Content Menu

● What is Tungsten Carbide?

● Properties of Tungsten Carbide

● What is Tungsten Carbide Scrap?

● Sources and Types of Tungsten Carbide Scrap

>> Main Sources

>> Common Types

● Identification of Tungsten Carbide Scrap

>> Visual and Physical Inspection

>> Simple Tests

>> Advanced Identification

● The Recycling Process of Tungsten Carbide Scrap

>> 1. Zinc Smelting Method

>> 2. Electrolytic Method

>> Additional Steps

● Economic and Environmental Impact

>> Economic Value

>> Environmental Benefits

● Applications of Recycled Tungsten Carbide

● The Global Tungsten Carbide Scrap Market

>> Market Trends

>> Key Players

● How to Maximize the Value of Your Tungsten Carbide Scrap

>> 1. Proper Sorting

>> 2. Bulk Collection

>> 3. Documentation

>> 4. Partner with Reputable Recyclers

>> 5. Stay Informed

● Safety Considerations in Handling and Recycling

>> Handling Precautions

>> Environmental Safety

>> Worker Training

● Conclusion

● FAQ: Tungsten Carbide Scrap

>> 1. What makes tungsten carbide scrap so valuable?

>> 2. How can I identify tungsten carbide scrap?

>> 3. What are the main methods for recycling tungsten carbide scrap?

>> 4. Where can I sell tungsten carbide scrap?

>> 5. What are the environmental benefits of recycling tungsten carbide scrap?

Tungsten carbide scrap is a highly valuable industrial material, often overlooked outside of manufacturing and recycling circles. As industries increasingly prioritize efficiency, sustainability, and cost-effectiveness, understanding the nature, sources, and recycling processes of tungsten carbide scrap has never been more crucial. This comprehensive guide will explore what tungsten carbide scrap is, its unique properties, how it is generated and recycled, its economic and environmental importance, and answer the most frequently asked questions on the topic.

What is Tungsten Carbide?

Tungsten carbide is a compound formed by combining tungsten and carbon atoms in equal proportions. Through a process called sintering, this gray powder is transformed into a dense, extremely hard metal widely used in industrial applications. Tungsten carbide is renowned for its exceptional hardness, ranking just below diamond on the Mohs scale, and its remarkable resistance to wear, heat, and corrosion.

Properties of Tungsten Carbide

Tungsten carbide's unique physical and chemical properties make it indispensable in demanding environments:

- Hardness: Mohs hardness of 9–9.5, second only to diamond.

- Density: Approximately twice as dense as steel.

- Stiffness: About twice as stiff as steel, with a Young's modulus of 530–700 GPa.

- Melting Point: Extremely high, around 2,870°C.

- Thermal Conductivity: High, making it suitable for applications involving heat.

- Corrosion Resistance: Resistant to most acids and oxidation.

These properties explain why tungsten carbide is so valuable and why recycling its scrap is economically and environmentally advantageous.

What is Tungsten Carbide Scrap?

Tungsten carbide scrap refers to discarded, worn-out, or unusable items made from tungsten carbide. These scraps are generated when tungsten carbide tools, components, or coatings reach the end of their service life or are damaged during use. Rather than being disposed of as waste, these scraps are collected and recycled, as the tungsten content remains valuable and can be reused in new products.

Sources and Types of Tungsten Carbide Scrap

Tungsten carbide scrap is generated across various industries and comes in multiple forms. Understanding these sources helps in efficient collection and recycling.

Main Sources

- Manufacturing and Machining: Cutting tools (drill bits, end mills, saw blades) become dull or break during use.

- Mining and Drilling: Wear parts, drill bits, and inserts used in harsh environments.

- Oil and Gas: Drilling and cutting equipment.

- Aerospace and Defense: Precision components and fasteners.

- Tool and Die Making: Molds, dies, and forming tools.

- Construction: Masonry drills, saws, chisels, and other heavy-duty tools.

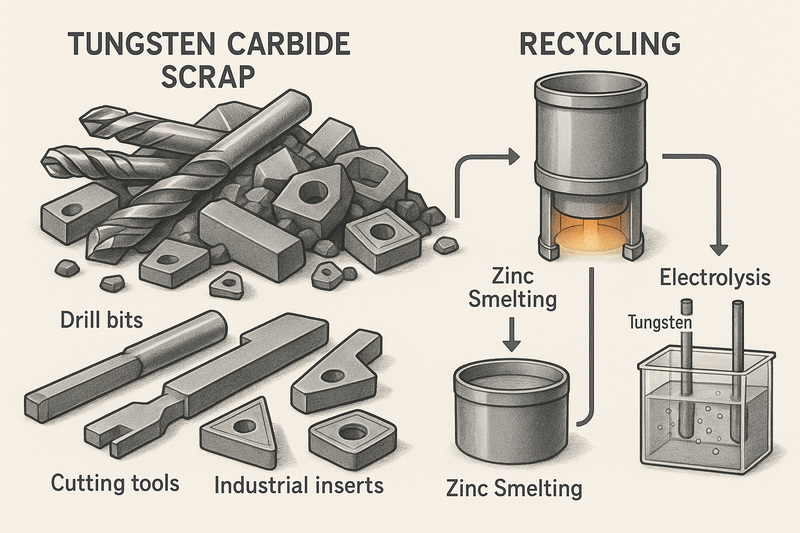

Common Types

- Used Tool Bits and Blades: Worn cutting tools from machining operations.

