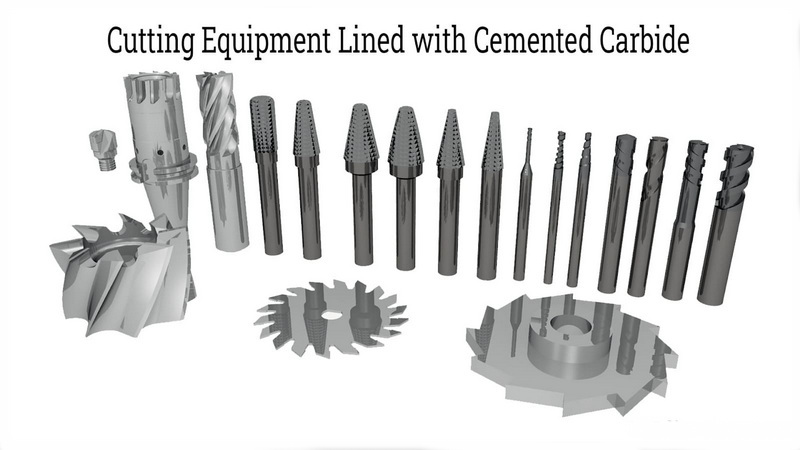

1. Composition and Manufacturing of Cobalt-Bonded Cemented Carbides

Cemented carbides consist of tungsten carbide (WC) grains bonded by a cobalt (Co) matrix, typically comprising 4–25% cobalt by weight. The sintering process at 1,300–1,500°C creates a dense structure ideal for cutting tools, mining equipment, and wear-resistant components.

Key Properties:

- Hardness: HRA 85–94

- Fracture Toughness: 8.5–14.5 MPa·m1/2

- Thermal Conductivity: 70–100 W/m·K

Cobalt's Role in Performance

Cobalt's ductility compensates for tungsten carbide's brittleness, enabling crack deflection and energy absorption. Higher cobalt content (e.g., 15–25%) improves toughness for impact-heavy applications like rock drilling, while lower levels (6–10%) prioritize wear resistance for precision cutting tools.

2. Health and Safety Risks of Cobalt Exposure

Inhalation Hazards

Grinding or machining cemented carbide releases fine cobalt-containing dust, which poses severe respiratory risks:

- Acute Effects: Coughing, wheezing, and shortness of breath within hours of exposure.

- Chronic Effects: "Hard Metal Lung Disease" (HMLD), a progressive fibrosis linked to cobalt inhalation. Studies show 12–25% of exposed workers develop lung abnormalities over 10 years.

- Carcinogenicity: IARC classifies cobalt-tungsten carbide as Group 2A (probably carcinogenic). A 2023 meta-analysis found a 1.7x increased lung cancer risk among long-term workers.

Skin and Eye Contact

- Dermal Sensitization: Cobalt particles may cause allergic dermatitis, with prevalence rates of 8–15% in exposed populations.

- Eye Irritation: Conjunctivitis from dust exposure; corneal abrasions reported in 5% of unprotected grinding operations.

Long-Term Systemic Effects

Prolonged exposure correlates with:

- Cardiovascular abnormalities: Elevated cobalt serum levels (>2 μg/L) linked to cardiomyopathy in animal models.

- Thyroid dysfunction: Cobalt inhibits iodine uptake, potentially causing hypothyroidism.

- Reproductive toxicity: Rat studies show reduced sperm motility at exposures above 0.05 mg/m³.

3. Insights from Cemented Carbide Product with Cobalt SDS

Safety Data Sheets provide critical guidelines for handling these materials. A typical cemented carbide product with cobalt SDS includes:

Key SDS Warnings

- OSHA Permissible Exposure Limit (PEL): 0.1 mg/m³ for cobalt (8-hour TWA).

- ACGIH Threshold Limit Value (TLV): 0.02 mg/m³ (respirable fraction).

- Fire/Explosion Risks: Cobalt dust is combustible at concentrations >40 g/m³ with ignition sources.

First Aid Measures

- Inhalation: Immediate removal to fresh air; administer oxygen if breathing is labored.

- Skin Contact: Flush with water for 15 minutes; use pH-neutral cleansers to avoid enhancing cobalt absorption.

4. Mitigation Strategies for Safe Handling

Personal Protective Equipment (PPE)

- Respirators: NIOSH-approved N95 masks (for dust <0.1 mg/m³) or powered air-purifying respirators (PAPRs) with P100 filters.

- Gloves and Coveralls: Nitrile (0.11 mm thickness) or neoprene suits with sealed seams.

Engineering Controls

- Local Exhaust Ventilation (LEV): Hoods capturing dust at 0.5–2.5 m/s velocity, paired with HEPA filtration.

- Wet Grinding Systems: Reduce airborne cobalt by 90% compared to dry methods.

