Content Menu

● Introduction

● The Spanish Carbide Plate Market: Overview

● Why Carbide Plates Are Essential

● Leading Carbide Plate Manufacturers and Suppliers in Spain

>> 1. Mitsubishi Materials España

>> 2. FMD Carbide

>> 3. Abraservice Ibérica

>> 4. Abrasivos Sadi

>> 5. Nova Abrasivos

● Additional Carbide Plate Suppliers and Features

● The Manufacturing Process of Carbide Plates

● Market Trends and Innovations

>> Heavy Industry Growth

>> Sustainability and Innovation

>> Customization and Global Outlook

● Applications of Carbide Plates in Industry

● Selecting a Carbide Plate Supplier in Spain: Key Considerations

● Comprehensive Guide to Working with Spanish Carbide Plate Manufacturers and Suppliers

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What factors should I consider when selecting a carbide plate manufacturer or supplier in Spain?

>> 2. How do carbide plates compare to traditional steel plates?

>> 3. Which industries most frequently rely on Spanish carbide plate manufacturers and suppliers?

>> 4. Can Spanish carbide plate suppliers accommodate custom orders and OEM production?

>> 5. What sustainability practices are found within Spain's carbide plate industry?

Introduction

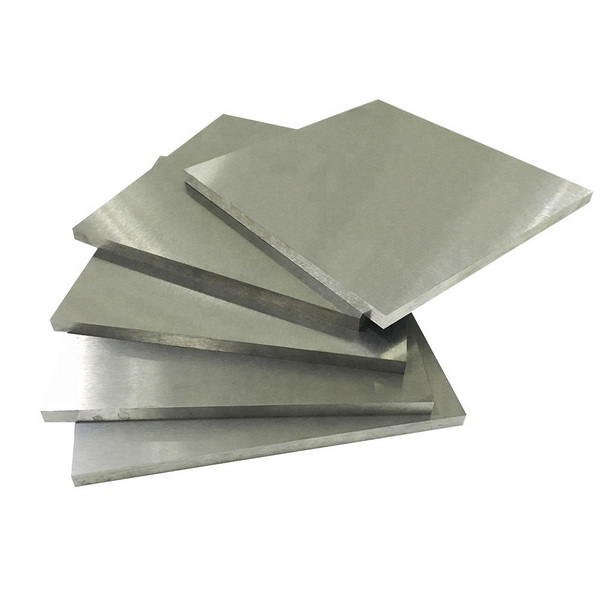

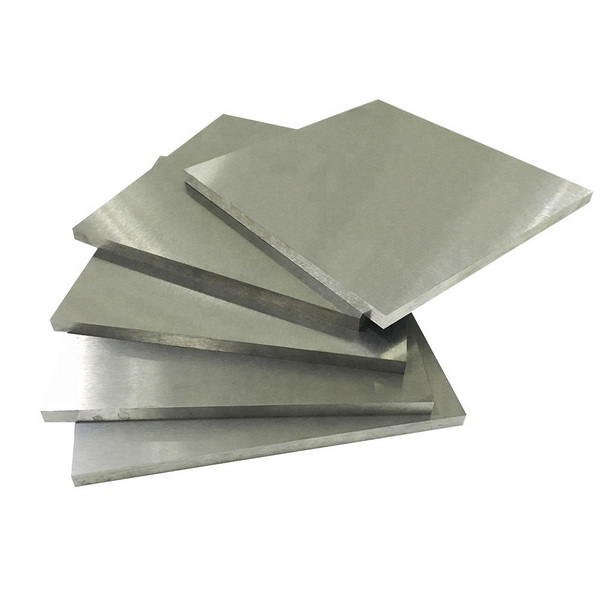

Carbide Plate Manufacturers and Suppliers are cornerstones of Spain's advanced industrial sector. Their ability to produce high-performance tungsten and silicon carbide plates not only supports Spain's domestic manufacturing and heavy industry but also powers global supply chains. This article offers an in-depth look into Spain's leading carbide plate manufacturers and suppliers, market trends, key applications, and what sets Spanish suppliers apart in the international marketplace.

The Spanish Carbide Plate Market: Overview

Spain, renowned for its robust engineering and metallurgical expertise, has seen its carbide plate sector flourish over recent decades. The local market benefits from close integration with both European Union standards and global technological advancements. Spanish manufacturers excel in producing tungsten carbide plates and silicon carbide products, meeting the strictest requirements for hardness, durability, and wear resistance. These products are in high demand by OEMs, wholesalers, and large-scale industrial end users in Europe, North Africa, and beyond.

Notably, the sector's growth is fueled by modernization in Spain's mining, automotive, energy, and tooling industries. Spanish manufacturers blend traditional craftsmanship with cutting-edge laboratory innovations, utilizing automation, digitalization, and eco-friendly processes to deliver quality and sustainability.

Why Carbide Plates Are Essential

Carbide plates are indispensable in contemporary industry due to their unique properties:

- Extreme Hardness: Outperforming regular steel in resistance to abrasion and impact, carbide plates prolong the service life of machinery and tools, minimizing downtime and replacement costs.

