Content Menu

● Overview of Silicon Carbide Production

● Types of Waste in Silicon Carbide Production

>> Solid Waste

>> Liquid Waste

>> Gas Emissions

● Environmental Impact of Silicon Carbide Production Waste

● Recycling and Waste Reduction Strategies

>> Solid Waste Recycling

>> Liquid Waste Treatment

>> Gas Emission Control

● Emerging Technologies and Innovations

● Market and Industry Trends

● Case Studies: Successful Waste Management in Silicon Carbide Production

>> Case Study 1: High-Tech Recycling Facility

>> Case Study 2: Renewable Energy Integration

>> Case Study 3: Closed-Loop Water Management

● Regulatory and Safety Considerations

● Future Outlook

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main types of silicon carbide production waste?

>> 2. How is silicon carbide grinding waste recycled?

>> 3. Why is silicon carbide refractory brick waste considered hazardous?

>> 4. What technologies are used to reduce emissions from silicon carbide production?

>> 5. How does flash Joule heating contribute to silicon carbide recycling?

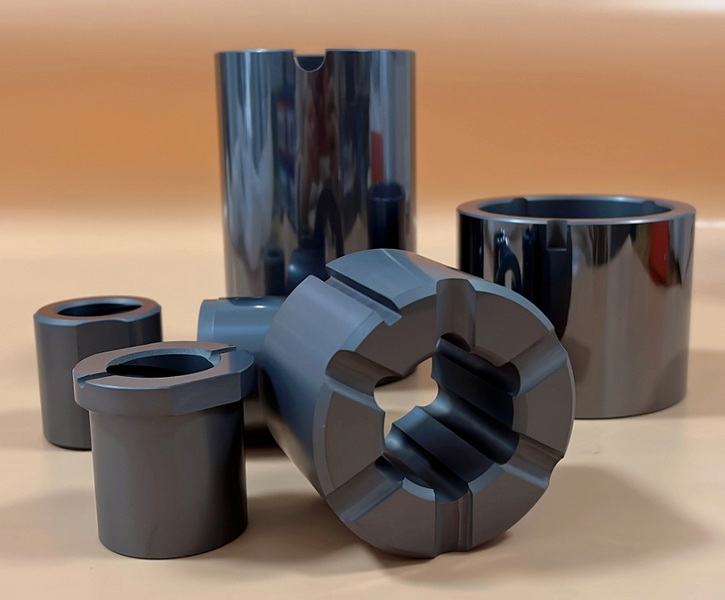

Silicon carbide (SiC) is an advanced synthetic ceramic material renowned for its remarkable hardness, thermal conductivity, and chemical inertness. As a high-tech enterprise specializing in the research, development, production, and sales of carbide products for industrial, military, metallurgical, oil drilling, mining, and construction applications, it is essential to understand the environmental and operational footprint of silicon carbide production. This article provides a detailed exploration of the waste streams generated during silicon carbide production, their environmental implications, and the evolving strategies for waste management and recycling.

Overview of Silicon Carbide Production

Silicon carbide is primarily manufactured through high-temperature processes, with the Acheson method being the most widely adopted. In this process, a mixture of quartz sand (silica) and petroleum coke (carbon source) is heated in an electric resistance furnace at temperatures exceeding 2,500°C. The reaction produces silicon carbide crystals, but it is an energy-intensive process that generates significant amounts of waste.

Other methods, such as the Lely process and chemical vapor deposition (CVD), are used for specific high-purity applications but are less common in large-scale industrial production. Each production method, however, introduces its own set of waste management challenges.

Types of Waste in Silicon Carbide Production

Solid Waste

Solid waste is the most visible and voluminous by-product of silicon carbide production. The primary sources include:

- Unreacted Raw Materials: Not all quartz sand and petroleum coke react completely in the furnace. These unreacted materials accumulate as solid waste and require disposal or recycling.

- Process By-Products: The edges and surfaces of the Acheson furnace often contain partially reacted material that does not reach the required temperature for full conversion. This material is separated from the main product and discarded.

- Grinding and Cutting Residues: The finishing of silicon carbide products involves grinding, slicing, and polishing, which generate fine powders, diamond wheel fragments, and cutting fluid mixtures. The particle size distribution of this silicon carbide grinding waste typically ranges from 0.1 to 15 micrometers.

