Content Menu

● Introduction to Calcium Carbide

>> Production Process

● Role of Calcium Carbide in Acetylene Production

>> Advantages of Calcium Carbide in Acetylene Production

● Applications of Acetylene Gas

>> Calcium Carbide in Other Industrial Applications

● Calcium Carbide in Magnesium Production

>> Advantages Over Traditional Methods

● Calcium Carbide in Steelmaking

>> Desulfurization Reaction

>> Deoxidation Reaction

● Calcium Carbide in Chemical Synthesis

>> Use in PVC Production

● Calcium Carbide as a Dehydrating Agent

● Conclusion

● FAQs

>> 1. What is the primary use of calcium carbide?

>> 2. How does calcium carbide react with water?

>> 3. What are the advantages of using calcium carbide in acetylene production?

>> 4. Can calcium carbide be used in magnesium production?

>> 5. What other industrial applications does calcium carbide have?

● Citations:

Calcium carbide, with the chemical formula CaC₂, is a crucial compound in the production of acetylene gas. This article will delve into the significance of calcium carbide in acetylene production, its applications, and its role in various industries.

Introduction to Calcium Carbide

Calcium carbide is a colorless compound, but its technical-grade form is often grey or brown due to impurities. It is primarily produced in electric arc furnaces from a mixture of lime and coke at high temperatures. The reaction is as follows:

CaO+3C→CaC2+CO

This process requires high temperatures and energy, making it an endothermic reaction.

Production Process

The production of calcium carbide involves several steps:

1. Raw Material Preparation: Coke and lime are prepared by drying and calcining.

2. Electric Arc Furnace: The mixture is heated in an electric arc furnace to produce calcium carbide.

3. Cooling and Crushing: The molten carbide is cooled and crushed into smaller lumps.

Role of Calcium Carbide in Acetylene Production

Calcium carbide reacts with water to produce acetylene gas and calcium hydroxide:

CaC2+2H2O→C2H2+Ca(OH)2

This reaction is the foundation of acetylene production and is widely used in industrial applications.

Advantages of Calcium Carbide in Acetylene Production

1. High Gas Yield: High-quality calcium carbide ensures a higher volume of acetylene gas is produced, improving production efficiency.

2. Gas Purity: Low impurity content in calcium carbide results in purer acetylene gas, which is crucial for downstream applications like welding and chemical synthesis.

Applications of Acetylene Gas

Acetylene gas is used in various industries:

- Welding and Metal Fabrication: Its high flame temperature makes it ideal for welding and cutting metals.

- Chemical Synthesis: Used in the production of PVC and other chemicals.

- Lighting: Historically used in carbide lamps.

Calcium Carbide in Other Industrial Applications

1. Steel Making: Used as a desulfurizer in steel production.

2. Fertilizer Production: Calcium carbide reacts with nitrogen to form calcium cyanamide, used as a fertilizer.

3. Magnesium Production: Calcium carbide can be used as a reducing agent in magnesium smelting.

Calcium Carbide in Magnesium Production

Calcium carbide can serve as a reducing agent in the production of magnesium metal. This process involves mixing calcium carbide with dolomite and other materials, then performing a reduction reaction under high temperature and vacuum conditions.

Advantages Over Traditional Methods

1. Cost Efficiency: Calcium carbide is less expensive than traditional reductants like ferrosilicon.

2. Energy Efficiency: The reaction temperature can be lowered, reducing energy consumption.

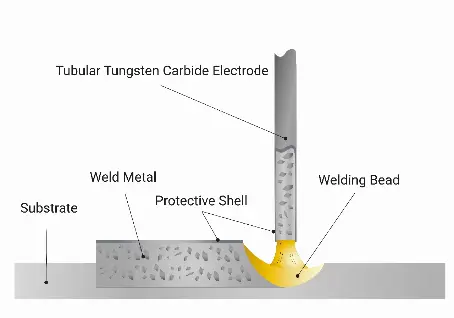

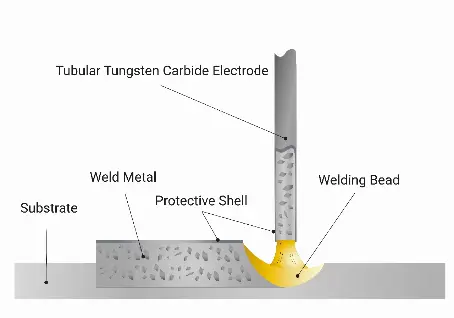

Calcium Carbide in Steelmaking

In the steelmaking process, calcium carbide is mainly used for desulfurization and deoxidation. Its chemical properties allow it to effectively react with harmful elements such as sulfur and oxygen in molten steel, forming harmless compounds, thus improving steel quality and reducing environmental pollution.

