Content Menu

● Introduction

● Raw Materials and Preparation

● Forming Methods

● Drying and Binder Removal

● Nitridation and Reaction Bonding

● Microstructure and Phase Composition

● Properties of Silicon Nitride Bonded Silicon Carbide Products

● Applications of Silicon Nitride Bonded Silicon Carbide Products

● Advantages Over Other Ceramics

● Quality Control and Testing

● Innovation and Future Trends

● Environmental Considerations in Manufacturing

● Challenges in Production

● Customization and Design Flexibility

● Future Research Directions

● Conclusion

● FAQ

>> 1. What are the main raw materials used in silicon nitride bonded silicon carbide products?

>> 2. How does the nitridation process work in manufacturing silicon nitride bonded silicon carbide products?

>> 3. What are the key properties of silicon nitride bonded silicon carbide products?

>> 4. What are the main applications of silicon nitride bonded silicon carbide products?

>> 5. How do silicon nitride bonded silicon carbide products compare to other silicon carbide ceramics?

Silicon nitride bonded silicon carbide (SNBSC) products are among the most advanced and versatile engineering materials today, widely used across industrial, military, metallurgical, oil drilling, mining, and construction applications. These materials are celebrated for their exceptional strength, thermal shock resistance, corrosion resistance, and longevity in harsh environments. This article explores the manufacturing process, properties, and applications of silicon nitride bonded silicon carbide products in detail.

Introduction

Silicon nitride bonded silicon carbide materials are composite ceramics where silicon carbide (SiC) particles are bonded together by a matrix of silicon nitride (Si₃N₄). This unique combination imparts outstanding mechanical and thermal properties, making SNBSC products indispensable in demanding sectors. Their manufacturing process is a sophisticated blend of materials science and engineering, tailored to achieve high performance and reliability.

Raw Materials and Preparation

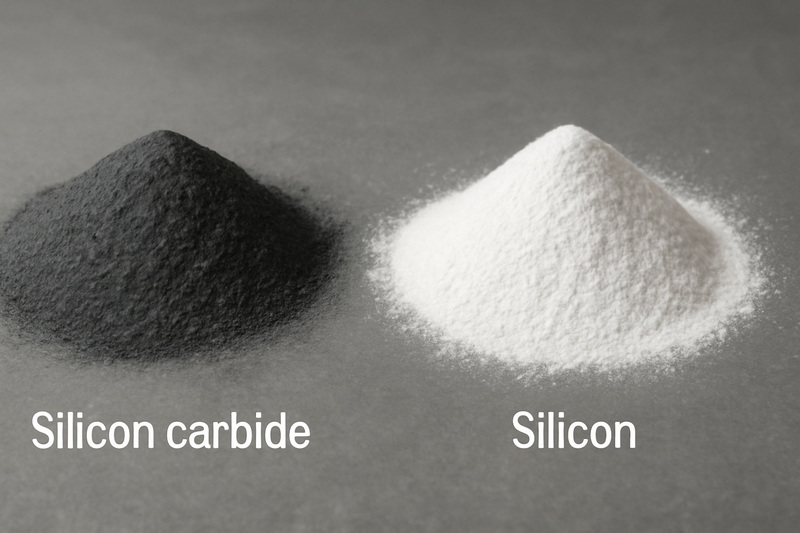

The production of silicon nitride bonded silicon carbide products begins with the selection of high-purity raw materials. The primary ingredients are silicon carbide powder and silicon metal powder. The silicon carbide powder typically ranges in particle size from a few hundred microns to over one millimeter, depending on the desired product characteristics. Silicon metal powder is chosen for its reactivity and fine particle size, which promotes efficient nitridation.

The powders are carefully blended, often with the addition of organic binders to improve green strength during shaping. The binder content is usually kept low (2–4 wt%) to minimize porosity and ensure high final density.

Forming Methods

Silicon nitride bonded silicon carbide products can be shaped using several techniques, each suited to different geometries and production volumes:

1. Uniaxial Pressing:

This method involves compacting the powder mixture in a die under high pressure. It is highly efficient for mass production of simple shapes and results in high-density green bodies.

