Content Menu

● Introduction to Tungsten Carbide

>> Synthesis of Tungsten Carbide

>>> Chemical Vapor Deposition (CVD) Methods

>> Cemented Carbide Production

● Challenges in Making Tungsten Carbide Bullets

● Innovations in Tungsten Carbide Ammunition

>> Tungsten Core Bullets

>>> MRX Bullets

>> Smart Munitions

● Production Process for Tungsten Carbide Bullets

● Advanced Techniques in Tungsten Carbide Production

>> 3D Printing and Additive Manufacturing

>> Nanomaterials and Composite Materials

>> Environmental Considerations

● Applications of Tungsten Carbide Bullets

>> Military Applications

>> Hunting and Sport Shooting

>> Law Enforcement

● Conclusion

● FAQ

>> 1. What are the primary challenges in using tungsten carbide for small arms ammunition?

>> 2. How is tungsten carbide synthesized for bullet production?

>> 3. What innovations have been made in tungsten carbide bullets?

>> 4. What are the advantages of using tungsten carbide in armor-piercing ammunition?

>> 5. Are tungsten carbide bullets widely used in hunting or military applications?

● Citations:

Tungsten carbide is renowned for its exceptional hardness and density, making it an ideal material for applications requiring high wear resistance and penetration capabilities, such as armor-piercing ammunition. However, manufacturing tungsten carbide bullets involves complex processes that require precise control over materials and conditions. This article will delve into the production process of tungsten carbide bullets, highlighting the challenges and innovations in this field.

Introduction to Tungsten Carbide

Tungsten carbide (WC) is a compound of tungsten and carbon, typically produced by reacting tungsten metal with carbon at high temperatures. It is often used in cemented form, mixed with a binder like cobalt, to enhance its mechanical properties for industrial applications.

Synthesis of Tungsten Carbide

The synthesis of tungsten carbide powder involves heating tungsten metal or powder with carbon at temperatures between 1,400°C and 2,000°C. Alternatively, a fluid bed process can be used at lower temperatures (900°C to 1,200°C) with a gas mixture of CO/CO2 and H2.

Chemical Vapor Deposition (CVD) Methods

CVD methods offer another route to producing tungsten carbide. For example, reacting tungsten hexachloride with hydrogen and methane at 670°C can yield WC.

WCl6 + H2 + CH4 → WC + 6HCl

Cemented Carbide Production

Cemented carbide is made by mixing tungsten carbide powder with a binder, typically cobalt, and then sintering the mixture at high temperatures (1,400°C to 1,600°C). This process creates a strong, wear-resistant material ideal for cutting tools and other industrial applications.

Challenges in Making Tungsten Carbide Bullets

While tungsten carbide offers superior hardness and density, its use in small arms ammunition poses several challenges:

1. Hardness and Wear: Tungsten carbide is much harder than traditional bullet materials like lead or copper-jacketed rounds. This hardness can lead to increased barrel wear and potential damage to firearms.

2. Cost and Machining: Tungsten carbide is more expensive and difficult to machine than lead or copper, making it less practical for mass production of small arms ammunition.

3. Impact Behavior: Unlike softer materials that mushroom upon impact, tungsten carbide tends to maintain its shape, potentially leading to over-penetration and reduced effectiveness in transferring energy to the target.

Innovations in Tungsten Carbide Ammunition

Despite the challenges, tungsten carbide is used in specialized ammunition, particularly for armor-piercing rounds where its high density and hardness are advantageous.

Tungsten Core Bullets

Some manufacturers have developed bullets with tungsten cores, often encased in a copper jacket to mitigate barrel wear and improve expansion characteristics. These bullets are designed for deep penetration and are effective in hunting large game.

MRX Bullets

MRX bullets feature a tungsten core covered by a copper jacket and have a polymer tip for improved long-range accuracy and expansion. These bullets are designed to transfer energy efficiently into the target, creating extensive wound channels.

Smart Munitions

Advanced tungsten bullets are being integrated into smart munitions systems, where their high density and controlled fragmentation can enhance the effectiveness of the ammunition by increasing the rate of energy transfer to targets.