- Superb Wear and Corrosion Resistance: Resistant to aggressive chemicals, high temperatures, and abrasive environments, they are ideal in mining, oil & gas, steel production, and high-load machining.

- Consistent Mechanical Strength: Carbide plates maintain full structural integrity under heat and pressure, ensuring steady performance in demanding applications.

- Low Maintenance: Their self-lubricating character and long wear life mean minimal servicing and efficient plant operations.

Leading Carbide Plate Manufacturers and Suppliers in Spain

1. Mitsubishi Materials España

Mitsubishi Materials España operates a flagship factory in Valencia, where it manufactures precision carbide plates for diverse industrial applications. This plant is recognized for its automation, comprehensive quality protocols, and the ability to deliver both standard and custom-engineered solutions. Leveraging its global R&D network, the company serves OEMs with unique technical demands, offering in-depth engineering support and fast turnaround.

2. FMD Carbide

FMD Carbide, based in Bilbao, pioneers “green machining,” which involves shaping carbide blanks in their unsintered state, reducing waste and improving geometrical accuracy. This innovative process supports the production of custom and near-net-shape carbide plates, serving industries that require complex or non-standard geometries. FMD Carbide's commitment to flexibility and customer-led design has made them a trusted partner for OEMs across Spain.

3. Abraservice Ibérica

Positioned near Barcelona, Abraservice Ibérica supplies a comprehensive range of wear-resistant steel and carbide products. Their offering includes CNC machining, laboratory-grade testing, and direct engineering support, ensuring their carbide plates meet client-specific standards. Serving the mining, construction, and energy sectors, Abraservice Ibérica holds ISO 9001 certification and prioritizes both material quality and operational transparency.

4. Abrasivos Sadi

With decades of experience, Abrasivos Sadi is renowned for their high-durability carbide plates, which are widely used in cutting, grinding, and polishing applications. Their expertise extends to flexible abrasives and silicon carbide, making them a go-to supplier for both traditional and cutting-edge applications. Sadi's focus on clean energy and eco-conscious production enhances their position with sustainability-focused buyers.

5. Nova Abrasivos

Nova Abrasivos, based in Barcelona, specializes in advanced flexible abrasives backed by carbide plates for the automotive and precision manufacturing sectors. Their robust R&D investment supports the rapid development of new products, giving them a competitive edge in supplying OEMs and the aftermarket. With just-in-time delivery and custom run options, they ensure customers achieve both operational flexibility and product consistency.

Additional Carbide Plate Suppliers and Features

A number of other suppliers in Spain focus on chromium carbide overlay plates and specialized steel plate distribution. These companies employ advanced welding techniques and offer plates specifically tailored for high-wear industrial uses, such as in cement manufacturing and bulk material handling. Steel distributors in Spain have also adapted to provide logistics solutions for heavy and large-batch carbide plates, serving both Spanish and international customers.

The Manufacturing Process of Carbide Plates

Producing high-quality carbide plates is a complex, multi-step process combining advanced chemistry, precision engineering, and strict quality control. The typical manufacturing workflow includes:

1. Raw Material Selection

High-purity tungsten carbide, silicon carbide, or chromium carbide powders are carefully selected and blended according to strict recipes to ensure desired hardness, toughness, and performance.

2. Mixing and Binding

The chosen powders are mixed with a cobalt binder (for tungsten carbide) or other binding agents, and combined with lubricants to achieve uniformity and workability.

3. Pressing (Compaction)

The mixture is compacted at high pressure into green “blanks” that approximate the final plate dimensions but remain fragile.

4. Green Machining

Some suppliers, like FMD Carbide, perform precision shaping at this stage, using computer-controlled equipment to set exact outlines and preform critical features.

5. Sintering

The blanks are heated in industrial furnaces at temperatures up to 1,500°C, causing the powders to bond, densify, and harden into an ultratough, monolithic structure.

6. Finishing

After sintering, plates are ground, milled, cut, and surface-finished to precise tolerances. Optional advanced coatings, such as PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition), may be applied to enhance surface hardness or chemical resistance.

7. Quality Control and Testing

Each production batch is subjected to rigorous inspection—including visual checks, dimensional analyses, hardness testing, and sometimes non-destructive evaluation techniques—to ensure each plate meets international and customer-specific standards.

Modern Spanish factories integrate automation, digital quality monitoring, and environmentally responsible practices throughout the process, ensuring both product reliability and eco-friendly manufacturing.

Market Trends and Innovations

Heavy Industry Growth

The main market drivers for carbide plates include sustained growth in mining, construction, energy, and precision tooling. With materials engineering advancing rapidly, premium carbide plates are now vital for extending tool life, reducing energy consumption, and minimizing maintenance intervals.

Sustainability and Innovation

Spanish manufacturers are increasingly prioritizing green production methods. This includes recycling carbide scrap, optimizing energy use within sintering furnaces, and reducing water and chemical waste. Many companies actively participate in circular economy programs, reclaiming spent carbide products and reintegrating them into new production cycles.