Workplace Monitoring

- Air Sampling: Weekly personal breathing zone tests using ICP-MS analysis (detection limit: 0.001 mg/m³).

- Biomonitoring: Urinary cobalt levels should not exceed 15 μg/g creatinine (BEI guideline).

5. Regulatory and Environmental Compliance

Global Standards

- EU REACH: Cobalt listed as a Substance of Very High Concern (SVHC) since 2017, requiring authorization for industrial use.

- China GBZ 2.1-2019: Workplace exposure limit of 0.05 mg/m³ for cobalt metal dust.

- ISO 4498:2022: Standardizes cemented carbide safety testing protocols.

Waste Management

- Recycling: 92% cobalt recovery rate via zinc process recycling.

- Landfill Restrictions: Cobalt leaching must be <0.2 mg/L (EPA TCLP test).

6. Advancements in Cobalt Reduction Technologies

Alternative Binders

- Iron-Nickel Alloys: Reduce cobalt content to 3–6% while maintaining 85% fracture toughness.

- Ceramic Binders (e.g., Al₂O₃): Eliminate cobalt but limit applications to low-impact uses.

Surface Coatings

- PVD/CVD Layers: Titanium nitride or diamond-like carbon coatings reduce grinding needs by 40%.

Conclusion

Cemented carbide products with cobalt binders offer unmatched performance in extreme conditions but require stringent safety protocols. Adherence to cemented carbide product with cobalt SDS guidelines, coupled with engineering controls and PPE, minimizes health risks. Emerging binder technologies promise to reduce cobalt dependency while maintaining material integrity, though complete substitution remains challenging for high-stress applications.

Frequently Asked Questions (FAQs)

1. Are cemented carbide products corrosive?

Yes. Cobalt binder reacts with moisture, leading to surface oxidation in humid environments. The cemented carbide product with cobalt SDS recommends storage at <60% relative humidity.

2. What PPE is required for welding cobalt-containing carbides?

Use supplied-air respirators (SARs) and heat-resistant gloves, as welding fumes may contain cobalt oxides.

3. How does cobalt content affect grinding parameters?

Higher cobalt grades require 20–30% lower grinding speeds to minimize dust generation.

4. Are cobalt-containing carbides MRI-safe?

No. Cobalt's ferromagnetism causes artifacts; use non-magnetic grades (e.g., nickel-bonded) for medical imaging tools.

5. Can cobalt exposure occur during product use?

Minimal risk if products are intact. Grinding or re-sharpening generates 95% of occupational exposure cases.

Citations:

[1] http://www.carbidetechnologies.com/wp-content/uploads/2018/12/SDS-CARBIDETECHNOLOGIES.pdf

[2] http://www.kanefusa.net/en/csr/sds12-pcd-en001.pdf

[3] https://www.carbide-products.com/es/blog/cemented-carbide-product-with-cobalt-binder/

[4] http://www.chinatungsten.com/tungsten-applications/Cemented-Carbides.html

[5] https://patents.google.com/patent/US20170057878A1/en

[6] https://osg.co.jp/en/media_dl/technical/file/sds_cabide_en.pdf

[7] https://us.ns-tool.com/en/download/pdf/SDS-WC-JA20171_en.pdf

[8] https://www.sanalloy.co.jp/en/q_a/

[9] https://www.ns-tool.com/en/download/pdf/SDS-WC-JA20171_en.pdf

[10] https://www.everloy-cemented-carbide.com/en/column/782/

[11] https://saturnmachineworks.com/wp-content/uploads/2020/11/20-07-03-Saturn-Safety-Data-Sheet-for-Tungsten-Carbide-with-Cobalt.pdf

[12] https://www.sigmaaldrich.com/PL/en/product/aldrich/gf50243059

[13] https://hesiway.en.made-in-china.com/product/UJbphxgduzYt/China-High-Quality-Cobalt-Powder-for-Cemented-Carbide.html

[14] http://www.casmetcarbide.com/images/Casmet_MSDS-WC.pdf

[15] https://www.tapmatic.com/product-line-msds-carbide-stylus-material.ydev

[16] http://www.carbidetechnologies.com/faqs/

[17] https://cementedcarbide.en.made-in-china.com/product/hEnRsfLATzcu/China-Tungsten-Carbide-Cobalt-10-Material-for-Rod-Bars.html

[18] https://sanalloy.co.jp/cn/img/top/sds_2018.pdf

[19] https://www.basiccarbide.com/assets/pdfs/basic-carbide-safety-data-sheet.pdf

[20] https://www.westernsupplies.com/admin/msds_pdfs/Cemented%20Carbide%20Grades%20(Cemented%20Tungsten%20Carbide%20wcobalt%20filler)_tv0egn3l.pdf

[21] https://www1.mscdirect.com/MSDS/MSDS00015/09906199-20171109.PDF

[22] https://www1.mscdirect.com/MSDS/MSDS00029/68789197-20100903.PDF

[23] https://asia.kyocera.com/products/cuttingtools/images/sds/pdf/msds_cemented_carbide_e.pdf

