Content Menu

● Introduction

● Overview of Carbide Plate Manufacturing in Portugal

● Top Carbide Plate Manufacturers and Suppliers in Portugal

>> 1. PALBIT SA

>> 2. FERRO — Grupo Ferpinta

>> 3. Mecachrome Portugal

>> 4. PM Additive

>> 5. SteelSkills – Stainless Steel Solutions Lda

>> Other Notable Suppliers

● Technological Innovations and Manufacturing Processes

>> Powder Preparation

>> Forming and Pressing

>> Sintering

>> Machining and Surface Finishing

>> Inspection and Quality Control

>> Environmental Responsibility

● Industrial Applications of Carbide Plates

>> Metalworking and Tooling

>> Mining and Quarrying

>> Construction and Earthmoving

>> Oil, Gas, and Energy

>> Woodworking and Agriculture

>> Recycling and Environmental Management

>> Medical and Precision Engineering

● Strategic Advantages of Portuguese Carbide Plate Suppliers

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of carbide plates can be sourced from Portuguese manufacturers?

>> 2. Which industries benefit most from carbide plate suppliers in Portugal?

>> 3. How is the quality of carbide plates assured by Portuguese suppliers?

>> 4. Can Portuguese suppliers offer custom OEM carbide plate design and bulk orders?

>> 5. What are the main advantages of choosing a Portuguese carbide plate partner?

Introduction

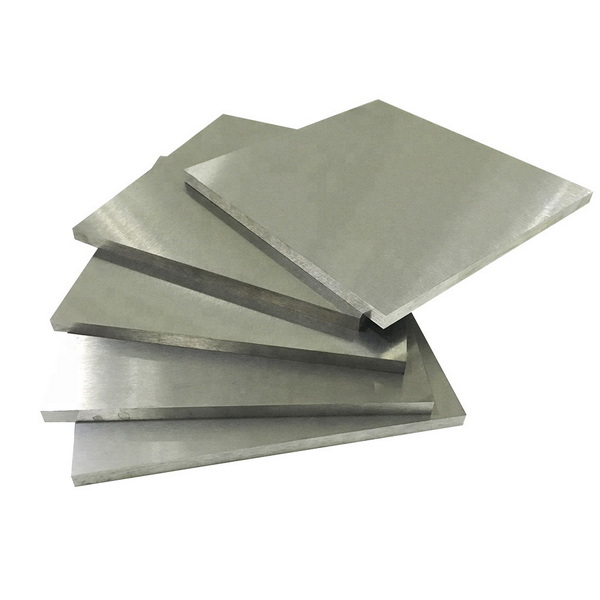

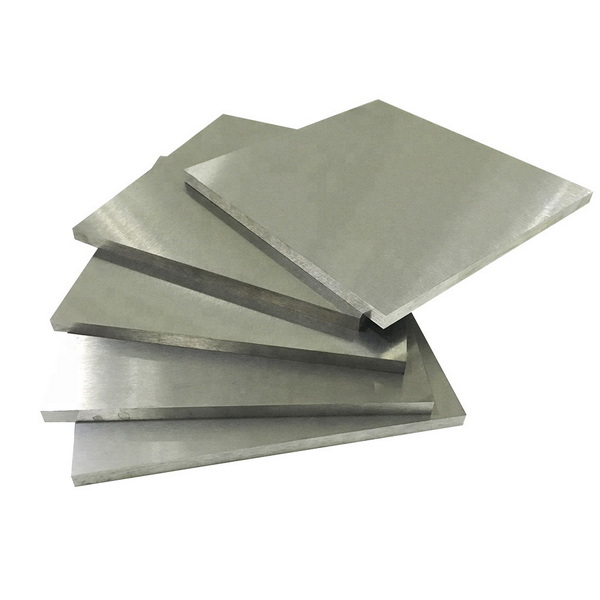

Carbide plates are essential components across various industries, renowned for their unparalleled hardness, durability, and resistance to wear and corrosion. As global manufacturing standards rise, the demand for high-quality carbide plates has also increased, driving the growth and technological advancement of manufacturers and suppliers worldwide. Among the European countries leading in this sector, Portugal stands out with its blend of traditional metallurgical expertise and modern engineering innovation. Portuguese carbide plate manufacturers and suppliers serve OEMs, wholesalers, and industrial brands, delivering bespoke solutions that cater to complex technical and performance requirements.