2. Slip Casting:

The powder mixture is suspended in water to form a slurry, which is poured into porous plaster molds. Water is absorbed by the mold, leaving a solid green body. Slip casting is ideal for complex shapes and large components.

3. Extrusion:

The mixture is forced through a die to create long, uniform shapes such as tubes or rods. This method is suitable for continuous production of specific profiles.

4. Isostatic Pressing:

The powder is compacted in a flexible mold under uniform pressure from all directions, resulting in highly uniform and dense green bodies.

Drying and Binder Removal

After shaping, the green bodies are dried to remove moisture. This step is critical to prevent cracking and ensure dimensional stability. The dried green bodies are then subjected to a binder burnout process, typically at temperatures between 500°C and 800°C. During this stage, organic binders are decomposed and removed, and any residual carbon is minimized to avoid bloating and contamination during subsequent nitridation.

Care must be taken to prevent excessive oxidation of silicon powder, which can form a silica layer on the surface and affect the nitridation process. The atmosphere and temperature profile during burnout are carefully controlled to optimize binder removal and minimize silicon oxidation.

Nitridation and Reaction Bonding

The core of the SNBSC manufacturing process is the nitridation step. The green body is placed in a furnace and heated in a nitrogen-rich atmosphere, typically between 1400°C and 1500°C. At these temperatures, silicon metal reacts with nitrogen to form silicon nitride (Si₃N₄), which acts as the bonding phase for the silicon carbide particles.

The reaction proceeds as follows:

3Si+2N2→Si3N4

The resulting silicon nitride forms a network that binds the silicon carbide particles together, creating a strong and dense composite. The process is highly efficient, with little dimensional change, allowing for near-net-shape production.

Microstructure and Phase Composition

The microstructure of silicon nitride bonded silicon carbide products consists of coarse silicon carbide grains embedded in a fine matrix of silicon nitride. The silicon nitride phase is typically a mixture of α- and β-Si₃N₄, formed under different conditions during nitridation:

- α-Si₃N₄:

Forms at lower temperatures and is stabilized by oxygen impurities.

- β-Si₃N₄:

Favored at higher temperatures and in the presence of liquid silicon or iron-silicon alloy.

The ratio of these phases can be adjusted by controlling the nitridation temperature, atmosphere, and starting material composition, allowing for fine-tuning of material properties.

Properties of Silicon Nitride Bonded Silicon Carbide Products

Silicon nitride bonded silicon carbide products exhibit a unique combination of properties that make them ideal for demanding applications:

1. High Strength:

Excellent mechanical strength at both room and elevated temperatures.

2. Thermal Shock Resistance:

Outstanding resistance to rapid temperature changes, making them suitable for applications with frequent thermal cycling.

3. Corrosion and Erosion Resistance:

Highly resistant to chemical attack and mechanical wear, even in aggressive environments.

4. Thermal Conductivity:

Good thermal conductivity, enabling efficient heat transfer and dissipation.

5. Oxidation Resistance:

Stable in oxidizing atmospheres up to 1600°C.

6. Low Thermal Expansion:

Minimal dimensional changes with temperature, reducing the risk of cracking and failure.

Applications of Silicon Nitride Bonded Silicon Carbide Products

Silicon nitride bonded silicon carbide products are used in a wide range of industrial and technological applications, including:

1. Metallurgy:

Linings for furnaces, crucibles, and ladles in steelmaking, aluminum smelting, and non-ferrous metal production.

2 Oil and Gas:

Components for drilling tools and equipment exposed to high temperatures and corrosive environments.

3. Mining:

Wear-resistant parts for mineral processing and handling.

4. Construction:

Refractory bricks and linings for high-temperature industrial equipment.

5. Military:

Armor components and structural materials for defense applications.

6. Semiconductor and Electronics:

Kiln furniture, setters, and carriers for semiconductor manufacturing.

Advantages Over Other Ceramics

Compared to other advanced ceramics such as hot-pressed or sintered silicon carbide, silicon nitride bonded silicon carbide products offer several advantages:

1. Cost-Effectiveness:

The reaction bonding process is less energy-intensive and allows for near-net-shape production, reducing machining costs.

