Contentus menu

● Introductio

● Material proprietatibus carbide Stamping moritur

>> Chemical compositionem

>> Physica proprietatibus

● Key commoda carbide Stamping moritur

>> Superior gerunt resistentia

>> Dimensional stabilitatem

● Processu

>> Pulveris metallicy

● Applications in modern vestibulum

>> Industry Sectors

>> Propria applications

● Tutela et cura

>> Praecaventur sustentationem

>> Troubleshooting

● Future Trends et Developments

>> Technicae progressus

● Frequenter Interrogata Quaestiones

>> Q1: Quid est typical lifespan de carbide Stamping moritur?

>> Q2: Quid est duritia carbide moritur compare traditional ferro moritur?

>> Q3: Quid sunt principalis factores afficiens carbide mori perficientur?

>> Q4: can carbide moritur reparari vel refurbished?

>> Q5: Quid sunt sumptus considerations carbide Stamping moritur?

Introductio

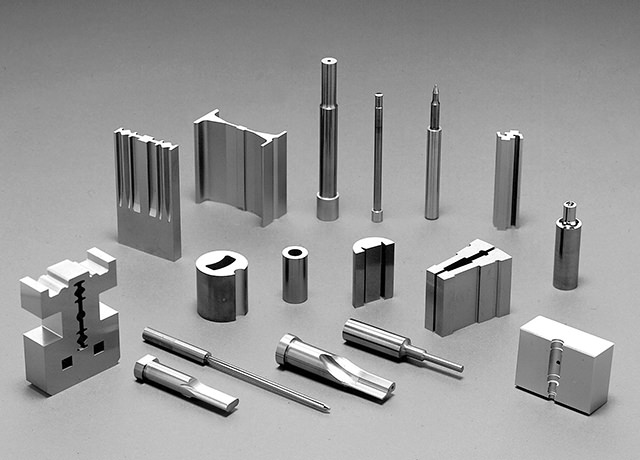

Carbide Stamming moritur represent pinnaculum modern vestibulum technology, combining superior materia proprietatibus cum praecisione engineering ut libera unica perficientur in metallum formatam operationes. Hoc comprehensive dux explorat materiam habet, commoda, et applications de carbide Stampide moritur in Industrial vestibulum.

Material proprietatibus carbide Stamping moritur

Chemical compositionem

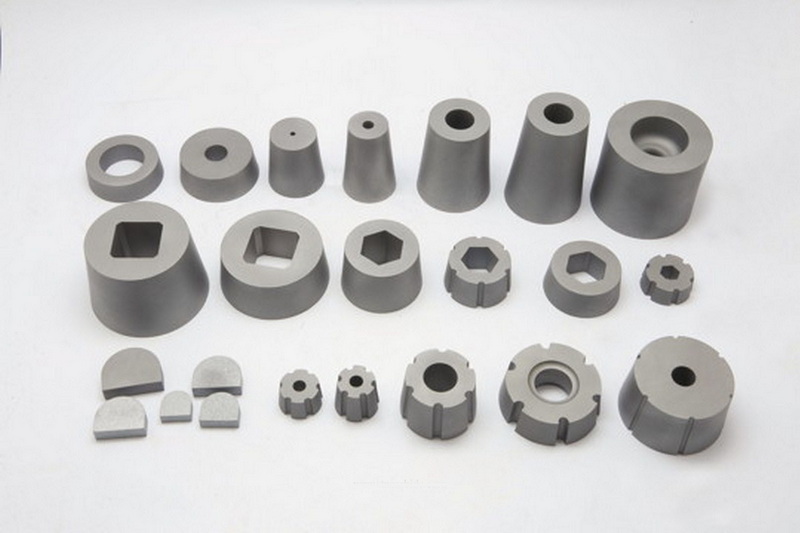

Carbide Stamped moritur sunt praesertim composito de Tungsten carbide particulis mutantur cum Cobalt. In typicam compositionem includit:

- Tungsten Carbide (WC) 85-95%

- Cobalt (Co) 5-15%

- Alii Carbides: Parvus percentages de Titanium, Tantalum, aut Niobium Carbides

Physica proprietatibus

- Density: 14.5-15.2 G / CM⊃3;

- Durness: 68-73 HRC (Rockwell C Sca)

- compressive fortitudinem: 2,000-7.000 MPa

- Young 's Modulus: 500-650 GPA

Key commoda carbide Stamping moritur

Superior gerunt resistentia

Et eximia gerunt resistentia carbide Stampide moritur caulibus a suis unique microstructure et materiam proprietatibus. Hoc proprium ensures:

- Extended tool vitae

- consistent parte species

- reducitur sustentacionem requisita

- Inferior sumptus per partem in summus volumine productio

Dimensional stabilitatem

Carbide Stamping moritur ponere eorum dimensional accurate etiam in extrema condiciones:

- minimal scelerisque expansion

- resistentia ad deformatio

- consistent pars tolerances

- Enhanced Processus Reliability

Processu

Pulveris metallicy

Productio Carbide Stamping moritur involves sophisticated pulveris Metallurgy Techniques:

I. Powder praeparatio et miscentes

II. Urgeat et effingens

III. Deining

IV. Final machining et consummatione

Applications in modern vestibulum

Industry Sectors

Carbide Stamping moritur invenies extensive usu in:

- Automotive components

- Electronics Manufacturing

- Aerospace partes

- Medical fabrica productio

- Consumer Electronics

Propria applications

- High-praecision electronic iungo

- Automotive Corpus Panels

- Altilium components

- Medical Implantare components

- Aerospace fasteners

Tutela et cura

Praecaventur sustentationem

- Ordinarius inspectionem protocols

- Propriis Purgato procedendi

- lubricatae requisitis

- repono considerations

Troubleshooting

- Common lapsum Patterns

- forsit idem

- emendatoriam actiones

- Optimization Insidijs

Future Trends et Developments

Technicae progressus

- Advanced coating Technologies

- melius binding materiae

- Enhanced Manufacturing Processus

- dolor Cras Systems

Frequenter Interrogata Quaestiones

Q1: Quid est typical lifespan de carbide Stamping moritur?

A1: Sub bene conditionibus et propriis sustentationem, carbide stamping moritur durare potest 3-5 temporibus diutius quam conventional ferro perit, saepe producendo millions of partibus ante postulantes.

Q2: Quid est duritia carbide moritur compare traditional ferro moritur?

A2: Carbide moritur typice habent duritiam 68-73 HRC, significantly altior quam traditum instrumentum ferro perit, quod plerumque range 58-62 HRC.

Q3: Quid sunt principalis factores afficiens carbide mori perficientur?

A3: Pelagus factors includit:

- materia gradu lectio

- operating conditionibus

- sustentacionem exercitia

- Workpiece Material Properties

- Productio celeritate

Q4: can carbide moritur reparari vel refurbished?

A4: Sic, carbide moritur perit potest per specialized processibus ut molere, Edm, aut replacement attritus components, quamquam options sunt limited comparari ferro perit.

Q5: Quid sunt sumptus considerations carbide Stamping moritur?

A5: Dum initial costs sunt altior quam ferro perit, summa sumptus dominium est saepe inferiori debitum:

- Extended tool vitae

- reducitur sustentacionem necessitates

- altius productio rates

- Melior pars qualis

- Pauciores replacements required