Content Menu

● Introduction

● What Are Carbide Saw Tips?

● The Role of Carbide Saw Tips in Modern Industry

● Criteria for Selecting Carbide Saw Tips Manufacturers and Suppliers

● Leading Carbide Saw Tips Manufacturers and Suppliers in the UK

>> Tungsten Carbide Solutions Ltd (TCS Carbide)

>> Dymet Alloys

>> Sheffield Industrial Saws Ltd

>> KR Saws

>> Hyperion Materials & Technologies

>> Additional Noteworthy Suppliers

● Innovations and Quality Standards

● OEM Services for Global Partners

● Applications and Industry Use Cases

● Maintenance and Longevity of Carbide Saw Tips

● Media Resources: Videos and Educational Content

● Conclusion

● FAQ

>> 1. What makes UK carbide saw tips superior in quality?

>> 2. Can I order custom-shaped saw tips for special applications?

>> 3. Are carbide saw tips suitable for both wood and metal cutting?

>> 4. What is the minimum order quantity from UK suppliers?

>> 5. How do I maintain and replace carbide saw tips?

Introduction

The UK stands at the forefront of Carbide Saw Tips manufacturing and supply, providing essential solutions to industries including woodworking, metalworking, construction, and manufacturing. The rising demand for efficiency, durability, and precision has propelled the market for carbide saw tips, with UK manufacturers favoring tungsten carbide due to its outstanding wear resistance and hardness. This comprehensive guide explores the landscape of leading Carbide Saw Tips Manufacturers and Suppliers in the UK, detailing their offerings, technologies, unique advantages, and how to select the best supplier for your needs. Inline images and videos will enhance your understanding of the product and industry.

What Are Carbide Saw Tips?

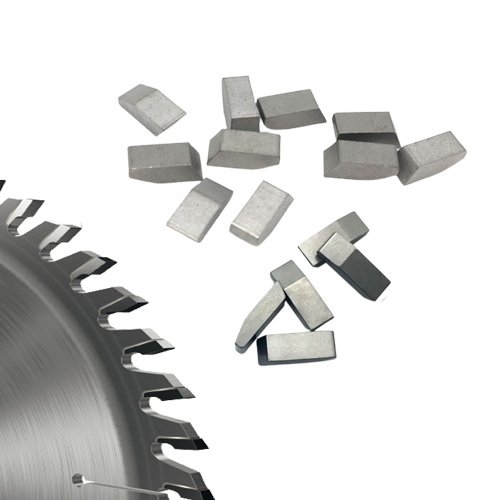

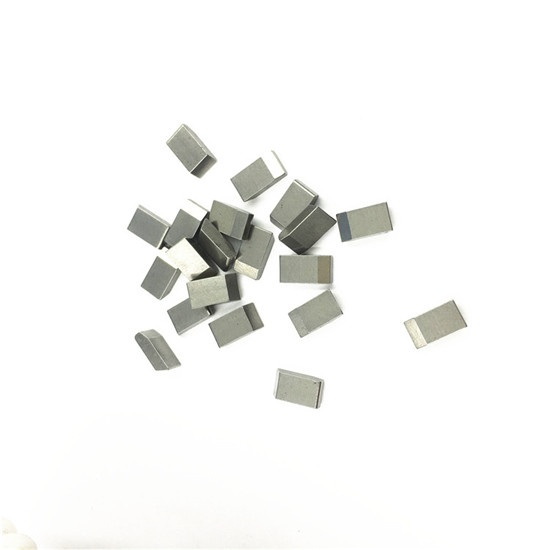

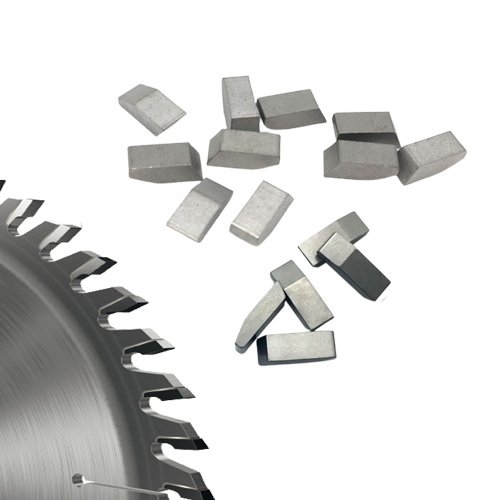

Carbide saw tips are small, brazed cutting inserts used on saw blade teeth to improve cutting performance, extend blade life, and allow for multiple sharpenings. They are mainly composed of tungsten carbide (WC) and cobalt, combining extreme hardness with toughness to withstand high-impact and abrasive applications.

Key features of carbide saw tips include exceptional wear resistance, prolonged operational life, sustained sharpness and cutting precision, and applicability across wood, non-ferrous and ferrous metals, plastics, and masonry.