Desulfurization Reaction

The reaction of calcium carbide with sulfur is represented as:

CaC2+S→CaS+2C

The calcium sulfide (CaS) produced in this reaction can effectively remove sulfur from molten steel, reducing sulfur content in the steel, thereby enhancing its quality and extending its service life.

Deoxidation Reaction

The deoxidizing action of calcium carbide occurs through its reaction with oxygen, producing carbon monoxide and calcium oxide, thereby lowering the oxygen content in molten steel and improving the properties of the steel. This reaction is crucial for enhancing the strength and ductility of the steel.

Calcium Carbide in Chemical Synthesis

Calcium carbide is also used in the synthesis of various chemicals, including solvents and organic compounds required in the pharmaceutical and dyestuff industries. Additionally, it is involved in the production of synthetic rubber and plastics. The versatility of calcium carbide makes it a valuable compound in diverse chemical applications.

Use in PVC Production

Acetylene gas, derived from calcium carbide, is an essential building block in the production of PVC. PVC is widely used in the construction, automotive, and packaging industries due to its durability and versatility.

Calcium Carbide as a Dehydrating Agent

Calcium carbide can be used as a dehydrating agent in chemical reactions. For instance, it is employed in the synthesis of carbamates from amines, CO₂, and methanol. This application highlights its potential in facilitating reactions that require the removal of water to achieve higher yields and efficiency.

Conclusion

Calcium carbide plays a pivotal role in acetylene gas production due to its high reactivity and efficiency in generating acetylene. Its applications extend beyond acetylene to steelmaking, fertilizer production, magnesium smelting, and chemical synthesis. The importance of calcium carbide in these industries underscores its versatility and value in modern industrial processes.

FAQs

1. What is the primary use of calcium carbide?

Calcium carbide is primarily used for the production of acetylene gas, which is a key component in oxyacetylene welding and chemical synthesis.

2. How does calcium carbide react with water?

Calcium carbide reacts with water to produce acetylene gas and calcium hydroxide: CaC₂ + 2H₂O → C₂H₂ + Ca(OH)₂.

3. What are the advantages of using calcium carbide in acetylene production?

High-quality calcium carbide offers high gas yield and low impurity content, ensuring efficient production and high purity of acetylene gas.

4. Can calcium carbide be used in magnesium production?

Yes, calcium carbide can be used as a reducing agent in magnesium smelting, offering cost and energy efficiency advantages over traditional methods.

5. What other industrial applications does calcium carbide have?

Calcium carbide is used in steelmaking as a desulfurizer, in fertilizer production to form calcium cyanamide, and in chemical synthesis for various organic compounds.

Citations:

[1] https://www.tjtywh.com/a-the-role-of-acetylene-calcium-carbide-in-industrial-applications.html

[2] https://www.ascconline.com/img/services/project_report/Calcium_Carbide_Project_Report_Sample.pdf

[3] https://corrosion-doctors.org/Electrowinning/Magnesium.htm

[4] https://www.tjtywh.com/the-application-trends-of-calcium-carbide-in-the-steelmaking-industry.html

[5] https://pubs.rsc.org/en/content/articlelanding/2020/gc/d0gc01402h

[6] https://www.alzchem.com/en/company/news/calcium-carbide-for-acetylene-production-1/

[7] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-industrial-processes-and-applications.html

[8] https://patents.google.com/patent/US2729689A/en

[9] http://www.crecompany.com/company_news_en/calcium-carbide284.html

[10] https://manu56.magtech.com.cn/progchem/EN/10.7536/PC190137

[11] https://www.tjtywh.com/a-the-importance-of-acetylene-calcium-carbide-in-industrial-applications.html

[12] https://www.taiwannews.com.tw/news/5880375

[13] https://patents.google.com/patent/CN1920072A/en

[14] http://www.crecompany.com/company_news_en/Calcium_Carbide136.html

[15] https://pubs.acs.org/doi/10.1021/acs.iecr.5b02821

[16] https://en.wikipedia.org/wiki/Calcium_carbide

[17] https://www.tjtywh.com/a-exploring-the-practical-applications-of-calcium-carbide.html

[18] https://www.metallurgical-research.org/articles/metal/pdf/2025/01/metal20240169.pdf

[19] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-steel-production-a-comprehensive-analysis.html

[20] https://chemistry-europe.onlinelibrary.wiley.com/doi/abs/10.1002/ejoc.202001324