- Refractory Bricks and Liners: Used silicon carbide refractory bricks, especially those contaminated with heavy metals from industrial processes like aluminum smelting, are classified as hazardous waste. Proper handling and disposal are critical to prevent environmental contamination.

Liquid Waste

Liquid waste is generated at several stages of silicon carbide production:

- Cutting Fluid Waste: The slicing of silicon ingots and wafers uses cutting fluids containing polyethylene glycol, silicon carbide particles, and metal fragments. This slurry is highly contaminated and requires specialized treatment before disposal or recycling.

- Cooling and Cleaning Wastewater: Water used for cooling and cleaning equipment can become contaminated with chemicals, heavy metals, and suspended solids. Strict protocols are necessary to ensure safe discharge or reuse.

Gas Emissions

The high-temperature production of silicon carbide results in the release of several harmful gases:

- Carbon Dioxide (CO₂): The Acheson process is a major emitter, releasing approximately 2.4 tons of CO₂ per ton of silicon carbide produced. Additional emissions come from electricity generation required for the process.

- Sulfur Dioxide (SO₂), Nitrogen Oxides (NOx), and Carbon Monoxide (CO): These pollutants are released during the combustion of fossil fuels and the reduction reactions in the furnace.

- Other Gaseous By-Products: In processes involving high-purity silicon production, chlorosilanes and silicon tetrachloride may be present, requiring specialized waste gas treatment systems.

Environmental Impact of Silicon Carbide Production Waste

The environmental challenges posed by silicon carbide production waste are multifaceted:

- High Carbon Footprint: The energy-intensive nature of silicon carbide production, coupled with substantial CO₂ emissions, contributes significantly to climate change.

- Resource Consumption: The process requires high-purity quartz sand and graphite, leading to resource depletion and environmental degradation in mining regions.

- Waste Management Challenges: The management of solid, liquid, and gaseous wastes demands advanced treatment and disposal methods to prevent soil, water, and air pollution.

- Hazardous Waste Classification: Certain by-products, such as spent refractory bricks, are classified as hazardous due to heavy metal content, necessitating strict handling and disposal protocols.

Recycling and Waste Reduction Strategies

Solid Waste Recycling

Several innovative approaches are being adopted to recycle silicon carbide production waste:

- Calcination and Acid Washing: Grinding waste is calcined at 900°C to burn off organic residues, followed by treatment with nitric and hydrofluoric acids to achieve high-purity silicon carbide suitable for reuse.

- High-Tech Furnace Recycling: Advanced recycling technologies, such as the RECOSiC process, use high-temperature furnaces to convert by-products and defective components back into high-quality silicon carbide, reducing energy consumption and emissions by up to 80% compared to traditional methods.

- Refractory Brick Processing: Used silicon carbide bricks are crushed, separated, and processed in closed systems to minimize dust and contamination, with strict safety measures for workers.

Liquid Waste Treatment

- Chemical Treatment: Acid leaching and alkaline dissolution are used to recover silicon carbide particles from cutting fluid waste, achieving recovery rates of up to 98.8% with purities above 97%.

- Wastewater Recycling: Comprehensive water treatment systems allow for the recovery and reuse of process water, reducing overall water consumption and minimizing discharge.

Gas Emission Control

- Gas Purification Systems: Catalytic converters, scrubbers, and filters are employed to capture and neutralize harmful gases before release into the atmosphere.

- Alternative Energy Sources: The integration of renewable energy, such as solar and wind, into production processes helps reduce carbon emissions.

Emerging Technologies and Innovations

Several cutting-edge technologies are being developed to further reduce the environmental impact of silicon carbide production:

- Flash Joule Heating (FJH): FJH technology enables the rapid conversion of waste silicon from photovoltaic cells into high-purity silicon carbide, consuming significantly less energy and emitting fewer greenhouse gases than traditional methods.

- Carbon Recycling: Projects are underway to synthesize silicon carbide using CO₂ and silicon-based industrial waste, contributing to both carbon recycling and industrial waste reutilization.

- Smart Manufacturing: Digital technologies, such as artificial intelligence and IoT, are being used to optimize production processes, reduce energy consumption, and minimize waste generation.