This comprehensive article explores the top carbide plate manufacturers and suppliers in Portugal. We will delve into their core strengths, production technologies, quality standards, and customized solutions. Furthermore, we will cover the carbide plate manufacturing process, key industrial applications, the benefits of working with Portuguese suppliers, and answer the most common questions buyers have about this specialized field. Whether you are a global distributor, a production manager, or an engineer seeking trusted partners for carbide plate sourcing, this guide is designed to provide a deep understanding of Portugal's capabilities in carbide plate manufacturing.

Overview of Carbide Plate Manufacturing in Portugal

Portugal has established a strong reputation in Europe's advanced engineering and specialty metals sector. Its strategic location, highly skilled workforce, and culture rooted in metallurgy have allowed it to foster an ecosystem of manufacturers excelling in the production of carbide plates. Portuguese suppliers are characterized by their commitment to continuous improvement, investment in research and development, and ability to meet stringent global quality standards.

Over time, the nation's carbide plate industry has diversified its offerings, catering not only to traditional applications but also to cutting-edge sectors that demand technical excellence and customization. Modern Portuguese carbide plate manufacturers integrate state-of-the-art machinery, quality management systems, and sustainable practices to remain at the forefront of global supply chains.

Top Carbide Plate Manufacturers and Suppliers in Portugal

1. PALBIT SA

PALBIT SA is Portugal's most prominent producer of tungsten carbide products and occupies a leading position in the domestic and international carbide plate market. With decades of experience and technical expertise, PALBIT produces a wide range of tungsten carbide plates used in metal cutting, surface wear, machining, and tooling applications. Their manufacturing facilities feature the full cycle of production, from powder preparation to precision grinding and coating, ensuring strict quality control throughout every phase.

Key strengths of PALBIT SA include a robust R&D department, advanced product testing, and in-house engineering teams that collaborate with customers to develop tailored carbide plate solutions. The company serves clients across Europe, North America, Asia, and other regions, offering both standard and customized dimensions for diverse industries. PALBIT's commitment to sustainability is reflected in its responsible sourcing of raw materials and continuous efforts to optimize energy usage during manufacturing.

2. FERRO — Grupo Ferpinta

As part of one of Portugal's largest groups in the steel and specialty metals sector, FERRO — Grupo Ferpinta extends its expertise to the production and processing of advanced alloy plates, including specialty solutions for industrial wear applications. FERRO's emphasis on complete service—spanning material selection, cutting, surface treatment, and logistics—makes it a reliable partner for clients seeking competitively priced, high-performance plates that can be integrated into various manufacturing systems.

FERRO offers efficient lead times and scalable production, which is especially advantageous for international clients engaged in large-scale OEM production or continuous operations that depend on consistent supply chains.

3. Mecachrome Portugal

Specializing in advanced engineered components, Mecachrome Portugal supports sectors such as aerospace, defense, and energy with high-precision carbide and hardened alloy parts. The company's use of advanced machining techniques and strict quality assurance protocols enables the fabrication of carbide plates and wear elements with exacting tolerances. Mecachrome's collaborative engineering approach includes co-design with customers, materials consulting, and rapid prototyping—all key for projects that require custom carbide plate solutions for technically demanding environments.

4. PM Additive

Standing at the intersection of powder metallurgy and additive manufacturing, PM Additive leverages modern sintering and molding techniques to produce tungsten carbide plates and related products. PM Additive is especially adept at serving OEM clients with custom dimensions, complex geometries, and batch production. Their laboratory equipment supports high-purity powder mixing, isostatic pressing, and the production of carbide plates designed for exceptional performance in abrasive and high-heat settings.

