Content Menu

● Introduction

● Why Choose Canadian Carbide Plate Manufacturers and Suppliers?

● Leading Carbide Plate Manufacturers and Suppliers in Canada

>> 1. Foothills Steel Foundry – Alberta

>> 2. Kubes Steel – Ontario

>> 3. Trimay Wear Plate

>> 4. Canadian Wear Technologies

>> 5. Canada Carbide – Ontario

>> 6. Flair Precision Inc.

>> 7. Epic Tool / Precimac Tool Ltd.

>> 8. General Carbide – Canada Distribution

>> 9. Hard Metals Canada Inc.

>> 10. AssetArmor™ – Alberta

>> 11. Structural Wear Products – BC

>> 12. Casmet Supply Ltd.

● Types of Carbide Plates

● Industrial Applications

● Choosing the Right Carbide Plate Supplier

● Industry Trends in Carbide Plate Manufacturing

● Conclusion

● FAQ

>> 1. What industries in Canada use carbide plates the most?

>> 2. What is the difference between tungsten carbide and chromium carbide plates?

>> 3. Do Canadian suppliers offer OEM and private-label solutions?

>> 4. How are carbide overlay plates made?

>> 5. Which certifications should I look for when selecting a Canadian supplier?

Introduction

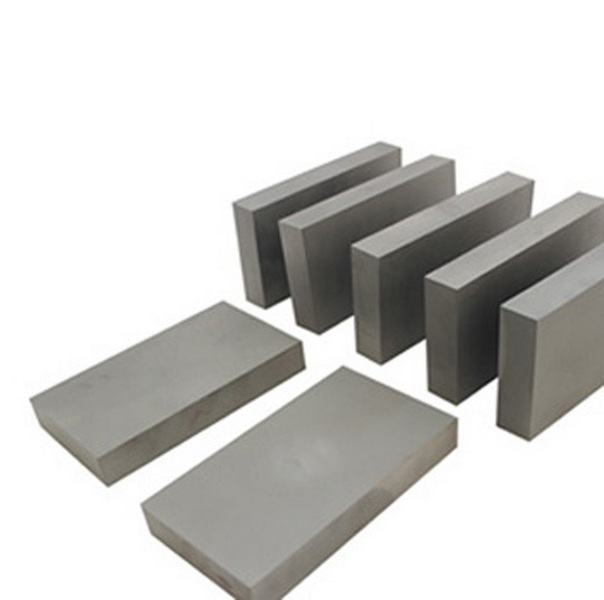

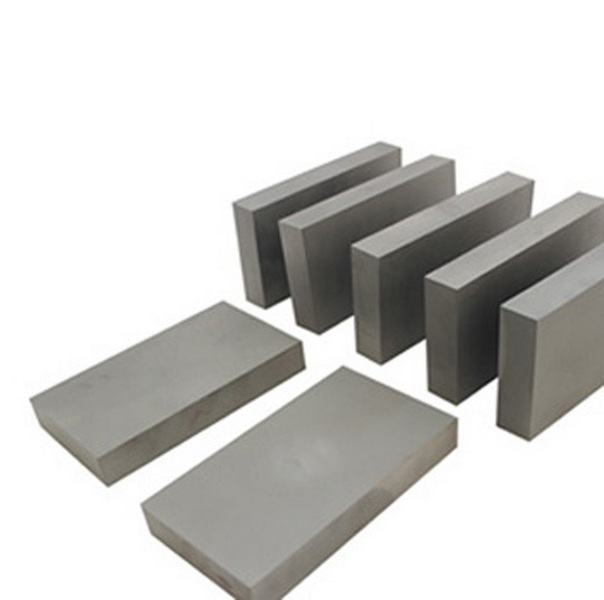

Carbide plates are an indispensable component in heavy-duty industries worldwide, particularly in sectors that require extreme resistance to abrasion, impact, and wear. From mining to oil and gas, construction, steel manufacturing, and material handling, carbide plates provide the durability and performance essential for productivity and cost efficiency.

Canada, with its strong resource-based economy and advanced manufacturing sector, has cultivated a thriving market for carbide plate manufacturers and suppliers. These companies not only serve domestic industries but also export high-quality, OEM-grade carbide products to global markets.

This guide explores the top carbide plate manufacturers and suppliers in Canada, their product offerings, industry applications, and the innovative technologies driving production standards higher than ever.

Why Choose Canadian Carbide Plate Manufacturers and Suppliers?

Canadian manufacturers stand out for their combination of advanced fabrication processes, strict adherence to quality standards, and customer-centered solutions. Here's why buyers worldwide seek their expertise:

- High Quality Assured: Most Canadian carbide suppliers comply with ISO 9001, ASME, and ASTM standards, ensuring longevity and performance in the toughest applications.

- OEM Customization: Components are frequently tailored for specific requirements—including thickness, hardness, overlay options, and geometric complexity.

- Broad Industrial Reach: Serving markets from mining and oilfield operations to steel plants, agriculture, and construction equipment.

- Technical Support and Aftermarket Service: Many suppliers provide wear analysis, product installation advice, and lifecycle improvement programs.

Leading Carbide Plate Manufacturers and Suppliers in Canada

1. Foothills Steel Foundry – Alberta

Providing chromium carbide overlay plates with hardness ratings between 55–62 HRC, Foothills Steel specializes in products that last up to ten times longer than standard steel plates. Their welding and formation techniques allow precision customization for high-impact use.

Key Strengths:

- Submerged and open-arc welding methods.

- Fully weldable bi-metallic wear plates.

- Proven performance in mining and quarrying machinery.