Market and Industry Trends

The global demand for silicon carbide is rising, driven by its use in power electronics, electric vehicles, and renewable energy applications. As production scales up, so does the generation of silicon carbide production waste. Industry leaders are increasingly adopting sustainable practices and circular economy principles to address these challenges.

- Circular Economy Initiatives: Companies are investing in closed-loop recycling systems to recover valuable materials from silicon carbide production waste and reintegrate them into the manufacturing process.

- Regulatory Pressure: Stricter environmental regulations are pushing manufacturers to adopt cleaner technologies and improve waste management practices.

- Consumer Awareness: End-users are becoming more environmentally conscious, driving demand for products made with sustainable and recycled materials.

Case Studies: Successful Waste Management in Silicon Carbide Production

Case Study 1: High-Tech Recycling Facility

A leading silicon carbide manufacturer in Europe has implemented a state-of-the-art recycling facility that processes grinding and cutting waste. By combining calcination, acid washing, and advanced sorting technologies, the facility achieves a recycling rate of over 95%, significantly reducing landfill use and raw material consumption.

Case Study 2: Renewable Energy Integration

A North American producer has integrated solar and wind energy into its silicon carbide production process. This shift has reduced the plant's carbon footprint by 40% and lowered energy costs, demonstrating the feasibility of renewable energy in high-temperature manufacturing.

Case Study 3: Closed-Loop Water Management

An Asian manufacturer has developed a closed-loop water management system that recycles all process water. The system has reduced water consumption by 70% and eliminated wastewater discharge, setting a new industry standard for sustainable water use.

Regulatory and Safety Considerations

The handling and disposal of silicon carbide production waste are subject to strict regulations:

- Hazardous Waste Classification: Certain by-products must be stored, transported, and processed according to hazardous waste management rules.

- Worker Safety: Personal protective equipment (PPE) and closed processing systems are required to protect workers from dust and chemical exposure.

- Environmental Compliance: Facilities must comply with local and international environmental standards to minimize the impact of emissions and discharges.

Future Outlook

The future of silicon carbide production lies in the continued development and adoption of sustainable technologies. Advances in recycling, renewable energy integration, and smart manufacturing will play a critical role in reducing the environmental impact of silicon carbide production waste. Industry collaboration and regulatory support will be essential to drive innovation and ensure the long-term viability of silicon carbide as a key material for advanced industrial applications.

Conclusion

Silicon carbide production generates a variety of solid, liquid, and gaseous wastes, each posing unique environmental and regulatory challenges. However, ongoing advancements in recycling technologies, waste treatment, and process optimization are enabling the industry to reduce its environmental footprint. By adopting innovative solutions such as high-tech recycling furnaces, flash Joule heating, and carbon recycling, companies can transform silicon carbide production waste into valuable resources, supporting a more sustainable and circular economy.

Frequently Asked Questions (FAQ)

1. What are the main types of silicon carbide production waste?

Silicon carbide production waste includes solid by-products (unreacted raw materials, grinding residues, refractory bricks), liquid waste (cutting fluid and wastewater), and gaseous emissions (CO₂, SO₂, NOx, and other pollutants).

2. How is silicon carbide grinding waste recycled?

Silicon carbide grinding waste is typically recycled through calcination at 900°C to remove organic residues, followed by acid washing with nitric and hydrofluoric acids to achieve high-purity silicon carbide for reuse in manufacturing.

3. Why is silicon carbide refractory brick waste considered hazardous?

Silicon carbide refractory brick waste is classified as hazardous due to the presence of heavy metals such as chromium and copper, which require special handling and disposal procedures to prevent environmental contamination.

4. What technologies are used to reduce emissions from silicon carbide production?

Technologies such as gas purification systems (scrubbers, catalytic converters), alternative energy sources (solar, wind), and smart manufacturing (AI, IoT) are used to reduce emissions and optimize energy use in silicon carbide production.

5. How does flash Joule heating contribute to silicon carbide recycling?

Flash Joule heating (FJH) enables the rapid conversion of waste silicon from photovoltaic cells into high-purity silicon carbide, using less energy and emitting fewer greenhouse gases compared to traditional methods.