The Role of Carbide Saw Tips in Modern Industry

Carbide saw tips are indispensable for precision wood cutting and joinery, metal fabrication and manufacturing, construction and demolition, and engineering composite and plastics processing. They minimize downtime, reduce tool replacement frequency, and significantly lower operational costs. Thanks to their hardness and durability, carbide tips maintain their cutting efficiency longer than traditional materials, saving businesses both time and money.

Moreover, carbide saw tips enable precise, clean cuts, which are crucial in high-quality manufacturing and assembly lines. Their ability to retain a sharp edge reduces inconsistencies in production, supporting higher-quality outputs that meet modern industry standards.

Criteria for Selecting Carbide Saw Tips Manufacturers and Suppliers

When evaluating Carbide Saw Tips Manufacturers and Suppliers in the UK, several key factors should be considered:

- Material Quality: Consistency in tungsten carbide grades and precise sintering processes affect the durability and performance of the carbide tips. Using high-purity raw materials with optimal cobalt binder percentage enhances toughness without sacrificing hardness.

- Customization: The flexibility to produce custom sizes, profiles, and grades allows users to tailor saw tips for specific applications, material types, and cutting conditions. Some manufacturers offer specialized geometries designed to optimize cutting efficiency for niche industries.

- Technical Expertise: Access to engineering consultation and ongoing technical support helps customers select the ideal carbide tip grade and design for their unique workflows while troubleshooting any issues that arise.

- Lead Time and Logistics: Prompt supply chains and order fulfillment, including the ability to handle large or urgent orders, are critical to maintaining continuous production schedules.

- Reputation: Proven track records supported by positive customer testimonials, strong industry certifications, and adherence to quality assurance standards instill confidence in buyers evaluating different suppliers.

Leading Carbide Saw Tips Manufacturers and Suppliers in the UK

Tungsten Carbide Solutions Ltd (TCS Carbide)

TCS Carbide is a prominent UK supplier offering an extensive range of saw tip grades tailored for diverse applications. Their range includes:

- K10: Versatile grade suited for both soft and hardwoods.

- K10T: Toughened version ideal for heavy-duty applications such as pallet dismantling.

- K10M: Specifically formulated for ferrous metal cutting.

They supply both pre-brazed and easy-coated tips, suitable for hobbyists and professional manufacturers, with attractive pricing for bulk orders. Their product consistency and reliable delivery schedules have made them a trusted name domestically and internationally.

Dymet Alloys

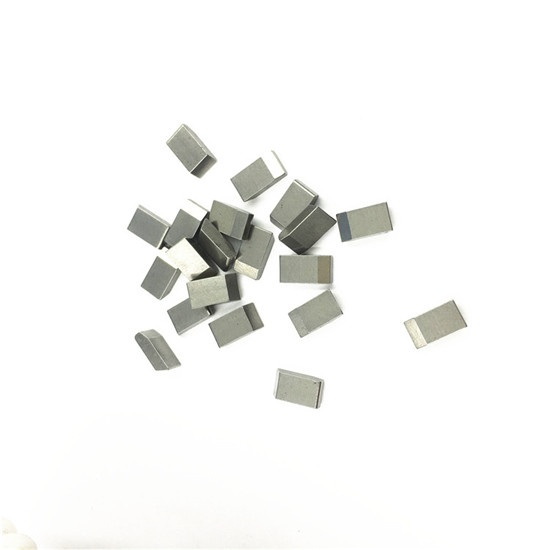

Dymet Alloys specializes in sintered tungsten carbide saw and groover tips designed for wood and metal cutting. They maintain a vast catalog of standard geometries and grades, while their ability to handle custom orders and non-standard profiles appeals to industries requiring tailored cutting solutions.

Key advantages include a 6% cobalt binder content for enhanced toughness and ready-to-braze options that accelerate assembly processes. Dymet's commitment to rapid fulfillment and technical support has positioned them strongly in the UK market.

Sheffield Industrial Saws Ltd

With over 30 years of expertise, Sheffield Industrial Saws manufactures tungsten carbide tipped (TCT) circular saw blades up to 1,820 mm in diameter. Utilizing advanced brazing and grinding techniques, they ensure strong adhesion of carbide tips and ultra-smooth finished surfaces. Their services also include custom geometries and engineering consultancy to address challenging cutting applications requiring precision and durability.

KR Saws

KR Saws, supported by Kinkelder BV, delivers a comprehensive range of high-quality carbide and cermet circular saw blades. Their products often feature advanced coatings to extend tool life and improve performance. Their dedicated technical service team aids clients in selecting appropriate blades and tips for specific materials, such as engineering steels and other metals.

Hyperion Materials & Technologies

Hyperion offers advanced cemented carbide and cermet saw tip blanks, capable of being customized to meet demanding industrial requirements. Their production includes blanks for band saws, circular saws, and hole saws, supporting a broad segment of cutting tool manufacturers globally.

