Content Menu

● Introduction

● What are Carbide Saw Tips?

● Russian Market Overview: Carbide Saw Tips Manufacturers and Suppliers

>> Why Russia?

● Leading Carbide Saw Tips Manufacturers and Suppliers in Russia

>> 1. Zhuzhou Xinpin Cemented Carbide Co., Ltd.

>> 2. Local Tungsten Carbide Factories

>> 3. International Brands Operating in Russia

>> 4. OEM/ODM Suppliers

● Manufacturing Process of Carbide Saw Tips

● Key Specifications and Standards

● Applications of Carbide Saw Tips

● Choosing the Right Carbide Saw Tips Manufacturer or Supplier

● Top Russian Carbide Saw Tips Manufacturers and Suppliers: Case Studies

>> Case Study 1: Saw Tips Supplier for Frozen Wood

>> Case Study 2: Custom-Profiled Saw Tips for Non-Ferrous Metal

>> Case Study 3: OEM Supply for Export-Oriented Woodworking OEMs

● Advances and Trends in Carbide Saw Tips Manufacturing

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main benefits of sourcing from Russian Carbide Saw Tips Manufacturers and Suppliers?

>> 2. How do I select the right carbide grade for my application?

>> 3. What certifications should I expect from top Carbide Saw Tips Manufacturers and Suppliers?

>> 4. Do Russian suppliers support OEM/ODM for international brands?

>> 5. How can I ensure ongoing tool performance and maintenance?

Introduction

In the ever-evolving world of industrial manufacturing and construction, carbide saw tips have become indispensable for their unrivaled durability and cutting efficiency. Particularly in Russia—a country renowned for its heavy industry, forestry, and manufacturing sectors—the demand for reliable carbide saw tips and the search for reputable manufacturers and suppliers is ever-increasing. This article takes a comprehensive, in-depth look at the Russian market for carbide saw tips, unveiling the leading manufacturers and suppliers, exploring their technologies, and providing valuable guidance for OEMs, brand owners, wholesalers, and industrial users around the world. Throughout, we maximize the appearance of the phrase “Carbide Saw Tips Manufacturers and Suppliers” to ensure keyword relevance while maintaining a natural flow.

What are Carbide Saw Tips?

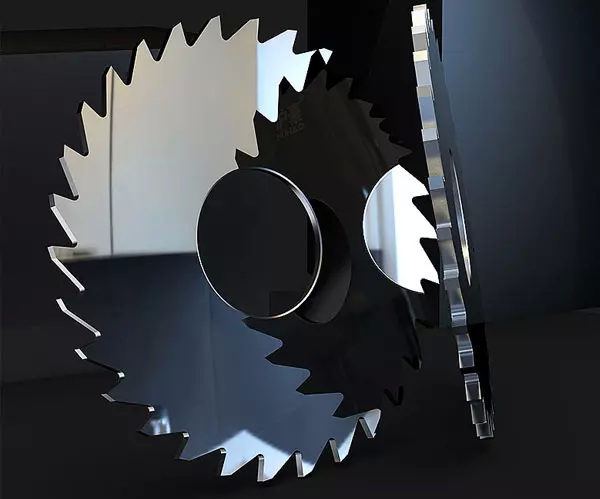

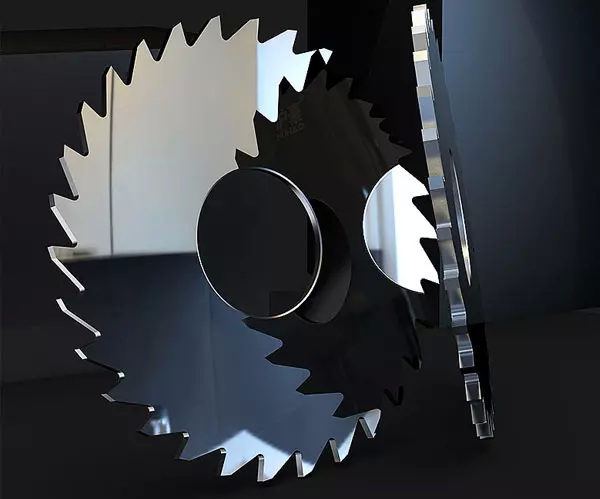

Carbide saw tips, also called tungsten carbide saw tips, are extremely hard inserts brazed onto the teeth of saw blades and cutting tools. Combined with a blade body—often steel—these tips allow for longer edge retention, resistance to abrasion, and the ability to cut even the toughest materials. Made predominantly of tungsten carbide and cobalt binders, these tips are essential in woodworking, metalworking, plastics, and composites for both industrial and DIY applications.

Carbide saw tips come in various shapes (rectangular, trapezoidal, round), sizes, and edge geometries, each tailored for specific cutting requirements. By choosing the right carbide saw tips manufacturers and suppliers, users ensure consistent performance and a long service life for their tools.

Russian Market Overview: Carbide Saw Tips Manufacturers and Suppliers

Why Russia?

