Content Menu

● Introduction

● Material Properties of Carbide Stamping Dies

>> Chemical Composition

>> Physical Properties

● Key Advantages of Carbide Stamping Dies

>> Superior Wear Resistance

>> Dimensional Stability

● Manufacturing Process

>> Powder Metallurgy

● Applications in Modern Manufacturing

>> Industry Sectors

>> Specific Applications

● Maintenance and Care

>> Preventive Maintenance

>> Troubleshooting

● Future Trends and Developments

>> Technological Advances

● Frequently Asked Questions

>> Q1: What is the typical lifespan of carbide stamping dies?

>> Q2: How does the hardness of carbide dies compare to traditional steel dies?

>> Q3: What are the main factors affecting carbide die performance?

>> Q4: Can carbide dies be repaired or refurbished?

>> Q5: What are the cost considerations for carbide stamping dies?

Introduction

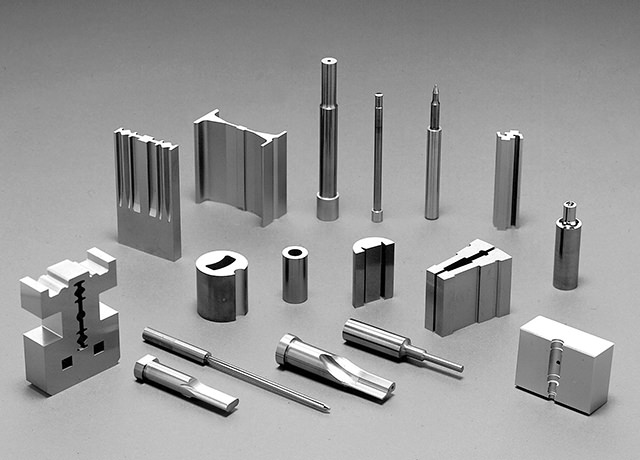

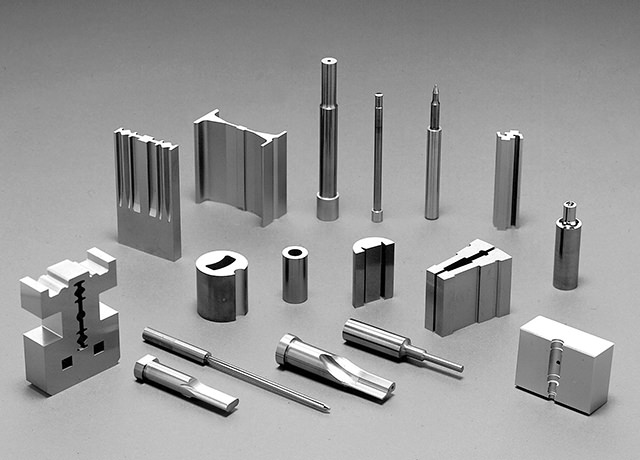

Carbide stamping dies represent the pinnacle of modern manufacturing technology, combining superior material properties with precision engineering to deliver unparalleled performance in metal forming operations. This comprehensive guide explores the material characteristics, advantages, and applications of carbide stamping dies in industrial manufacturing.

Material Properties of Carbide Stamping Dies

Chemical Composition

Carbide stamping dies are primarily composed of tungsten carbide particles bonded together with cobalt. The typical composition includes:

- Tungsten carbide (WC): 85-95%

- Cobalt (Co): 5-15%

- Other carbides: Small percentages of titanium, tantalum, or niobium carbides

Physical Properties

- Density: 14.5-15.2 g/cm³

- Hardness: 68-73 HRC (Rockwell C scale)

- Compressive strength: 2,000-7,000 MPa

- Young's modulus: 500-650 GPa

Key Advantages of Carbide Stamping Dies

Superior Wear Resistance

The exceptional wear resistance of carbide stamping dies stems from their unique microstructure and material properties. This characteristic ensures:

- Extended tool life

- Consistent part quality

- Reduced maintenance requirements

- Lower cost per part in high-volume production

Dimensional Stability

Carbide stamping dies maintain their dimensional accuracy even under extreme conditions:

- Minimal thermal expansion

- Resistance to deformation

- Consistent part tolerances

- Enhanced process reliability

Manufacturing Process

Powder Metallurgy

The production of carbide stamping dies involves sophisticated powder metallurgy techniques:

1. Powder preparation and mixing

2. Pressing and shaping

3. Sintering

4. Final machining and finishing

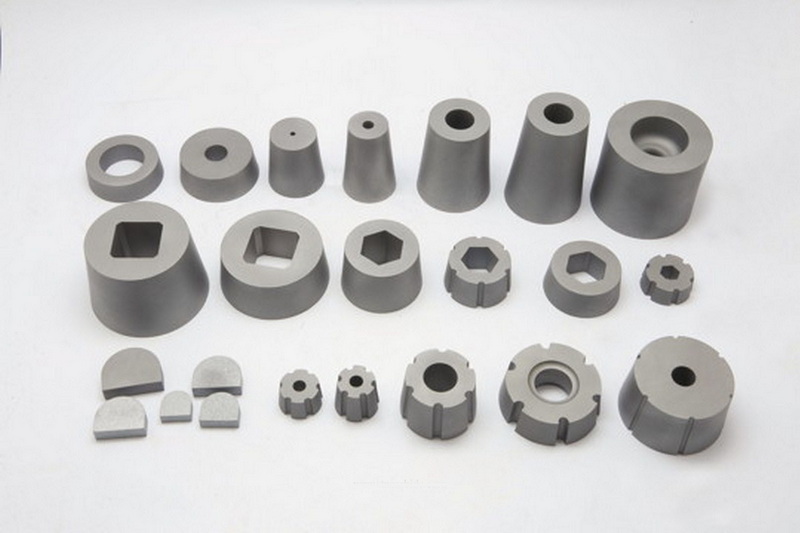

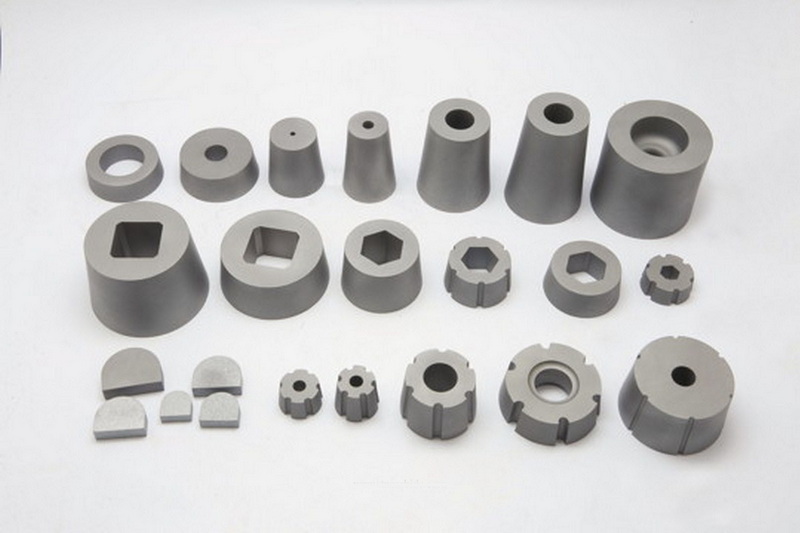

Applications in Modern Manufacturing

Industry Sectors

Carbide stamping dies find extensive use in:

- Automotive components

- Electronics manufacturing

- Aerospace parts

- Medical device production

- Consumer electronics

Specific Applications

- High-precision electronic connectors

- Automotive body panels

- Battery components

- Medical implant components

- Aerospace fasteners

Maintenance and Care

Preventive Maintenance

- Regular inspection protocols

- Proper cleaning procedures

- Lubrication requirements

- Storage considerations

Troubleshooting

- Common wear patterns

- Problem identification

- Corrective actions

- Optimization strategies

Future Trends and Developments

Technological Advances

- Advanced coating technologies

- Improved binding materials

- Enhanced manufacturing processes

- Smart monitoring systems

Frequently Asked Questions

Q1: What is the typical lifespan of carbide stamping dies?

A1: Under optimal conditions and proper maintenance, carbide stamping dies can last 3-5 times longer than conventional steel dies, often producing millions of parts before requiring replacement.

Q2: How does the hardness of carbide dies compare to traditional steel dies?

A2: Carbide dies typically have a hardness of 68-73 HRC, significantly higher than traditional tool steel dies which usually range from 58-62 HRC.

Q3: What are the main factors affecting carbide die performance?

A3: The main factors include:

- Material grade selection

- Operating conditions

- Maintenance practices

- Workpiece material properties

- Production speed

Q4: Can carbide dies be repaired or refurbished?

A4: Yes, carbide dies can be repaired through specialized processes such as grinding, EDM, or replacement of worn components, though the options are more limited compared to steel dies.

Q5: What are the cost considerations for carbide stamping dies?

A5: While initial costs are higher than steel dies, the total cost of ownership is often lower due to:

- Extended tool life

- Reduced maintenance needs

- Higher production rates

- Better part quality

- Fewer replacements required