- Wear Parts: Crusher jaws, wear plates, and linings.

- Industrial Inserts: Tooling inserts, tips, and nozzles.

- Cemented Carbide Rings: Used in seals, bearings, and specialized applications.

- Customized Components: Specially designed carbide parts for unique machinery.

Identification of Tungsten Carbide Scrap

Proper identification is crucial for maximizing the value and ensuring the correct recycling of tungsten carbide scrap. Here are some practical methods:

Visual and Physical Inspection

- Color and Texture: Tungsten carbide usually appears grayish or metallic and may have a slightly textured surface due to its binder content.

- Weight: Significantly heavier than most metals of similar size due to its high density.

- Hardness: Extremely hard—can easily scratch glass.

Simple Tests

- Magnet Test: Tungsten carbide is non-magnetic. If a piece is attracted to a magnet, it is likely not pure tungsten carbide.

- Density Test: Calculating density (tungsten carbide is about 15.63 g/cm³) can help differentiate it from other metals.

- Scratch Test: Tungsten carbide can scratch most other metals and glass.

Advanced Identification

- Markings and Labels: Many carbide tools have engravings indicating their composition.

- X-Ray Fluorescence (XRF) Analyzer: Provides a precise analysis of the metal's composition.

The Recycling Process of Tungsten Carbide Scrap

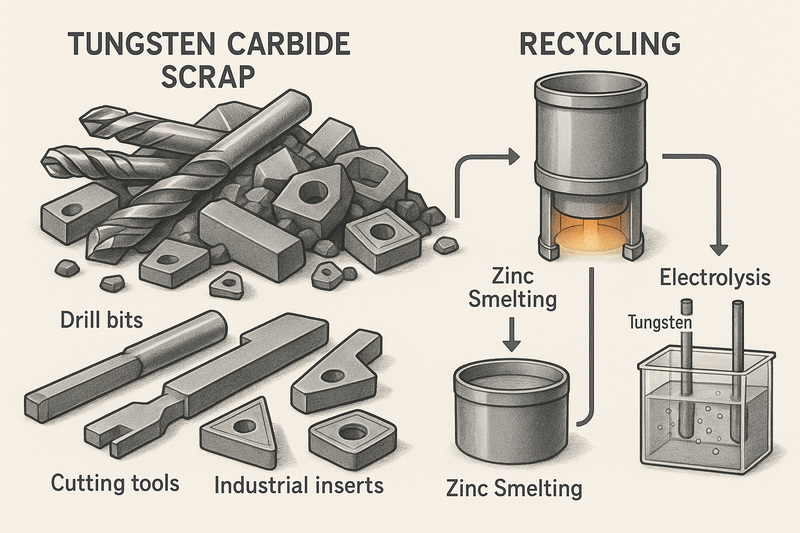

Recycling tungsten carbide scrap involves several sophisticated methods to recover the valuable tungsten and cobalt content. The two most common processes are the Zinc Smelting Method and the Electrolytic Method.

1. Zinc Smelting Method

- Process: Scrap is mixed with metallic zinc and heated in a vacuum furnace. Cobalt reacts with zinc to form a zinc-cobalt alloy, which is then separated, leaving behind tungsten carbide powder and cobalt.

- Advantages: Suitable for low-cobalt content waste, produces powder close to the original grade.

- Limitations: Requires high temperatures and specialized equipment.

2. Electrolytic Method

- Process: Scrap is placed in an acidic solution, and electrolysis is used to dissolve cobalt, separating it from tungsten carbide.

- Advantages: Efficient for high-cobalt content scrap, low energy and reagent consumption.

- Limitations: Best for scrap with significant cobalt content.

Additional Steps

- Sorting and Cleaning: Scrap is sorted by type and cleaned to remove contaminants.

- Crushing and Milling: Larger pieces are crushed and milled into powder.

- Purification: Chemical processes remove impurities.

- Re-sintering: The recovered powder is sintered to form new tungsten carbide products.

Economic and Environmental Impact

Economic Value

- High Market Value: Tungsten is a rare and expensive metal, making its scrap highly valuable.

- Cost Savings: Recycling reduces the need for raw tungsten mining, lowering production costs for manufacturers.

- Revenue Stream: Companies can sell scrap to recyclers, generating additional income.

Environmental Benefits

- Resource Conservation: Recycling conserves limited tungsten resources.

- Reduced Mining Impact: Less mining means reduced habitat destruction and lower carbon emissions.

- Circular Economy: Promotes sustainable industrial practices and waste reduction.