Production Process for Tungsten Carbide Bullets

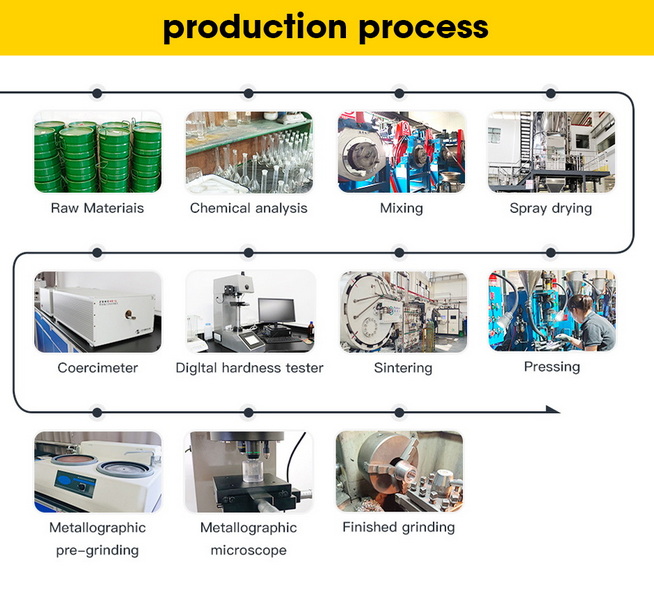

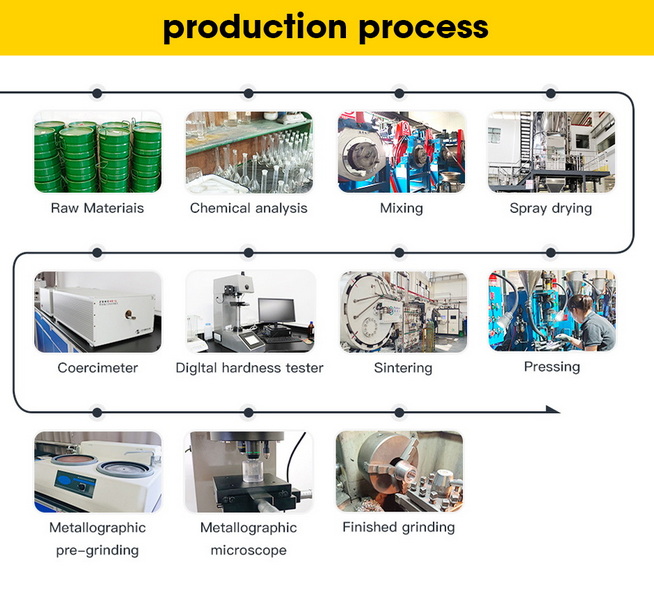

The production of tungsten carbide bullets involves several steps:

1. Synthesis of Tungsten Carbide Powder: This can be achieved through high-temperature reactions or CVD methods.

2. Mixing with Binder: Tungsten carbide powder is mixed with a binder, such as cobalt, to form a uniform blend.

3. Pressing and Sintering: The mixture is pressed into the desired shape and then sintered at high temperatures to form a solid, cohesive material.

4. Machining and Finishing: The sintered carbide is machined into bullet cores, which may then be encased in a copper jacket or other materials to enhance performance.

Advanced Techniques in Tungsten Carbide Production

Recent advancements in materials science and manufacturing have led to more efficient and cost-effective methods for producing tungsten carbide components:

3D Printing and Additive Manufacturing

Techniques like selective laser sintering (SLS) and electron beam melting (EBM) allow for the creation of complex geometries that cannot be achieved through traditional machining. This can improve the performance of tungsten carbide bullets by optimizing their shape for better aerodynamics and penetration.

Nanomaterials and Composite Materials

Research into nanoscale tungsten carbide and composite materials with enhanced mechanical properties is ongoing. These materials could potentially offer improved hardness and toughness, further expanding the applications of tungsten carbide in ammunition.

Environmental Considerations

The use of tungsten carbide in ammunition raises environmental concerns due to the potential for tungsten contamination in soil and water. Manufacturers are exploring more sustainable production methods and materials to mitigate these risks.

Applications of Tungsten Carbide Bullets

Tungsten carbide bullets are primarily used in specialized applications where their unique properties are advantageous:

Military Applications

In military contexts, tungsten carbide is used in armor-piercing rounds to penetrate hardened targets. Its high density allows for effective kinetic energy transfer, making it ideal for anti-tank and anti-aircraft munitions.

Hunting and Sport Shooting

For hunting large game, tungsten carbide bullets offer deep penetration and reliable expansion, ensuring quick and humane kills. However, their cost and potential for over-penetration limit their widespread adoption.

Law Enforcement

Law enforcement agencies may use tungsten carbide bullets in specific scenarios where penetration through barriers is necessary. However, their use is typically limited due to concerns about collateral damage.

Conclusion

Manufacturing tungsten carbide bullets is a complex process that leverages the material's exceptional hardness and density. While challenges exist, innovations in bullet design and materials have made tungsten carbide a valuable component in specialized ammunition. As technology continues to evolve, we can expect further advancements in the use of tungsten carbide in ammunition.

FAQ

1. What are the primary challenges in using tungsten carbide for small arms ammunition?

Tungsten carbide is harder and more expensive than traditional materials, leading to increased barrel wear and higher production costs. Additionally, its hardness can result in over-penetration and reduced effectiveness in transferring energy to targets.

2. How is tungsten carbide synthesized for bullet production?

Tungsten carbide is synthesized by reacting tungsten metal with carbon at high temperatures or through chemical vapor deposition methods.

3. What innovations have been made in tungsten carbide bullets?

Innovations include encasing tungsten cores in copper jackets to reduce barrel wear and improve expansion characteristics, as well as integrating tungsten into smart munitions systems for enhanced energy transfer.

4. What are the advantages of using tungsten carbide in armor-piercing ammunition?

Tungsten carbide offers superior hardness and density, making it ideal for penetrating armor. Its high density also allows for more efficient energy transfer into targets.

5. Are tungsten carbide bullets widely used in hunting or military applications?

While not widely used in small arms due to cost and machining challenges, tungsten carbide is utilized in specialized armor-piercing rounds and some hunting ammunition where its penetration capabilities are advantageous.

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten_carbide

[2] https://www.reddit.com/r/askscience/comments/ylu71/ballistics_question_how_effective_would_bullets/

[3] https://www.ee.cityu.edu.hk/~gchen/pdf/Writing.pdf

[4] https://www.notoalloy.co.jp/english/product/ccpp.html

[5] https://news.ycombinator.com/item?id=15294227

[6] https://blog.csdn.net/qq_34917728/article/details/125122327

[7] https://patents.google.com/patent/US4356034A/en

[8] https://www.africahunting.com/threads/tungsten-core-solid.41718/

[9] https://www.samaterials.com/content/characteristics-of-advanced-tungsten-bullets.html