Content Menu

● Introduction

● Understanding Dillon Carbide Reloading Dies

● Key Features of Dillon Carbide Reloading Dies

● Advantages of Using Dillon Carbide Reloading Dies

● Comparison with Other Reloading Dies

● User Testimonials and Experiences

● Conclusion

● Frequently Asked Questions

>> Q1. What are the main benefits of using Dillon carbide reloading dies?

>> Q2. How do Dillon carbide dies compare to steel dies?

>> Q3. Can I use Dillon carbide dies with any reloading press?

>> Q4. How do I maintain my Dillon carbide reloading dies?

>> Q5. Are Dillon carbide reloading dies worth the investment?

Introduction

Reloading ammunition is a vital skill for shooting enthusiasts, competitive shooters, and hunters alike. It allows for customization of loads, cost savings, and improved accuracy. Among the various tools available for reloading, Dillon Precision stands out as a leader in the industry, particularly with their carbide reloading dies. This article explores the benefits of using Dillon carbide reloading dies, their features, and why they are an excellent choice for anyone serious about precision reloading.

Understanding Dillon Carbide Reloading Dies

Dillon carbide reloading dies are specifically designed to enhance the reloading process. Unlike traditional steel dies, carbide dies are made from a harder material that offers several advantages. The primary benefit of carbide is its durability; it can withstand the wear and tear of resizing brass cases much better than steel. This means that Dillon carbide reloading dies can last significantly longer, making them a cost-effective choice in the long run.

Carbide dies are particularly beneficial for resizing operations. They provide a smoother surface that reduces friction, allowing for easier case resizing. This is especially important for high-volume reloaders who need to process large quantities of brass efficiently. The precision engineering that goes into Dillon carbide dies ensures that they maintain their shape and performance over time, providing consistent results with every reload.

Key Features of Dillon Carbide Reloading Dies

Dillon carbide reloading dies come with several key features that set them apart from other options on the market.

- Durability and Longevity: The carbide material used in these dies is significantly harder than steel, which means they resist wear and tear much better. This durability translates to a longer lifespan, making them a worthwhile investment for serious reloaders.

- Precision Engineering: Dillon is known for its high manufacturing standards. Each die is crafted with precision to ensure that it meets the exact specifications required for reloading. This attention to detail results in dies that produce consistent and accurate ammunition.

