Content Menu

● Introduction to Carbide Plate Manufacturing in Korea

● The Market Landscape: Size, Trends & Growth

● Top Carbide Plate Manufacturers and Suppliers in Korea

>> 1. KORLOY INC

>> 2. YG 1 MIDDLE EAST

>> 3. TAEGUTEC LTD

>> 4. Kumha

>> 5. IBCHE

>> 6. NGK Spark Plug Co. Ltd.

>> 7. Other Noteworthy Manufacturers

● Manufacturing Excellence: Korean Carbide Plate Standards

● OEM & Custom Services: Why Korea is Preferred

● How to Choose the Right Carbide Plate Supplier

● Industry Applications of Carbide Plates

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What makes Korean carbide plate manufacturers competitive internationally?

>> 2. Do Korean manufacturers offer quick turnaround on OEM orders?

>> 3. What industries rely most heavily on Korean carbide plates?

>> 4. How can I verify a Korean supplier's quality?

>> 5. Are customized carbide blends available from Korean suppliers?

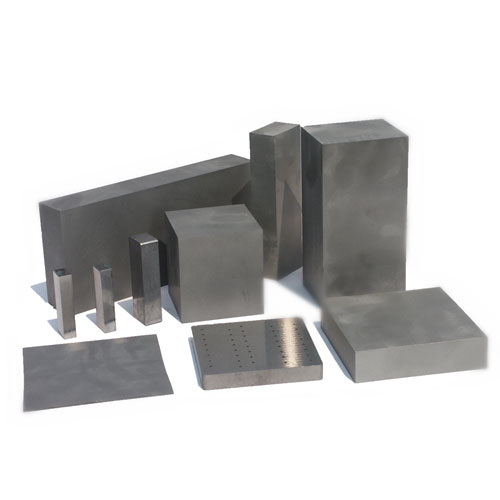

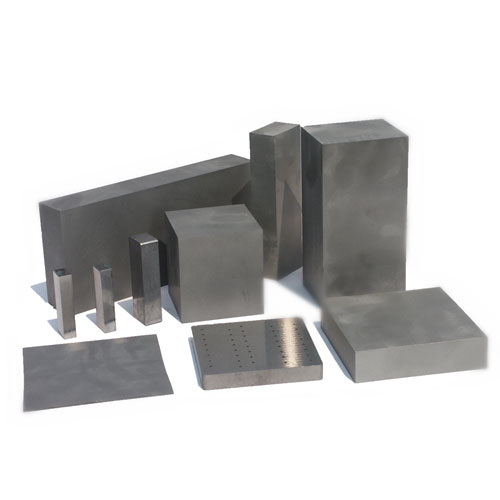

Carbide plate manufacturers and suppliers in Korea play a crucial role in the global metalworking, tooling, and heavy industry supply chain. Korea is recognized for its advanced engineering, impeccable production standards, and reliable OEM services, making it a vital hub for brands, wholesalers, and manufacturers seeking premium carbide solutions. This comprehensive guide profiles the top companies, examines industry trends, outlines manufacturing excellence, and provides practical insights for businesses sourcing from Korea.

Introduction to Carbide Plate Manufacturing in Korea

South Korea stands at the forefront of the carbide plate manufacturing industry. With a thriving base of technologically advanced factories, skilled technicians, and an export-oriented industrial policy, the nation has earned a strong reputation for producing high-quality carbide products tailored to demanding applications. Carbide plates are widely used in heavy-duty cutting tools, wear-resistant equipment, and precision components essential for industries ranging from aerospace to mining.

The country's manufacturers operate using state-of-the-art sintering and pressing technologies. Combined with rigorous quality control systems, these ensure that carbide plates meet or exceed global standards for durability, toughness, and dimensional accuracy.

The Market Landscape: Size, Trends & Growth

The carbide industry in Korea continues to grow as global demand for wear-resistant and precision-engineered products expands. With the rise of automation, precision metalworking, and intelligent machining systems, carbide plates have become critical to improving productivity and lowering downtime.

Notable market trends include:

- Increased demand for specialized grades: Many end-users require carbide compositions that balance hardness and toughness for unique applications.

- Expansion into new industries: Beyond traditional tooling, carbide plates are finding uses in energy, recycling, and defense.

- Sustainability and recycling: Korean manufacturers are investing in closed-loop recycling systems to recover tungsten and cobalt from worn-out plates.

- Rapid OEM customization: Clients demand shorter lead times for custom shapes, including unusual geometries and composite materials.

Korean suppliers export carbide plates and related products to markets in Europe, North America, Southeast Asia, the Middle East, and beyond.

Top Carbide Plate Manufacturers and Suppliers in Korea

1. KORLOY INC

One of Korea's most prominent carbide plate manufacturers, KORLOY serves as a benchmark in the industry. With decades of expertise, the company offers an extensive lineup ranging from standard rectangular carbide plates to complex CNC-milled geometries. It employs advanced R&D and automation to produce consistent, high-performance products at scale.

Strengths:

- Cutting-edge material science research

- Extensive global distribution network

- Comprehensive OEM capabilities

2. YG 1 MIDDLE EAST

YG 1 is a global leader in carbide cutting solutions and one of the largest exporters of Korean carbide products. Known for cutting tool plates made of cemented carbide blended with cobalt binders, YG 1 products are widely used in high-speed machining operations across multiple industries.