[24] https://webshop.iscar.de/downloads/action/show_file/product/1949183/file_type/MSDS

[25] https://www.mmc-carbide.com/download_file/e1ddff69-1c32-4b83-a52d-bfc1ac118bb3/9519

[26] https://ntp.niehs.nih.gov/sites/default/files/ntp/roc/content/profiles/cobalttungstencarbide.pdf

[27] https://pubs.rsc.org/en/content/articlelanding/2020/ra/d0ra02602f

[28] https://wyburtools.com/Images/Wybur%20Tools%20Safety%20Data%20Sheet-Carbide%20Burs.pdf

[29] https://www.sciencedirect.com/science/article/pii/0048969794901252

[30] https://www.linkedin.com/pulse/carbide-production-environmental-impact-bd-drill-brade-54xec

[31] https://www.vistametalsinc.com/sds.pdf

[32] https://pubmed.ncbi.nlm.nih.gov/1472440/

[33] https://www.sciencedirect.com/science/article/pii/S0959652618332992

[34] https://tsapps.nist.gov/srmext/msds/888-MSDS.pdf

[35] https://www.alibaba.com/product-detail/yg6widia-c122-cobalt-Co-material-cemented_62341250618.html

[36] https://www.goodfellow.com/eu/material/compounds/ceramic-composites/tungsten-carbide-cobalt-co-10-tube

[37] https://www.carbide-products.com/blog/cemented-carbide-product-with-cobalt-binder/

[38] https://www.ceratizit.com/int/en/sustainability/blog/2021/blogposting-cemented-carbide.html

[39] https://www.sciencedirect.com/science/article/pii/S026343681830533X

[40] https://www.sciencedirect.com/science/article/abs/pii/S0925963522008251

[41] https://www.sciencedirect.com/science/article/pii/S0042207X24000988

[42] https://rivictory.en.made-in-china.com/product/CwefcvWyymhq/China-China-Factory-Tungsten-Titanium-Cobalt-Cemented-Carbide-Rod-in-Reliable-Performance-with-Competitive-Price.html

[43] https://www.diva-portal.org/smash/get/diva2:1237216/FULLTEXT01.pdf

[44] https://shop.gfii.com/images/GFI%20SDS%2002%20-%20Carbide%20Product%20-%20March%202025.pdf

[45] https://www.instagram.com/sandvikcoromantindia/p/DApZ8z_oHxx/?locale=my

[46] https://ceramics.onlinelibrary.wiley.com/doi/abs/10.1111/ijac.13966

[47] https://www.sciencedirect.com/science/article/pii/S2238785423027643

[48] https://www.westernsupplies.com/admin/msds_pdfs/Cemented%20Carbide%20Grades%20(Cemented%20Tungsten%20Carbide%20wcobalt%20filler)_tv0egn3l.pdf

[49] https://mastercuttool.com/wp-content/uploads/2022/09/SDS-R3-2022.pdf

[50] https://www.kanefusa.net/en/csr/csr/sds12-pcd-en003(2025).pdf

[51] https://shop.gfii.com/images/GFI%20SDS%2002%20-%20Carbide%20Product%20-%20December%202019.pdf

[52] https://www1.mscdirect.com/MSDS/MSDS00073/91644021-20190628.PDF

[53] https://www1.mscdirect.com/MSDS/MSDS00022/78017944-20170802.PDF

[54] https://www.eng.uwo.ca/files/departments-units/student-shop/2015/sds-cementred-carbide-mitsubishi.pdf

[55] https://www.nj.gov/health/eoh/rtkweb/documents/fs/0520.pdf

[56] http://www.osha.gov/laws-regs/standardinterpretations/1987-02-11

[57] https://nj.gov/health/eoh/rtkweb/documents/fs/1960.pdf

[58] https://www.q8oils.com/metalworking/leaching-cobalt/

[59] https://www.everloy-cemented-carbide.com/en/knowledge/faq.html

[60] https://nora.nerc.ac.uk/id/eprint/534486/1/cobalt_faqs.pdf

[61] https://app.croneri.co.uk/feature-articles/cobalt-health-hazards-and-control-measures?product=135

[62] https://www.linkedin.com/pulse/9-safety-precautions-while-using-tungsten-carbide-tools-

[63] https://www.sandvik.coromant.com/en-gb/services/recycling/faq-carbide-recycling

[64] https://health.ec.europa.eu/document/download/347c3594-def2-486f-bd09-3ae49fb9efba_en?filename=scheer_o_043.pdf

[65] https://pubmed.ncbi.nlm.nih.gov/7588496/

[66] https://www.ns-tool.com/en/download/pdf/SDS-WC-JA20171_en.pdf

[67] https://pubs.acs.org/doi/10.1021/acssuschemeng.2c01969