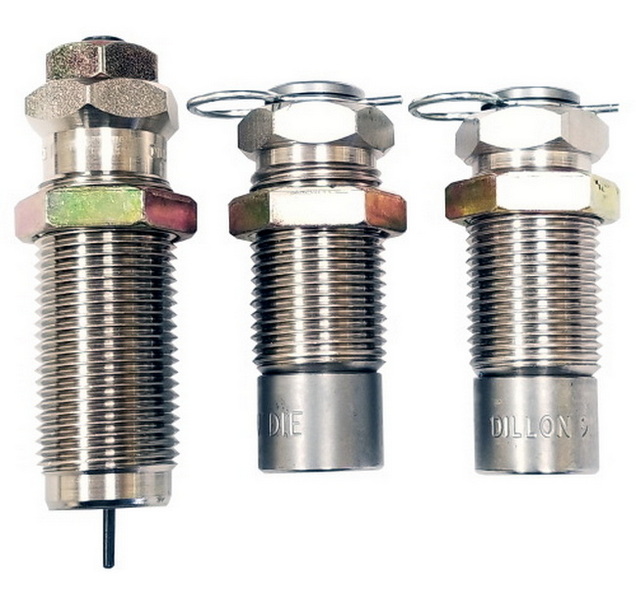

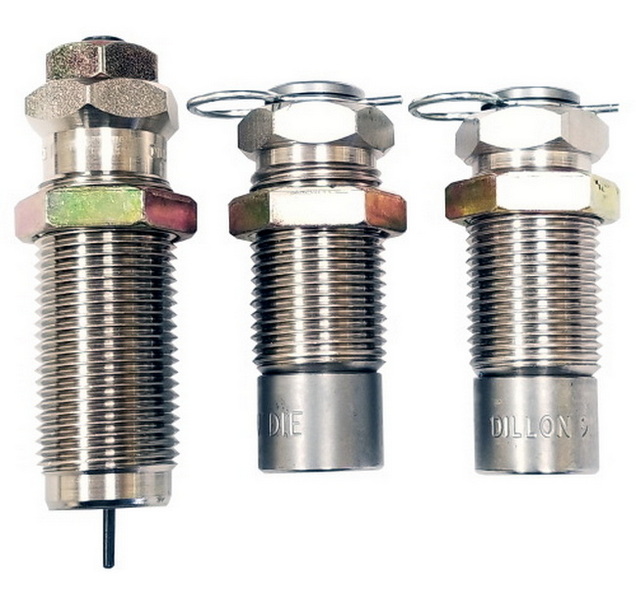

- Three-Die Set: Dillon offers a comprehensive three-die set that includes a sizing die, a seating die, and a crimping die. This set is designed to handle the entire reloading process, from resizing the brass to seating the bullet and crimping the case.

- Ease of Use: Dillon carbide reloading dies are designed for user-friendliness. They feature easy-to-follow instructions and are compatible with Dillon's reloading presses, making the setup process straightforward.

Advantages of Using Dillon Carbide Reloading Dies

The advantages of using Dillon carbide reloading dies are numerous, particularly for those who engage in high-volume reloading.

- Enhanced Performance: The smooth surface of carbide dies reduces friction during the resizing process. This means that cases can be resized more easily, which is crucial for maintaining the integrity of the brass. The result is more consistent ammunition that performs better in the field.

- Reduced Friction and Improved Case Life: Because carbide dies create less friction, they help to extend the life of your brass cases. This is particularly important for reloaders who want to maximize the number of times they can reload a single case.

- Ease of Cleaning and Maintenance: Dillon carbide dies are easier to clean than their steel counterparts. The smooth surface does not hold onto residue as much, allowing for quicker and more efficient cleaning after use.

Comparison with Other Reloading Dies

When comparing Dillon carbide reloading dies to other brands and types of reloading dies, several factors come into play.

- Material Differences: While many brands offer steel dies, Dillon's carbide options provide superior durability and performance. Steel dies can wear down over time, leading to inconsistent resizing and potential issues with ammunition quality.

- Cost-Effectiveness: Although carbide dies may have a higher initial cost, their longevity and performance make them a more cost-effective choice in the long run. Reloaders who frequently process brass will find that Dillon carbide dies save them money over time due to their durability.

- User Experience: Dillon carbide reloading dies are designed with the user in mind. Many users report that they find Dillon dies easier to work with compared to other brands, thanks to their precision engineering and thoughtful design.

User Testimonials and Experiences

Many experienced reloaders have shared their positive experiences with Dillon carbide reloading dies. Users often highlight the ease of use and the quality of the ammunition produced. For instance, a competitive shooter may note that switching to Dillon carbide dies has improved their accuracy and consistency in matches.

Additionally, many reloaders appreciate the customer service provided by Dillon Precision. The company is known for its commitment to customer satisfaction, ensuring that users have the support they need when using their products.

Conclusion

In conclusion, Dillon carbide reloading dies are an excellent choice for anyone serious about precision reloading. Their durability, precision engineering, and user-friendly design make them a standout option in the reloading community. Whether you are a competitive shooter, a hunter, or a hobbyist, investing in Dillon carbide reloading dies will enhance your reloading experience and improve the quality of your ammunition.

Frequently Asked Questions

Q1. What are the main benefits of using Dillon carbide reloading dies?

Dillon carbide reloading dies offer enhanced durability, reduced friction, and improved case life. They are designed for high-volume reloading, making them a cost-effective choice for serious reloaders.

Q2. How do Dillon carbide dies compare to steel dies?

Carbide dies are harder and more durable than steel dies, which means they last longer and provide more consistent results. They also create less friction during resizing, leading to better performance.

Q3. Can I use Dillon carbide dies with any reloading press?

Dillon carbide reloading dies are designed to be compatible with Dillon's reloading presses. However, they may also work with other brands, but it's essential to check compatibility before use.

Q4. How do I maintain my Dillon carbide reloading dies?

Maintaining Dillon carbide reloading dies is straightforward. Clean them regularly to remove any residue, and store them in a dry place to prevent damage. The smooth surface of carbide makes cleaning easier compared to steel dies.

Q5. Are Dillon carbide reloading dies worth the investment?

Yes, Dillon carbide reloading dies are worth the investment due to their durability, performance, and the quality of ammunition they produce. For serious reloaders, the long-term savings and improved results make them a valuable addition to any reloading setup.