2. Kubes Steel – Ontario

Kubes Steel is a major name in abrasion-resistant wear products across North America. Their focus on Chromium Carbide overlays enhances material life in demanding environments. Kubes also offers bending, rolling, and forming services to shape plates for complex OEM applications.

3. Trimay Wear Plate

Trimay designs and manufactures wear-resistant plates, pipes, and welding consumables for highly abrasive conditions. Their overlays protect components from corrosion, erosion, and chemical wear, making them valuable in cement production, power generation, and mining.

4. Canadian Wear Technologies

Well known for custom wear materials, Canadian Wear Technologies supplies both traditional wear liners and carbide overlay solutions for mining chutes, crushers, and mills. Their engineering support ensures that OEMs receive optimal designs for specific wear points.

5. Canada Carbide – Ontario

Since 1969, Canada Carbide has been fabricating cemented carbide blanks and tools. Their reliability in providing consistent carbide plate quality has secured their status among OEM manufacturers requiring precise tolerances.

6. Flair Precision Inc.

Flair Precision manufactures carbide and tipped tools, including custom carbide plate elements for integrated tooling systems. Their ability to produce specialized lots in small or large quantities makes them a flexible OEM partner.

7. Epic Tool / Precimac Tool Ltd.

Epic Tool, operating under the Precimac Tool name in certain projects, focuses on custom carbide cutting tools and special-purpose carbide plates. They emphasize collaboration with clients to deliver solutions optimized for both lifespan and performance.

8. General Carbide – Canada Distribution

With an extensive range of tungsten carbide products, General Carbide delivers ISO-certified tooling and wear components. Their vertically integrated processes guarantee consistency from powder preparation to final grinding.

9. Hard Metals Canada Inc.

Hard Metals specializes in tungsten carbide blanks, grits, and polycrystalline diamond composites. They engineer solutions for drilling, cutting, and excavation equipment operating in severe service conditions.

10. AssetArmor™ – Alberta

AssetArmor's in-house manufactured chromium carbide overlay plates are designed to resist severe impact and abrasion. They've built a reputation on strict quality testing, adherence to CWB and ASME certifications, and tailored OEM solutions.

11. Structural Wear Products – BC

Structural Wear Products works extensively with both complex carbide and tungsten carbide plates. They offer consulting and design support to help mining, transport, and construction clients extend the service life of machinery.

12. Casmet Supply Ltd.

Casmet supports OEM customers with tungsten carbide grades ranging from as-sintered blanks to precision-ground plates. Their supply chain flexibility enables them to respond efficiently to urgent custom orders.

Types of Carbide Plates

- Chromium Carbide Overlay Plates (CCO): Best suited for high-abrasion and medium-impact scenarios.

- Tungsten Carbide Plates: Provide unmatched hardness for extreme wear conditions and high-impact applications.

- Cemented Carbide Plates: Powder metallurgy-based plates with precise mechanical properties for specialized sectors.

Industrial Applications

Carbide plates supplied by Canadian companies are applied in diverse sectors, including:

- Mining & Quarrying: Loader buckets, wear liners, cyclone parts.

- Oil & Gas: Downhole tools, pumps, valve seats.

- Cement & Steel Production: Mill liners, transfer chutes, kiln components.

- Construction Equipment: Grader blades, bulldozer undercarriages.

- Agriculture: Soil tillage tools, harvesting blades.

Choosing the Right Carbide Plate Supplier

When selecting from Canadian carbide plate manufacturers and suppliers, consider:

- Certifications and Compliance (ISO, ASTM, ASME, CWB).

- Customization Capabilities for size, composition, and shape.

- Turnaround Time and logistics reliability.

- After-Sales Services such as installation guidance and wear analysis.

Industry Trends in Carbide Plate Manufacturing

1. Digital Fabrication – CAD-driven plate design for precise fit and performance predictions.

2. Environment-Friendly Processes – Recycling of scrap carbide materials and reduced carbon processes.

3. OEM Branding Partnerships – Co-branded solutions for global markets.

4. Hybrid Overlays – Combining chromium and tungsten carbide layers for multi-property performance.

5. Rapid Prototyping – Accelerated small-batch production for urgent field testing.

Conclusion

Canada's carbide plate manufacturing sector is built on precision engineering, materials science expertise, and a strong OEM focus. The country's carbide plate manufacturers and suppliers excel in delivering tailored solutions that stand up to the most aggressive industrial environments. Whether your priority is longevity, impact resistance, or custom-fit fabrication, Canadian suppliers have the systems and expertise to meet your operational demands and global quality expectations.

FAQ

1. What industries in Canada use carbide plates the most?

Mining, construction, oil and gas, steel production, cement manufacturing, and agriculture are key industries utilizing carbide plates for wear resistance and extended service life.

2. What is the difference between tungsten carbide and chromium carbide plates?

Tungsten carbide plates offer supreme hardness and wear resistance; chromium carbide plates excel in abrasion resistance with moderate impact tolerance.

3. Do Canadian suppliers offer OEM and private-label solutions?

Yes, many Canadian carbide plate manufacturers and suppliers provide OEM and private-label manufacturing for international brands, including customization of design, composition, and branding.

4. How are carbide overlay plates made?

Overlay plates are created by welding a carbide-rich alloy onto a steel base, using advanced techniques such as submerged arc welding to ensure consistent hardness and adhesion.

5. Which certifications should I look for when selecting a Canadian supplier?

ISO 9001, ASME, ASTM compliance, and CWB certification are common indicators of a reliable and quality-focused carbide plate manufacturer.