5. SteelSkills – Stainless Steel Solutions Lda

While primarily focused on stainless steel plate and sheet solutions, SteelSkills offers composite and laminated plates that include hard metals such as carbides as wear surfaces. Their expertise in metal forming, sheet processing, and surface finishing allows for integration of carbide plate segments into advanced assemblies, serving clients in the mechanical, construction, and industrial fabrication sectors.

Other Notable Suppliers

Portugal's growing reputation as a reliable source of advanced engineering materials means that more companies are entering the market with mastery in sheet metal processing, rapid prototyping, and supply of bespoke wear-resistant components. OEMs and global distributors seeking to diversify their supply chain can leverage Portugal's broad ecosystem for both large and small volume orders.

Technological Innovations and Manufacturing Processes

The manufacturing of carbide plates is a multi-stage process that demands precision, material science expertise, and rigorous quality management. Here's a closer look at each step:

Powder Preparation

The journey begins with the careful selection and blending of carbide powders—most commonly tungsten carbide, silicon carbide, or other high-hardness variants. The powders are then mixed with metallic binders, such as cobalt or nickel, to enhance toughness and promote sintering. Homogeneous mixing is paramount to the plate's final structural integrity.

Forming and Pressing

Once mixed, the powder is shaped into slabs or plates using uniaxial, isostatic, or extrusion pressing methods. This step is crucial for achieving density distribution and preliminary geometric accuracy. Advanced manufacturers use automated presses that allow for precise control over pressure and compaction time.

Sintering

Sintering is the heart of carbide plate production. The pressed "green" plates are subjected to extremely high temperatures—often in the range of 1,300°C to 1,500°C—in an inert or vacuum atmosphere. This process bonds the carbide particles, creating a dense and exceptionally hard structure that is able to withstand extreme compressive forces and abrasive environments.

Machining and Surface Finishing

After sintering, plates are machined and ground to the desired dimensions, with tolerances often reaching the micron level. High-precision CNC machines, specialized grinding wheels, and diamond tools are used to achieve superior surface finishes. Some products are further enhanced with advanced coatings—such as physical vapor deposition (PVD) or chemical vapor deposition (CVD)—which provide additional resistance to wear, corrosion, and high temperatures.

Inspection and Quality Control

Each carbide plate undergoes intensive quality checks, including dimensional inspection, density analysis, and surface hardness testing. Manufacturers invest in non-destructive examination (NDE) techniques to identify potential micro-structural flaws and guarantee product reliability before shipment.

Environmental Responsibility

Many Portuguese manufacturers are aligned with European Union directives on sustainability, focusing on energy efficiency, waste reduction, and responsible sourcing of raw materials. Recycling initiatives are commonplace, ensuring both environmental protection and cost-effective production.

Industrial Applications of Carbide Plates

Carbide plates possess an exceptional combination of hardness, toughness, and chemical resistance, making them indispensable in diverse applications. Let's explore a range of sectors where these plates are vital:

Metalworking and Tooling

Carbide plates form the backbone of metal cutting tooling—used as inserts, cutters, dies, and blades in machinery that demands high-speed, high-precision metal removal. Their long service life reduces downtime and maintenance costs in heavy manufacturing, automotive, and aerospace production lines.

Mining and Quarrying

One of the harshest environments, mining operations rely on carbide plates as wear-resistant liners in chutes, hoppers, crushers, and conveyor systems. Their resistance to impact and abrasion ensures fewer interruptions and lower replacement rates over time.

Construction and Earthmoving

Machinery such as bulldozers, excavators, and road milling equipment incorporate carbide plates into cutting edges, teeth, and protection linings. The exceptional strength and durability of these plates maximize operational efficiency and minimize operating expenditure for contractors.

Oil, Gas, and Energy

Carbide plates are fundamental in drilling, extraction, and refining equipment, where they serve as bearing surfaces and protective layers. Their ability to endure extreme pressure, corrosive fluids, and temperature swings makes them critical for safety and efficiency in energy exploration.