Customization and Global Outlook

OEM customers in Spain and across Europe demand not only high-quality standard plates but also custom geometries, composite overlays, and specialized finishes. Spanish suppliers excel in providing technical support, co-development, and bespoke manufacturing both for local and international projects. The export share of Spanish carbide plate output continues to rise, especially to neighboring European countries, North Africa, and parts of the Americas.

Applications of Carbide Plates in Industry

Carbide plates have a vast and growing range of uses throughout modern industry:

- Mining and Construction: Use as wear-resistant plates for chutes, buckets, crushers, and drilling tools.

- Automotive: Forming dies, stamping plates, and parts exposed to repeated vibration or impact.

- Oil & Gas: Valve plates, erosion-resistant washers, and downhole tools exposed to abrasive fluids.

- Steel and Cement Manufacturing: Liners, wear bars, and guide plates in bulk material handling.

- Precision Manufacturing: Electronic heat sinks, non-magnetic shielding, and custom tooling.

- Energy Sector: High-temperature and pressure-resistant applications, especially in renewable power generation.

Their superior performance over conventional steel extends the intervals between replacements, significantly enhancing productivity and cost efficiency for end-users.

Selecting a Carbide Plate Supplier in Spain: Key Considerations

Choosing a supplier for carbide plates in Spain should be guided by several critical criteria:

- Technical Expertise: Suppliers should demonstrate a deep technical understanding of carbide production, including the ability to develop custom solutions for challenging requirements.

- Quality Assurance: Look for suppliers holding international certifications—such as ISO 9001—with transparent quality control systems.

- Customization Capabilities: The best suppliers offer tailored manufacturing, from dimensions and material grades to advanced coatings and surface engineering.

- After-sales Support: Reliable suppliers provide technical assistance, logistics help, and clear communication throughout the supply chain.

- Sustainability Commitment: Environmental responsibility is increasingly important; top suppliers use recycled materials and energy-efficient production.

- International Logistics: Effective export documentation, robust packaging, and flexible delivery options are essential for foreign buyers and OEM partners.

Working with suppliers who score highly in these areas ensures both product quality and a seamless sourcing experience for international customers.

Comprehensive Guide to Working with Spanish Carbide Plate Manufacturers and Suppliers

For foreign brand owners, wholesalers, and OEMs, sourcing carbide plates from Spain offers a blend of quality, innovation, and service. To maximize the benefits, consider the following steps:

- Clearly Define Your Application: Understanding the exact operating environment, wear conditions, and performance expectations enables suppliers to recommend the most appropriate plate formulation and geometry.

- Ask About Customization: Leading Spanish manufacturers thrive on challenging, non-standard requirements. Request custom dimensions, coatings, or assembly integration as needed.

- Request Testing Documentation: Reputable suppliers readily provide mechanical properties, dimensional inspection records, and compliance certifications.

- Clarify Lead Times and Logistics: The best suppliers coordinate every aspect of export, from packaging to customs paperwork and after-sales technical support.

- Discuss Sustainability Initiatives: If environmental responsibility matters to your organization, inquire about recycled powder use, emissions controls, and participation in carbon-reduction programs.

By following these guidelines, buyers develop long-term, strategic partnerships with Spanish Carbide Plate Manufacturers and Suppliers, ensuring consistent access to some of the world's highest quality industrial materials.

Conclusion

Spain's carbide plate manufacturers and suppliers exemplify a unique combination of innovation, traditional expertise, and dedication to quality. With state-of-the-art facilities, a customer-centric approach, and a strong focus on both environmental responsibility and advanced engineering, Spanish companies stand out as reliable partners in the global market. Whether you are sourcing standard plates, seeking fully custom OEM solutions, or prioritizing sustainability, Spain offers a robust network of factories and suppliers ready to exceed modern industrial needs. By choosing Spain as your sourcing destination for carbide plates, you are guaranteed access to world-class materials, responsive service, and future-ready technology that empowers success in even the most challenging applications.

Frequently Asked Questions (FAQ)

1. What factors should I consider when selecting a carbide plate manufacturer or supplier in Spain?

Look for technical expertise, quality certifications, customization options, after-sales support, a focus on sustainability, and strong export logistics. Engaging in direct dialogue with the supplier about your specific needs ensures the best fit for your business.

2. How do carbide plates compare to traditional steel plates?

Carbide plates offer much greater hardness, wear and corrosion resistance, and heat tolerance than steel. This leads to longer life cycles, lower overall costs, and improved performance in tough environments.

3. Which industries most frequently rely on Spanish carbide plate manufacturers and suppliers?

Key sectors include mining, construction, automotive, steel, cement, energy, oil & gas, and precision component manufacturing. These industries depend on the durability and reliability of carbide plates to maximize productivity and minimize downtime.

4. Can Spanish carbide plate suppliers accommodate custom orders and OEM production?

Yes. Most Spanish suppliers are well-versed in providing tailor-made solutions to meet unique OEM requirements, offering engineering support, fast sample turnaround, and full series production capabilities.

5. What sustainability practices are found within Spain's carbide plate industry?

Spain's leading suppliers adhere to strict environmental standards, using recycled powders, minimizing emissions, reusing energy and water, and advancing circular economy initiatives. Buyers can often request detailed documentation on a supplier's eco-friendly practices.