Additional Noteworthy Suppliers

- Carbide Online: Offers a comprehensive online catalog for indexable carbide tips tailored to various applications.

- TUNGSTEN MAN: Recognized for precision-crafted, heavy-duty carbide saw tips focusing on durability and strength.

- Kennametal: An international provider known for premium tungsten carbide and Stellite saw tips, especially used in forestry and lumber industries.

Innovations and Quality Standards

UK carbide saw tip manufacturers are committed to continuous innovation and adherence to rigorous quality standards, contributing to their global reputation.

- Precision Tooling: CNC grinding technologies enable perfect tip geometries essential for stable cutting and reduced wear.

- Advanced Sintering: Optimized sintering processes yield uniform hardness and density throughout the carbide tips, balancing toughness and resistance to fracture.

- Quality Assurance: Most manufacturers operate under ISO 9001 quality management systems, with full traceability of raw materials and production processes.

- Sustainable Manufacturing: Efforts include recycling scrap tungsten carbide and improving materials processing efficiency to minimize environmental impact.

OEM Services for Global Partners

Many UK manufacturers extend Original Equipment Manufacturer (OEM) services to foreign brands, wholesalers, and production companies. OEM offerings typically include:

- Custom branding and packaging solutions.

- Large-scale manufacturing tailored to the client's specifications.

- Engineered solutions integrating customer requirements for size, grade, coating, and performance.

- Global logistics support ensuring timely delivery to diverse markets.

These services have expanded the reach of UK carbide saw tip producers, enabling them to serve specialized industries worldwide.

Applications and Industry Use Cases

Carbide saw tips produced in the UK find applications across multiple industries:

- Woodworking and Joinery: Providing precision cutting for furniture production, cabinetry, and flooring with durability for abrasive hardwoods.

- Metal Fabrication: Assisting in cutting ferrous and non-ferrous metals such as aluminum, brass, and steel, where tip toughness and edge retention are critical.

- Composite Materials: Enabling efficient processing of fiber-reinforced plastics and laminates without excessive blade wear or material chipping.

- Construction and Demolition: Heavy-duty tips withstand impact and dirt contamination when cutting lumber, plywood, and other building materials.

- Automotive Manufacturing: Specialized tips contribute to component cutting during assembly lines with strict tolerance requirements.

Maintenance and Longevity of Carbide Saw Tips

Proper maintenance enhances the usable life of carbide saw tips, including:

- Regular inspection for chipping, cracks, and tip loss.

- Professional sharpening and rebrazing as needed to restore cutting edges.

- Avoiding overheating during use to prevent cobalt binder degradation.

- Using manufacturer-recommended feed rates and speeds to optimize performance and prevent premature wear.

Some UK suppliers offer repair and replacement programs alongside expert technical support, helping customers maximize their tool investment.

Media Resources: Videos and Educational Content

UK manufacturers also provide rich multimedia resources to educate customers on product selection, manufacturing processes, and maintenance techniques. These include factory tours, tutorials on carbide tip installation, and material-specific cut optimization.

Conclusion

The UK's Carbide Saw Tips Manufacturers and Suppliers are globally recognized for their exceptional quality, engineering expertise, and ability to provide tailored solutions for the most demanding applications. Whether you are a local distributor, global OEM, or a precision tool user, UK carbide saw tip manufacturers stand ready to deliver products that maximize efficiency, durability, and cutting performance. Their commitment to innovation, quality, and customer service ensures that buyers receive top-tier carbide saw tips optimized for their specific industrial needs.

FAQ

1. What makes UK carbide saw tips superior in quality?

UK manufacturers adhere to stringent material standards, employ advanced sintering and grinding technologies, and maintain ISO-certified quality systems. This ensures consistently high-grade, durable tips tailored for diverse industrial applications.

2. Can I order custom-shaped saw tips for special applications?

Yes, leading suppliers like Dymet Alloys and Tungsten Carbide Solutions offer custom design and engineering services for shapes, sizes, and grades, suiting niche industrial needs.

3. Are carbide saw tips suitable for both wood and metal cutting?

Absolutely. Different tungsten carbide grades and tip geometries are formulated to optimize cutting performance for wood, ferrous, and non-ferrous metals, plastics, and composites.

4. What is the minimum order quantity from UK suppliers?

Minimum order quantities vary between suppliers. Some offer small pack sizes ideal for hobbyists, while others require larger minimums such as 500 pieces. Bulk pricing and flexible order arrangements are common to support OEM and distributor needs.

5. How do I maintain and replace carbide saw tips?

Periodic inspection, professional re-sharpening, and timely replacement of damaged tips are essential. Many suppliers provide technical support, repair services, and guidance to extend carbide saw tip lifespan.