Woodworking and Agriculture

Carbide plates form long-lasting blades and cutting instruments in woodworking machinery and agricultural implements such as tillage tools and harvester teeth. Their sharpness and resilience outperform traditional steel in demanding conditions.

Recycling and Environmental Management

Robust carbide plates enable efficient shredding and cutting in waste management, recycling plants, and composting facilities. Their reliability ensures uninterrupted operations and reduced downtime.

Medical and Precision Engineering

Carbide plates, when manufactured to ultra-high tolerances, become key elements in precision instrumentation, surgical tools, and high-end measuring devices. Their stability and inertness meet the stringent requirements of critical industries.

Strategic Advantages of Portuguese Carbide Plate Suppliers

Portuguese carbide plate manufacturers and suppliers stand out in the global arena for several strategic reasons:

- Quality Assurance: Portuguese companies adhere to strict European quality assurance standards and certifications. This focus on excellence is reflected in the dependability and performance of every carbide plate produced, giving customers confidence in both standard and bespoke solutions.

- Customization and Flexibility: The ability to work closely with clients, understand their technical needs, and deliver made-to-order carbide plate solutions is a core strength. Whether needed for high-volume OEM production or highly specialized one-off applications, Portuguese firms excel in adaptability.

- Advanced Technology and Engineering: Investment in modern production lines, integrated R&D, and digital engineering has elevated Portugal's carbide plate industry to global competitiveness. Customers benefit from novel products, reduced lead times, and continuous innovation.

- Competitive Pricing with Value-Added Support: By combining cost-efficient manufacturing with comprehensive technical and after-sales support, Portuguese suppliers deliver outstanding value. This is particularly important for global partners seeking to optimize their procurement and inventory strategies.

- Proximity and Logistics: Portugal's location provides easy and effective logistical connections to Europe, Africa, the Americas, and beyond, streamlining the delivery process and simplifying coordination for international partners.

- Sustainable Manufacturing: Manufacturers are deeply committed to sustainability through energy management, recycling programs, and eco-responsible production, helping customers align with international environmental standards.

Conclusion

Portugal's carbide plate manufacturers and suppliers have achieved notoriety for combining engineering excellence, technological innovation, and client-focused service. From advanced metallurgical research to personalized customer collaboration, the Portuguese approach offers a compelling proposition for global OEMs, distributors, and end-users. Businesses that source carbide plates from Portugal benefit from quality, reliability, and strategic partnership—attributes that contribute to greater efficiency, operational savings, and a competitive edge in today's demanding industrial landscape.

Frequently Asked Questions (FAQ)

1. What types of carbide plates can be sourced from Portuguese manufacturers?

Portuguese factories provide various carbide plate types, including tungsten carbide, silicon carbide, and cemented carbide plates. These can be supplied in standard or customized sizes tailored to specific industrial applications, offering a balance between hardness, toughness, and resistance to wear and heat.

2. Which industries benefit most from carbide plate suppliers in Portugal?

Key sectors include metalworking, mining, oil and gas, construction, aerospace, woodworking, agriculture, recycling, and medical device manufacturing. Carbide plates are vital wherever long-term resistance to wear, impact, and extreme environments is required.

3. How is the quality of carbide plates assured by Portuguese suppliers?

Manufacturers employ advanced material testing, strict process controls, accredited management systems, and thorough final inspections. Many adhere to ISO and European Union quality standards, ensuring consistency and reliability in every batch shipped.

4. Can Portuguese suppliers offer custom OEM carbide plate design and bulk orders?

Yes, leading manufacturers collaborate with OEMs, distributors, and producers to deliver custom-designed, application-specific carbide plates—ranging from small, complex parts to large-scale productions. Their flexible manufacturing lines accommodate varying order sizes.

5. What are the main advantages of choosing a Portuguese carbide plate partner?

Portuguese suppliers excel in precision engineering, close client collaboration, competitive pricing, logistics efficiency, and adherence to sustainability standards. The combination of technical expertise and responsive service makes them ideal partners for global businesses seeking optimal carbide plate solutions.