Applications of Recycled Tungsten Carbide

Recycled tungsten carbide is used in a wide array of applications, including:

- Cutting Tools: Drill bits, end mills, saw blades, and inserts.

- Mining Equipment: Wear parts and drilling components.

- Abrasives: Grinding wheels and sandblasting nozzles.

- Jewelry: Scratch-resistant rings and watch bands.

- Industrial Machinery: Bearings, seals, and specialized components.

The Global Tungsten Carbide Scrap Market

The global market for tungsten carbide scrap is dynamic and influenced by several factors, including industrial demand, geopolitical issues, and the availability of primary tungsten sources. Major producers and recyclers are located in regions with advanced manufacturing sectors, such as North America, Europe, and Asia.

Market Trends

- Growing Demand: As industries such as automotive, aerospace, and electronics continue to expand, the demand for tungsten carbide and its recycled forms increases.

- Price Fluctuations: The price of tungsten carbide scrap can be volatile, influenced by global supply chains, mining output, and recycling rates.

- Regulatory Influence: Environmental regulations and policies promoting recycling have a direct impact on the tungsten carbide scrap market.

Key Players

- Manufacturers: Large tool and machinery manufacturers often have dedicated recycling programs.

- Recycling Companies: Specialized firms process and refine tungsten carbide scrap for resale.

- Traders and Brokers: Facilitate the exchange of scrap between sellers and recyclers.

How to Maximize the Value of Your Tungsten Carbide Scrap

If you handle or generate tungsten carbide scrap, there are several ways to ensure you get the most value from it:

1. Proper Sorting

Segregate tungsten carbide scrap from other metals and contaminants. Clean, uncontaminated scrap fetches a higher price.

2. Bulk Collection

Accumulate scrap in bulk before selling. Larger quantities are more attractive to recyclers and may command better rates.

3. Documentation

Keep records of the source and composition of your scrap. This transparency builds trust with buyers and can streamline transactions.

4. Partner with Reputable Recyclers

Work with established recycling companies that offer fair pricing and responsible processing.

5. Stay Informed

Monitor market trends and prices to sell your scrap at the most advantageous times.

Safety Considerations in Handling and Recycling

While tungsten carbide is not considered highly hazardous, certain precautions should be taken during handling and recycling:

Handling Precautions

- Wear Protective Gear: Gloves and safety glasses should be worn when handling sharp or heavy scrap.

- Avoid Inhalation: Dust generated during crushing or grinding can be harmful if inhaled. Use dust masks and proper ventilation.

- Proper Storage: Store scrap in secure, labeled containers to prevent accidental mixing or contamination.

Environmental Safety

- Waste Management: Ensure that any waste generated during recycling (such as chemical residues) is disposed of in accordance with environmental regulations.

- Spill Prevention: Prevent the release of fine tungsten carbide particles into the environment.

Worker Training

- Training Programs: Workers involved in recycling should be trained in safe handling, emergency procedures, and the proper use of equipment.

Conclusion

Tungsten carbide scrap is far more than industrial waste; it is a critical resource that supports both economic efficiency and environmental sustainability. Its unique properties and high value make it essential to recycle and reuse wherever possible. As industries grow and technology advances, the demand for tungsten carbide—and the importance of its recycling—will only increase. By understanding what tungsten carbide scrap is, how to identify and recycle it, and its broader impact, businesses and individuals alike can contribute to a more sustainable and profitable future. Whether you are a manufacturer, recycler, or simply someone interested in sustainable materials, recognizing the value of tungsten carbide scrap is a step toward a greener and more resource-efficient world.

FAQ: Tungsten Carbide Scrap

1. What makes tungsten carbide scrap so valuable?

Tungsten carbide scrap is valuable because it contains tungsten, a rare and expensive metal. Its extreme hardness and resistance to wear make it indispensable in many industrial applications, and recycling helps conserve natural resources and reduce costs.

2. How can I identify tungsten carbide scrap?

You can identify tungsten carbide scrap by its grayish metallic color, high density (much heavier than steel), non-magnetic properties, and extreme hardness (it can scratch glass). Advanced tools like XRF analyzers can provide precise composition analysis.

3. What are the main methods for recycling tungsten carbide scrap?

The two main recycling methods are the Zinc Smelting Method, suitable for low-cobalt scrap, and the Electrolytic Method, ideal for high-cobalt content scrap. Both processes recover tungsten carbide powder for reuse in new products.

4. Where can I sell tungsten carbide scrap?

Tungsten carbide scrap can be sold to specialized metal recycling facilities, scrap dealers, or directly to manufacturers who use recycled tungsten carbide in their production processes. Prices vary based on purity, quantity, and current market demand.

5. What are the environmental benefits of recycling tungsten carbide scrap?

Recycling tungsten carbide scrap reduces the need for mining, conserves scarce resources, lowers energy consumption, and minimizes environmental impact. It supports a circular economy and helps industries meet sustainability goals.