2. Ease of Processing:

The ability to form complex shapes using conventional ceramic forming techniques.

3. Dimensional Stability:

Minimal shrinkage during processing, ensuring precise final dimensions.

Quality Control and Testing

Quality control is essential throughout the manufacturing process. Key parameters monitored include:

1. Chemical Composition:

Ensuring the correct ratio of SiC and Si₃N₄.

2. Density and Porosity:

High density and low porosity are critical for mechanical strength and thermal performance.

3. Mechanical Properties:

Testing for flexural strength, compressive strength, and thermal shock resistance.

Innovation and Future Trends

Ongoing research focuses on optimizing the microstructure, improving thermal shock resistance, and reducing production costs. Additive manufacturing and advanced forming techniques are being explored to create complex, lightweight, and high-performance silicon nitride bonded silicon carbide products for next-generation applications.

Environmental Considerations in Manufacturing

The production of silicon nitride bonded silicon carbide products also takes into account environmental factors. Manufacturers strive to minimize emissions and waste during the nitridation and binder removal processes. Advanced filtration systems and controlled atmospheres help reduce the release of harmful gases. Recycling of raw materials and scrap products is increasingly common, contributing to sustainable manufacturing practices.

Challenges in Production

Despite the advantages, producing silicon nitride bonded silicon carbide products presents challenges. Controlling the nitridation reaction uniformly throughout large or complex shapes requires precise temperature and atmosphere management. Any deviation can lead to incomplete bonding or defects. Additionally, the removal of binders without causing cracks or distortion demands careful process control.

Customization and Design Flexibility

One of the key benefits of silicon nitride bonded silicon carbide products is their design flexibility. Manufacturers can tailor the composition, microstructure, and shape to meet specific application requirements. This customization extends to thermal conductivity, mechanical strength, and corrosion resistance, enabling optimized performance for diverse industrial needs.

Future Research Directions

Research continues to explore novel additives and processing techniques to enhance the properties of SNBSC materials. Nanostructured reinforcements, improved sintering aids, and hybrid bonding methods are under investigation. These innovations aim to push the limits of strength, toughness, and thermal stability, opening new possibilities for high-performance applications.

Further advancements in manufacturing technology and material science are expected to drive the evolution of silicon nitride bonded silicon carbide products, making them even more integral to future industrial applications.

Conclusion

Silicon nitride bonded silicon carbide products represent a pinnacle of modern engineering ceramics, combining exceptional mechanical, thermal, and chemical properties with cost-effective manufacturing. Their versatility and reliability make them indispensable in industries ranging from metallurgy and oil drilling to construction and defense. As technology advances, the applications and performance of silicon nitride bonded silicon carbide products will continue to expand, driving innovation and efficiency across multiple sectors.

FAQ

1. What are the main raw materials used in silicon nitride bonded silicon carbide products?

The primary raw materials are silicon carbide powder and silicon metal powder. These are blended with small amounts of organic binders to facilitate shaping before the nitridation process.

2. How does the nitridation process work in manufacturing silicon nitride bonded silicon carbide products?

During nitridation, the shaped green body is heated in a nitrogen-rich atmosphere at 1400–1500°C. The silicon metal reacts with nitrogen to form silicon nitride, which bonds the silicon carbide particles together, resulting in a strong, dense composite.

3. What are the key properties of silicon nitride bonded silicon carbide products?

Key properties include high mechanical strength, excellent thermal shock resistance, corrosion and erosion resistance, good thermal conductivity, oxidation resistance, and low thermal expansion.

4. What are the main applications of silicon nitride bonded silicon carbide products?

These products are widely used in metallurgy (furnace linings, crucibles), oil and gas (drilling tools), mining (wear-resistant parts), construction (refractory bricks), military (armor), and semiconductor manufacturing (kiln furniture).

5. How do silicon nitride bonded silicon carbide products compare to other silicon carbide ceramics?

Silicon nitride bonded silicon carbide products are more cost-effective and easier to process than hot-pressed or sintered silicon carbide, with minimal shrinkage and the ability to form complex shapes. They offer slightly lower density and mechanical properties but excel in applications requiring thermal shock resistance and dimensional stability.