Highlights:

- Strong OEM services for custom geometries

- High-precision rotational and non-rotational plates

- Presence in major trade hubs worldwide

3. TAEGUTEC LTD

Taegutec specializes in heavy-duty wear plates, inserts, and custom carbide solutions. Its products are widely used in construction, mining, and automotive component manufacturing. The company is known for fast prototyping and durable alloy formulations that extend tool life.

Distinguishing features:

- Global technical support network

- Proprietary carbide blends for extreme conditions

- Sophisticated QC inspection curves for dimensional stability

4. Kumha

Kumha focuses on carbide saw tips and related wear-proof components. Its products are engineered to withstand tough conditions in timber cutting, metal slitting, and construction materials processing.

Key aspects:

- Precision in small, high-tolerance components

- Long-standing OEM partnerships with European tool brands

5. IBCHE

IBCHE is widely respected for its large-scale production capacity and cost-effective OEM services. It serves a diverse base of clients looking for high-volume orders that still meet strict quality thresholds.

Notable points:

- Flexible manufacturing of multiple carbide grades

- Competitive pricing without sacrificing performance

6. NGK Spark Plug Co. Ltd.

Although renowned for spark plugs, NGK also manufactures carbide plates and rods for industrial applications. Its products emphasize fine-grain structures for improved strength and thermal stability.

7. Other Noteworthy Manufacturers

Beyond the giants, Korea hosts many specialized carbide plate suppliers offering niche solutions such as chrome carbide overlay plates, brazed-on wear plates, and ultra-hard coatings. These innovative SMEs provide options for custom and small-batch orders suited to specialized project timelines.

Manufacturing Excellence: Korean Carbide Plate Standards

Korean carbide plate manufacturers and suppliers follow global industry benchmarks such as ISO-certified processes, computer-aided design integration, and smart factory systems. Key characteristics of Korean manufacturing include:

1. Advanced Materials Science: Extensive use of tungsten carbide, titanium carbide, and composite blends to suit diverse industrial needs.

2. Precision Engineering: CNC grinding, EDM cutting, and laser inspection ensure dimensional tolerances that match rigorous tooling specifications.

3. Durability: Products engineered to withstand high temperatures, abrasive wear, and mechanical loads.

4. Consistency: Batch-to-batch uniformity ensures predictable performance in long-term industrial operations.

OEM & Custom Services: Why Korea is Preferred

Korea's carbide plate producers excel in OEM manufacturing thanks to:

- Customization flexibility: Able to produce plates in unusual shapes, holes, chamfers, or surface treatments.

- Engineering collaboration: Direct technical support teams for co-developing new product lines.

- Scalable capacity: Equipped to handle prototype runs and mass production alike.

- Supply reliability: Strong export logistics and shipping efficiency minimize delivery risks.

For many overseas buyers, having a partner in Korea means streamlined communication, quality assurance, and predictable supply — essential factors in maintaining competitive edge.

How to Choose the Right Carbide Plate Supplier

When sourcing from Korea, consider:

- Track record & export volume: Long-standing companies with global distribution are safer bets.

- Certifications: Look for ISO 9001, ISO 14001, and industry-specific accreditations.

- Material range: High-grade tungsten carbide options for specialized performance requirements.

- Lead times: Consider delivery speed for custom orders.

- Technical support: Suppliers that offer engineering assistance can help optimize application results.

Industry Applications of Carbide Plates

Korean-made carbide plates are integral to numerous global industries:

- Metalworking: Inserts for milling machines, lathes, and saws.

- Automotive: Wear-resistant dies, press tools, and engine parts.

- Aerospace: High-precision drilling and cutting tools for composite materials.

- Oil and Gas: Drill stabilizers, wear-resistant seals, and downhole tools.

- Recycling & Waste Management: Shredding blades and impact liners.

The exceptional hardness and wear resistance of carbide mean reduced downtime, fewer tool changes, and higher efficiency for end-users.

Conclusion

South Korea's carbide plate manufacturers and suppliers lead the world in innovation, reliability, and manufacturing quality. Companies such as KORLOY INC, YG 1, TAEGUTEC LTD, and Kumha offer a blend of technical expertise, material science, and OEM flexibility that appeals to international clients. Whether sourcing for high-volume production or specialized engineering projects, buyers can expect unmatched consistency, competitive pricing, and responsive service from Korean suppliers. The country's capacity to adapt quickly to market changes ensures its continued dominance in the carbide sector.

Frequently Asked Questions (FAQ)

1. What makes Korean carbide plate manufacturers competitive internationally?

Korean suppliers combine advanced technology, high-grade raw materials, and strict quality control. This synergy allows them to deliver consistent, durable, and precisely engineered products across the globe.

2. Do Korean manufacturers offer quick turnaround on OEM orders?

Yes. Thanks to flexible manufacturing systems and strong logistics, many suppliers can produce and ship customized carbide plate orders within weeks, depending on order complexity.

3. What industries rely most heavily on Korean carbide plates?

Metalworking, automotive, construction, aerospace, oil and gas, and recycling industries use Korean carbide plates extensively due to their hardness and wear resistance.

4. How can I verify a Korean supplier's quality?

Request product samples, review certification documents, assess their export history, and if possible, arrange an audit of their production site.

5. Are customized carbide blends available from Korean suppliers?

Absolutely. Many Korean manufacturers offer tailored carbide grades to optimize wear resistance, impact resistance, or thermal stability for unique applications.