Russia's substantial demand for carbide saw tips originates from its massive woodworking, mining, construction, and metal processing industries. The market is supplied by both domestic and international carbide saw tips manufacturers and suppliers, with an increasing contingent of local factories focusing on cost-effective customization, quick delivery, and OEM/ODM services, especially for imported brands and global production chains. The unique climatic and geological conditions in Russia, including harsh winters and frozen woods, have driven innovation among manufacturers to develop specialized carbide tips capable of enduring these challenges, boosting demand for advanced, reliable products.

Leading Carbide Saw Tips Manufacturers and Suppliers in Russia

1. Zhuzhou Xinpin Cemented Carbide Co., Ltd.

- Location: Major exporter serving Russia, with local distribution networks

- Products: YG6, YG8, K10, K20, K30, YG11 tungsten carbide saw tips for woodworking (soft/hard), frozen wood, metal and non-ferrous sawing

- Key Features:

- 100% virgin raw material

- ISO-certified quality

- Wide range of standard/custom grades and dimensions

- Pre-tinned carbide teeth for easier brazing/welding

- Fast delivery (OEM/ODM services for foreign brands)

- Main Applications: Wood, HDF/MDF, chipboard, plywood, aluminum, copper, steel

- Export Markets: Russia, Brazil, Turkey, Korea, Japan, India

2. Local Tungsten Carbide Factories

- Product Focus: Circular saw blade tips, band saw tips, customized geometries

- Typical Grades: YG6, YG11, K10, K20, K30

- Competitive Advantages:

- Customization for regional wood species and climate (e.g., frozen wood)

- Factory-direct pricing

- Responsive technical support

- Both small-quantity and large-volume supply options

Many local manufacturers emphasize developing tips that meet the specific requirements of the Russian market, such as increased toughness and impact resistance for frozen or extremely hard wood. Their ability to adapt quickly to changing industrial demands makes them vital suppliers in the region.

3. International Brands Operating in Russia

Leading global companies such as Kennametal, Sandvik Coromant, and Kyocera maintain active distribution and support channels in Russia. They offer:

- Advanced carbide grades and advanced coating technologies

- High precision manufacturing tolerances

- Longer tool lifespan with specialized designs for metal and composite cutting

- Knowledge transfer and localized technical support for Russian clients

These brands often serve high-end industrial customers that require premium-quality carbide saw tips and are willing to pay a premium for such features.

4. OEM/ODM Suppliers

OEM and ODM producers play a critical role by offering tailor-made carbide saw tips designed for specific company brands and projects. Their services include:

- Complete design support and prototyping

- Material and grade optimization depending on client applications

- Private labeling and packaging solutions

- Flexibility in production volumes from small batch to mass manufacturing

This allows foreign brands and wholesalers to enter the Russian market smoothly, backed by manufacturing partners skilled in localized requirements.

Manufacturing Process of Carbide Saw Tips

Understanding how Carbide Saw Tips Manufacturers and Suppliers produce top-quality products offers insight into performance and value.

1. Raw Material Mixing & Powder Metallurgy

- Pure tungsten carbide powder is blended with cobalt or other binders.

- The mix is pressed into tip shapes under high pressure and sintered at over 1,400°C for maximum density and hardness.

2. Preforming and Sintering

- Precision molds enable consistent tip size and geometry.

- Strict control ensures minimal porosity and flawless bonds.

3. Surface Treatment

- Sandblasting, polishing, or nickel/tin pre-coating prepares tips for brazing onto the blade.

- Additional coatings such as titanium nitride (TiN) or chromium nitride (CrN) may be applied to improve wear resistance and reduce friction.

4. Quality Assurance

- Optical and mechanical inspection, measurement of tolerances, and strength testing guarantee every shipment meets demanding industrial standards.

- Traceability and batch testing ensure consistent product quality.

These manufacturing steps highlight the advanced technology and attention to detail that underpin reliable carbide saw tip performance.

Key Specifications and Standards

| Attribute | Typical Range/Standard |

| Size | Thickness 0.5-5mm, Width up to 20mm |

| Grade | YG6, YG8, K10, K20, K30, YG11 |

| Edge Geometry | Flat, beveled, rounded, pointed |

| International Standards | ISO, ANSI, DIN |

| Tolerance | ±0.001mm to ±0.01mm |

| Coatings | Optional: TiN, CrN, others |

| Price Per Tip | $2.00–$20.00 (dependent on grade/volume) |

These specifications serve as fundamental criteria when evaluating potential suppliers to ensure a perfect match for the intended industrial use.

Applications of Carbide Saw Tips

Leading Carbide Saw Tips Manufacturers and Suppliers cater to diverse industrial and commercial needs:

- Woodworking: Soft/hard wood, plywood, HDF, MDF, chipboard, frozen wood

- Metalworking: Aluminum, copper, steel, non-ferrous metals

- Stone and Masonry: Concrete, stone, tiles (with specialized tips designed for masonry cutting)

- Plastic and Composite Materials: Laminates, engineered boards, composites for automotive and aerospace sectors

The versatility of carbide saw tips expands their market potential across industries, with each supplier often specializing in niche applications depending on material demands and cutting environments.

Choosing the Right Carbide Saw Tips Manufacturer or Supplier

When sourcing for Russia or global markets, consider:

- Material Quality: Ensure 100% virgin material and correct binder ratios for the intended application to avoid premature failure.

- Customization Capacity: Whether standard or unique profiles, top suppliers offer quick prototyping and small batch options.

- Certifications: Look for ISO9001, CE, or other internationally recognized quality marks that guarantee product reliability.

- OEM/ODM Experience: Vital for private brand owners and global wholesalers who need custom-tailored solutions.

- Technical Support: Local language support, after-sales service, and detailed technical documentation help optimize tool usage.

- Pricing and Delivery: Competitive, transparent pricing; on-time shipment and flexible logistics are crucial for supply chain stability.

- Sustainability Practices: Environmentally conscious manufacturing and recycling efforts are becoming factors in supplier selection.

Establishing a strong partnership with a reliable carbide saw tips manufacturer and supplier can yield long-term benefits, including improved product quality and reduced downtime.

Top Russian Carbide Saw Tips Manufacturers and Suppliers: Case Studies

Case Study 1: Saw Tips Supplier for Frozen Wood

Russia's harsh climate means special requirements for carbide tips used in frozen wood cutting. Manufacturers like Zhuzhou Xinpin and their local partners offer pre-tinned, impact-resistant grades and free design support for such conditions. These carbide saw tips maintain sharpness and resist chipping even under extremely low temperatures, ensuring efficient cutting during winter logging operations.

Case Study 2: Custom-Profiled Saw Tips for Non-Ferrous Metal

For the vast Russian non-ferrous metal industry, custom carbide formulations and tip geometries address unique chip loads and minimize tool breakage. Suppliers collaborate closely with end-users to optimize hardness, toughness, and edge design, which results in longer tool life and smoother cutting performance in aluminum, copper, and brass processing.

Case Study 3: OEM Supply for Export-Oriented Woodworking OEMs

Several Russian manufacturers have expanded their services to provide OEM/ODM solutions for export-oriented woodworking equipment brands. This partnership model includes product design consultation, material optimization, and packaging customization, enabling foreign companies to enter and compete in international markets efficiently.

Advances and Trends in Carbide Saw Tips Manufacturing

- Nano-Grade Carbides: Incorporating nanotechnology improves toughness and sharpness at micro scales, offering longer tool life.

- Sustainable Production: Increasing use of recycled tungsten and eco-friendly binders to decrease environmental impact.

- Smart Coatings: Development of multilayer coatings that reduce cutting temperatures and extend tool lifespan.

- Automation and AI: Robots and AI-driven quality control systems improve manufacturing precision and reduce defects.

- Regional Innovation: Russian manufacturers are experimenting with tip geometries optimized for local wood species and operating conditions, enhancing competitiveness.

Staying informed about these trends enables buyers to understand product evolution and anticipate performance improvements.

Conclusion

Carbide saw tips manufacturers and suppliers in Russia play a crucial role both domestically and internationally, serving as key nodes in the supply chain for woodworking, metal processing, and construction. From innovative, OEM-friendly factories with advanced powder metallurgy to international brands supplying tailored solutions, the Russian market offers a strong mix of quality, technical expertise, and cost advantages. By leveraging strong supplier relationships and clearly defining technical requirements, OEMs, wholesalers, and industrial users can maximize tool performance and business value. Staying up to date with technological advances and local market conditions ensures procurement of carbide saw tips that truly meet the demands of varied industrial environments.

Frequently Asked Questions (FAQ)

1. What are the main benefits of sourcing from Russian Carbide Saw Tips Manufacturers and Suppliers?

Russian suppliers offer localized expertise for hard or frozen wood, competitive pricing, custom design capabilities, and faster delivery for regional markets. Their ability to provide OEM/ODM services also supports private label and export needs.

2. How do I select the right carbide grade for my application?

Grade selection depends on what you're cutting:

- K20/K30: For hard/abrasive materials.

- YG6/YG8: For standard woodworking.

- YG11: For frozen or very hard woods and metal cutting.

Consulting with the supplier about your operational conditions can help tailor the choice.

3. What certifications should I expect from top Carbide Saw Tips Manufacturers and Suppliers?

Look for ISO9001 quality management, export licenses, CE marking, SGS inspection reports, and adherence to DIN or ANSI standards to ensure compliance and product reliability.

4. Do Russian suppliers support OEM/ODM for international brands?

Yes. Many Russian and China-based suppliers servicing the Russian market offer full OEM/ODM design and packaging services for foreign brands, enabling customized products with flexible order volumes.

5. How can I ensure ongoing tool performance and maintenance?

Choose suppliers who provide technical documentation, recommended operating guidelines, and after-sales support such as sharpening protocols and troubleshooting advice tailored to different materials and cutting conditions.